ignition LEXUS SC300 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC300, Model: LEXUS SC300 1991Pages: 4087, PDF Size: 75.75 MB

Page 1703 of 4087

COMPRESSION CHECK

HINT: If there is lack of power, excessive oil consumption or

poor fuel economy, measure the compression pressure.

1. WARM UP AND STOP ENGINE Allow the engine to warm up to normal operating tempera-

ture.

2. REMOVE NO.3 TIMING BELT COVERS (See steps 1, 5 to 10 and 14 on pages EM±11 to 13)

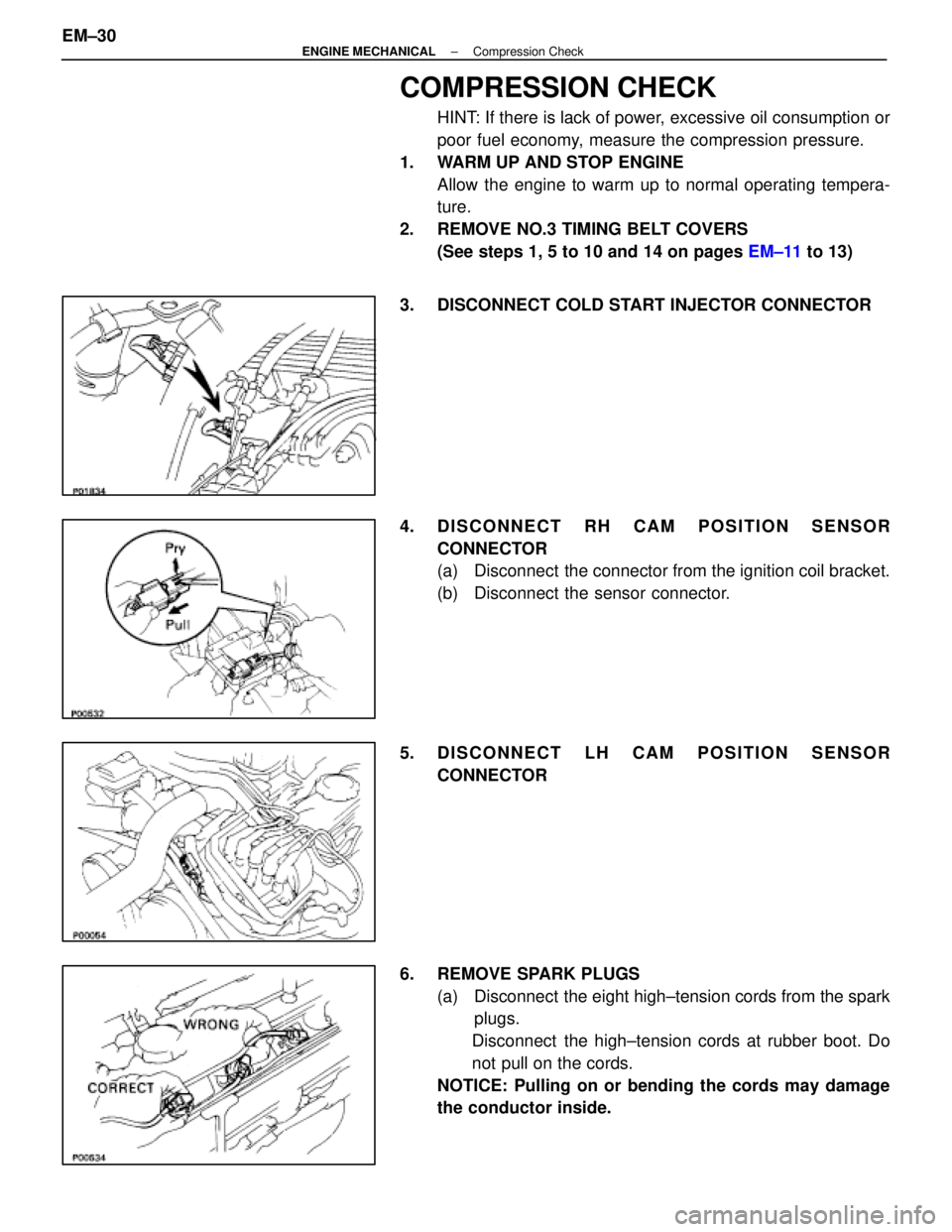

3. DISCONNECT COLD START INJECTOR CONNECTOR

4. DISCONNECT RH CAM POSITION SENSOR CONNECTOR

(a) Disconnect the connector from the ignition coil bracket.

(b) Disconnect the sensor connector.

5. DISCONNECT LH CAM POSITION SENSOR CONNECTOR

6. REMOVE SPARK PLUGS (a) Disconnect the eight high±tension cords from the sparkplugs.

Disconnect the high±tension cords at rubber boot. Do

not pull on the cords.

NOTICE: Pulling on or bending the cords may damage

the conductor inside.

EM±30

±

ENGINE MECHANICAL Compression Check

WhereEverybodyKnowsYourName

Page 1705 of 4087

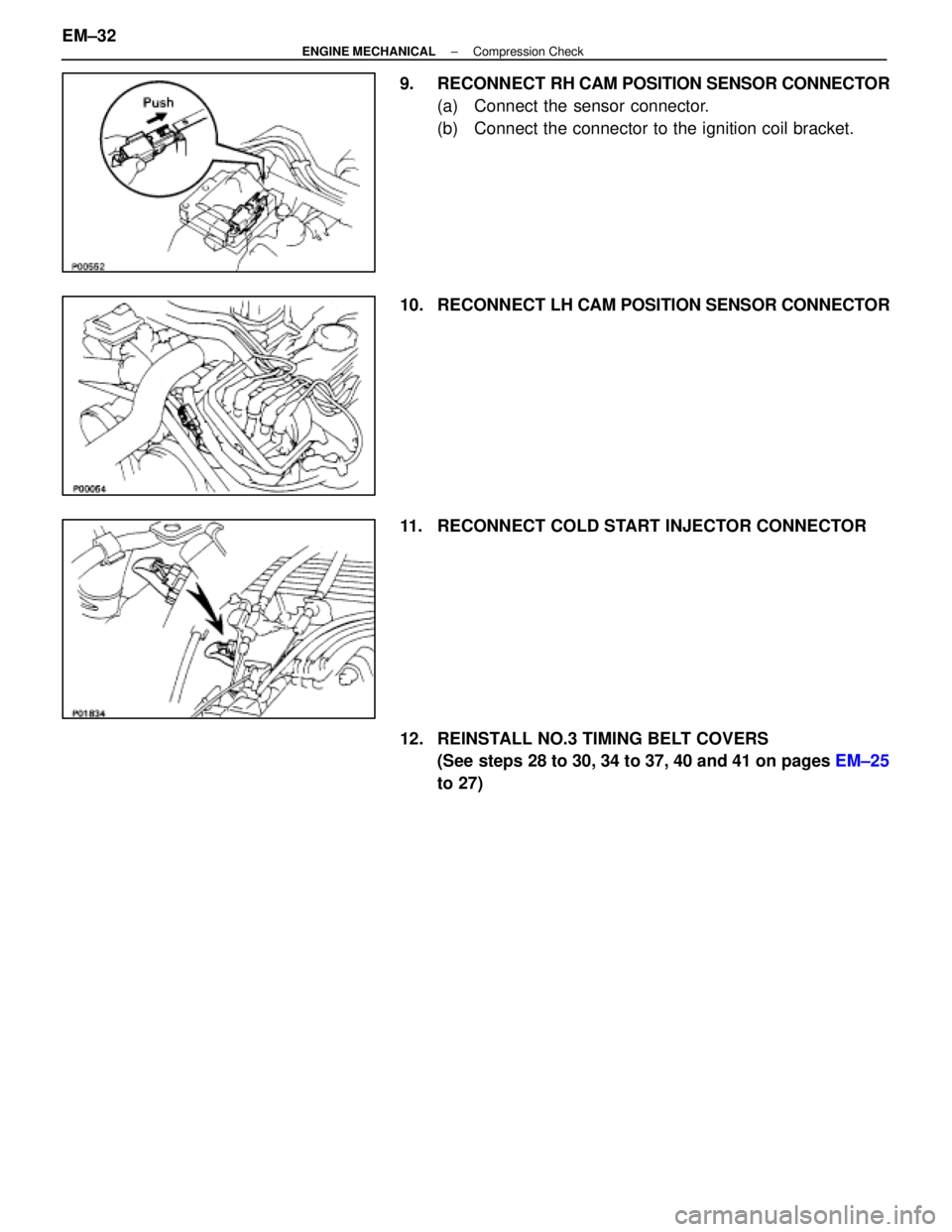

9. RECONNECT RH CAM POSITION SENSOR CONNECTOR

(a) Connect the sensor connector.

(b) Connect the connector to the ignition coil bracket.

10. RECONNECT LH CAM POSITION SENSOR CONNECTOR

11. RECONNECT COLD START INJECTOR CONNECTOR

12. REINSTALL NO.3 TIMING BELT COVERS (See steps 28 to 30, 34 to 37, 40 and 41 on pages EM±25

to 27)

EM±32

±

ENGINE MECHANICAL Compression Check

WhereEverybodyKnowsYourName

Page 1708 of 4087

REMOVAL OF TIMING BELT

(See Components on pages EM±33 and 34)

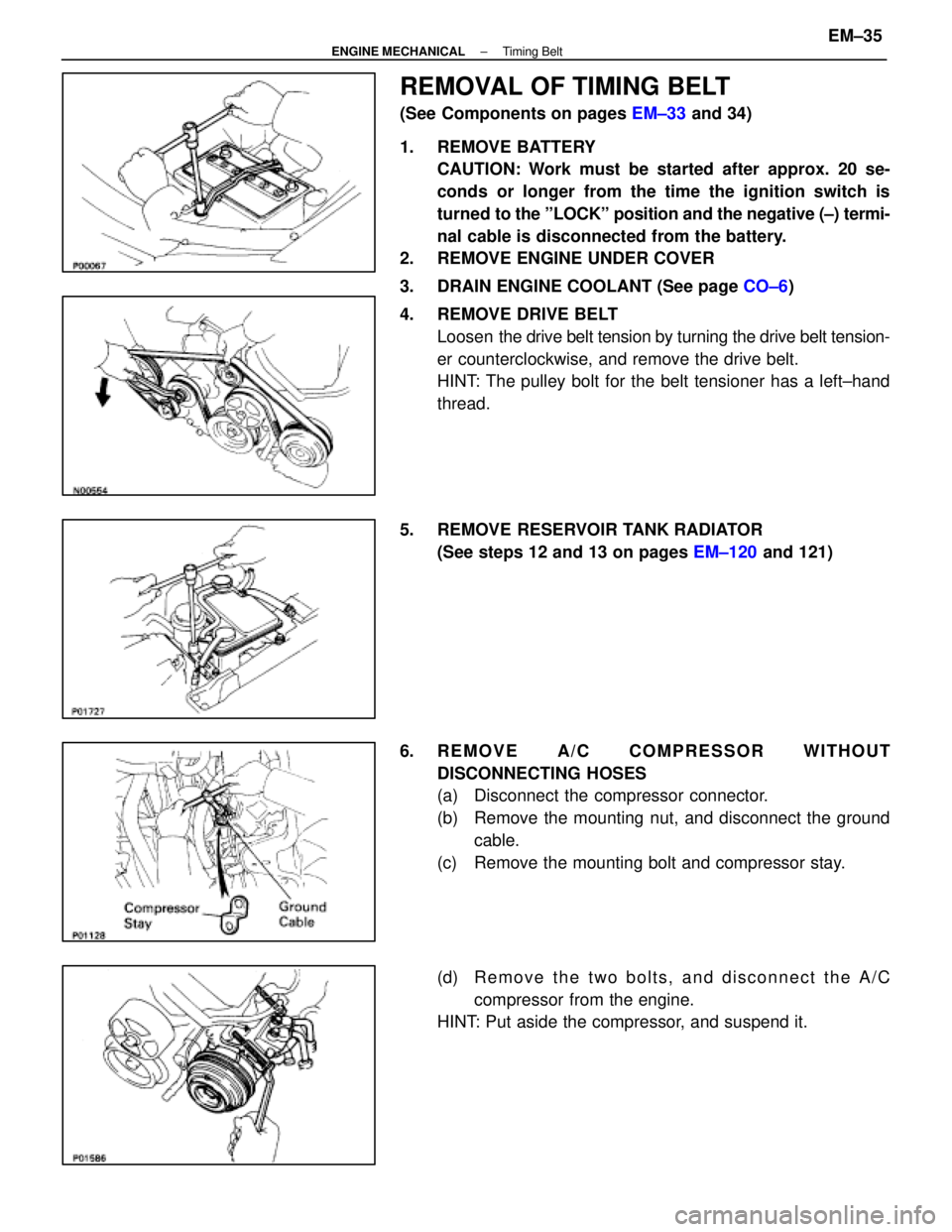

1. REMOVE BATTERY CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE ENGINE UNDER COVER

3. DRAIN ENGINE COOLANT (See page CO±6)

4. REMOVE DRIVE BELT Loosen the drive belt tension by turning the drive belt tension-

er counterclockwise, and remove the drive belt.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

5. REMOVE RESERVOIR TANK RADIATOR (See steps 12 and 13 on pages EM±120 and 121)

6. REMOVE A/C COMPRESSOR WITHOUT DISCONNECTING HOSES

(a) Disconnect the compressor connector.

(b) Remove the mounting nut, and disconnect the groundcable.

(c) Remove the mounting bolt and compressor stay.

(d) R e m o v e t h e t w o b o l t s , a n d d i s c onnect the A/C

compressor from the engine.

HINT: Put aside the compressor, and suspend it.

±

ENGINE MECHANICAL Timing BeltEM±35

WhereEverybodyKnowsYourName

Page 1709 of 4087

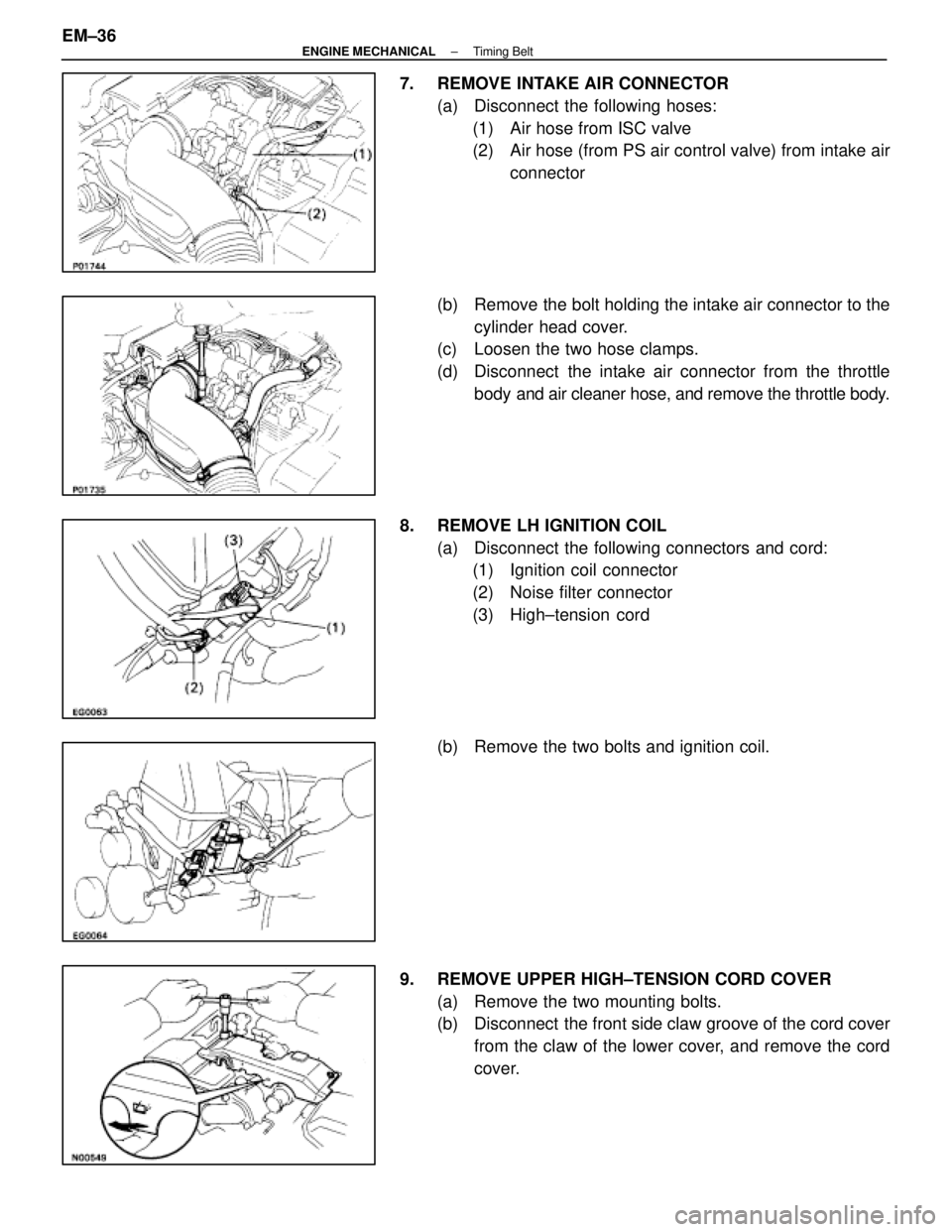

7. REMOVE INTAKE AIR CONNECTOR(a) Disconnect the following hoses:(1) Air hose from ISC valve

(2) Air hose (from PS air control valve) from intake air connector

(b) Remove the bolt holding the intake air connector to the cylinder head cover.

(c) Loosen the two hose clamps.

(d) Disconnect the intake air connector from the throttle

body and air cleaner hose, and remove the throttle body.

8. REMOVE LH IGNITION COIL (a) Disconnect the following connectors and cord:(1) Ignition coil connector

(2) Noise filter connector

(3) High±tension cord

(b) Remove the two bolts and ignition coil.

9. REMOVE UPPER HIGH±TENSION CORD COVER (a) Remove the two mounting bolts.

(b) Disconnect the front side claw groove of the cord coverfrom the claw of the lower cover, and remove the cord

cover.

EM±36

±

ENGINE MECHANICAL Timing Belt

WhereEverybodyKnowsYourName

Page 1711 of 4087

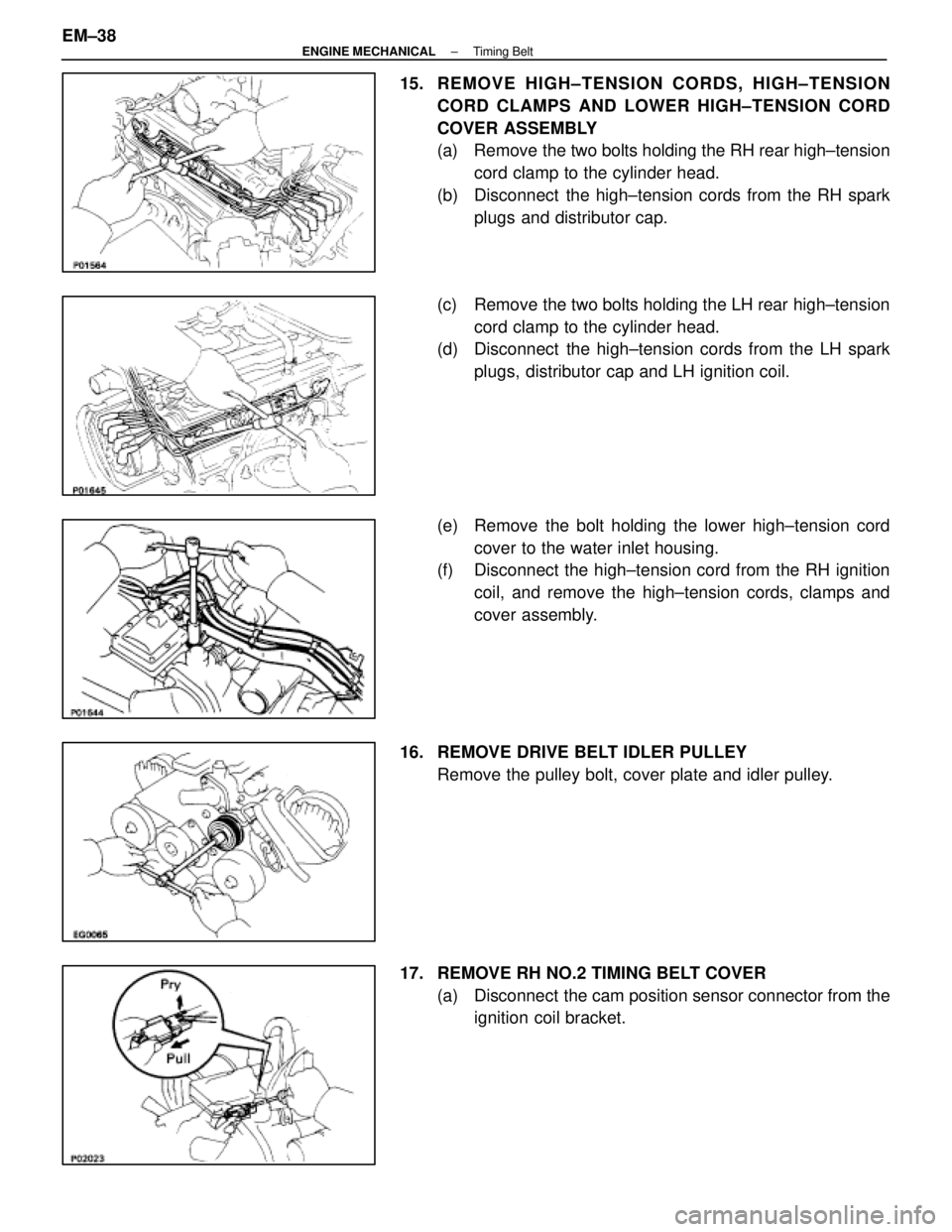

15. REMOVE HIGH±TENSION CORDS, HIGH±TENSIONCORD CLAMPS AND LOWER HIGH±TENSION CORD

COVER ASSEMBLY

(a) Remove the two bolts holding the RH rear high±tensioncord clamp to the cylinder head.

(b) Disconnect the high±tension cords from the RH spark plugs and distributor cap.

(c) Remove the two bolts holding the LH rear high±tension cord clamp to the cylinder head.

(d) Disconnect the high±tension cords from the LH spark

plugs, distributor cap and LH ignition coil.

(e) Remove the bolt holding the lower high±tension cord cover to the water inlet housing.

(f) Disconnect the high±tension cord from the RH ignition

coil, and remove the high±tension cords, clamps and

cover assembly.

16. REMOVE DRIVE BELT IDLER PULLEY Remove the pulley bolt, cover plate and idler pulley.

17. REMOVE RH NO.2 TIMING BELT COVER (a) Disconnect the cam position sensor connector from theignition coil bracket.

EM±38

±

ENGINE MECHANICAL Timing Belt

WhereEverybodyKnowsYourName

Page 1726 of 4087

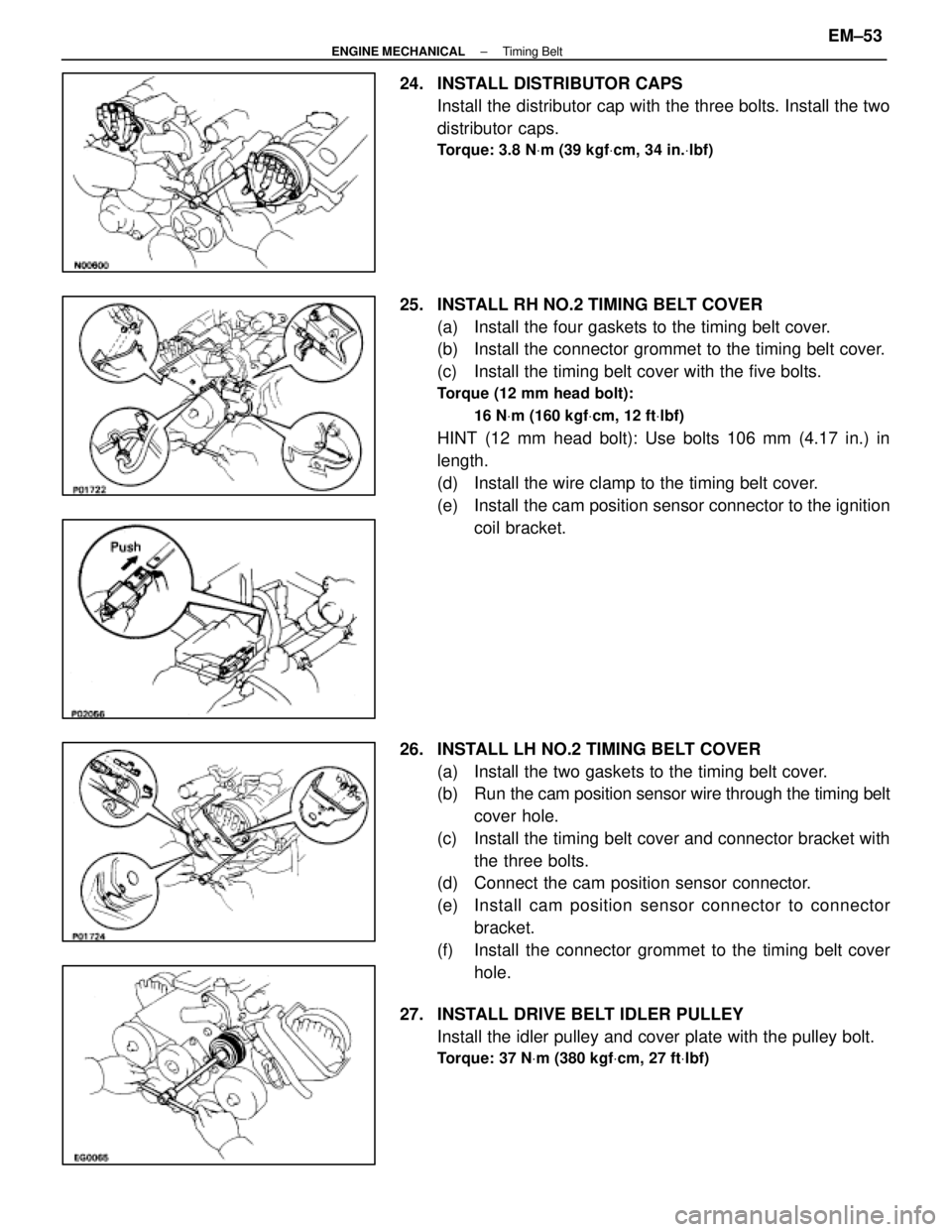

24. INSTALL DISTRIBUTOR CAPSInstall the distributor cap with the three bolts. Install the two

distributor caps.

Torque: 3.8 N Vm (39 kgf Vcm, 34 in. Vlbf)

25. INSTALL RH NO.2 TIMING BELT COVER

(a) Install the four gaskets to the timing belt cover.

(b) Install the connector grommet to the timing belt cover.

(c) Install the timing belt cover with the five bolts.

Torque (12 mm head bolt):

16 NVm (160 kgf Vcm, 12 ft Vlbf)

HINT (12 mm head bolt): Use bolts 106 mm (4.17 in.) in

length.

(d) Install the wire clamp to the timing belt cover.

(e) Install the cam position sensor connector to the ignition

coil bracket.

26. INSTALL LH NO.2 TIMING BELT COVER (a) Install the two gaskets to the timing belt cover.

(b) Run the cam po sition sensor wire through the timing belt

cover hole.

(c) Install the timing belt cover and connector bracket with the three bolts.

(d) Connect the cam position sensor connector.

(e) Install cam position sensor c onnector to connector

bracket.

(f) Install the connector grommet to the timing belt cover hole.

27. INSTALL DRIVE BELT IDLER PULLEY Install the idler pulley and cover plate with the pulley bolt.

Torque: 37 N Vm (380 kgf Vcm, 27 ft Vlbf)

±

ENGINE MECHANICAL Timing BeltEM±53

WhereEverybodyKnowsYourName

Page 1727 of 4087

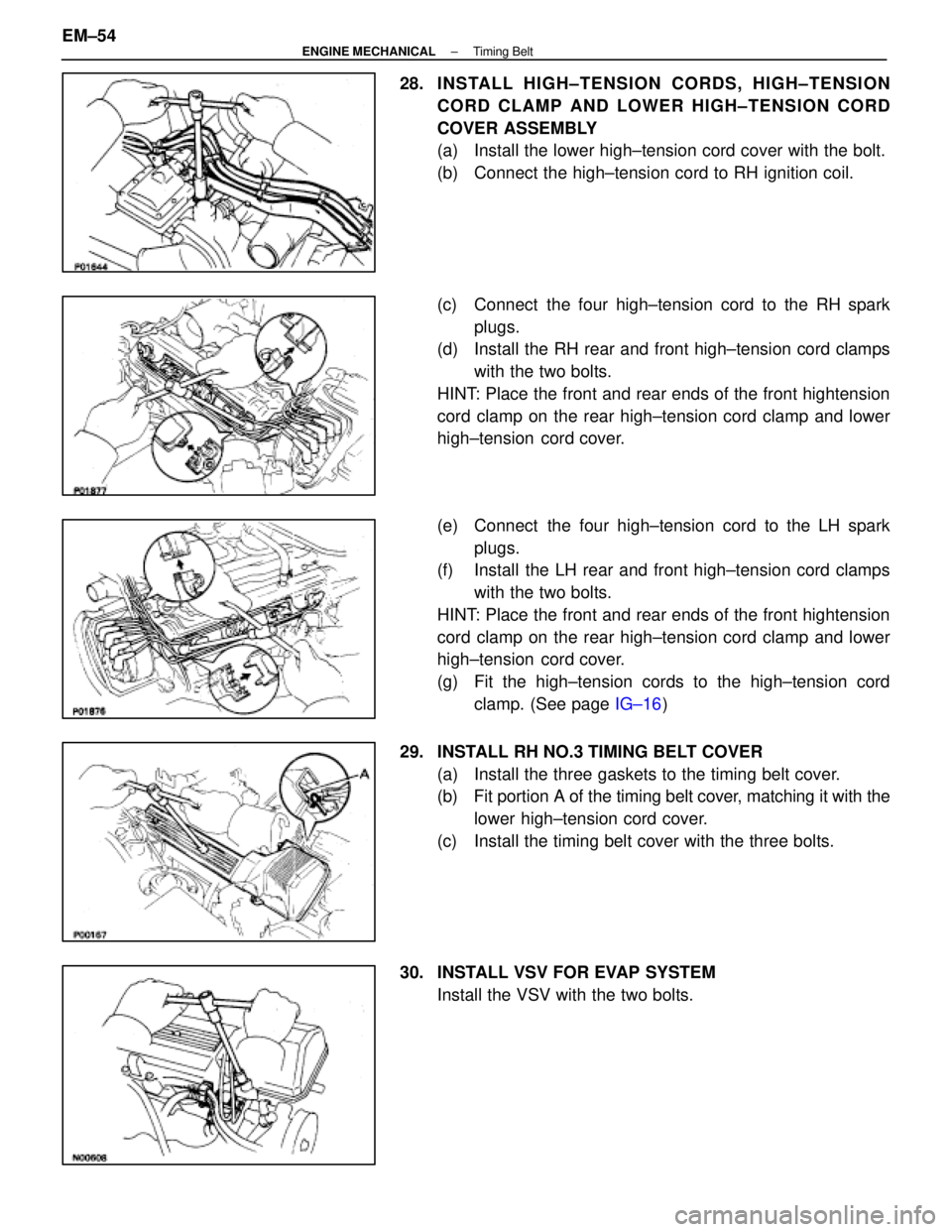

28. INSTALL HIGH±TENSION CORDS, HIGH±TENSIONCORD CLAMP AND LOWER HIGH±TENSION CORD

COVER ASSEMBLY

(a) Install the lower high±tension cord cover with the bolt.

(b) Connect the high±tension cord to RH ignition coil.

(c) Connect the four high±tension cord to the RH sparkplugs.

(d) Install the RH rear and front high±tension cord clamps

with the two bolts.

HINT: Place the front and rear ends of the front hightension

cord clamp on the rear high±tension cord clamp and lower

high±tension cord cover.

(e) Connect the four high±tension cord to the LH spark plugs.

(f) Install the LH rear and front high±tension cord clamps

with the two bolts.

HINT: Place the front and rear ends of the front hightension

cord clamp on the rear high±tension cord clamp and lower

high±tension cord cover.

(g) Fit the high±tension cords to the high±tension cord clamp. (See page IG±16)

29. INSTALL RH NO.3 TIMING BELT COVER (a) Install the three gaskets to the timing belt cover.

(b) Fit portion A of the timing belt cover, matching it with the

lower high±tension cord cover.

(c) Install the timing belt cover with the three bolts.

30. INSTALL VSV FOR EVAP SYSTEM Install the VSV with the two bolts.

EM±54

±

ENGINE MECHANICAL Timing Belt

WhereEverybodyKnowsYourName

Page 1729 of 4087

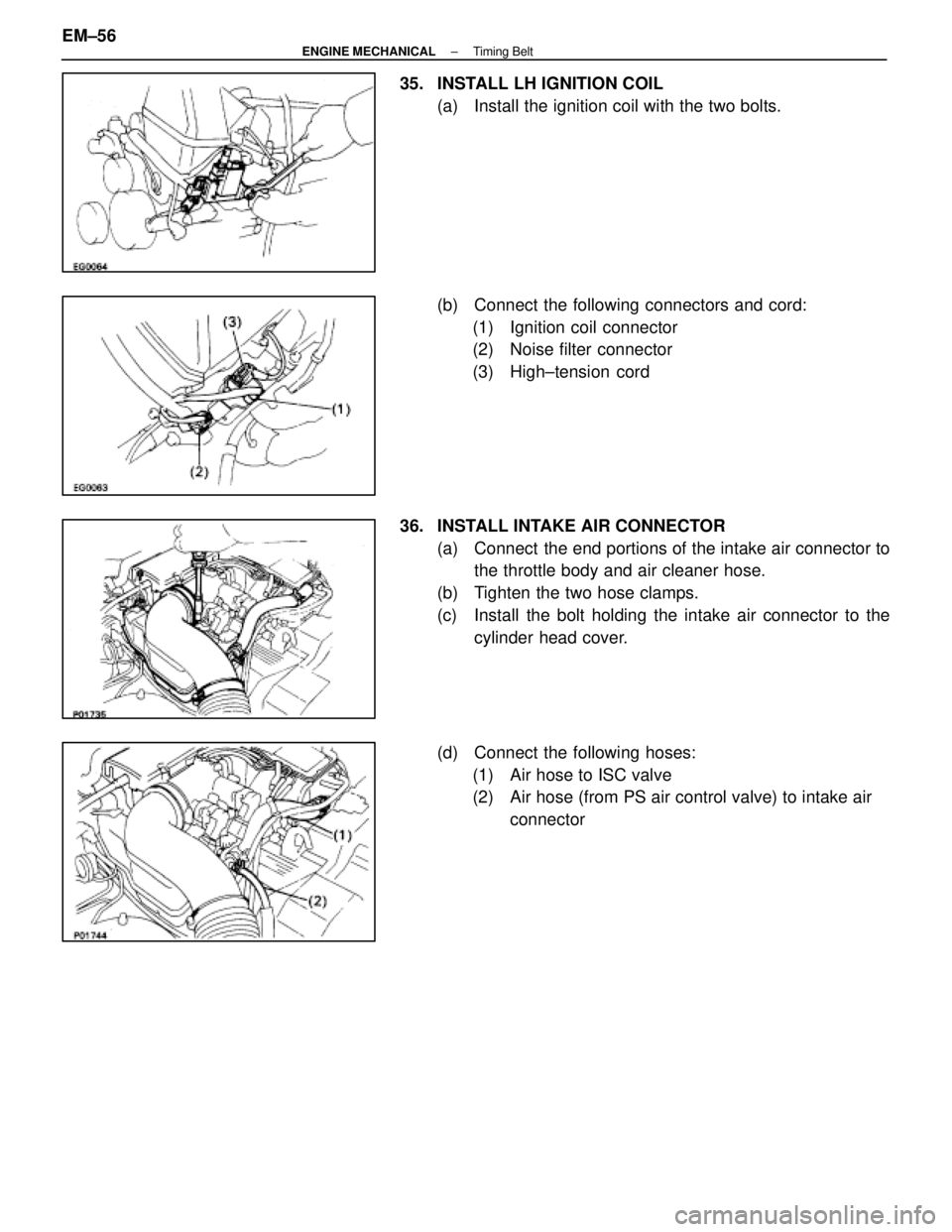

35. INSTALL LH IGNITION COIL(a) Install the ignition coil with the two bolts.

(b) Connect the following connectors and cord:(1) Ignition coil connector

(2) Noise filter connector

(3) High±tension cord

36. INSTALL INTAKE AIR CONNECTOR (a) Connect the end portions of the intake air connector tothe throttle body and air cleaner hose.

(b) Tighten the two hose clamps.

(c) Install the bolt holding the intake air connector to the cylinder head cover.

(d) Connect the following hoses: (1) Air hose to ISC valve

(2) Air hose (from PS air control valve) to intake air connector

EM±56

±

ENGINE MECHANICAL Timing Belt

WhereEverybodyKnowsYourName

Page 1730 of 4087

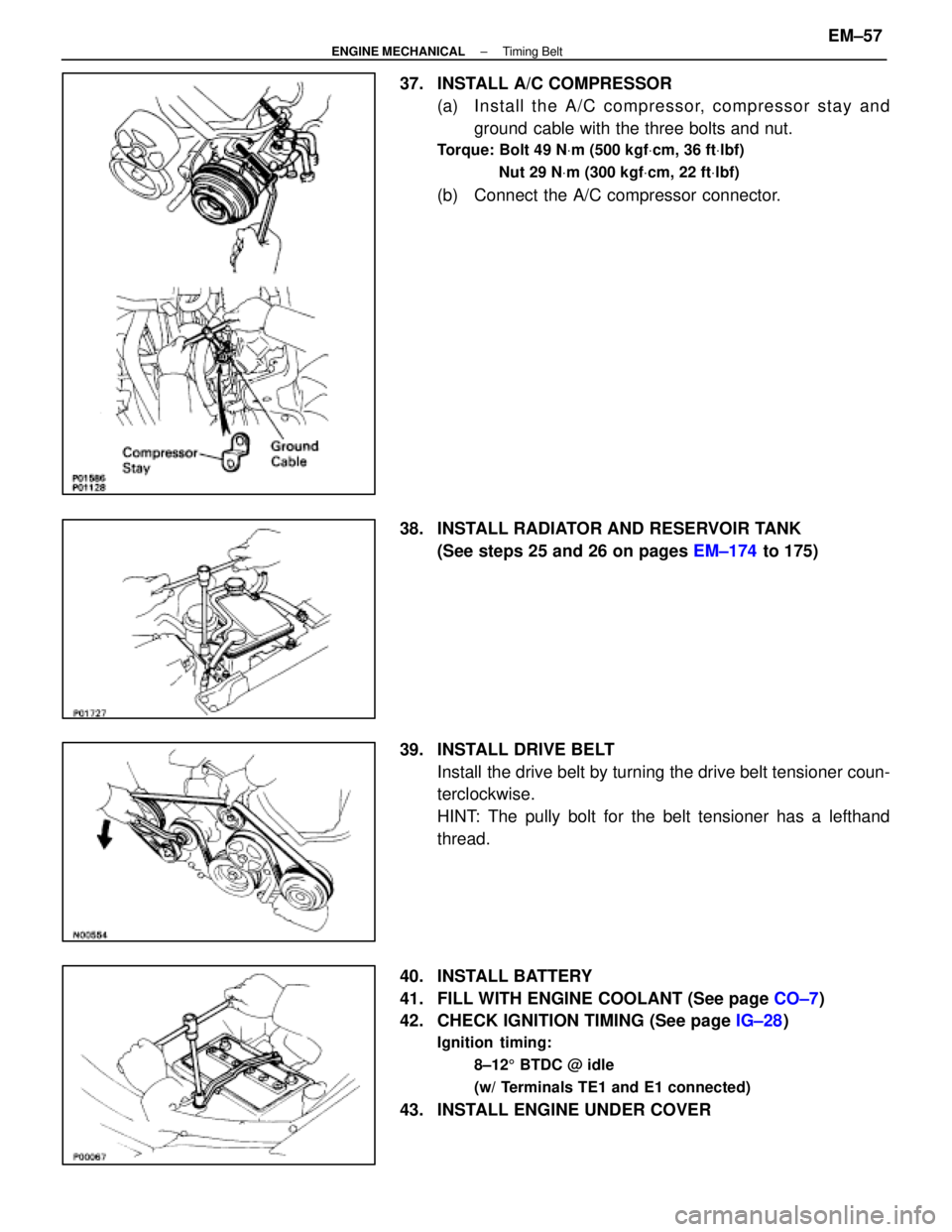

37. INSTALL A/C COMPRESSOR(a) In sta ll th e A/C co mp re sso r, co mp re sso r sta y an dground cable with the three bolts and nut.

Torque: Bolt 49 N Vm (500 kgf Vcm, 36 ft Vlbf)

Nut 29 N Vm (300 kgf Vcm, 22 ft Vlbf)

(b) Connect the A/C compressor connector.

38. INSTALL RADIATOR AND RESERVOIR TANK (See steps 25 and 26 on pages EM±174 to 175)

39. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pully bolt for the belt tensioner has a lefthand

thread.

40. INSTALL BATTERY

41. FILL WITH ENGINE COOLANT (See page CO±7)

42. CHECK IGNITION TIMING (See page IG±28)

Ignition timing:

8±125 BTDC @ idle

(w/ Terminals TE1 and E1 connected)

43. INSTALL ENGINE UNDER COVER

±

ENGINE MECHANICAL Timing BeltEM±57

WhereEverybodyKnowsYourName

Page 1758 of 4087

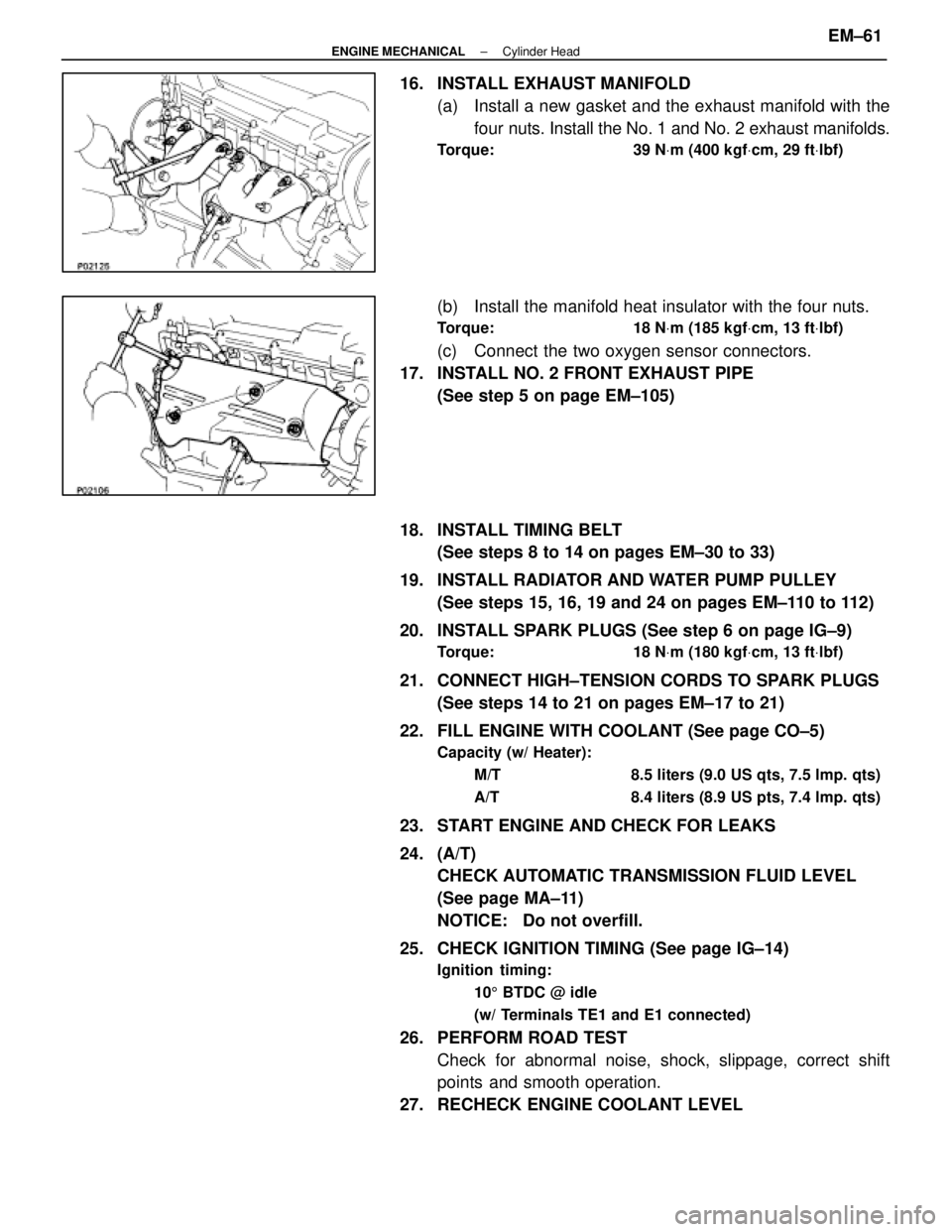

16. INSTALL EXHAUST MANIFOLD(a) Install a new gasket and the exhaust manifold with thefour nuts. Install the No. 1 and No. 2 exhaust manifolds.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(b) Install the manifold heat insulator with the four nuts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

(c) Connect the two oxygen sensor connectors.

17. INSTALL NO. 2 FRONT EXHAUST PIPE (See step 5 on page EM±105)

18. INSTALL TIMING BELT (See steps 8 to 14 on pages EM±30 to 33)

19. INSTALL RADIATOR AND WATER PUMP PULLEY (See steps 15, 16, 19 and 24 on pages EM±110 to 112)

20. INSTALL SPARK PLUGS (See step 6 on page IG±9)

Torque: 18 N Vm (180 kgf Vcm, 13 ft Vlbf)

21. CONNECT HIGH±TENSION CORDS TO SPARK PLUGS

(See steps 14 to 21 on pages EM±17 to 21)

22. FILL ENGINE WITH COOLANT (See page CO±5)

Capacity (w/ Heater): M/T 8.5 liters (9.0 US qts, 7.5 lmp. qts)

A/T 8.4 liters (8.9 US pts, 7.4 lmp. qts)

23. START ENGINE AND CHECK FOR LEAKS

24. (A/T)CHECK AUTOMATIC TRANSMISSION FLUID LEVEL

(See page MA±11)

NOTICE: Do not overfill.

25. CHECK IGNITION TIMING (See page IG±14)

Ignition timing: 105 BTDC @ idle

(w/ Terminals TE1 and E1 connected)

26. PERFORM ROAD TEST Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

27. RECHECK ENGINE COOLANT LEVEL

±

ENGINE MECHANICAL Cylinder HeadEM±61

WhereEverybodyKnowsYourName