Air Conditioning Compressor LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 210 of 4500

Fig. 6: Air Conditioning System Diagram (2 Of 2)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1.GENERAL

a. The air conditioning system has the following features:

In compliance with the temperature set at the temperature control switch, the neural network

control calculates the outlet temperature based on the input signals from various sensors. In

addition, corrections in accordance with the signals from the evaporative temperature sensor

and the water temperature sensor are added to control the outlet air temperature.

Controls the front and rear blower motors in accordance with the airflow volume that has

been calculated by the neural network control based on the input signals from various

sensors.

Automatically switches the outlets in accordance with the outlet mode ratio that has been

calculated by the neural network control based on the input signals from various sensors.

Automatically controls the air inlet control damper in accordance with the airflow volume

that has been calculated by the neural network control.

Turns the compressor on/off and controls the discharge capacity based on the signals from

various sensors.

Based on the signals from the ambient temperature sensor, this control calculates the outside

temperature, which is then corrected in the air conditioner ECU, and shown in the multi-

information display in the combination meter.

Switched the rear defogger and outside rear view mirror heaters on for 15 minutes when the

rear defogger switch is switched on. Switched them off if the switch is pressed while they are

operating.

Controls the orientation and the angle of the front center register based on the input signals

from various sensors and on the outlet mode.

Determines whether the clean air filter (for the front A/C) is clogged by monitoring the air

inlets, and airflow volume.

The A/C amplifier automatically controls the air inlets based on the signals from the smog

ventilation sensor.

Improves the air quality by linking the air inlet control damper and the blower motor (for the

rear A/C and air purifier), based on the signals from the exhaust gas sensor and the smoke

sensor.

Checks the sensors in accordance with operation of the air conditioner switches.

2.MODEL POSITION AND DAMPER OPERATION

Page 230 of 4500

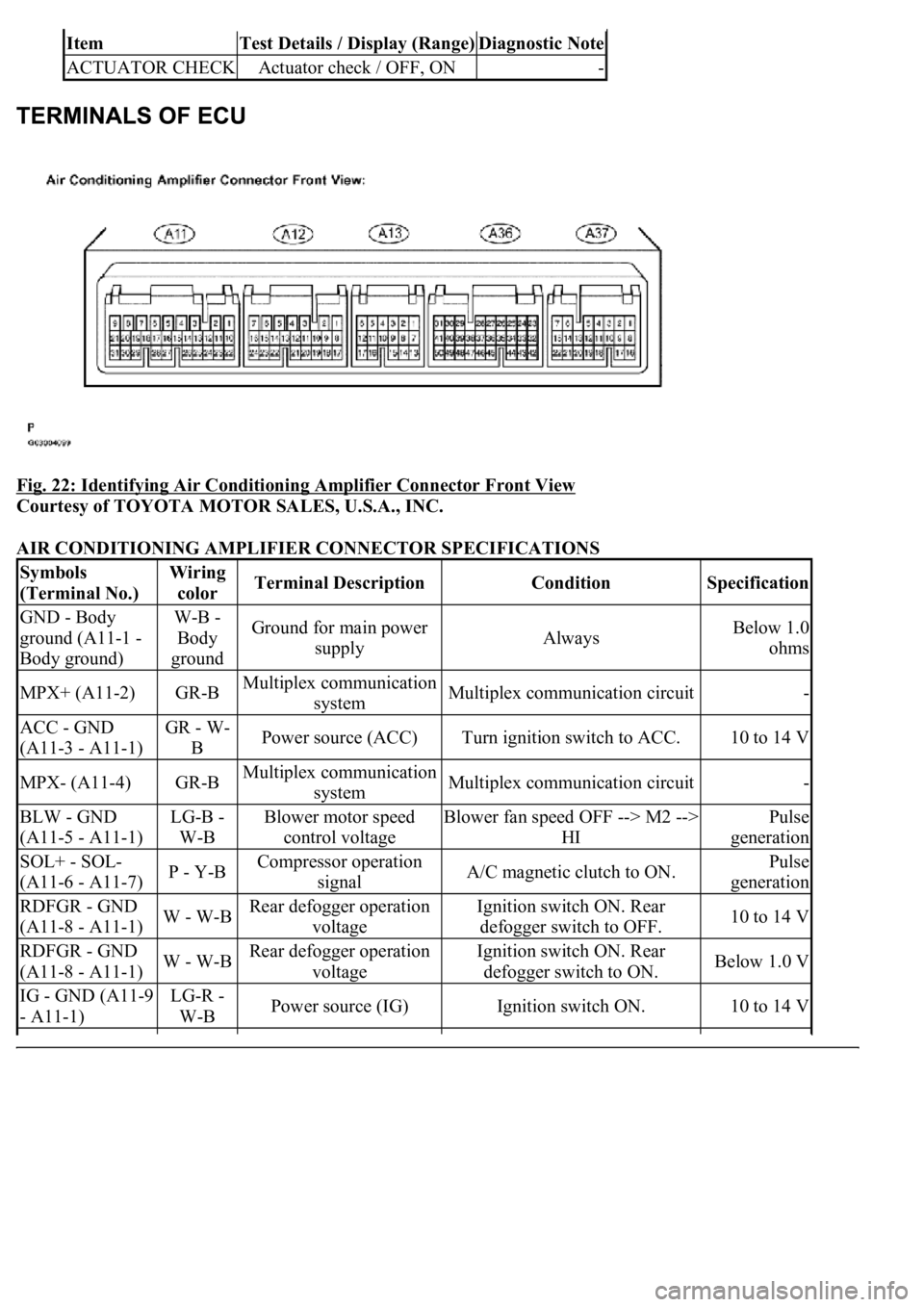

Fig. 22: Identifying Air Conditioning Amplifier Connector Front View

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

AIR CONDITIONING AMPLIFIER CONNECTOR SPECIFICATIONS

ItemTest Details / Display (Range)Diagnostic Note

ACTUATOR CHECKActuator check / OFF, ON-

Symbols

(Terminal No.)Wiring

colorTerminal DescriptionConditionSpecification

GND - Body

ground (A11-1 -

Body ground)W-B -

Body

groundGround for main power

supplyAlwaysBelow 1.0

ohms

MPX+ (A11-2)GR-BMultiplex communication

systemMultiplex communication circuit-

ACC - GND

(A11-3 - A11-1)GR - W-

BPower source (ACC)Turn ignition switch to ACC.10 to 14 V

MPX- (A11-4)GR-BMultiplex communication

systemMultiplex communication circuit-

BLW - GND

(A11-5 - A11-1)LG-B -

W-BBlower motor speed

control voltageBlower fan speed OFF --> M2 -->

HIPulse

generation

SOL+ - SOL-

(A11-6 - A11-7)P - Y-BCompressor operation

signalA/C magnetic clutch to ON.Pulse

generation

RDFGR - GND

(A11-8 - A11-1)W - W-BRear defogger operation

voltageIgnition switch ON. Rear

defogger switch to OFF.10 to 14 V

RDFGR - GND

(A11-8 - A11-1)W - W-BRear defogger operation

voltageIgnition switch ON. Rear

defogger switch to ON.Below 1.0 V

IG - GND (A11-9

- A11-1)LG-R -

W-BPower source (IG)Ignition switch ON.10 to 14 V

Page 241 of 4500

1.STEP MOTORS INITIALIZING FUNCTION

STEP motor initializing procedure (Automatic initializing)

1. When the battery is reconnected and the ignition switch is turned to the ON position for the first

time, the initializing function of the STEP motors is activated. In this case, the "FRONT DEF"

indicator blinks.

SET TEMP SHIFT

(Set Temperature

Shift)

NORMALTo control with the shifted temperature

against the display temperature.+2C/+1C/ NORMAL -

1C / -2C

AIR INLET MODE

(Air Inlet Mode)AUTO

In case of turning the A/C ON when you

desire to make the compartment cool down

quickly, this is the function to change the

mode automatically to RECIRCULATED

mode.

MANUAL / AUTO

COMPRESSOR

MODE (Compressor

Mode)

AUTO

Function to turn the A/C ON automatically

by pressing the AUTO button when the

blower is ON and the A/C is OFF.

MANUAL / AUTO

COMPRS/DEF OPER

(Compressor/Air Inlet

DEF Operation)

LINK

Function to turn the A/C ON automatically

linking with the FRONT DEF button when

A/C is OFF.

NORMAL / LINK

MOTOR INITIALIZ

(STEP Motor

Initializing (IG/off))

OFFFunction to initialize the STEP motor after

the ignition switch is OFF.ON / OFF

EVAP CTRL

(External Variable

Control OFF)

AUTO

Function to set the evaporator control to the

AUTOMATIC position (AUTO) to save

power or to the coldest position

(MANUAL) to dehumidify the air and to

prevent the windows from fogging up.

MANUAL / AUTO

GAS SENS SHIFT

(Shift Emission Gas

Sensor Sensitivity)

NORMALFunction to change the sensitivity of the

exhaust gas sensor.

MU MORE /MORE / LI

MORE / NORMAL / LI

LESS / LESS / MU

LESS

AUTO MODE

(Cancel Auto Mode)AUTOFunction to swing the vent vans

automatically when A/C is ON.MANUAL / AUTO

BUTTON PRS BUS

(Cancel Operating

Switch Sound)

ONFunction to sound a buzzer when a button

is pressed.OFF / ON

FILTER SENS (Shift

Filter Clog Sensitivity)NORMALFunction to change the sensitivity of the air

conditioning filter choking sensor.LESS / NORMAL /

MORE

FOOT AIR LEAK

(Cancel Air Outlet

Foot II)

ONFunction to cut off the airstream felt

underfoot while the vehicle is moving.OFF / ON

Page 298 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK: REPLACE AIR CONDITIONING AMPLIFIER (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

The pressure switch sends the appropriate signals to the A/C amplifier when the A/C refrigerant pressure drops

too low or rises too high.

When the A/C amplifier receives these signals, the compressor does not compress refrigerant.

Fig. 75: DTC Detection Item Trouble Area Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

WIRING DIAGRAM

Page 351 of 4500

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK: REPLACE AIR CONDITIONING AMPLIFIER (SEE REPLACEMENT )

CIRCUIT DESCRIPTION

In this circuit, the compressor assembly receives a signal on refrigerant compression required by the air

conditioning amplifier. Based on the signal, the compressor assembly changes the degree of refrigerant

compression.

Fig. 116: DTC Detection Item Trouble Area Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

WIRING DIAGRAM

Fig. 117: Compressor Solenoid Circuit

Page 353 of 4500

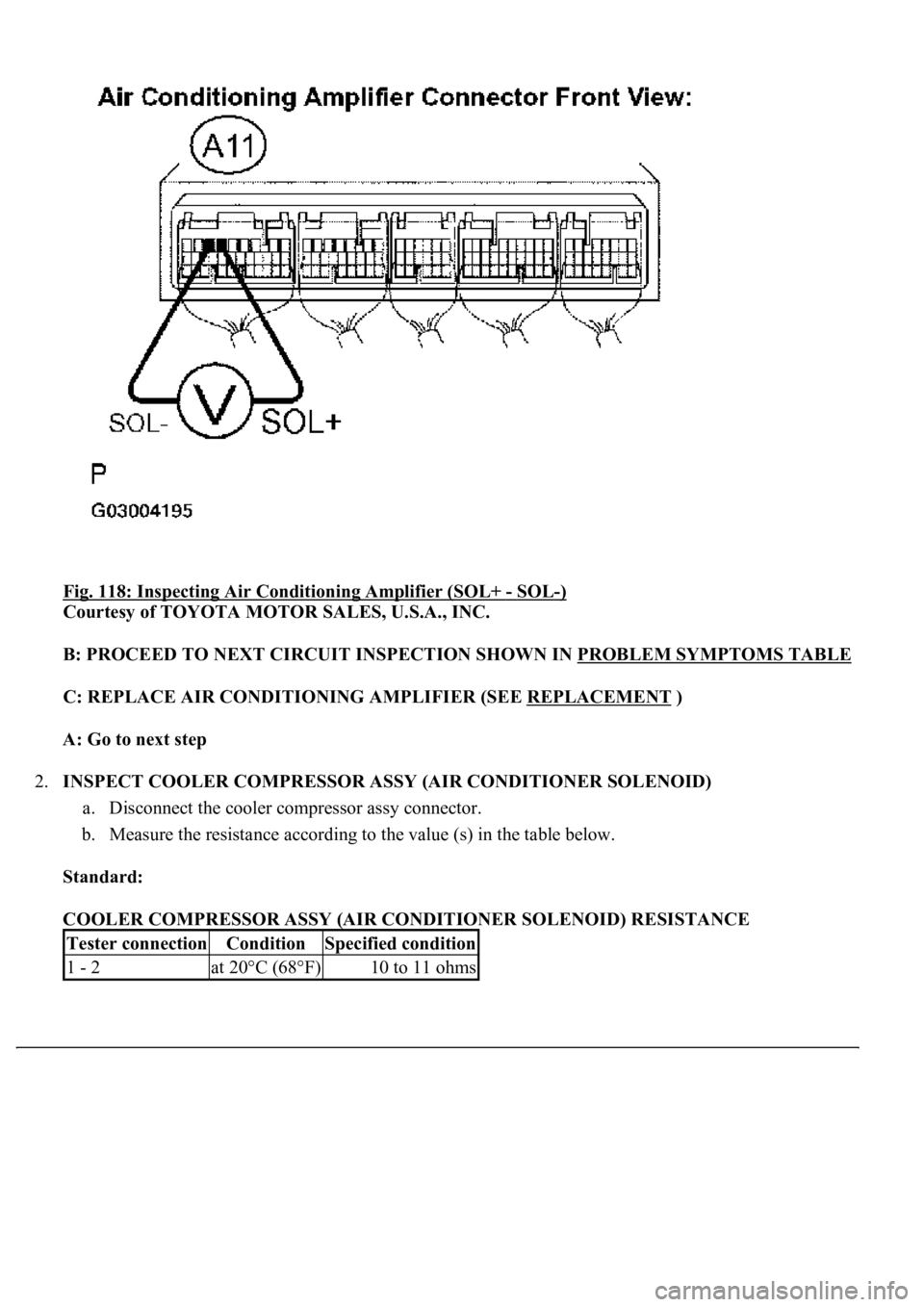

Fig. 118: Inspecting Air Conditioning Amplifier (SOL+ - SOL-)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

B: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

C: REPLACE AIR CONDITIONING AMPLIFIER (SEE REPLACEMENT )

A: Go to next step

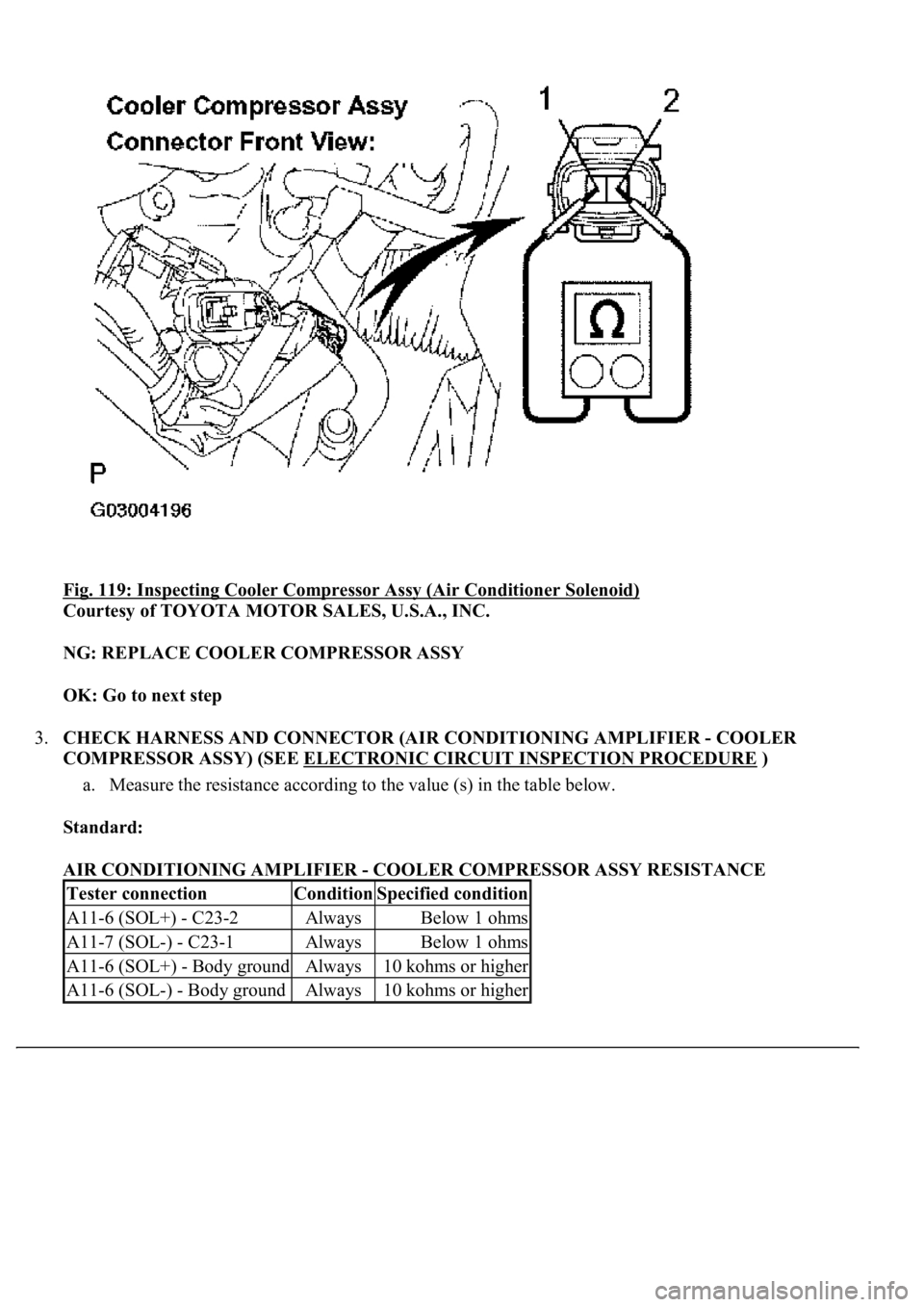

2.INSPECT COOLER COMPRESSOR ASSY (AIR CONDITIONER SOLENOID)

a. Disconnect the cooler compressor assy connector.

b. Measure the resistance according to the value (s) in the table below.

Standard:

COOLER COMPRESSOR ASSY (AIR CONDITIONER SOLENOID) RESISTANCE

Tester connectionConditionSpecified condition

1 - 2at 20°C (68°F)10 to 11 ohms

Page 354 of 4500

Fig. 119: Inspecting Cooler Compressor Assy (Air Conditioner Solenoid)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPLACE COOLER COMPRESSOR ASSY

OK: Go to next step

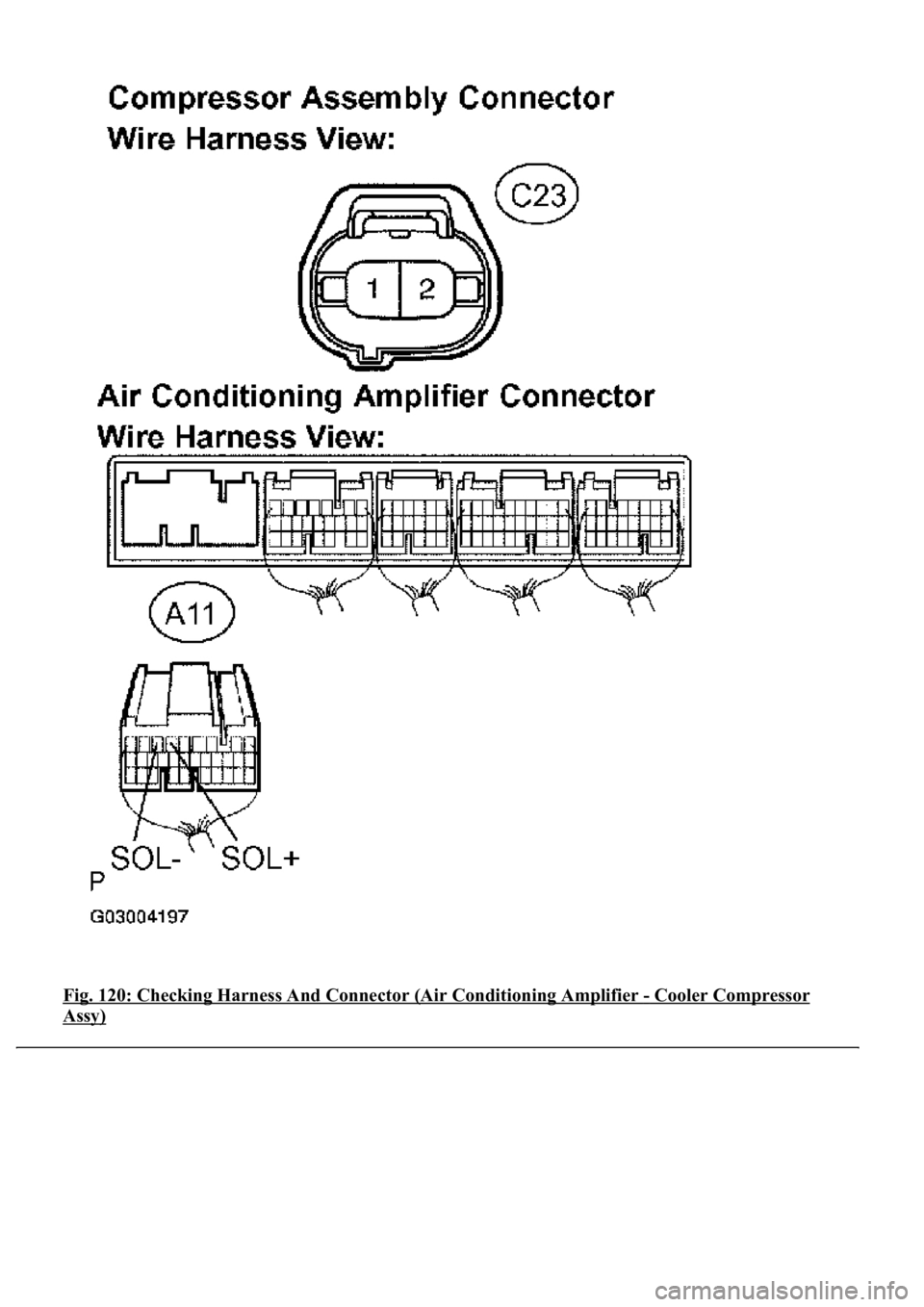

3.CHECK HARNESS AND CONNECTOR (AIR CONDITIONING AMPLIFIER - COOLER

COMPRESSOR ASSY) (SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Measure the resistance according to the value (s) in the table below.

Standard:

AIR CONDITIONING AMPLIFIER - COOLER COMPRESSOR ASSY RESISTANCE

Tester connectionConditionSpecified condition

A11-6 (SOL+) - C23-2AlwaysBelow 1 ohms

A11-7 (SOL-) - C23-1AlwaysBelow 1 ohms

A11-6 (SOL+) - Body groundAlways10 kohms or higher

A11-6 (SOL-) - Body groundAlways10 kohms or higher

Page 355 of 4500

Fig. 120: Checking Harness And Connector (Air Conditioning Amplifier - Cooler Compressor

Assy)

Page 4244 of 4500

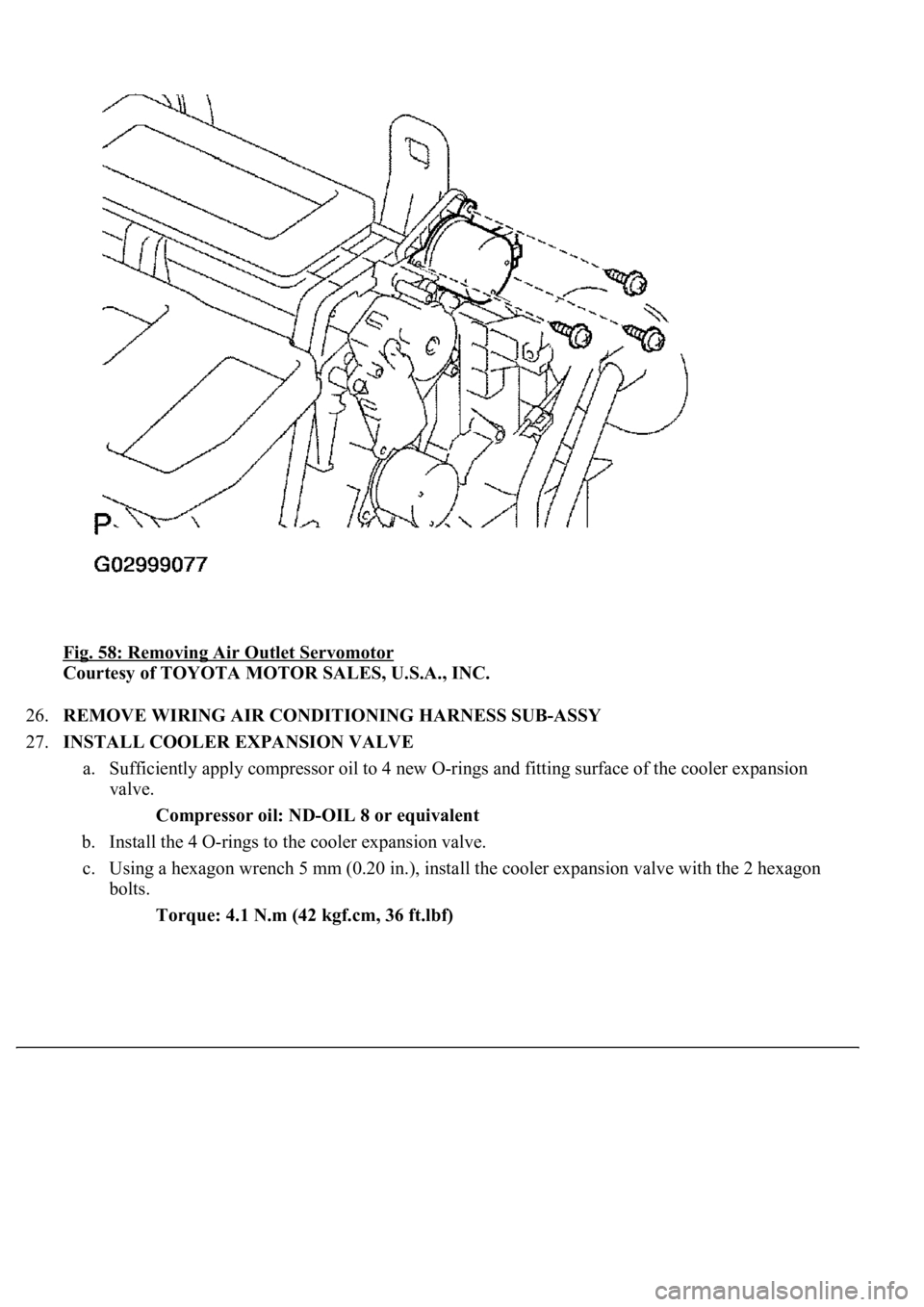

Fig. 58: Removing Air Outlet Servomotor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

26.REMOVE WIRING AIR CONDITIONING HARNESS SUB-ASSY

27.INSTALL COOLER EXPANSION VALVE

a. Sufficiently apply compressor oil to 4 new O-rings and fitting surface of the cooler expansion

valve.

Compressor oil: ND-OIL 8 or equivalent

b. Install the 4 O-rings to the cooler expansion valve.

c. Using a hexagon wrench 5 mm (0.20 in.), install the cooler expansion valve with the 2 hexagon

bolts.

Torque: 4.1 N.m (42 kgf.cm, 36 ft.lbf)

Page 4318 of 4500

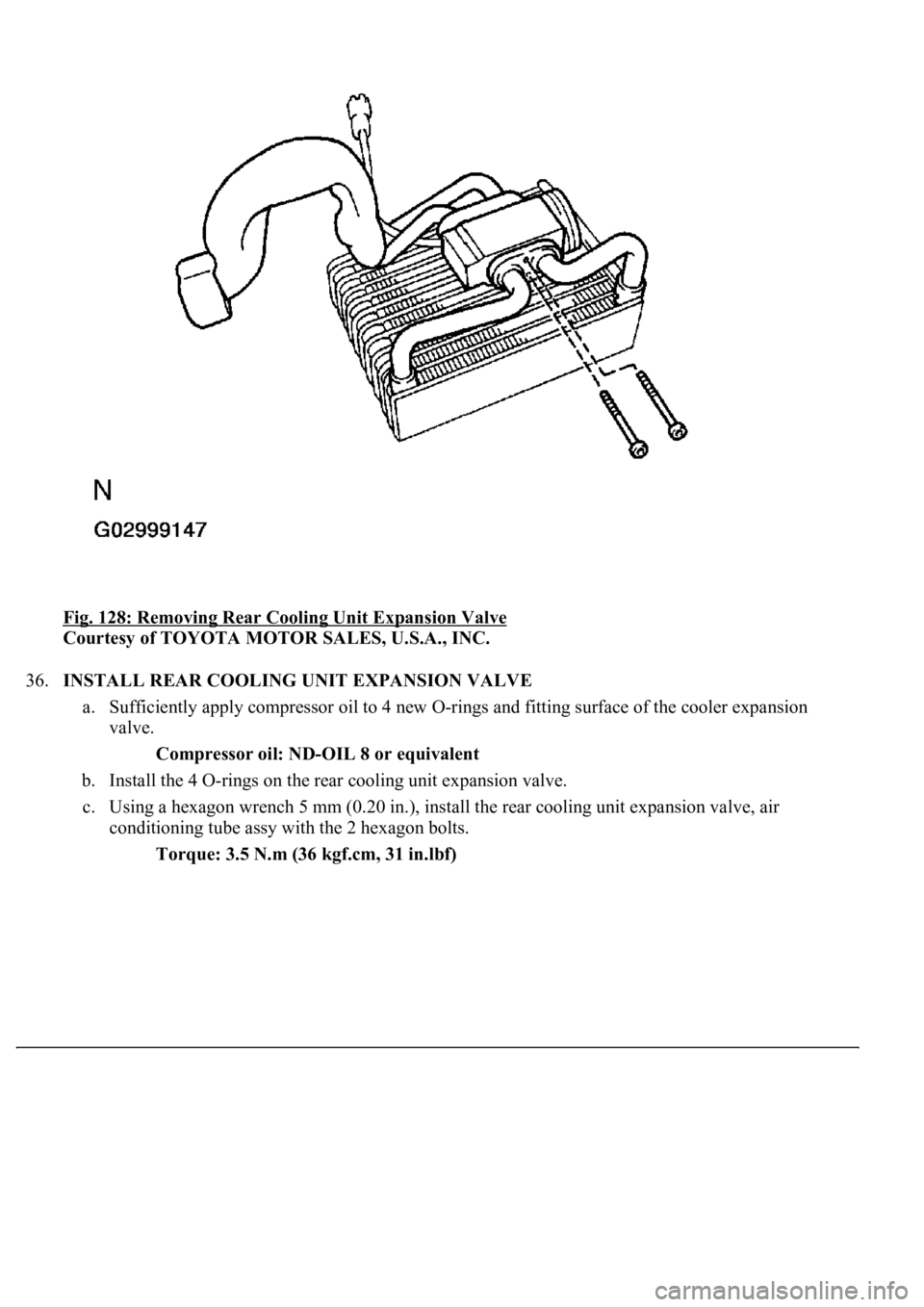

Fig. 128: Removing Rear Cooling Unit Expansion Valve

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

36.INSTALL REAR COOLING UNIT EXPANSION VALVE

a. Sufficiently apply compressor oil to 4 new O-rings and fitting surface of the cooler expansion

valve.

Compressor oil: ND-OIL 8 or equivalent

b. Install the 4 O-rings on the rear cooling unit expansion valve.

c. Using a hexagon wrench 5 mm (0.20 in.), install the rear cooling unit expansion valve, air

conditioning tube assy with the 2 hexagon bolts.

Torque: 3.5 N.m (36 kgf.cm, 31 in.lbf)