lock LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 7 of 4500

1.SYSTEM DESCRIPTION

HINT:

The skid control ECU is a single unit with ABS & TRACTION ACTUATOR.

The skid control ECU also works as a TPMS (Tire Pressure Monitor System) ECU.

The yaw rate sensor and deceleration sensor are combined and in a single unit. This unit

communicates with the skid control ECU through CAN communication.

a. ABS (Anti-lock Brake System)

The ABS helps prevent the wheels from locking when the brakes are applied firmly or when

braking on a slippery surface.

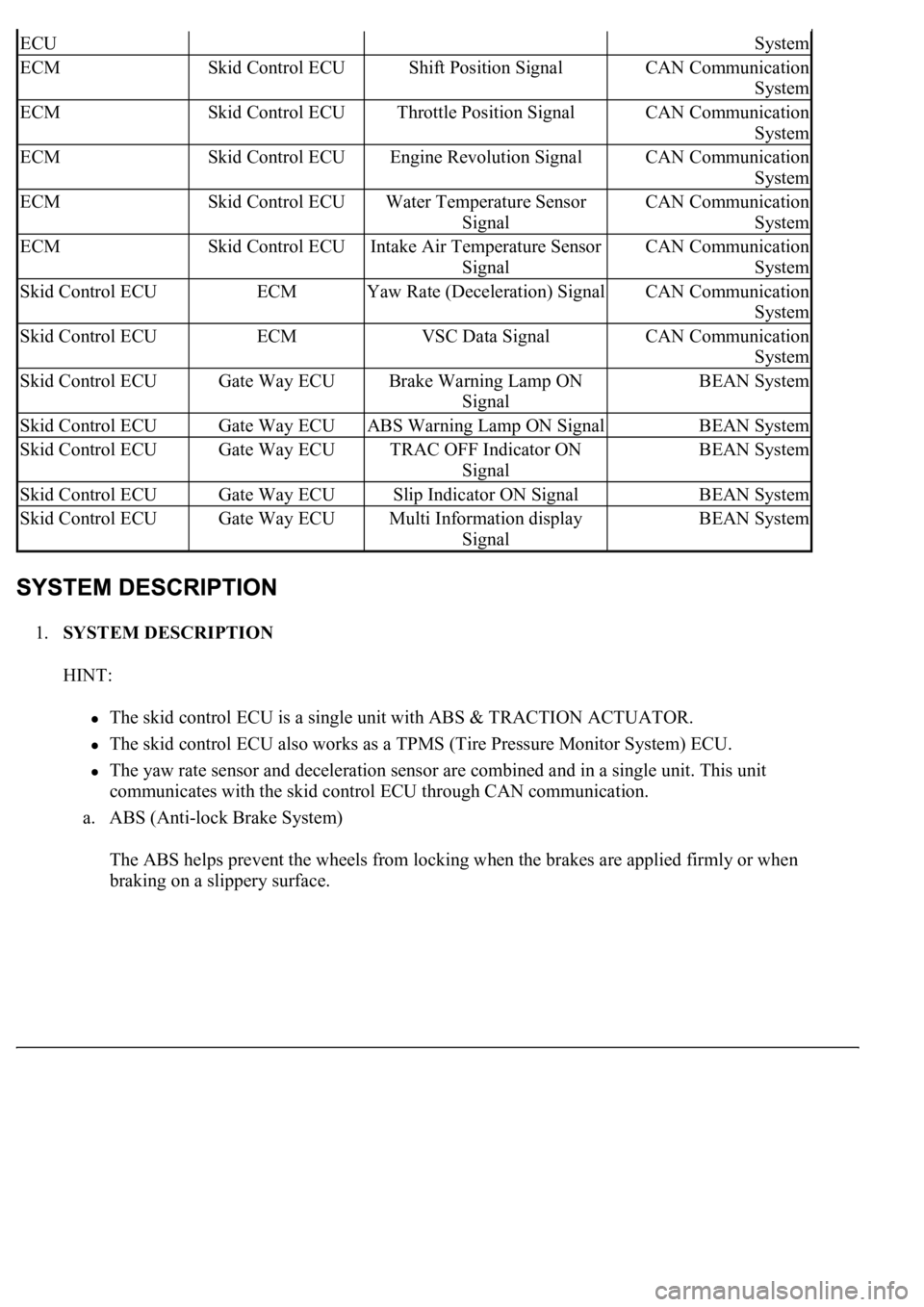

ECUSystem

ECMSkid Control ECUShift Position SignalCAN Communication

System

ECMSkid Control ECUThrottle Position SignalCAN Communication

System

ECMSkid Control ECUEngine Revolution SignalCAN Communication

System

ECMSkid Control ECUWater Temperature Sensor

SignalCAN Communication

System

ECMSkid Control ECUIntake Air Temperature Sensor

SignalCAN Communication

System

Skid Control ECUECMYaw Rate (Deceleration) SignalCAN Communication

System

Skid Control ECUECMVSC Data SignalCAN Communication

System

Skid Control ECUGate Way ECUBrake Warning Lamp ON

SignalBEAN System

Skid Control ECUGate Way ECUABS Warning Lamp ON SignalBEAN System

Skid Control ECUGate Way ECUTRAC OFF Indicator ON

SignalBEAN System

Skid Control ECUGate Way ECUSlip Indicator ON SignalBEAN System

Skid Control ECUGate Way ECUMulti Information display

SignalBEAN System

Page 8 of 4500

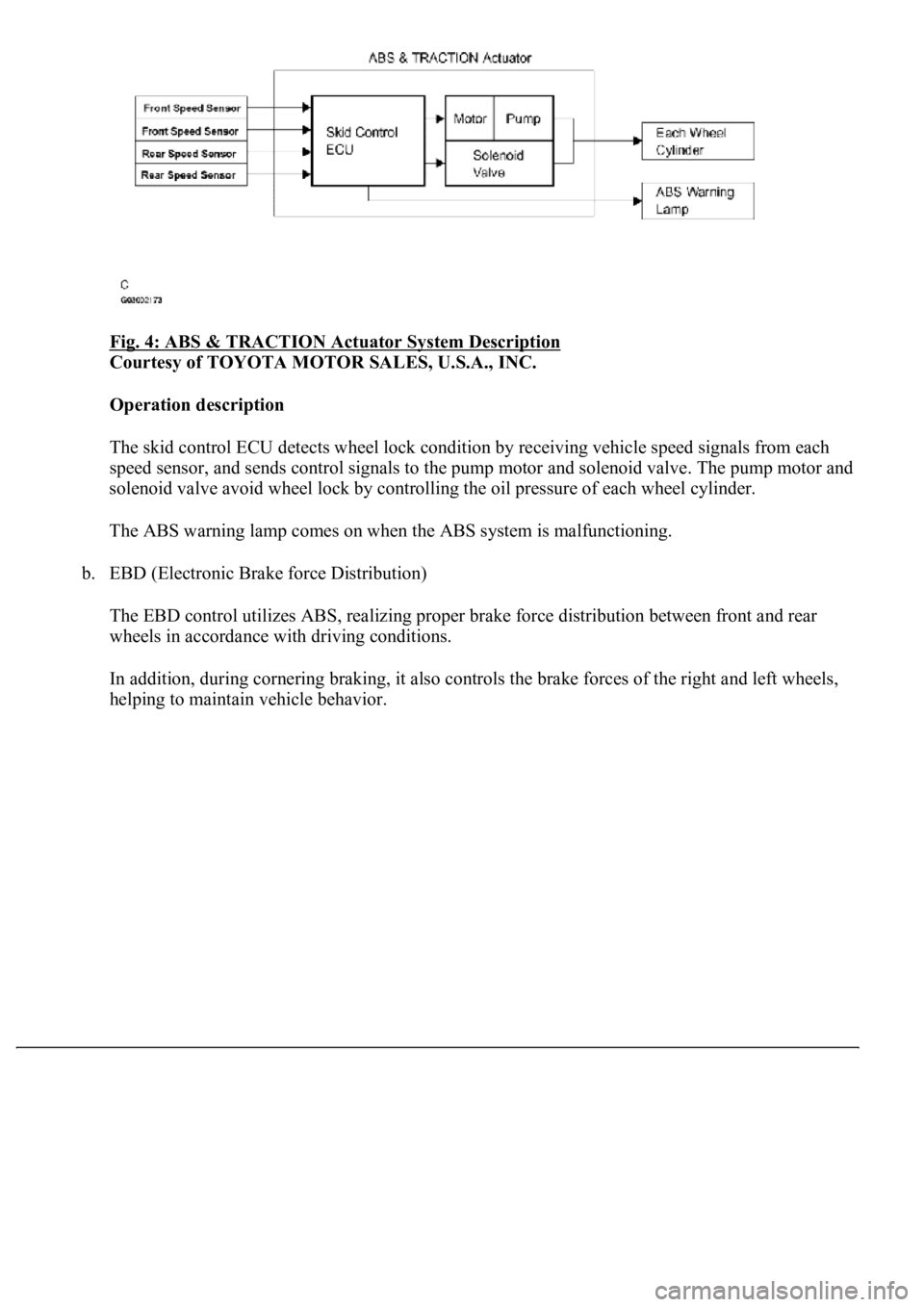

Fig. 4: ABS & TRACTION Actuator System Description

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Operation description

The skid control ECU detects wheel lock condition by receiving vehicle speed signals from each

<005600530048004800470003005600480051005600520055000f00030044005100470003005600480051004700560003004600520051005700550052004f00030056004c004a00510044004f005600030057005200030057004b0048000300530058005000

53000300500052005700520055000300440051004700030056[olenoid valve. The pump motor and

solenoid valve avoid wheel lock by controlling the oil pressure of each wheel cylinder.

The ABS warning lamp comes on when the ABS system is malfunctioning.

b. EBD (Electronic Brake force Distribution)

The EBD control utilizes ABS, realizing proper brake force distribution between front and rear

wheels in accordance with driving conditions.

In addition, during cornering braking, it also controls the brake forces of the right and left wheels,

helping to maintain vehicle behavior.

Page 27 of 4500

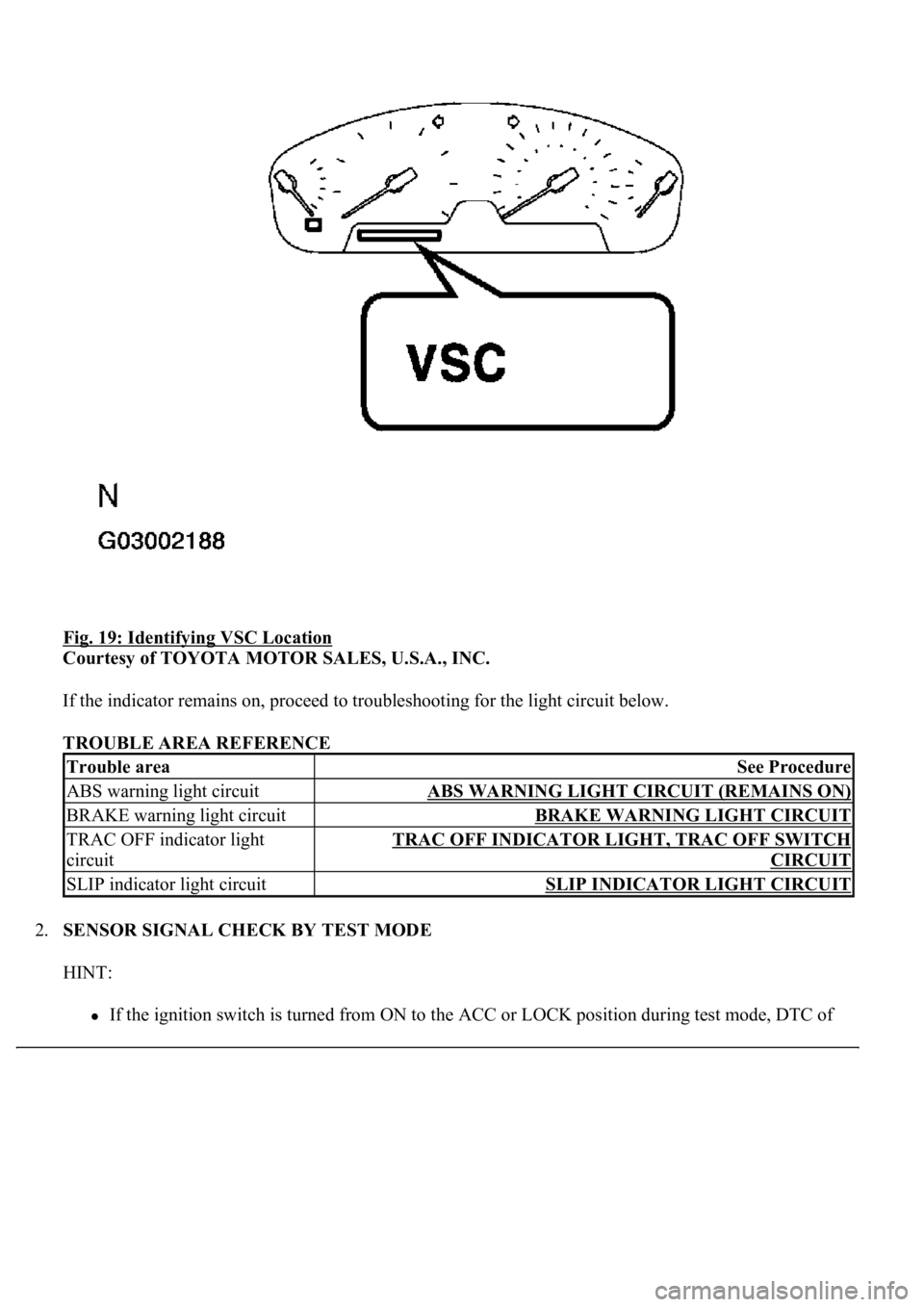

Fig. 19: Identifying VSC Location

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

If the indicator remains on, proceed to troubleshooting for the light circuit below.

TROUBLE AREA REFERENCE

2.SENSOR SIGNAL CHECK BY TEST MODE

HINT:

If the ignition switch is turned from ON to the ACC or LOCK position during test mode, DTC of

Trouble areaSee Procedure

ABS warning light circuitABS WARNING LIGHT CIRCUIT (REMAINS ON)

BRAKE warning light circuitBRAKE WARNING LIGHT CIRCUIT

TRAC OFF indicator light

circuitTRAC OFF INDICATOR LIGHT, TRAC OFF SWITCH

CIRCUIT

SLIP indicator light circuitSLIP INDICATOR LIGHT CIRCUIT

Page 56 of 4500

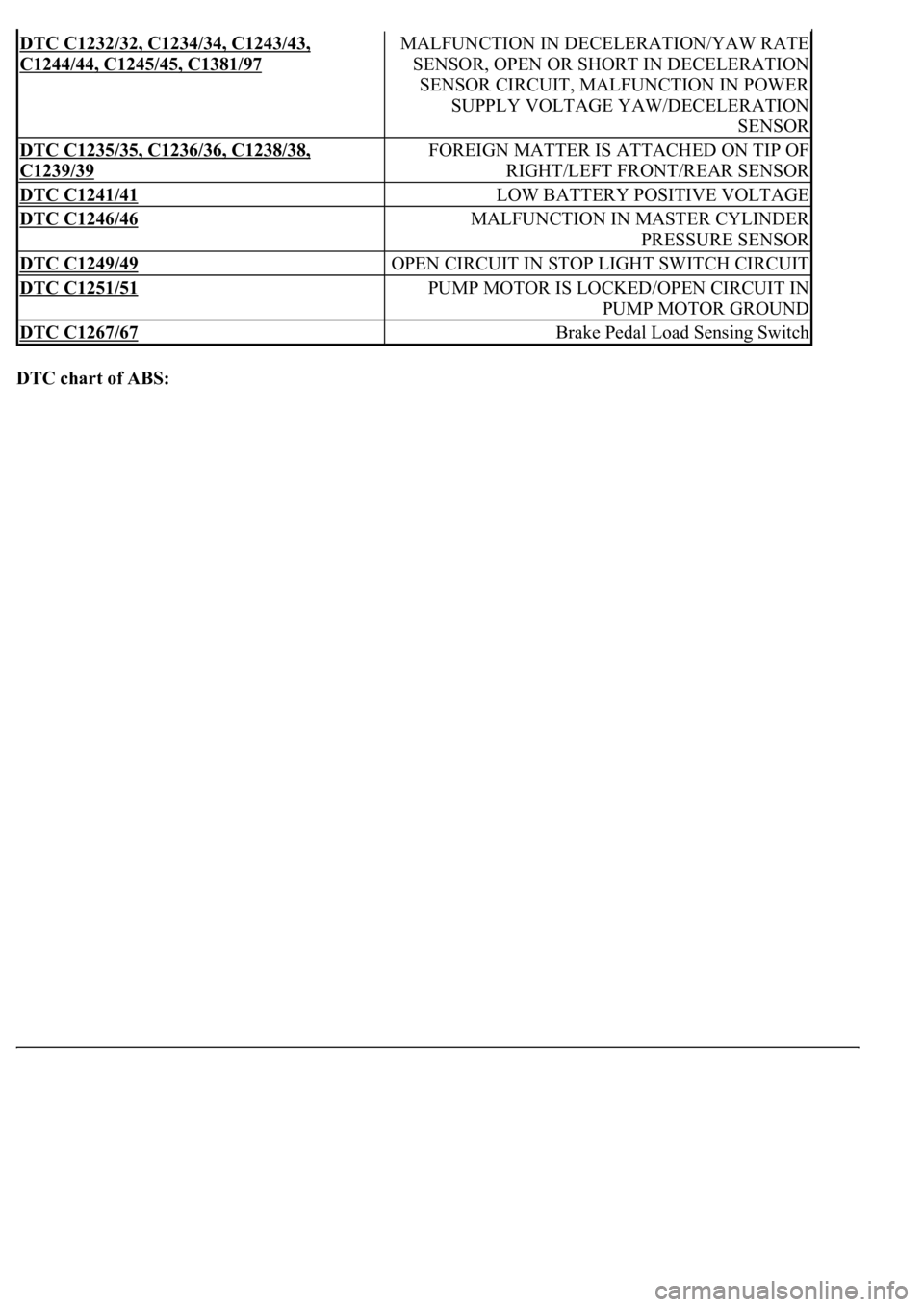

DTC chart of ABS:

DTC C1232/32, C1234/34, C1243/43,

C1244/44, C1245/45, C1381/97

MALFUNCTION IN DECELERATION/YAW RATE

SENSOR, OPEN OR SHORT IN DECELERATION

SENSOR CIRCUIT, MALFUNCTION IN POWER

SUPPLY VOLTAGE YAW/DECELERATION

SENSOR

DTC C1235/35, C1236/36, C1238/38,

C1239/39

FOREIGN MATTER IS ATTACHED ON TIP OF

RIGHT/LEFT FRONT/REAR SENSOR

DTC C1241/41LOW BATTERY POSITIVE VOLTAGE

DTC C1246/46MALFUNCTION IN MASTER CYLINDER

PRESSURE SENSOR

DTC C1249/49OPEN CIRCUIT IN STOP LIGHT SWITCH CIRCUIT

DTC C1251/51PUMP MOTOR IS LOCKED/OPEN CIRCUIT IN

PUMP MOTOR GROUND

DTC C1267/67Brake Pedal Load Sensing Switch

Page 66 of 4500

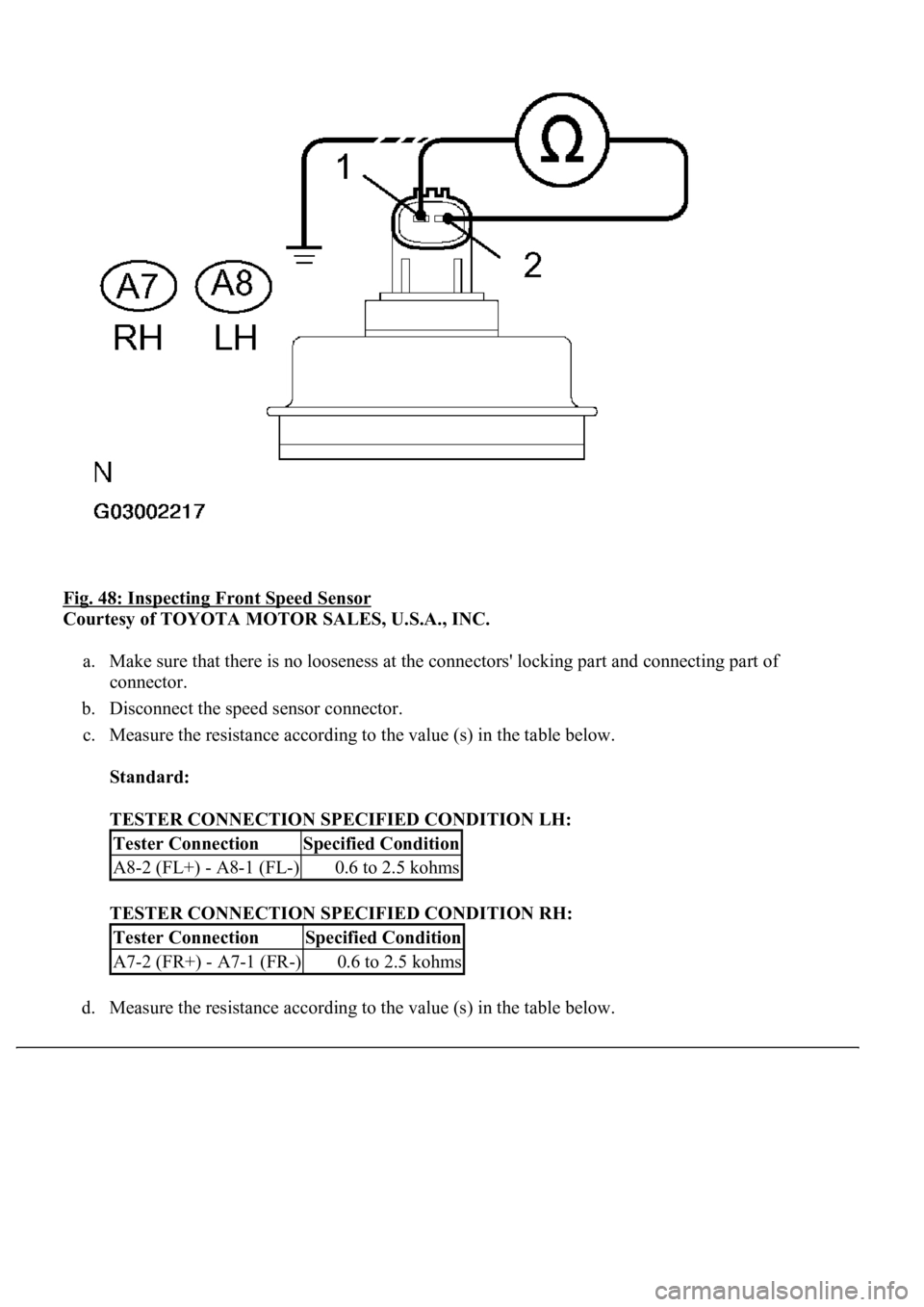

Fig. 48: Inspecting Front Speed Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Make sure that there is no looseness at the connectors' locking part and connecting part of

connector.

b. Disconnect the speed sensor connector.

c. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION LH:

TESTER CONNECTION SPECIFIED CONDITION RH:

d. Measure the resistance accordin

g to the value (s) in the table below.

Tester ConnectionSpecified Condition

A8-2 (FL+) - A8-1 (FL-)0.6 to 2.5 kohms

Tester ConnectionSpecified Condition

A7-2 (FR+) - A7-1 (FR-)0.6 to 2.5 kohms

Page 89 of 4500

VEHICLE CONDITION / TEST DETAILS DESCRIPTION

OK: Go to next step

<0037004b00480003005200530048005500440057004c0052005100030056005200580051004700030052004900030057004b0048000300240025003600030050005200570052005500030056004b00520058004f00470003004500480003004b0048004400

5500470011[

NG: Go to step 2

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

2.INSPECT FUSE (ABS2 FUSE)

a. Remove the ABS 2 fuse from fusible link block.

b. Measure the resistance according to the value (s) in the table below.

Standard:

ABS 2 FUSE DESCRIPTION

ItemVehicle Condition / Test DetailsVehicle Condition / Test Details

ABS MOT RELAYTurns ABS motor relay / ON or OFFON: Motor relay ON

ABS 2 FuseBelow 1 ohms (Continuity)

Page 98 of 4500

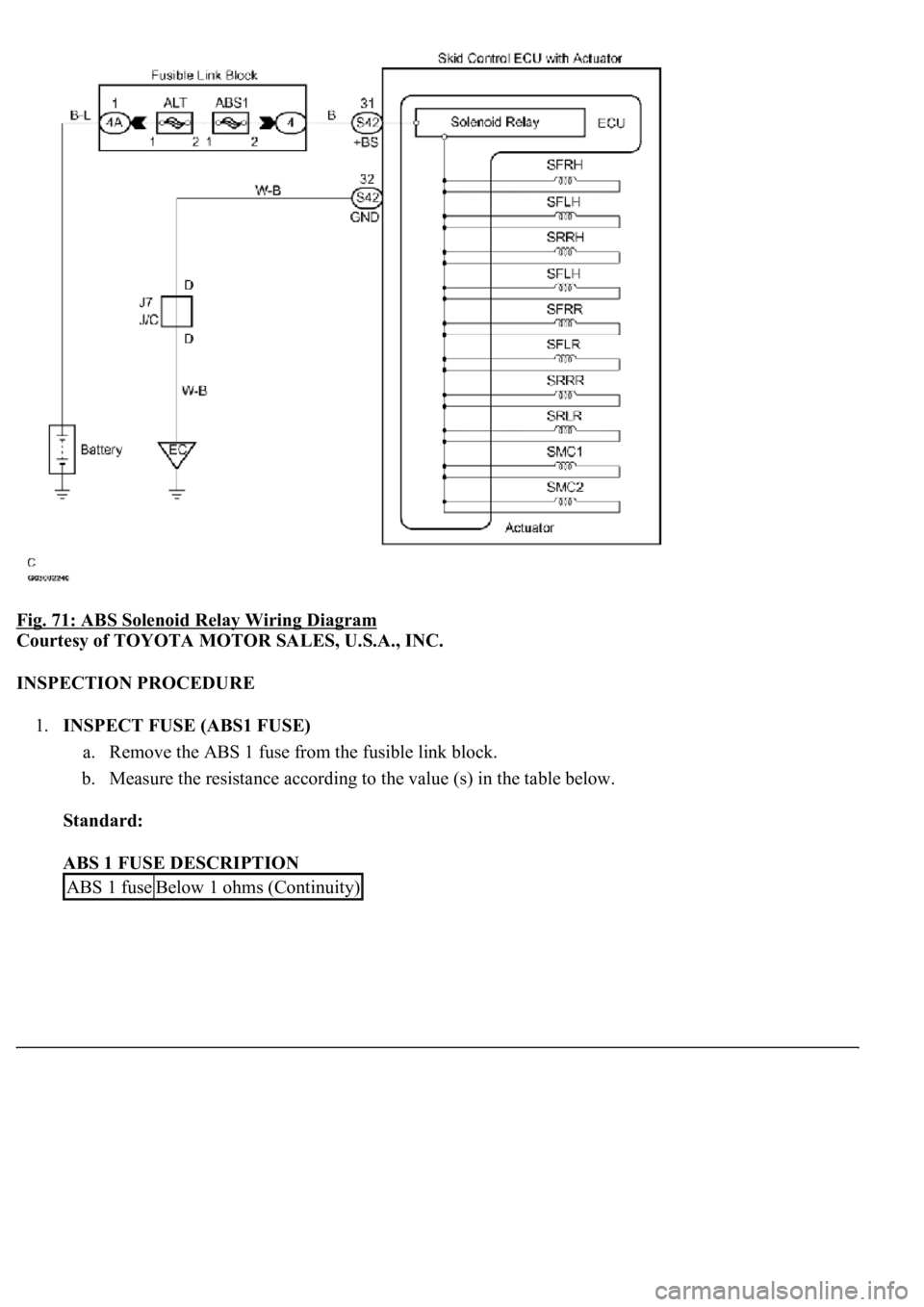

Fig. 71: ABS Solenoid Relay Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.INSPECT FUSE (ABS1 FUSE)

a. Remove the ABS 1 fuse from the fusible link block.

b. Measure the resistance according to the value (s) in the table below.

Standard:

ABS 1 FUSE DESCRIPTION

ABS 1 fuseBelow 1 ohms (Continuity)

Page 414 of 4500

b. Turn the radio and receiver assy on.

c. Set the radio channels and register them.

d. Turn the ignition switch off.

e. Turn the ignition switch to the ON position.

f. Turn the radio and receiver assy on.

g. Check if the registered memory is deleted or not.

OK:

The registered memory is not deleted.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (DRIVER SIDE J/B - BATTERY)

OK: Go to next step

4.INSPECT FUSE (HEATER)

a. Remove the HEATER fuse from the FL block.

b. Measure the resistance according to the value (s) in the table below.

Standard:

FUSE (HEATER) RESISTANCE

NG: CHECK FOR SHORT IN ALL HARNESSES AND COMPONENTS CONNECTED TO

FAILURE FUSE

Tester itemConditionSpecified condition

HEATER fuseAlwaysBelow 1 ohms

Page 482 of 4500

FBL+ (A21-6) -

FBL- (A21-16)G-W - G-

OSuspension control

actuator (FL)IG switch ONBelow 1

ohms

SLRL (A21-7) -

GND (A20-4)P-L - W-BHeight control solenoid

valve (RL)IG switch ONBelow 1 V

SLRL (A21-7) -

GND (A20-4)P-L - W-BHeight control solenoid

valve (RL)Engine idling, height control switch

from "NORM" to "HIGH" or

reverse

8 V or more

SLRR (A21-8) -

GND (A20-4)P - W-BHeight control solenoid

valve (RR)IG switch ONBelow 1 V

SLRR (A21-8) -

GND (A20-4)P - W-BHeight control solenoid

valve (RR)Engine idling, height control switch

from "NORM" to "HIGH" or

reverse

8 V or more

RM+ (A21-17) -

GND (A20-4)BR-Y - W-

BMotor lock (+)

Engine idling, height control switch

from "NORM" to "HIGH" during

compressor operation

Below 1 V

RM- (A21-18) -

GND (A20-4)BR-B - W-

BMotor lock (-)AlwaysBelow 1

ohms

SHR2 (A21-19) -

GND (A20-4)W - W-BHeight control sensor

(HID rear)IG switch ON0.5 to 4.5 V

SHFR (A21-20) -

GND (A20-4)B-W - W-

BHeight control sensor

(FR)IG switch ON0.5 to 4.5 V

SHFR (A21-20) -

GND (A20-4)B-W - W-

BHeight control sensor

(FR)Engine idling, height control switch

"NORM"Approx. 2.5

V

SHF2 (A21-21) -

GND (A20-4)V-G - W-BHeight control sensor

(HID front)IG switch ON0.5 to 4.5 V

SHFL (A21-22) -

GND (A20-4)L - W-BHeight control sensor

(FL)IG switch ON0.5 to 4.5 V

SHFL (A21-22) -

GND (A20-4)L - W-BHeight control sensor

(FL)Engine idling, height control switch

"NORM"Approx. 2.5

V

SBL3 (A21-23) -

GND (A20-4)B - W-BHeight control sensor

power source (HID)IG switch ON4.5 to 5.5 V

SGL3 (A21-24) -

GND (A20-4)V-Y - W-BHeight control sensor

ground (HID)AlwaysBelow 1

ohms

RAR+ (A22-2) -

RAR- (A22-3)Y - SBSuspension control

actuator (RR)IG switch ONBelow 1

ohms

RBR+ (A22-4) -

RBR- (A22-5)LG - PSuspension control

actuator (RR)IG switch ONBelow 1

ohms

RAL+ (A22-6) -

RAL- (A22-7)L - GSuspension control

actuator (RL)IG switch ONBelow 1

ohms

RBL+ (A22-8) -

RBL- (A22-9)O - BRSuspension control

actuator (RLIG switch ONBelow 1

ohms

SGR3 (A22-12) -

GND (A20-4)W - W-BAcceleration sensor

ground (rear)AlwaysBelow 1

ohms

SBR3 (A22-15) -

GND (A20-4)R - W-BAcceleration sensor

power source (rear)IG switch ON4.5 to 5.5 V

Page 568 of 4500

POWER SOURCE CIRCUIT ) is displayed, carry out the necessary inspection. If they are output at the

same time, carry out the necessary inspection for DTC C1774 first.

NG: REPAIR CIRCUIT INDICATED BY OUTPUT CODE

OK:Go to next step

2.PERFORM ACTIVE TEST BY HAND-HELD TESTER

a. Connect the hand-held tester to the DLC3.

b. Turn the ignition switch to the ON position and turn the hand-held tester main switch on.

c. Select the item below in the ACTIVE TEST and operate it with the hand-held tester.

VEHICLE CONDITION / TEST DETAILS

d. Check the operation sound of the AIR SUS relay when operating it with the hand-held tester.

OK:

The operation sound of the AIR SUS relay can be heard.

NG: Go to step 3

OK: REPLACE SUSPENSION CONTROL ECU (SEE REPLACEMENT

)

3.INSPECT AIR SUS RELAY

a. Remove the AIR SUS relay from the fusible link block.

b. Measure the resistance according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

NG: REPLACE AIR SUS RELAY

OK:Go to next step

Item

Vehicle Condition / Test

Details

Diagnostic Note

MOTOR RELAYAIR SUS relay / ON or OFFOperation of solenoid (clicking sound) can

be heard

Tester ConnectionSpecified Condition

1 - 210 Kohms higher

1 - 2Below 1 ohms (When battery voltage is applied to terminals 3 and 4)