spare wheel LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 31 of 3229

Invert the compres s or and gravi ty drain the oi l into a calibrated meas uri ng cyl inder. Rotat e t he compres sor clut ch tomake s ure the compres s or is complet el y drai ned.Note the quanti ty of oi l drained (Y cm³).Calculate the quanti ty of oi l to be drained from t he new compres sor us ing t he fol lowi ng formula:X cm³ — (Y cm³ +20 cm³) = Q cm³Remove the drain pl ug from the new compres s or and drain Q cm3 of oi l. ins t al l and tight en t he compres sor drai nplug.

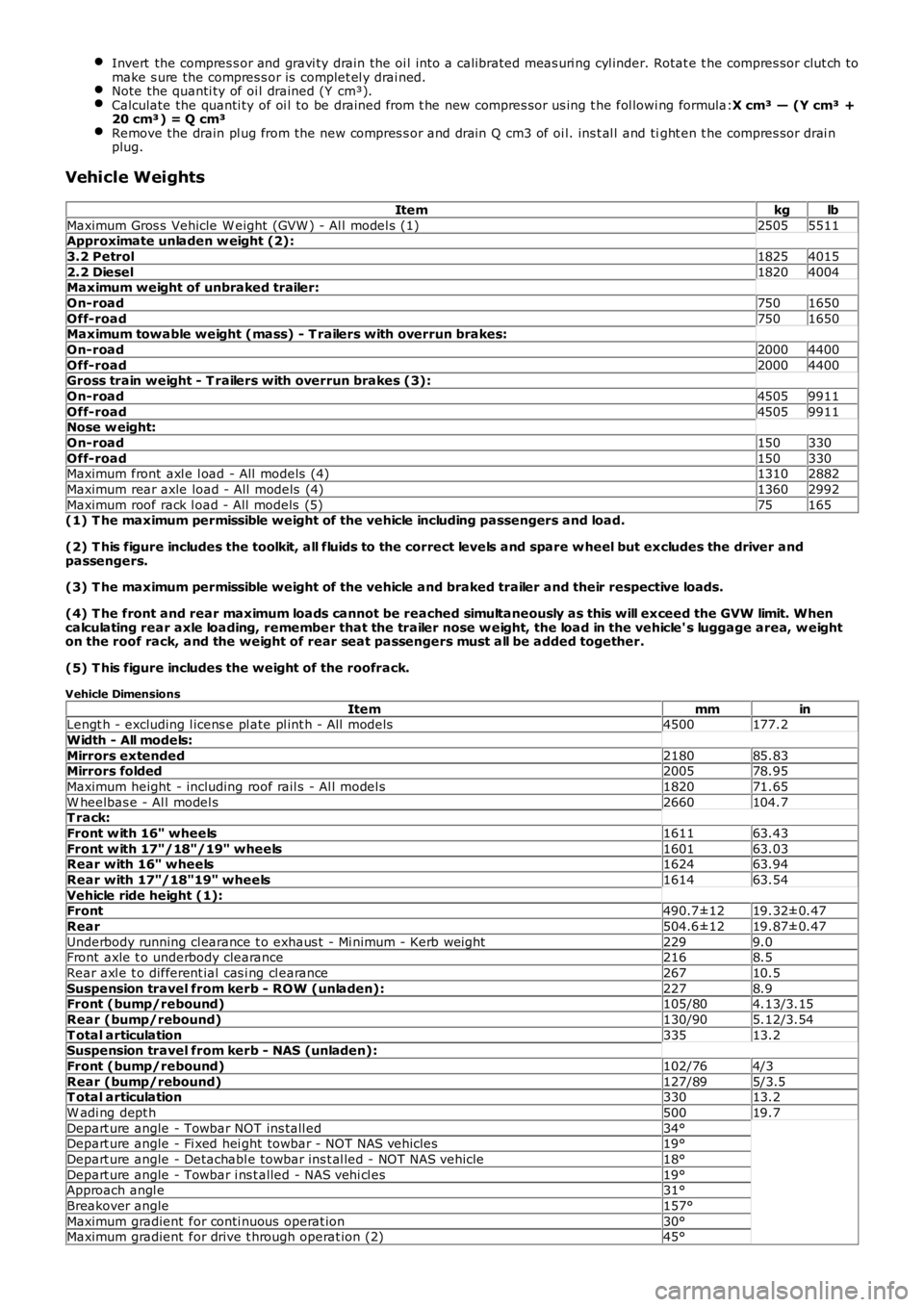

Vehicle Weights

Itemkglb

Maximum Gros s Vehicle W eight (GVW ) - Al l model s (1)25055511Approximate unladen w eight (2):

3.2 Petrol18254015

2.2 Diesel18204004Maximum weight of unbraked trailer:

On-road7501650

Off-road7501650Maximum towable weight (mass) - T railers with overrun brakes:

On-road20004400

Off-road20004400Gross train weight - T railers with overrun brakes (3):

On-road45059911

Off-road45059911Nose w eight:

On-road150330

Off-road150330Maximum front axl e l oad - All models (4)13102882

Maximum rear axle load - All models (4)13602992

Maximum roof rack l oad - All models (5)75165(1) T he maximum permissible weight of the vehicle including passengers and load.

(2) T his figure includes the toolkit, all fluids to the correct levels and spare w heel but excludes the driver andpassengers.

(3) T he maximum permissible weight of the vehicle and braked trailer and their respective loads.

(4) T he front and rear maximum loads cannot be reached simultaneously as this will exceed the GVW limit. Whencalculating rear axle loading, remember that the trailer nose w eight, the load in the vehicle' s luggage area, w eighton the roof rack, and the weight of rear seat passengers must all be added together.

(5) T his figure includes the weight of the roofrack.

Vehicle Dimensions

ItemmminLengt h - excluding l icens e pl ate pl int h - All models4500177.2

Width - All models:

Mirrors extended218085.83Mirrors folded200578.95

Maximum height - including roof rail s - Al l model s182071.65

W heelbas e - Al l model s2660104.7T rack:

Front w ith 16" wheels161163.43

Front w ith 17"/18"/19" wheels160163.03Rear with 16" wheels162463.94

Rear with 17"/18"19" wheels161463.54

Vehicle ride height (1):Front490.7±1219.32±0.47

Rear504.6±1219.87±0.47

Underbody running cl earance t o exhaus t - Mi nimum - Kerb wei ght2299.0Front axle t o underbody clearance2168.5

Rear axl e t o different ial cas i ng cl earance26710.5

Suspension travel from kerb - ROW (unladen):2278.9Front (bump/rebound)105/804.13/3.15

Rear (bump/rebound)130/905.12/3.54

T otal articulation33513.2Suspension travel from kerb - NAS (unladen):

Front (bump/rebound)102/764/3

Rear (bump/rebound)127/895/3.5T otal articulation33013.2

W adi ng dept h50019.7

Depart ure angle - Towbar NOT ins tall ed34°Depart ure angle - Fi xed hei ght towbar - NOT NAS vehicles19°

Depart ure angle - Detachabl e towbar ins t al led - NOT NAS vehicle18°

Depart ure angle - Towbar i ns t alled - NAS vehi cl es19°Approach angl e31°

Breakover angle157°

Maximum gradient for conti nuous operat ion30°Maximum gradient for drive t hrough operat ion (2)45°

Page 154 of 3229

Publi s hed: 29-Nov-2011

Identification Codes - Identification Codes

Des cript ion and Operat ion

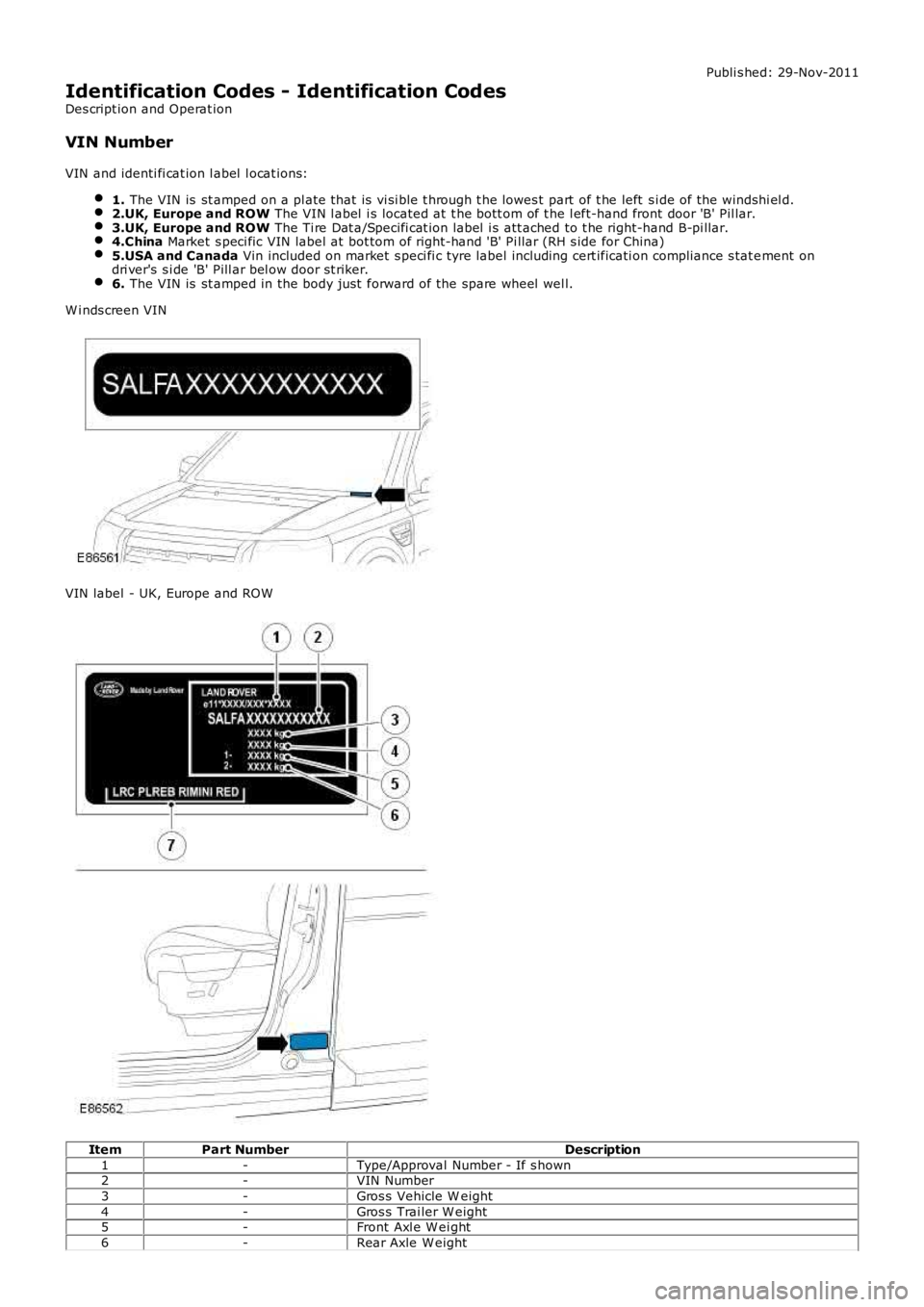

VIN Number

VIN and identi fi cat ion l abel l ocat ions:

1. The VIN is st amped on a pl ate t hat is vi si ble t hrough t he lowes t part of t he left si de of the windshi el d.2.UK, Europe and ROW The VIN l abel i s located at t he bott om of t he l eft-hand front door 'B' Pil lar.3.UK, Europe and ROW The Ti re Dat a/Specifi cat ion label i s att ached to t he right-hand B-pi llar.4.China Market s peci fic VIN label at bot tom of ri ght -hand 'B' Pi llar (RH s ide for China)5.USA and Canada Vin included on market s peci fi c tyre label including cert ificati on compliance s tat ement ondri ver's s i de 'B' Pill ar bel ow door st riker.6. The VIN is st amped in the body just forward of the spare wheel wel l.

W i nds creen VIN

VIN label - UK, Europe and ROW

ItemPart NumberDescription

1-Type/Approval Number - If s hown2-VIN Number

3-Gros s Vehicle W eight

4-Gros s Trai ler W eight5-Front Axl e W ei ght

6-Rear Axle W eight

Page 276 of 3229

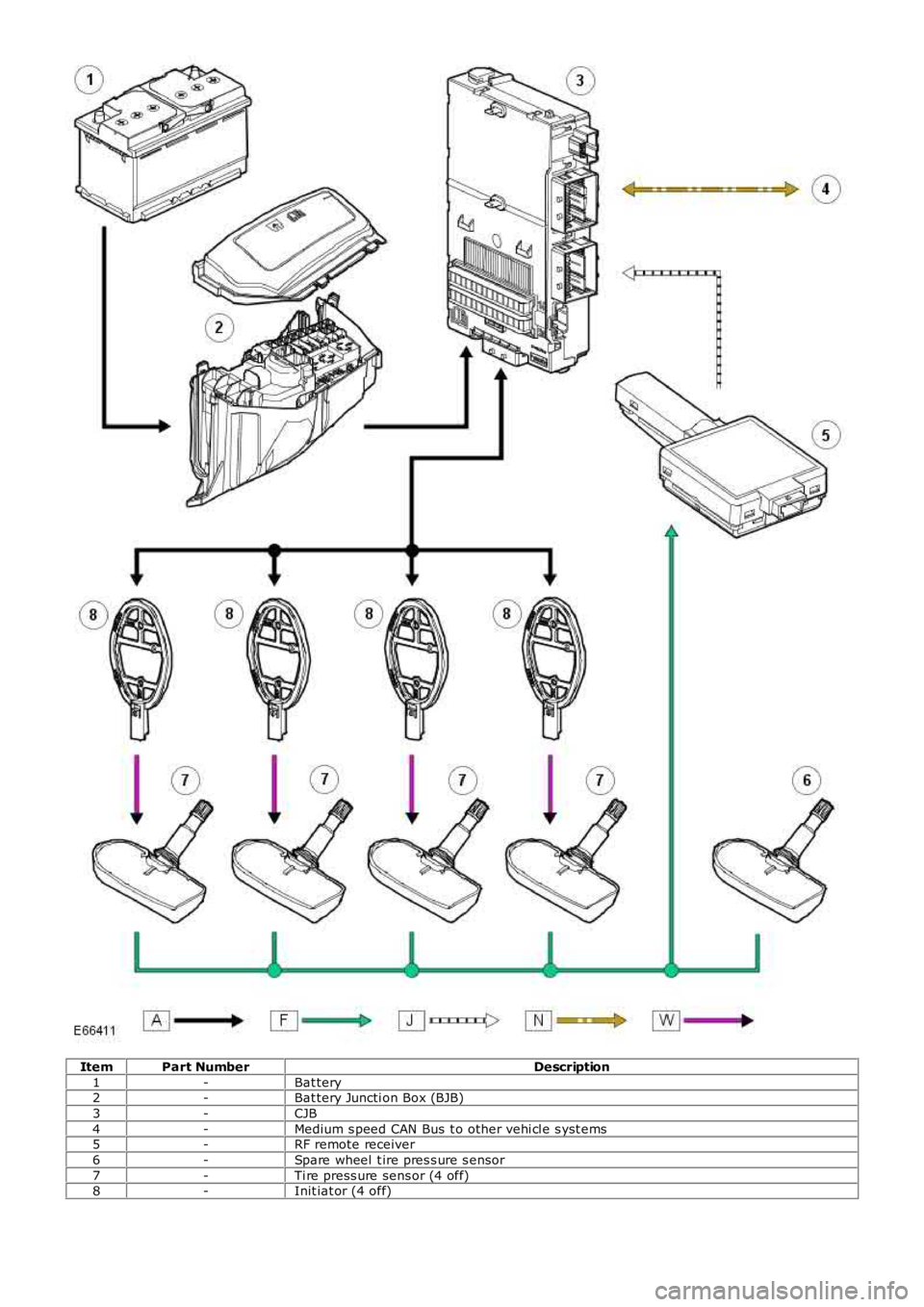

The cont rol ling software for t he TPMS i s located wi thi n t he CJB. The s oft ware det ects t he fol lowing:

t he ti re press ure is bel ow t he recommended low pres sure value - under infl ated t iret he pos i ti on of the t ire on t he vehi cle.

The s ys t em compri s es a Radio Frequency (RF) receiver, 4 init iat ors and 4 ti re press ure s ens ors (5 if t he spare wheel has as ens or fi tt ed).

The 4 i nit iators are hard wi red t o t he CJB. The i nit iators t rans mit 125 KHz Low Frequency (LF) s ignals t o t he t ire pres s ures ens ors which res pond by modifying t he mode s t at us wi thin the RF trans mi s si on. The 315 or 433 MHZ RF s ignals aredetected by the RF recei ver whi ch is l ocat ed at the rear of t he vehicle, behi nd t he headl ining. The RF receiver is connect edt o the CJB on the Local Interconnect Net work (LIN) bus . The received RF s i gnals from t he t ire pres s ure s ensors are pas s edt o the CJB on the LIN bus and contain identi fi cat ion, pres sure, temperat ure and accel erat ion i nformat ion for each wheeland t ire.

The TPMS s oft ware communi cat es wit h t he ins trument cl ust er via t he medium s peed Control ler Area Net work (CAN) bus toprovide t he driver wit h appropri at e warnings. The TPMS s oftware als o i ndi cat es s tat us or fail ure of t he TPMS orcomponents .

Tire Location and Identification

The TPMS can identi fy the pos it ion of t he wheel s on t he vehi cle and as s ign a recei ved ti re press ure s ens or identi fi cat ion t oa s peci fi c posi ti on on t he vehi cl e, for exampl e FL (front l eft ), FR (front ri ght ), RL (rear left ) and RR (rear right). Thi s feat ureis required because of the di fferent pres sure t argets and t hres hold bet ween the front and rear t ires.

The wheel l ocat ion i s performed aut omati cal ly by t he TPMS s oft ware us i ng an 'auto-locati on' funct ion. Thi s functi on is full yautomat ic and requi res no i nput from t he dri ver. The TPMS software automat icall y re-learns t he pos it ion of t he wheel s ont he vehi cl e if t he t ire pres s ure s ensors are replaced or the wheel posi ti ons on t he vehi cl e are changed.

The TPMS s oft ware can aut omat icall y detect, under all operati ng condit ions , the following:

one or more new t ire pres sure s ensors have been fit t edone or more ti re press ure s ens ors have s t opped t rans mi tt ingTPMS s oft ware can reject identi fi cat ions from ti re press ure sens ors whi ch do not belong to the vehiclet he spare wheel and one of t he 'runni ng' wheels on the vehicle have changed pos it ions .

If a new t ire pres s ure s ensor i s fi tt ed on any 'running' wheel , the s oft ware can learn t he new s ens or i dent ificati onautomat ically when the vehicle is driven for more t han 15 mi nut es at a s peed of more than 20 km/h (12.5 mph).

• NOTE: The s pare wheel is not fit ted wit h a t ire pres s ure s ens or.

TPMS Operation

Each ti me t he vehi cl e i s dri ven the TPMS s oft ware act ivates each i ni ti ator i n turn to t rans mit a LF 125 KHz s ignal t o eacht ire pres sure s ensor. The LF si gnal i s received by t he ti re pres sure s ens or which responds by t rans mit ti ng a 315 or 433MHZ (depending on market ) si gnal whi ch is received by t he RF recei ver. The si gnal contains coded data which corres pondst o s ens or identi fi cat ion, air pres s ure, air t emperature and accel erati on data. This i s t hen pas s ed to the CJB on the ISO9141 K Line.

If the vehicle has been parked for more than 15 minutes and t hen dri ven at a s peed of more t han 12.5 mph (20 km/h), t heini ti at ors each fire an LF s ignal in turn for 18 s econds i n t he fol lowing order:

Front LHFront RHRear RHRear LH.

Each ti re press ure s ens or res ponds i n t urn whi ch allows the TPMS s oftware to est ablis h the s ensor pos it ions at t he st art oft he drive cycle. This proces s is repeat ed up t o t hree t imes but l ess if t he s ens or pos i ti ons are already known. The processis known as 'Auto Locati on' and t akes 2 to 4 mi nut es t o compl ete.

Duri ng thi s peri od the t ire pres s ure sens ors t rans mi t at regular int ervals , once every 5 s econds (once every 15 s econds onNAS vehicles ). For the remainder of the drive cycl e t he t ire pres sure s ensors transmit once every 60 s econds or more oft enif a change of ti re pres sure is sens ed unti l the vehicle st ops and the TPMS ret urns t o t he parking mode.

Once the wheel pos it ions have been es t abl is hed, t he i ni ti ators s top t rans mit t ing t he LF s ignal and do not t rans mi t agai nunti l the vehicle has been parked for more than 15 minutes .

The warni ng appears in t he i ns t rument clus ter mes s age cent re when the i nfl at ion press ure has fal len t o 25% of t henominal pres s ure. The dis played mes sage wi ll als o i ncl ude the pos it ion(s) of t he affect ed wheel(s).

The TPMS enters 'Parki ng Mode' aft er the vehicl e s peed has been l es s t han 20 km/h (12.5 mph) for 15 minut es . In parkingmode t he t ire pres sure s ensors transmit a coded RF s ignal once every 13 hours. If t he ti re pres sure decreas es by more

t han 0.06 bar (1 lbf/in2 ), t he s ens or wil l trans mi t more oft en if pres s ure in t he t ire is bei ng los t.

The s pare wheel ti re press ure s ens or als o t rans mit s a si gnal once every 13 hours i n t he s ame manner as the 'running

wheels ' when in parki ng mode. If t he t ire pres sure decreases by more t han 0.06 bar (1 l bf/i n2 ), the s ensor wi ll t rans mitmore oft en if press ure in t he t ire is bei ng los t .

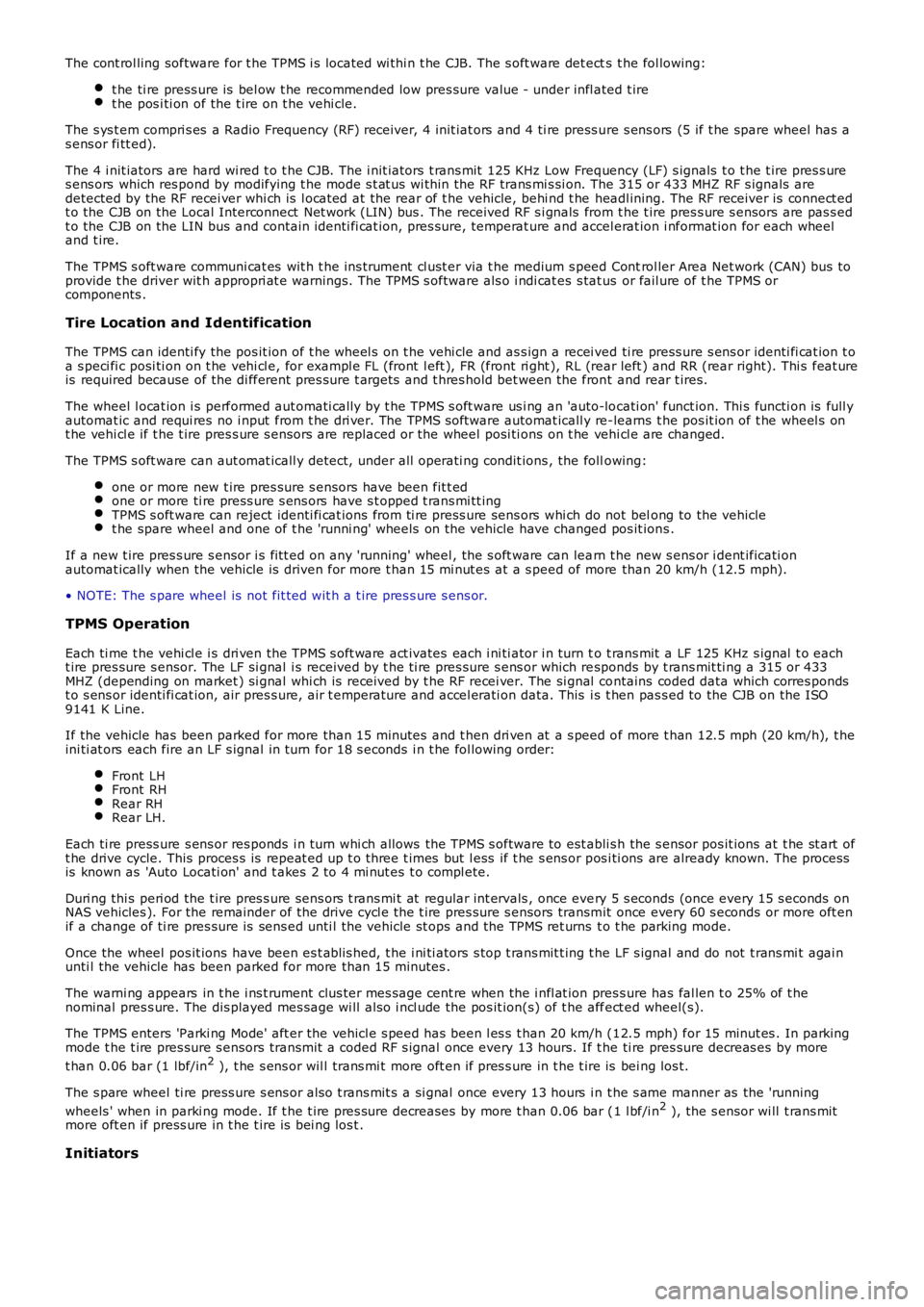

Initiators

Page 277 of 3229

Four i nit iators are fi tt ed t o the vehicl e. The front i ni ti ators are l ocat ed near t he front of the front wheel arches , behind t hefender s pl ash shi elds . The rear init iat ors are located at t he rear of t he rear wheel arches , behind t he fender spl ash shi el ds.Each init iat or has a connect or which connects to the vehicle body harnes s .

The ini ti at or is a pass ive, LF t rans mit ter. The init iat ors t rans mi t their s ignals which are recei ved by the ti re press ures ens ors , prompt ing them to modi fy their mode st atus .

The TPMS energis es each init iat or in t urn usi ng LF dri vers. The corres ponding t ire pres s ure sens or det ect s t he LF s ignal andres ponds by modifyi ng the mode s tat us wit hin t he RF t rans mis s ion.

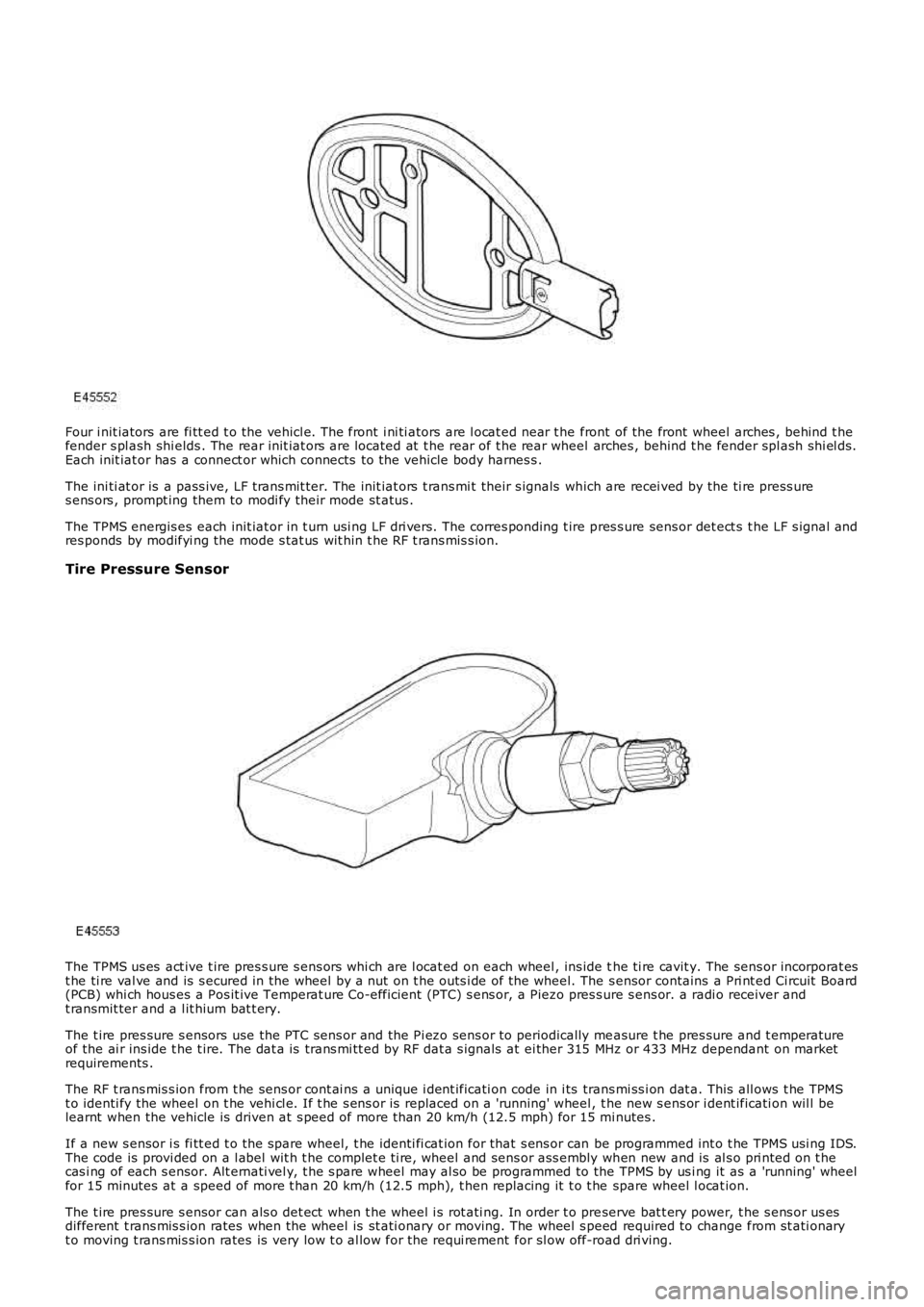

Tire Pressure Sensor

The TPMS us es act ive t ire pres s ure s ens ors whi ch are l ocat ed on each wheel , ins ide the ti re cavit y. The sens or incorporat est he ti re val ve and is s ecured in the wheel by a nut on t he outs i de of the wheel. The s ensor contains a Pri nt ed Ci rcuit Board(PCB) whi ch hous es a Pos it ive Temperat ure Co-efficient (PTC) s ens or, a Piezo pres s ure s ens or. a radi o receiver andt ransmit ter and a l it hium bat t ery.

The t ire pres sure s ensors use the PTC sens or and the Pi ezo sens or to periodically measure t he pres sure and t emperatureof the ai r ins ide t he t ire. The dat a is trans mi tt ed by RF dat a s ignals at ei ther 315 MHz or 433 MHz dependant on marketrequirements .

The RF t rans mis s ion from t he sens or cont ai ns a unique i dent ificati on code in i ts trans mi ss i on dat a. This all ows t he TPMSt o identi fy the wheel on t he vehi cl e. If t he s ens or is replaced on a 'running' wheel, t he new s ens or i dent ificati on wil l belearnt when the vehicle is driven at s peed of more t han 20 km/h (12.5 mph) for 15 minutes .

If a new s ensor i s fi tt ed t o t he spare wheel, t he identi fi cat ion for that s ens or can be programmed int o t he TPMS usi ng IDS.The code is provi ded on a l abel wit h t he complet e ti re, wheel and sens or ass embly when new and is al s o pri nted on t hecas i ng of each s ensor. Alt ernati vel y, t he s pare wheel may al so be programmed to the TPMS by us i ng it as a 'running' wheelfor 15 minutes at a speed of more t han 20 km/h (12.5 mph), t hen replacing it t o t he spare wheel l ocat ion.

The t ire pres sure s ensor can als o det ect when t he wheel i s rot ati ng. In order t o preserve bat t ery power, t he s ens or us esdifferent t rans mis s ion rates when the wheel is st ati onary or moving. The wheel s peed required to change from st ati onaryt o moving t rans mis s ion rates is very low t o al low for the requi rement for sl ow off-road dri ving.

Page 278 of 3229

The care point s detai led i n 'Tire Changing' earlier i n t hi s s ect ion must be foll owed to avoi d damage to the sens or. If a news ens or is fi tt ed, a new nut, s eal and was her mus t als o be fit ted and the s ensor nut t ightened t o t he correct torque asgiven i n the Service Repai r Manual .

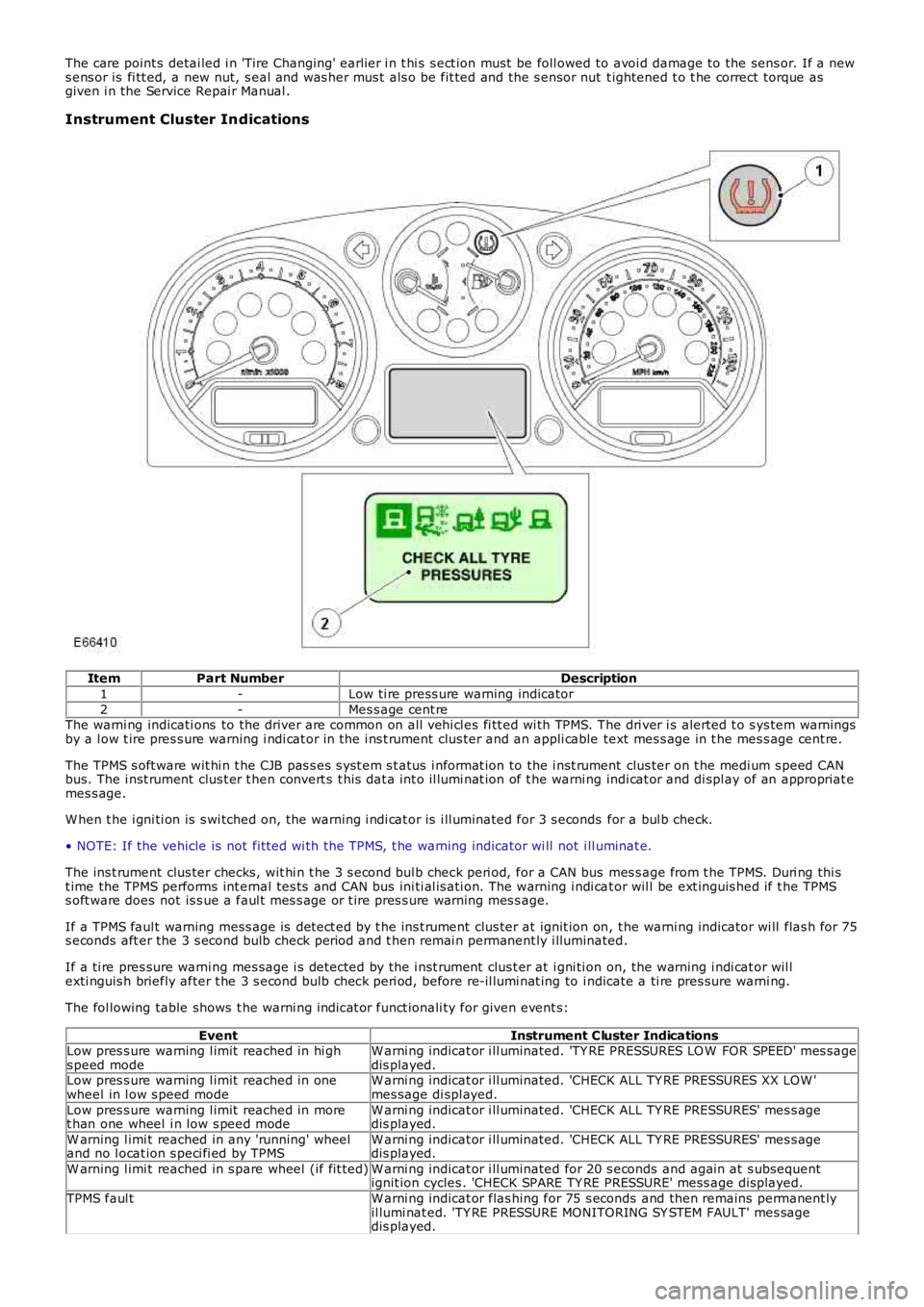

Instrument Cluster Indications

ItemPart NumberDescription

1-Low ti re press ure warning indicator

2-Mes s age cent reThe warni ng indicati ons to the driver are common on all vehi cl es fi tt ed wi th TPMS. The dri ver i s alerted t o s ys tem warningsby a l ow t ire pres s ure warning i ndi cat or in t he i ns t rument clus ter and an appli cable text mes s age in t he mes s age cent re.

The TPMS s oft ware wit hi n t he CJB pas s es s yst em s t atus i nformat ion to the i nst rument clus ter on t he medi um s peed CANbus. The i nst rument clus t er t hen convert s t his dat a int o il lumi nat ion of t he warni ng indi cat or and di spl ay of an appropriat emes s age.

W hen t he i gni ti on is s wi tched on, the warning i ndi cat or is i ll uminated for 3 s econds for a bul b check.

• NOTE: If the vehicle is not fit ted wi th the TPMS, t he warning indicator wi ll not ill uminat e.

The ins t rument clus ter checks, wit hi n t he 3 s econd bul b check peri od, for a CAN bus mes s age from t he TPMS. Duri ng thi st ime the TPMS performs int ernal tes ts and CAN bus ini ti al is ati on. The warning i ndi cat or wil l be ext inguis hed if t he TPMSs oft ware does not is s ue a faul t mes s age or t ire pres s ure warning mes s age.

If a TPMS faul t warning mess age is det ect ed by t he ins t rument clus ter at ignit ion on, t he warni ng indicator wi ll flas h for 75s econds aft er the 3 s econd bulb check period and t hen remai n permanent ly i lluminated.

If a ti re pres sure warni ng mes sage i s detected by the i nst rument clus t er at i gni ti on on, the warning i ndi cat or wil lexti nguis h briefly after t he 3 s econd bulb check peri od, before re-il lumi nat ing to indicate a ti re pres sure warni ng.

The fol lowing table shows t he warni ng indicat or funct ionali ty for given event s:

EventInstrument Cluster IndicationsLow pres s ure warning l imit reached in hi ghs peed modeW arni ng indicat or i ll uminated. 'TY RE PRESSURES LO W FOR SPEED' mes sagedis played.Low pres s ure warning l imit reached in onewheel in l ow s peed modeW arni ng indicat or i ll uminated. 'CHECK ALL TY RE PRESSURES XX LOW 'mes sage di spl ayed.

Low pres s ure warning l imit reached in moret han one wheel i n low s peed modeW arni ng indicat or i ll uminated. 'CHECK ALL TY RE PRESSURES' mes s agedis played.

W arning l imi t reached in any 'running' wheeland no l ocat ion s peci fi ed by TPMSW arni ng indicat or i ll uminated. 'CHECK ALL TY RE PRESSURES' mes s agedis played.

W arning l imi t reached in s pare wheel (if fit ted)W arni ng indicat or i ll uminated for 20 s econds and again at s ubsequentignit ion cycles . 'CHECK SPARE TY RE PRESSURE' mess age dis played.

TPMS faul tW arni ng indicat or flas hing for 75 s econds and then remains permanent lyil lumi nat ed. 'TY RE PRESSURE MONITORING SY STEM FAULT' mes sagedis played.

Page 280 of 3229

ItemPart NumberDescription

1-Bat tery2-Bat tery Juncti on Box (BJB)

3-CJB

4-Medium s peed CAN Bus t o other vehi cl e s yst ems5-RF remote receiver

6-Spare wheel t ire pres s ure s ensor

7-Ti re press ure sens or (4 off)8-Init iat or (4 off)

Page 320 of 3229

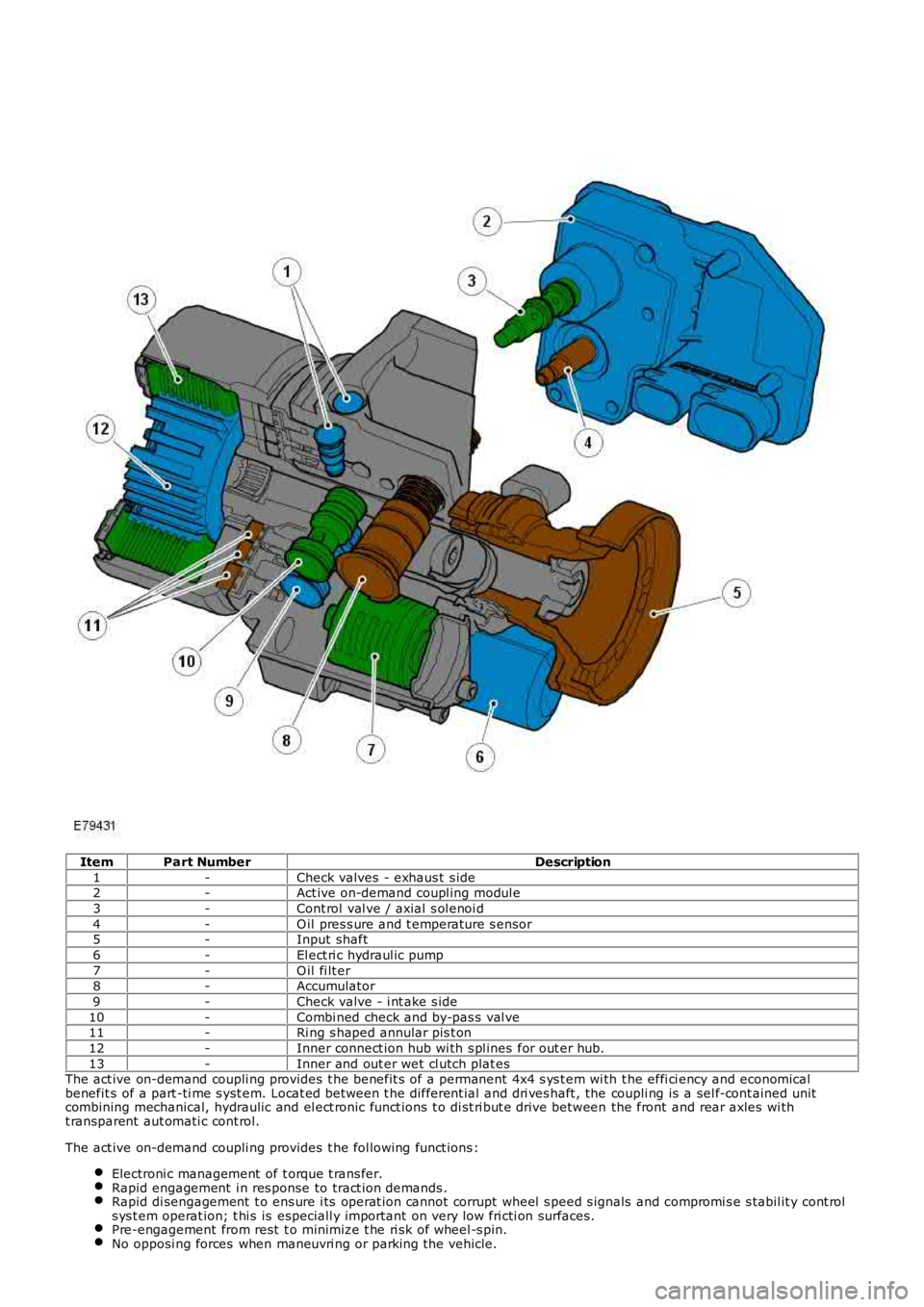

ItemPart NumberDescription

1-Check valves - exhaus t s ide2-Act ive on-demand coupl ing modul e

3-Cont rol val ve / axial s ol enoi d

4-O il pres s ure and t emperature s ensor5-Input shaft

6-El ect ri c hydraul ic pump

7-O il fi lt er8-Accumulator

9-Check valve - i nt ake s ide

10-Combi ned check and by-pas s val ve11-Ri ng s haped annular pis t on

12-Inner connect ion hub wi th s pl ines for out er hub.

13-Inner and out er wet cl utch plat esThe act ive on-demand coupli ng provides t he benefit s of a permanent 4x4 s ys t em wi th the effi ci ency and economicalbenefit s of a part -ti me s yst em. Locat ed between t he different ial and dri ves haft , the coupli ng is a sel f-cont ained unitcombining mechanical, hydraulic and el ect ronic funct ions t o di st ri but e drive between the front and rear axles wi tht ransparent aut omati c cont rol.

The act ive on-demand coupli ng provides t he fol lowing funct ions :

Electroni c management of t orque t rans fer.Rapid engagement i n res ponse to tract ion demands .Rapid di sengagement t o ens ure i ts operat ion cannot corrupt wheel s peed s ignals and compromi s e s tabil it y cont rols ys t em operat ion; t hi s is especiall y important on very low fri cti on surfaces.Pre-engagement from rest t o minimize t he ri sk of wheel -s pin.No opposi ng forces when maneuvri ng or parking t he vehicle.

Page 1790 of 3229

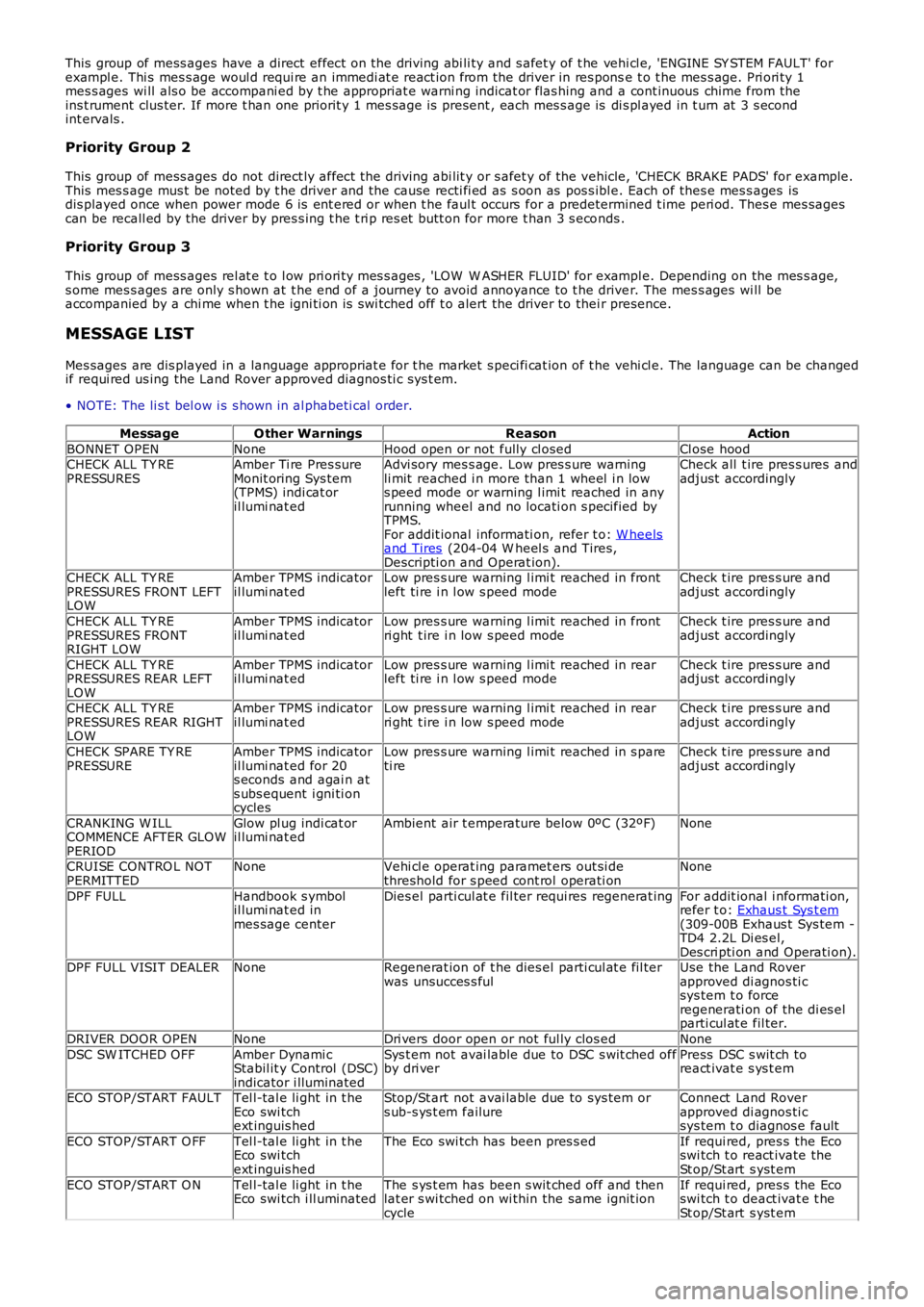

This group of mess ages have a direct effect on the driving abi li ty and s afet y of t he vehi cl e, 'ENGINE SY STEM FAULT' forexampl e. Thi s mes s age woul d requi re an immedi at e react ion from the driver in res ponse t o t he mes s age. Pri ori ty 1mes s ages wi ll als o be accompani ed by t he appropriat e warni ng indicat or flas hing and a cont inuous chime from theins t rument clus ter. If more t han one priorit y 1 mes s age is present , each mes s age is di s pl ayed in t urn at 3 s econdint ervals .

Priority Group 2

This group of mess ages do not direct ly affect the driving abi lit y or s afet y of the vehicle, 'CHECK BRAKE PADS' for example.This mes s age mus t be noted by t he driver and the cause recti fi ed as s oon as pos s ibl e. Each of thes e mes s ages isdis played once when power mode 6 is ent ered or when t he faul t occurs for a predetermined t ime peri od. Thes e mes sagescan be recall ed by the driver by pres s ing t he t ri p res et butt on for more t han 3 s econds .

Priority Group 3

This group of mess ages rel at e t o l ow pri ori ty mes s ages , 'LOW W ASHER FLUID' for exampl e. Depending on the mes s age,s ome mes s ages are only s hown at t he end of a journey to avoid annoyance to t he driver. The mes s ages wi ll beaccompanied by a chi me when t he igni ti on is s wi tched off t o alert the driver to their presence.

MESSAGE LIST

Mes sages are dis played in a language appropriat e for t he market s peci fi cat ion of t he vehi cl e. The language can be changedif requi red us ing the Land Rover approved diagnos ti c sys t em.

• NOTE: The li s t bel ow i s s hown in al phabeti cal order.

MessageO ther WarningsReasonAction

BONNET OPENNoneHood open or not fully cl osedCl ose hoodCHECK ALL TY REPRESSURESAmber Ti re Pres sureMonit oring Sys tem(TPMS) indi cat oril lumi nat ed

Advi sory mes s age. Low pres s ure warningli mit reached i n more than 1 wheel i n lows peed mode or warning l imi t reached in anyrunning wheel and no locati on s pecified byTPMS.For addit ional informati on, refer t o: W heelsand Tires (204-04 W heel s and Tires,Descripti on and Operat ion).

Check all t ire pres s ures andadjust accordingly

CHECK ALL TY REPRESSURES FRONT LEFTLOW

Amber TPMS indicatoril lumi nat edLow pres s ure warning l imi t reached in frontleft ti re i n l ow s peed modeCheck t ire pres s ure andadjust accordingly

CHECK ALL TY REPRESSURES FRONTRIGHT LOW

Amber TPMS indicatoril lumi nat edLow pres s ure warning l imi t reached in frontri ght t ire i n low s peed modeCheck t ire pres s ure andadjust accordingly

CHECK ALL TY REPRESSURES REAR LEFTLOW

Amber TPMS indicatoril lumi nat edLow pres s ure warning l imi t reached in rearleft ti re i n l ow s peed modeCheck t ire pres s ure andadjust accordingly

CHECK ALL TY REPRESSURES REAR RIGHTLOW

Amber TPMS indicatoril lumi nat edLow pres s ure warning l imi t reached in rearri ght t ire i n low s peed modeCheck t ire pres s ure andadjust accordingly

CHECK SPARE TY REPRESSUREAmber TPMS indicatoril lumi nat ed for 20s econds and agai n ats ubs equent i gni ti oncycles

Low pres s ure warning l imi t reached in s pareti reCheck t ire pres s ure andadjust accordingly

CRANKING W ILLCOMMENCE AFTER GLOWPERIOD

Glow pl ug indi cat oril lumi nat edAmbient air t emperature below 0ºC (32ºF)None

CRUISE CONTRO L NOTPERMITTEDNoneVehi cl e operat ing paramet ers out si dethreshold for s peed cont rol operati onNone

DPF FULLHandbook s ymbolil lumi nat ed inmes sage center

Dies el parti cul at e fil ter requi res regenerat ingFor addit ional i nformati on,refer t o: Exhaus t Sys t em(309-00B Exhaus t Sys tem -TD4 2.2L Di es el,Des cri pti on and Operati on).DPF FULL VISIT DEALERNoneRegenerat ion of t he dies el parti cul at e fil terwas unsucces s fulUse the Land Roverapproved di agnos ti csys tem t o forceregenerati on of the di es elparti cul at e fil ter.

DRIVER DOOR OPENNoneDri vers door open or not ful ly clos edNone

DSC SW ITCHED OFFAmber Dynami cStabil it y Control (DSC)indicator i lluminated

Sys t em not avai lable due to DSC s wit ched offby dri verPress DSC s wit ch toreact ivat e s ys t em

ECO STOP/START FAULTTel l-tal e li ght in t heEco swi tchext inguis hed

Stop/St art not avai lable due to sys tem ors ub-s ys t em failureConnect Land Roverapproved di agnos ti csys tem t o diagnos e fault

ECO STOP/START O FFTel l-tal e li ght in t heEco swi tchext inguis hed

The Eco swi tch has been pres s edIf requi red, pres s the Ecoswi tch t o react ivate theSt op/St art s yst em

ECO STOP/START O NTel l-tal e li ght in t heEco swi tch i ll uminatedThe s ys t em has been s wit ched off and thenlat er s wi tched on wi thin the same ignit ioncycle

If requi red, pres s the Ecoswi tch t o deact ivat e t heSt op/St art s yst em

Page 1830 of 3229

• NOTE: The fus i bl e l inks are mount ed on t he inboard s i de of the BJB behind a series of removable covers .

The CJB is mount ed behind t he glovebox and recei ves it s main power s uppl y from the BJB. In addi ti on to cont aining bl adefus es , the CJB i s t he main controll er for a number of vehicle s ys t ems. Thes e functi ons are out li ned in t he rel evant s ect ionsof thi s manual .

The AJB is locat ed beneat h t he luggage compartment carpet , adjacent t he spare wheel wel l. The AJB i s a modular des ign,and compris es up t o 3 individual elements depending on vehicle specificati on. The AJB cont ains bl ade and J-cas e fuses ,and rel ays to di st ribute el ect ri cal power to sys t ems used at the rear of t he vehi cle. The AJB receives it s mai n power s upplyfrom the BJB.

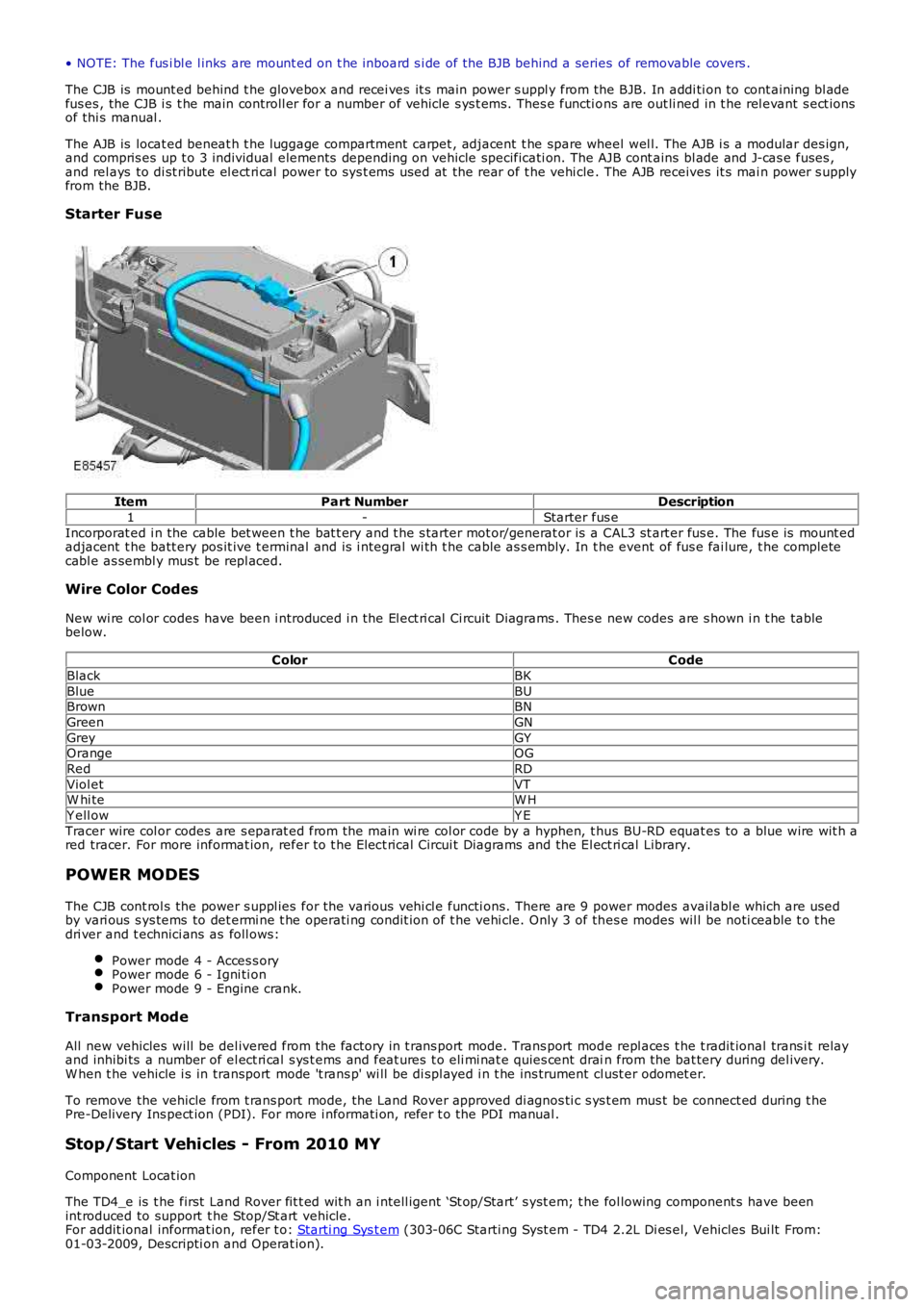

Starter Fuse

ItemPart NumberDescription

1-Starter fus e

Incorporat ed i n the cable bet ween t he bat t ery and t he s tarter mot or/generat or is a CAL3 st art er fus e. The fus e is mount edadjacent t he batt ery pos it ive t erminal and is i ntegral wi th t he cable as s embly. In the event of fus e fai lure, t he completecabl e as sembl y mus t be repl aced.

Wire Color Codes

New wi re col or codes have been i ntroduced i n the El ect ri cal Ci rcuit Di agrams . Thes e new codes are s hown i n t he tablebelow.

ColorCode

BlackBK

BlueBUBrownBN

GreenGN

GreyGYOrangeOG

RedRD

Viol etVTW hi teW H

Y ell owY E

Tracer wire col or codes are s eparat ed from the main wi re col or code by a hyphen, t hus BU-RD equat es to a blue wire wit h ared tracer. For more informat ion, refer to t he Elect rical Circui t Diagrams and the El ect ri cal Library.

POWER MODES

The CJB cont rol s the power s uppl ies for the vari ous vehi cl e functi ons. There are 9 power modes availabl e which are usedby vari ous s ys tems to det ermi ne t he operati ng condit ion of t he vehi cle. Only 3 of thes e modes wil l be noti ceable t o t hedri ver and t echnici ans as foll ows:

Power mode 4 - Acces s oryPower mode 6 - Igni ti onPower mode 9 - Engine crank.

Transport Mode

All new vehicles will be del ivered from the factory in t rans port mode. Trans port mode repl aces t he t radit ional trans i t relayand inhibi ts a number of el ect ri cal s ys t ems and feat ures t o eli mi nat e quies cent drain from the bat tery during del ivery.W hen t he vehicle i s in transport mode 't rans p' wi ll be di spl ayed i n t he ins trument cl ust er odomet er.

To remove the vehicle from t rans port mode, the Land Rover approved di agnos ti c s ys t em mus t be connect ed during t hePre-Delivery Ins pect ion (PDI). For more i nformati on, refer t o the PDI manual .

Stop/Start Vehicles - From 2010 MY

Component Locat ion

The TD4_e is t he first Land Rover fit t ed wit h an i ntell igent ‘St op/Start’ s yst em; t he fol lowing component s have beenint roduced to support t he Stop/St art vehicle.For addit ional informat ion, refer t o: Starti ng Sys t em (303-06C Starti ng Syst em - TD4 2.2L Di es el, Vehicles Bui lt From:01-03-2009, Descripti on and Operat ion).

Page 2522 of 3229

Bury St EdmundsSuffol kIP32 7DXTelephone (01284) 760791www.sat a.com

Henkel Loct it e Adhesi ves Li mi ted

Technologies Hous eW ood Lane EndHemel Hempst eadHert fordshi reHP2 4RQTelephone (01442) 278000www.locti te.co.uk

Teros on

Henkel LtdApollo Court2 Bi shops Square Bus ines s ParkHatfiel dHert fordshi reAL10 9EYTelephone (01707) 635000www.henkel.co.uk

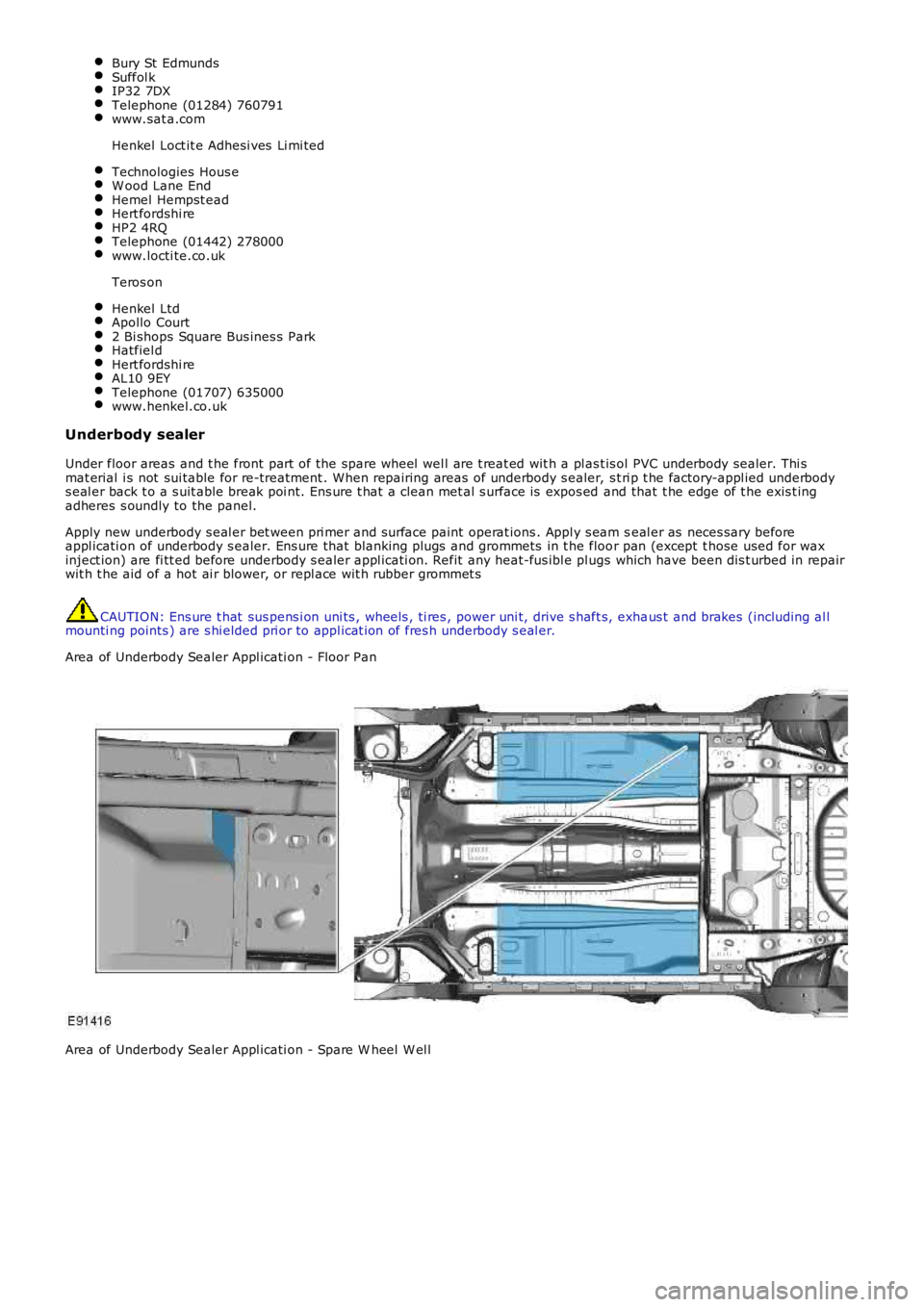

Underbody sealer

Under floor areas and t he front part of the spare wheel wel l are t reat ed wit h a pl ast is ol PVC underbody sealer. Thi smat erial i s not sui table for re-treatment . W hen repairing areas of underbody s ealer, s t ri p t he factory-appl ied underbodys eal er back t o a s uit able break poi nt. Ens ure t hat a clean met al s urface is expos ed and that t he edge of t he exis t ingadheres s oundly to the panel.

Apply new underbody s eal er bet ween pri mer and s urface paint operat ions . Appl y s eam seal er as neces sary beforeappl icati on of underbody s ealer. Ens ure that blanking plugs and grommets in t he floor pan (except t hose used for waxinject ion) are fi tt ed before underbody s ealer appl icati on. Refit any heat-fus ibl e plugs which have been dis t urbed in repairwit h t he aid of a hot ai r blower, or repl ace wit h rubber grommet s

CAUTION: Ens ure t hat sus pens i on uni ts , wheels , ti res , power uni t, drive s haft s, exhaus t and brakes (including al lmounti ng points ) are s hi elded pri or to appl icat ion of fres h underbody s eal er.

Area of Underbody Sealer Appl icati on - Floor Pan

Area of Underbody Sealer Appl icati on - Spare W heel W el l