height adjustment LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 1968 of 4500

a. Preparation for adjusting the radar beam axis

1. Adjust the tire pressure properly (see INSPECTION

).

2. Luggage in the vehicle, such as in the trunk, should be unloaded.

b. Adjust the standard vehicle height (vehicle with air suspension) (see INSPECTION

)

c. Adjustment in vertical direction of the millimeter wave radar sensor.

1. Remove dust and oil on the level rack of the millimeter wave radar sensor.

2. Set the specified level on the center of the level rack of the millimeter wave radar sensor.

Fig. 21: Setting Specified Level

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Using a hexagon wrench, turn and adjust screw A for vertical adjustment of the millimeter

wave radar sensor so that the air bubble is within the red frame on the level.

Standard:

Adjustable range within the red frame of the level is ± 0.2°.

Page 1970 of 4500

Fig. 23: Adjustment Direction Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

d. Adjust the reflector height

1. Adjust the reflector so that the center of the SST reflector is the same height as the millimeter

wave radar sensor.

SST 09870-60000 (09870-60010, 09870-60040)

HINT:

Prepare a 10 m (32.81 ft) string, with a sharp-pointed weight (plumb bob), and a 5 m (16.41 ft) tape

measure.

Page 2177 of 4500

a. Fill the rear differential carrier assy with differential gear oil equivalent.

Oil type: Differential synthetic gear oil GL-5 75W-90 or equivalent

Capacity: 1.35 +/- 0.05 liters (1.43 +/- 0.05 US qts, 1.19 +/- 0.04 Imp. qts)

67.INSPECT DIFFERENTIAL OIL (SEE ADJUSTMENT

)

68.INSTALL REAR DIFFERENTIAL FILLER PLUG

a. Using a hexagon wrench (10 mm), install the filler plug with a new gasket.

Torque: 49 N.m (500 kgf.cm, 36 ft.lbf)

69.INSTALL REAR DRIVE SHAFT ASSY LH (SEE REPLACEMENT

)

70.INSTALL REAR DRIVE SHAFT ASSY RH

HINT:

Installation procedure of the RH side is the same as that of the LH side.

71.INSTALL FRONT FLOOR HEAT INSULATOR NO.1

a. Install the front floor heat insulator No.1 with the 4 bolts.

Torque: 5.4 N.m (55 kgf.cm, 48 in..lbf)

72.INSTALL REAR WHEEL

a. Install the rear wheel with the 5 nuts.

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

73. Install the ornament with the 10 bolts.

Torque: 20 N.m (204 kgf.cm, 15 ft.lbf)

74.INSTALL PROPELLER W/CENTER BEARING SHAFT ASSY (SEE OVERHAUL

)

75.FULLY TIGHTEN CENTER SUPPORT BEARING ASSY NO.1 (SEE OVERHAUL

)

SST 09922-10010

76.INSPECT AND ADJUST NO.2 AND NO.3 JOINT ANGLE (SEE OVERHAUL

)

77.INSTALL PROPELLER SHAFT HEAT INSULATOR (SEE OVERHAUL

)

78.INSTALL EXHAUST PIPE ASSY (SEE REPLACEMENT

)

79.INSTALL OXYGEN SENSOR (SEE REPLACEMENT

)

80.INSPECT AND ADJUST REAR WHEEL ALIGNMENT (SEE ADJUSTMENT

)

81.ADJUST VEHICLE HEIGHT (W/ AIR SUSPENSION) (SEE ON

-VEHICLE INSPECTION )

82.INSPECT HEADLIGHT AIM ONLY (SEE ADJUSTMENT

)

83.CHECK ABS SPEED SENSOR SIGNAL (SEE TEST MODE PROCEDURE

)

84.INSPECT AIR LEAK (W/ AIR SUSPENSION) (SEE REPLACEMENT

)

HINT:

Perform this operation onl

y when the rear differential mount cushion is replaced.

Page 2391 of 4500

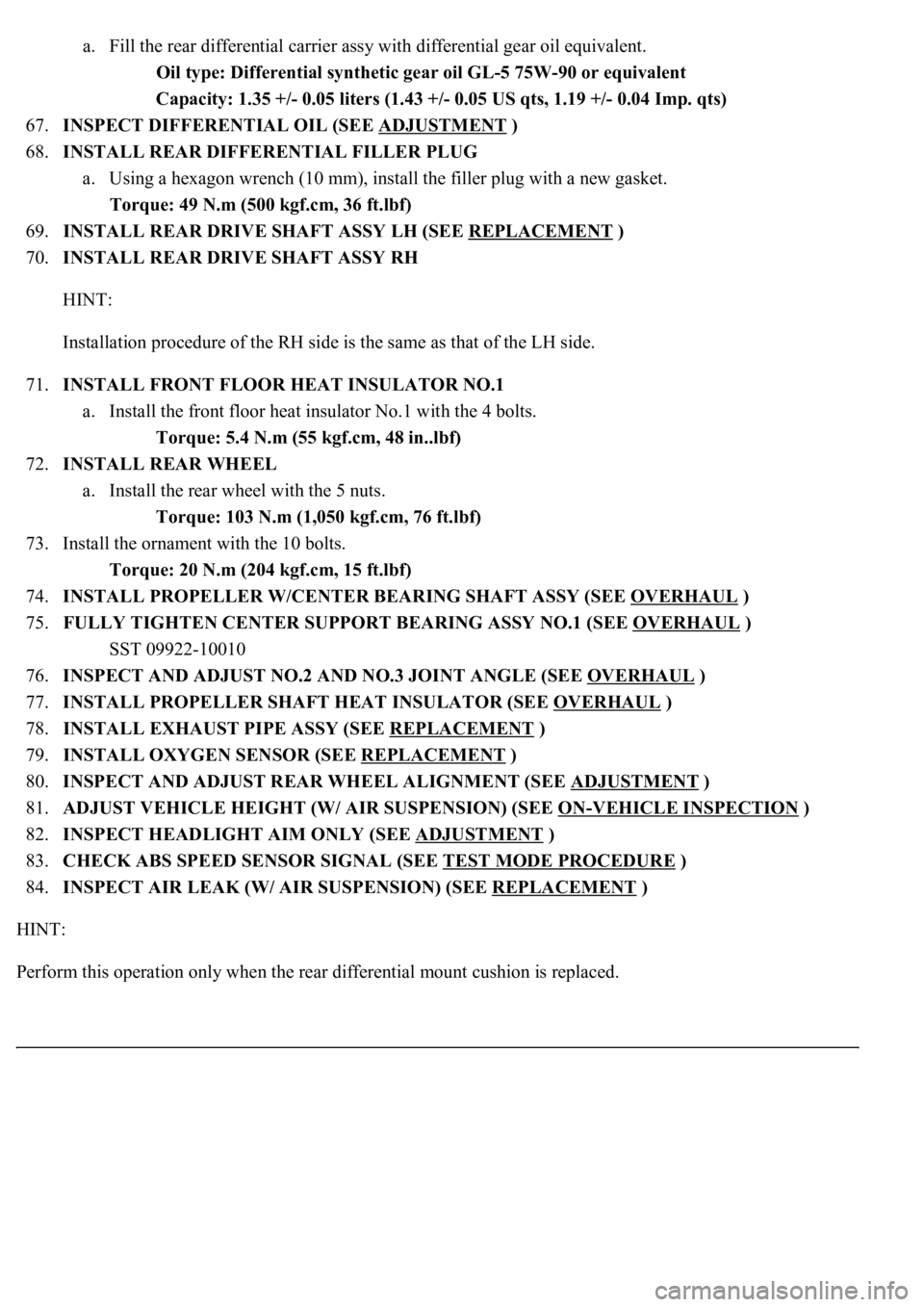

Fig. 85: Aligning Matchmarks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

33.INSTALL REAR TIRE

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

34.ADJUST VEHICLE HEIGHT (W/ AIR SUSPENSION) (See ON

-VEHICLE INSPECTION )

35.INSPECT HEADLIGHT AIM ONLY (See ADJUSTMENT

)

36.INSPECT AND ADJUST REAR WHEEL ALIGNMENT (See ADJUSTMENT

)

37.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

REPLACEMENT

HINT:

See COMPONENTS

<00380056004800030057004b00480003005600440050004800030053005500520046004800470058005500480056000300490052005500030057004b004800030035002b00030056004c0047004800030044005100470003002f002b00030056004c004700

4800110003[

Page 2407 of 4500

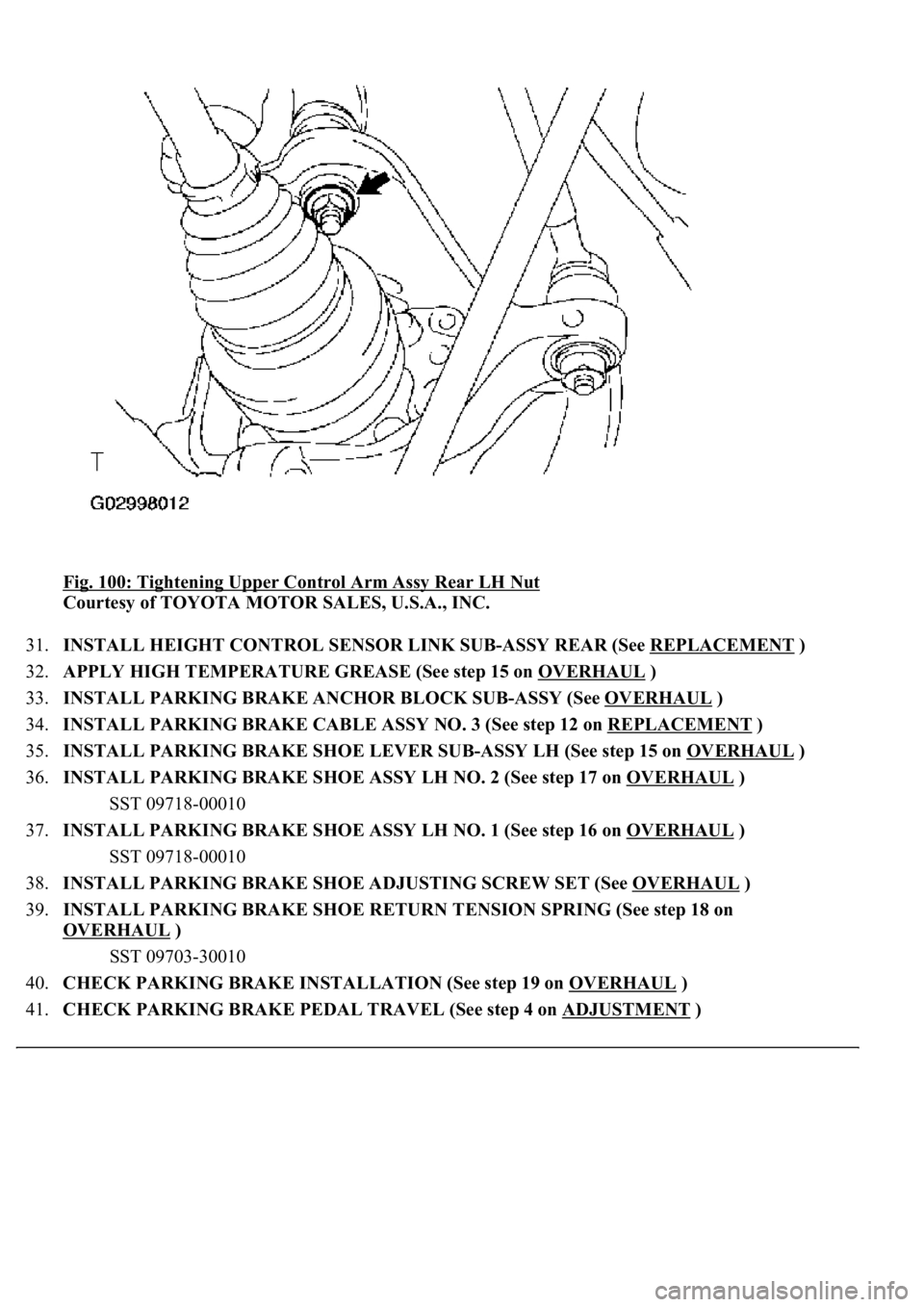

Fig. 100: Tightening Upper Control Arm Assy Rear LH Nut

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

31.INSTALL HEIGHT CONTROL SENSOR LINK SUB-ASSY REAR (See REPLACEMENT

)

32.APPLY HIGH TEMPERATURE GREASE (See step 15 on OVERHAUL

)

33.INSTALL PARKING BRAKE ANCHOR BLOCK SUB-ASSY (See OVERHAUL

)

34.INSTALL PARKING BRAKE CABLE ASSY NO. 3 (See step 12 on REPLACEMENT

)

35.INSTALL PARKING BRAKE SHOE LEVER SUB-ASSY LH (See step 15 on OVERHAUL

)

36.INSTALL PARKING BRAKE SHOE ASSY LH NO. 2 (See step 17 on OVERHAUL

)

SST 09718-00010

37.INSTALL PARKING BRAKE SHOE ASSY LH NO. 1 (See step 16 on OVERHAUL

)

SST 09718-00010

38.INSTALL PARKING BRAKE SHOE ADJUSTING SCREW SET (See OVERHAUL

)

39.INSTALL PARKING BRAKE SHOE RETURN TENSION SPRING (See step 18 on

OVERHAUL

)

SST 09703-30010

40.CHECK PARKING BRAKE INSTALLATION (See step 19 on OVERHAUL

)

41.CHECK PARKING BRAKE PEDAL TRAVEL (See step 4 on ADJUSTMENT

)

Page 2408 of 4500

42.ADJUST PARKING BRAKE PEDAL TRAVEL (See step 5 on ADJUSTMENT )

43.INSTALL SPEED SENSOR REAR LH

a. Install the speed sensor with the bolt.

Torque: 8.0 N.m (82 kgf.cm, 71 in.lbf)

44.INSTALL REAR DISC (See step 16 on OVERHAUL

)

45.ADJUST PARKING BRAKE SHOE CLEARANCE (See step 21 on OVERHAUL

)

46.INSTALL REAR DISC BRAKE CALIPER ASSY LH (See step 20 on REPLACEMENT

)

47.INSTALL REAR AXLE SHAFT NUT (See REPLACEMENT

)

48.INSPECT AXLE HUB BEARING LOOSENESS (See ON

-VEHICLE INSPECTION )

49.INSPECT AXLE HUB BEARING RUNOUT (See ON

-VEHICLE INSPECTION )

50.STABILIZE SUSPENSION (See step 23 on REPLACEMENT

)

51.FULLY TIGHTEN SHOCK ABSORBER ASSY REAR LH

a. Fully tighten the shock absorber assy LH with the new nut.

Torque: 70 N.m (714 kgf.cm, 52 ft.lbf)

52.INSTALL REAR TIRE

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

53.ADJUST VEHICLE HEIGHT (W/ AIR SUSPENSION) (See ON

-VEHICLE INSPECTION )

54.INSPECT HEADLIGHT AIM ONLY (See ADJUSTMENT

)

55.INSPECT AND ADJUST REAR WHEEL ALIGNMENT (See ADJUSTMENT

)

56.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

REPLACEMENT

HINT:

See COMPONENTS

Use the same procedures for the RH side and LH side.

The procedures listed below are for the LH side.

1.REMOVE REAR TIRE

2.REMOVE REAR DISC BRAKE CALIPER ASSY LH (See REPLACEMENT

)

3.REMOVE REAR DISC (See step 15 on OVERHAUL

)

4.REMOVE REAR AXLE LH HUB BOLT

a. Using SST and a screwdriver or an equivalent to hold, remove the hub bolt.

SST 09628-10011

Page 3916 of 4500

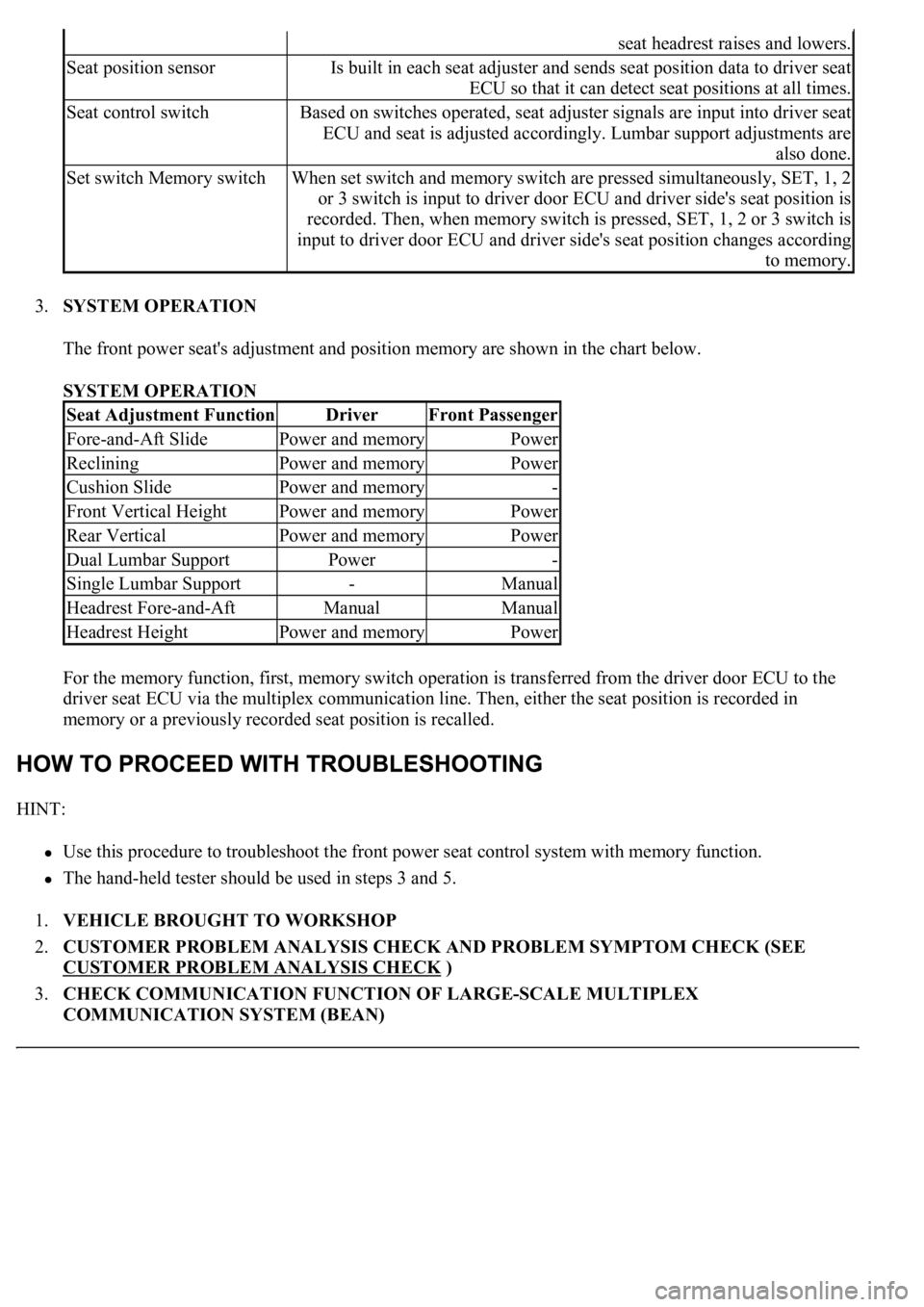

3.SYSTEM OPERATION

The front power seat's adjustment and position memory are shown in the chart below.

SYSTEM OPERATION

For the memory function, first, memory switch operation is transferred from the driver door ECU to the

driver seat ECU via the multiplex communication line. Then, either the seat position is recorded in

memory or a previously recorded seat position is recalled.

HINT:

Use this procedure to troubleshoot the front power seat control system with memory function.

<0037004b00480003004b0044005100470010004b0048004f0047000300570048005600570048005500030056004b00520058004f0047000300450048000300580056004800470003004c005100030056005700480053005600030016000300440051004700

030018001100030003[

1.VEHICLE BROUGHT TO WORKSHOP

2.CUSTOMER PROBLEM ANALYSIS CHECK AND PROBLEM SYMPTOM CHECK (SEE

CUSTOMER PROBLEM ANALYSIS CHECK

)

3.CHECK COMMUNICATION FUNCTION OF LARGE-SCALE MULTIPLEX

COMMUNICATION SYSTEM (BEAN)

seat headrest raises and lowers.

Seat position sensorIs built in each seat adjuster and sends seat position data to driver seat

ECU so that it can detect seat positions at all times.

Seat control switchBased on switches operated, seat adjuster signals are input into driver seat

ECU and seat is adjusted accordingly. Lumbar support adjustments are

also done.

Set switch Memory switchWhen set switch and memory switch are pressed simultaneously, SET, 1, 2

or 3 switch is input to driver door ECU and driver side's seat position is

recorded. Then, when memory switch is pressed, SET, 1, 2 or 3 switch is

input to driver door ECU and driver side's seat position changes according

to memory.

Seat Adjustment FunctionDriverFront Passenger

Fore-and-Aft SlidePower and memoryPower

RecliningPower and memoryPower

Cushion SlidePower and memory-

Front Vertical HeightPower and memoryPower

Rear VerticalPower and memoryPower

Dual Lumbar SupportPower-

Single Lumbar Support-Manual

Headrest Fore-and-AftManualManual

Headrest HeightPower and memoryPower

Page 3998 of 4500

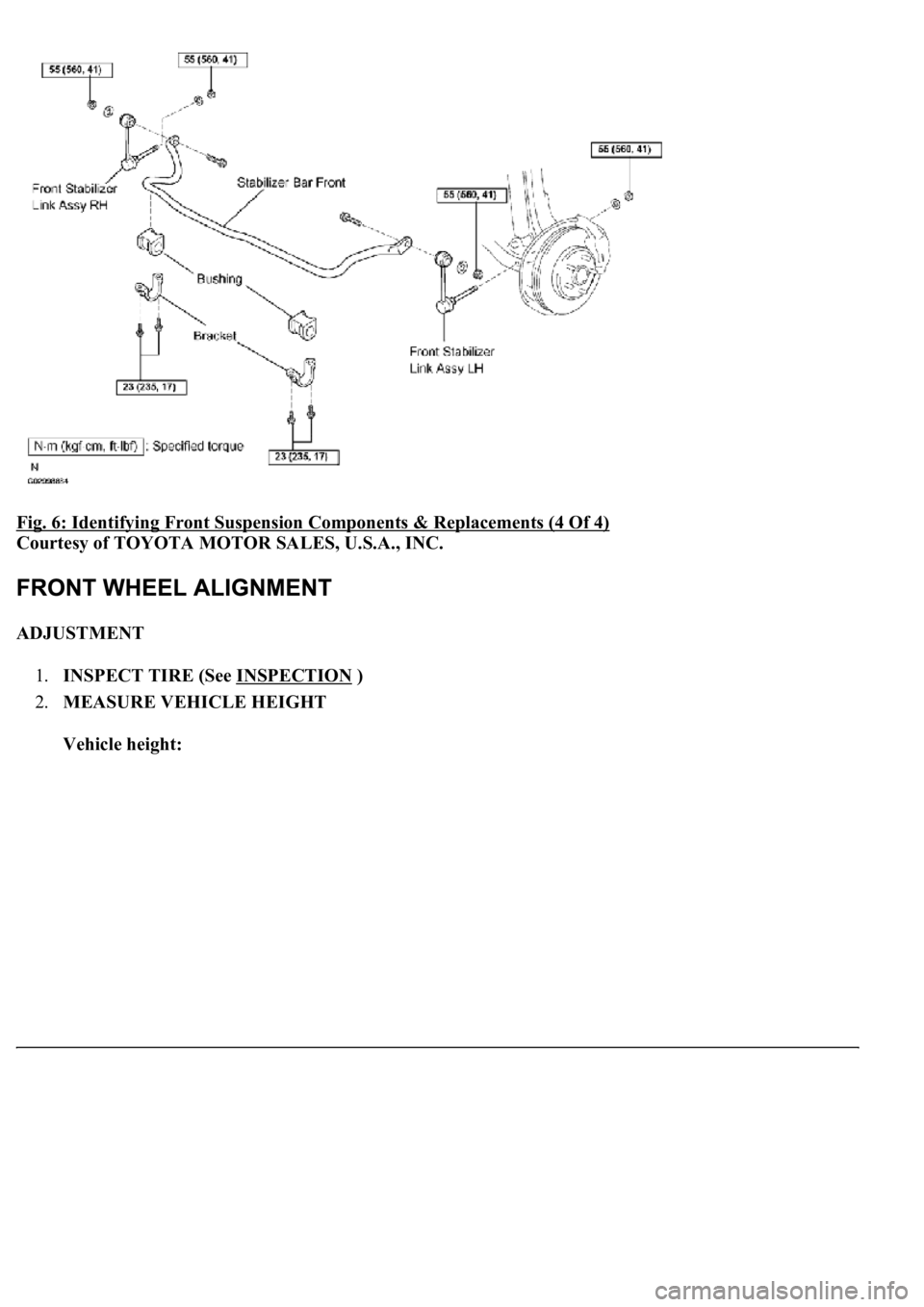

Fig. 6: Identifying Front Suspension Components & Replacements (4 Of 4)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

ADJUSTMENT

1.INSPECT TIRE (See INSPECTION

)

2.MEASURE VEHICLE HEIGHT

Vehicle height:

Page 4023 of 4500

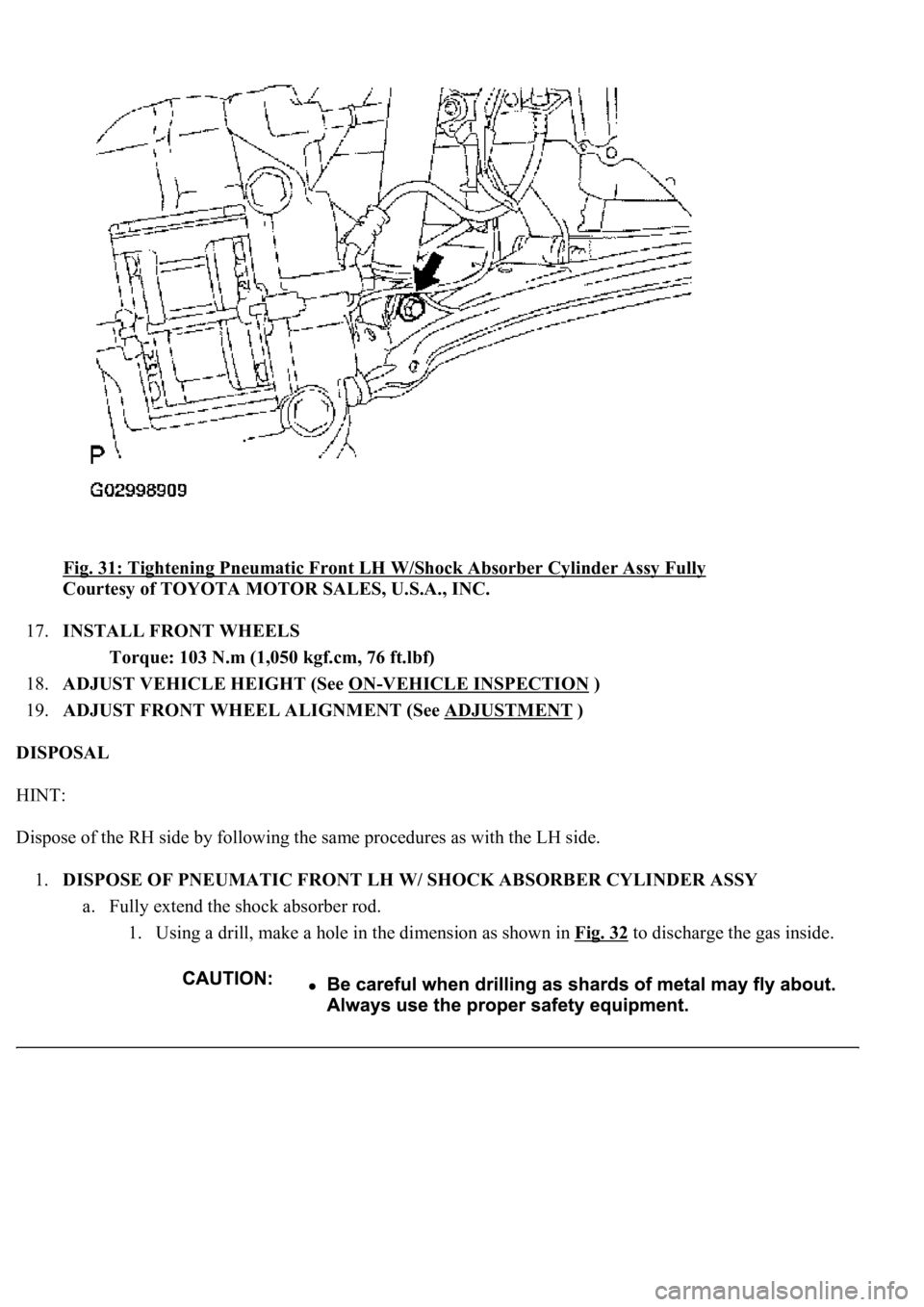

Fig. 31: Tightening Pneumatic Front LH W/Shock Absorber Cylinder Assy Fully

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

17.INSTALL FRONT WHEELS

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

18.ADJUST VEHICLE HEIGHT (See ON

-VEHICLE INSPECTION )

19.ADJUST FRONT WHEEL ALIGNMENT (See ADJUSTMENT

)

DISPOSAL

HINT:

Dispose of the RH side by following the same procedures as with the LH side.

1.DISPOSE OF PNEUMATIC FRONT LH W/ SHOCK ABSORBER CYLINDER ASSY

a. Fully extend the shock absorber rod.

1. Using a drill, make a hole in the dimension as shown in Fig. 32

to discharge the gas inside.

Page 4043 of 4500

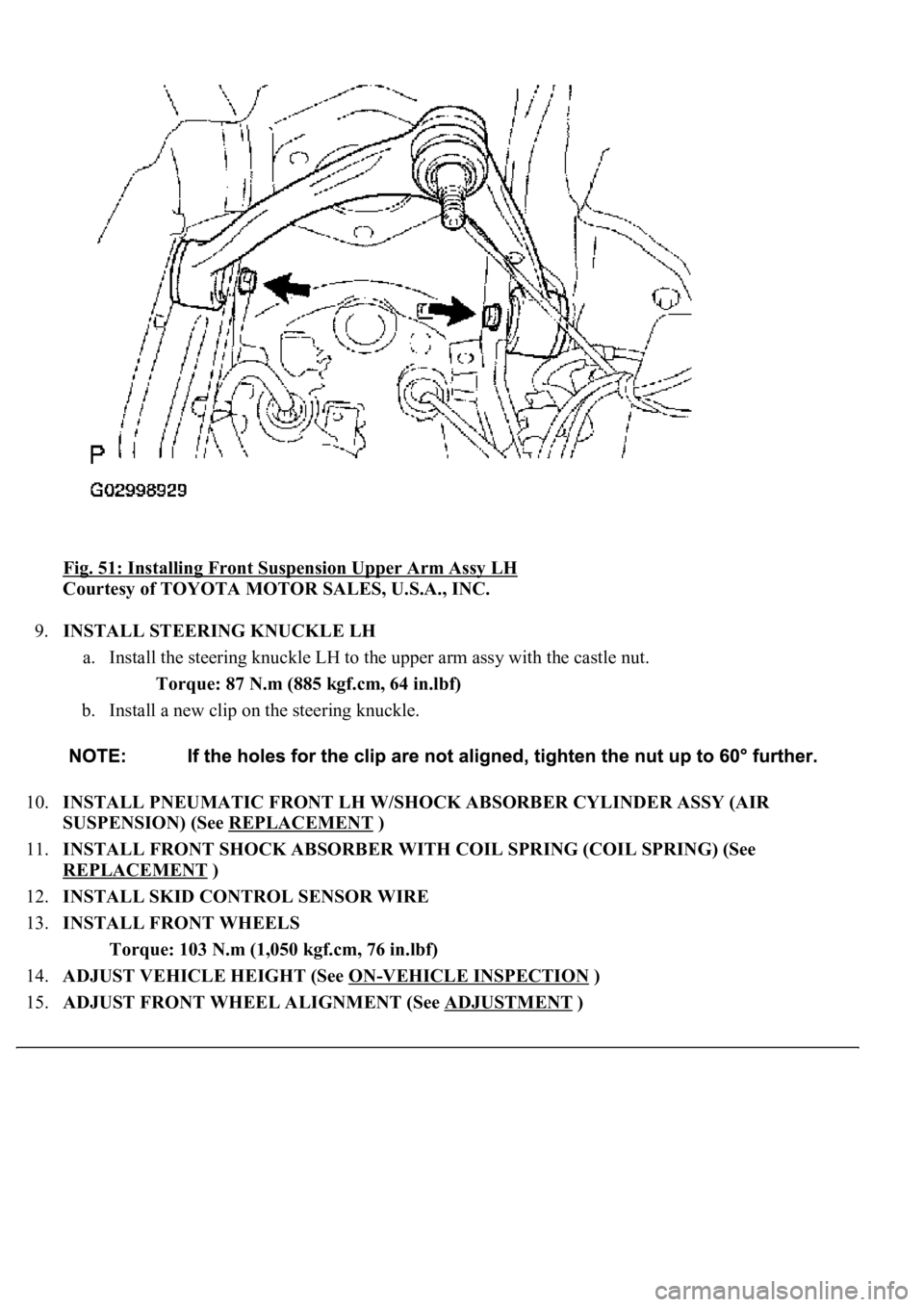

Fig. 51: Installing Front Suspension Upper Arm Assy LH

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

9.INSTALL STEERING KNUCKLE LH

a. Install the steering knuckle LH to the upper arm assy with the castle nut.

Torque: 87 N.m (885 kgf.cm, 64 in.lbf)

b. Install a new clip on the steering knuckle.

10.INSTALL PNEUMATIC FRONT LH W/SHOCK ABSORBER CYLINDER ASSY (AIR

SUSPENSION) (See REPLACEMENT

)

11.INSTALL FRONT SHOCK ABSORBER WITH COIL SPRING (COIL SPRING) (See

REPLACEMENT

)

12.INSTALL SKID CONTROL SENSOR WIRE

13.INSTALL FRONT WHEELS

Torque: 103 N.m (1,050 kgf.cm, 76 in.lbf)

14.ADJUST VEHICLE HEIGHT (See ON

-VEHICLE INSPECTION )

15.ADJUST FRONT WHEEL ALIGNMENT (See ADJUSTMENT

)