ignition LEXUS SC300 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC300, Model: LEXUS SC300 1991Pages: 4087, PDF Size: 75.75 MB

Page 1762 of 4087

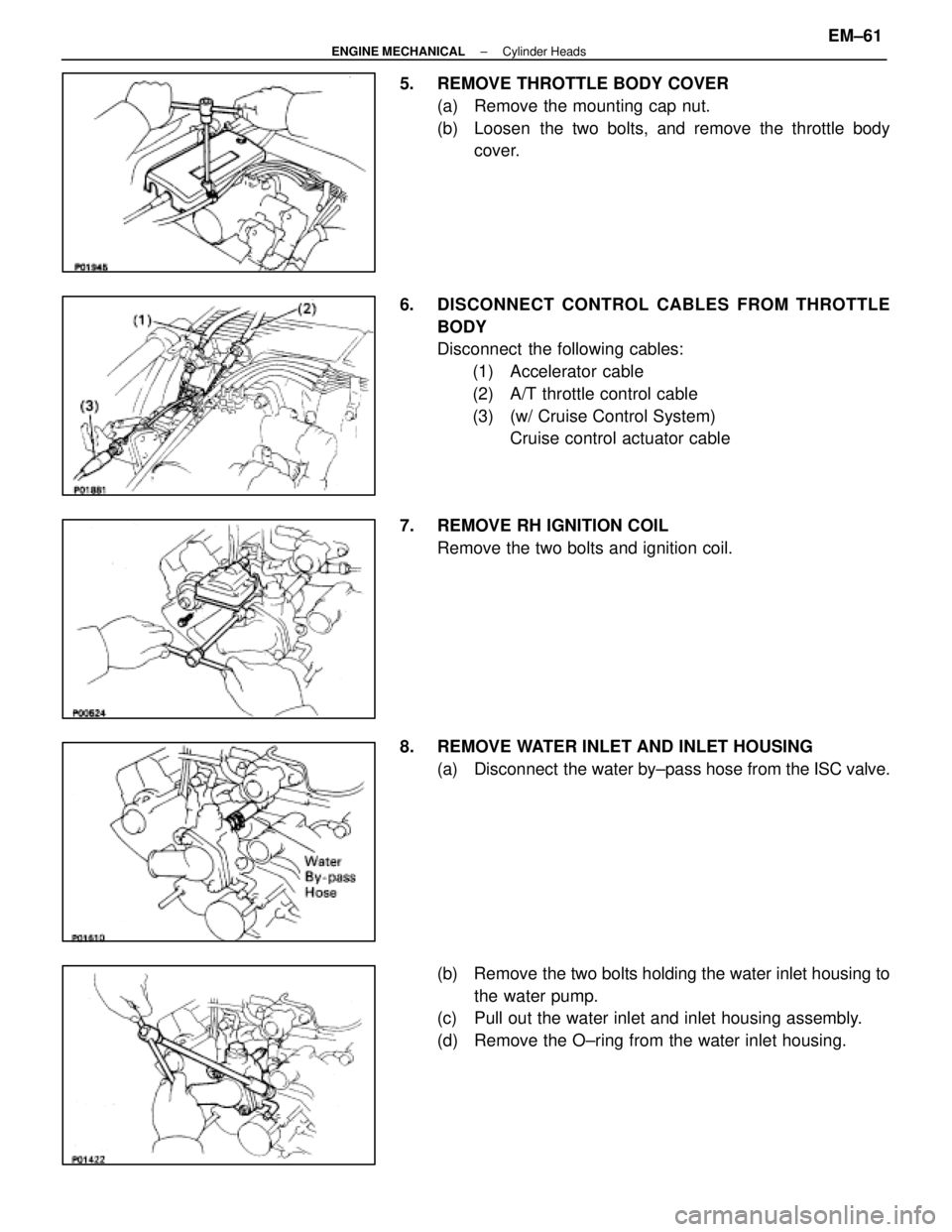

5. REMOVE THROTTLE BODY COVER(a) Remove the mounting cap nut.

(b) Loosen the two bolts, and remove the throttle bodycover.

6. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System) Cruise control actuator cable

7. REMOVE RH IGNITION COIL Remove the two bolts and ignition coil.

8. REMOVE WATER INLET AND INLET HOUSING (a) Disconnect the water by±pass hose from the ISC valve.

(b) Remove the two bolts holding the water inlet housing to the water pump.

(c) Pull out the water inlet and inlet housing assembly.

(d) Remove the O±ring from the water inlet housing.

±

ENGINE MECHANICAL Cylinder HeadsEM±61

WhereEverybodyKnowsYourName

Page 1815 of 4087

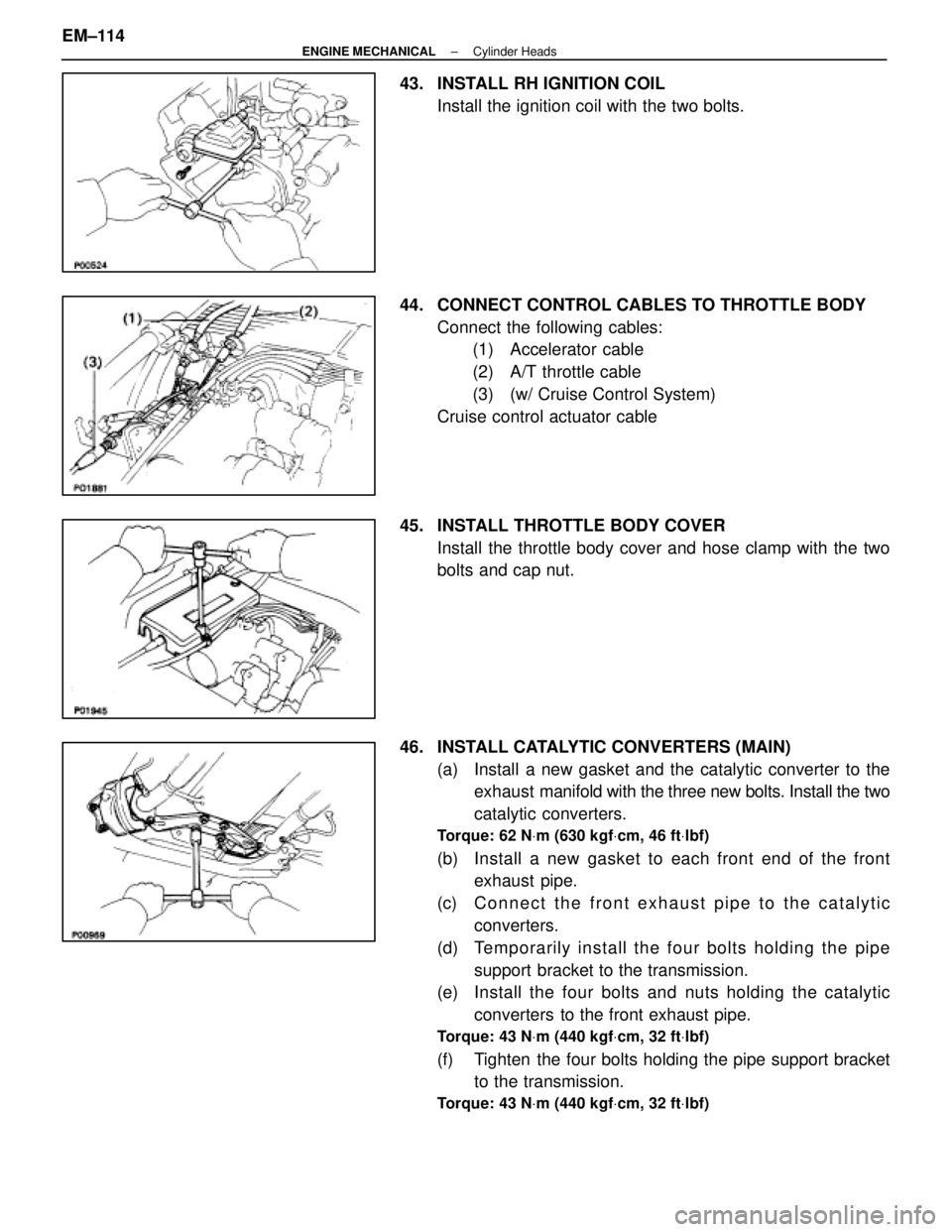

43. INSTALL RH IGNITION COILInstall the ignition coil with the two bolts.

44. CONNECT CONTROL CABLES TO THROTTLE BODY Connect the following cables:(1) Accelerator cable

(2) A/T throttle cable

(3) (w/ Cruise Control System)

Cruise control actuator cable

45. INSTALL THROTTLE BODY COVER Install the throttle body cover and hose clamp with the two

bolts and cap nut.

46. INSTALL CATALYTIC CONVERTERS (MAIN) (a) Install a new gasket and the catalytic converter to theexhaust manifold with the three new bolts. Install the two

catalytic converters.

Torque: 62 N Vm (630 kgf Vcm, 46 ft Vlbf)

(b) Install a new gasket to each front end of the front

exhaust pipe.

(c) C onnect the front exhaust pipe to the catalytic

converters.

(d) Te mp o ra rily in sta ll th e fo u r bo lts ho ld in g th e pip e support bracket to the transmission.

(e) Install the four bolts and nuts holding the catalytic

converters to the front exhaust pipe.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

(f) Tighten the four bolts holding the pipe support bracket

to the transmission.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

EM±114±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 1819 of 4087

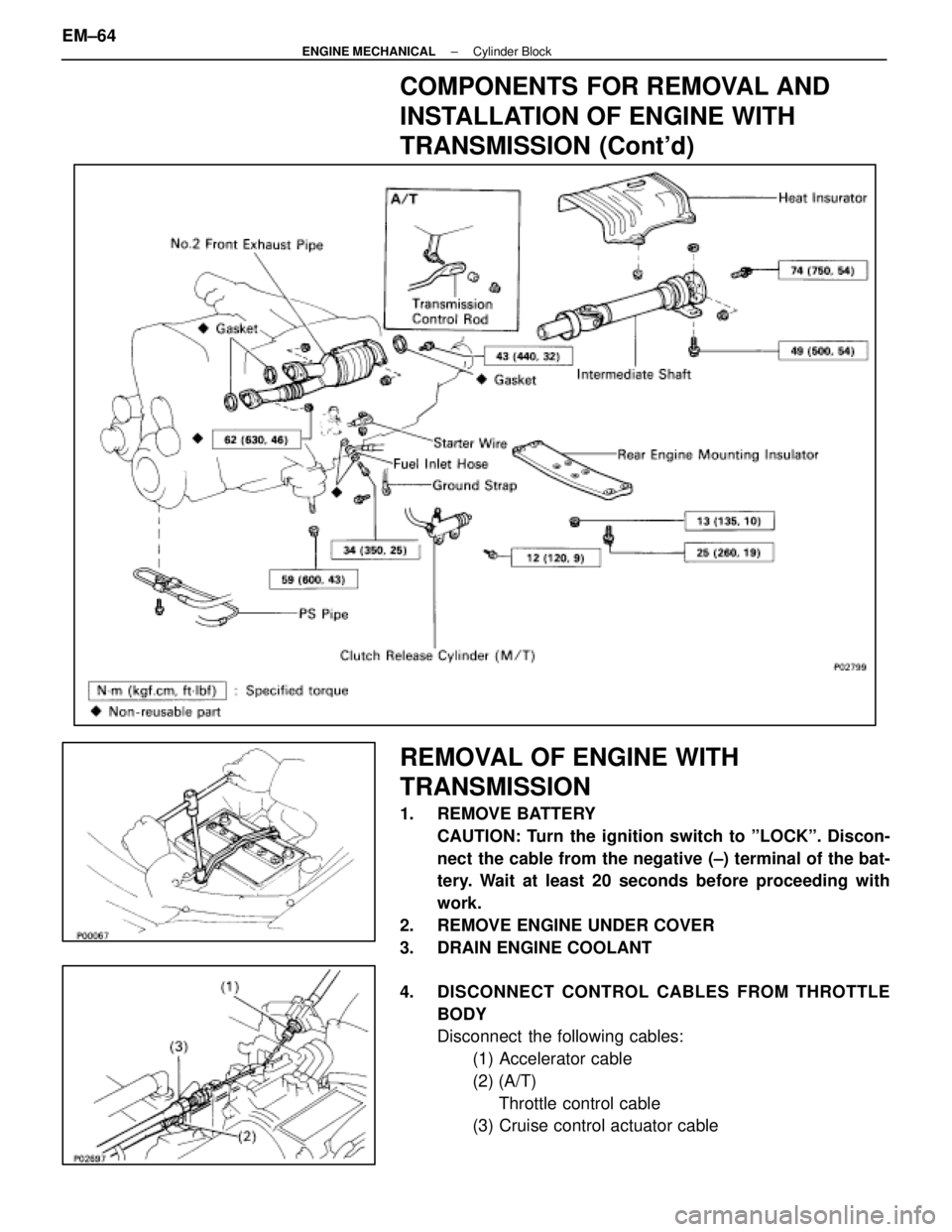

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION (Cont'd)

REMOVAL OF ENGINE WITH

TRANSMISSION

1. REMOVE BATTERYCAUTION: Turn the ignition switch to ºLOCKº. Discon-

nect the cable from the negative (±) terminal of the bat-

tery. Wait at least 20 seconds before proceeding with

work.

2. REMOVE ENGINE UNDER COVER

3. DRAIN ENGINE COOLANT

4. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) (A/T)Throttle control cable

(3) Cruise control actuator cable

EM±64

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1820 of 4087

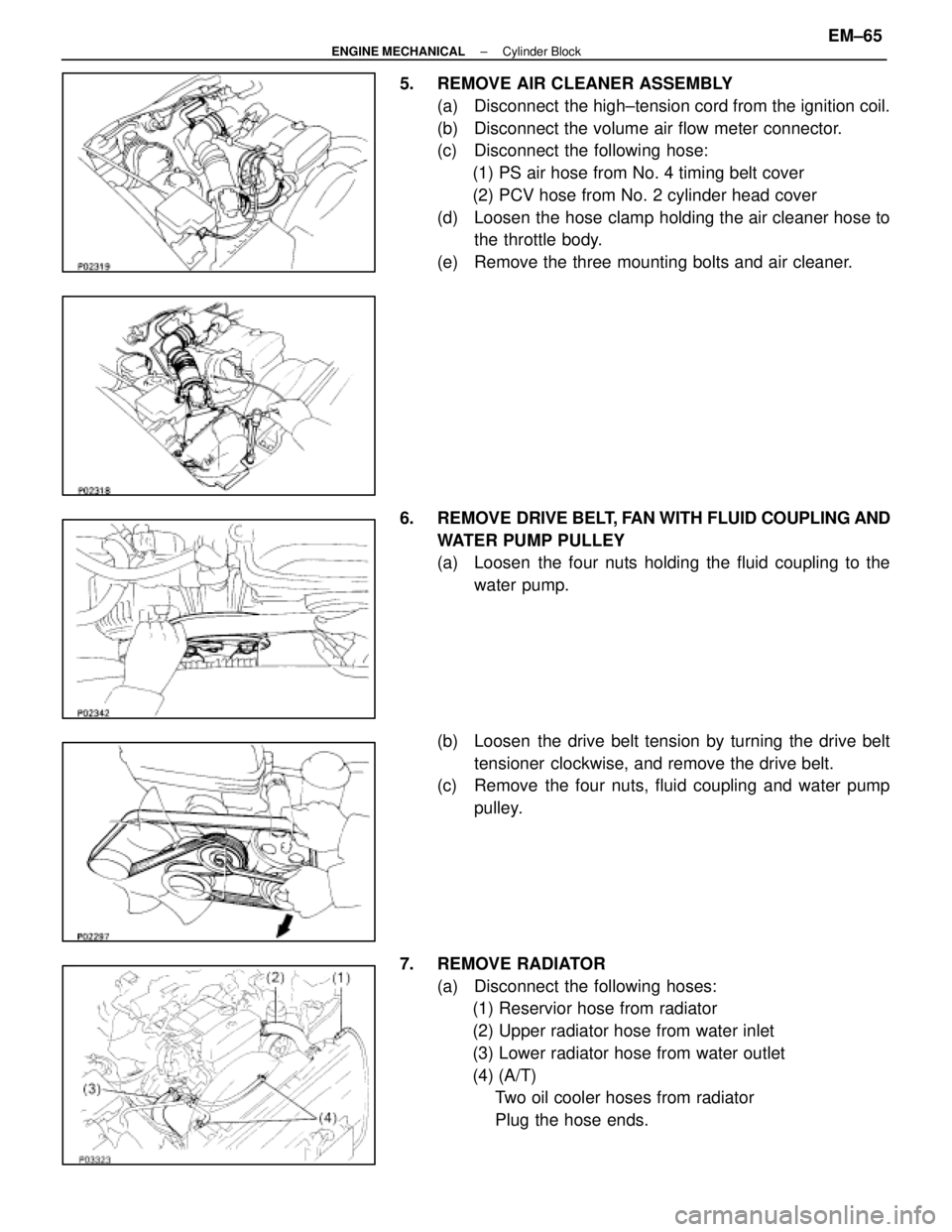

5. REMOVE AIR CLEANER ASSEMBLY(a) Disconnect the high±tension cord from the ignition coil.

(b) Disconnect the volume air flow meter connector.

(c) Disconnect the following hose:(1) PS air hose from No. 4 timing belt cover

(2) PCV hose from No. 2 cylinder head cover

(d) Loosen the hose clamp holding the air cleaner hose to the throttle body.

(e) Remove the three mounting bolts and air cleaner.

6. REMOVE DRIVE BELT, FAN WITH FLUID COUPLING AND

WATER PUMP PULLEY

(a) Loosen the four nuts holding the fluid coupling to the water pump.

(b) Loosen the drive belt tension by turning the drive belt tensioner clockwise, and remove the drive belt.

(c) Remove the four nuts, fluid coupling and water pump

pulley.

7. REMOVE RADIATOR (a) Disconnect the following hoses:(1) Reservior hose from radiator

(2) Upper radiator hose from water inlet

(3) Lower radiator hose from water outlet

(4) (A/T)Two oil cooler hoses from radiator

Plug the hose ends.

±

ENGINE MECHANICAL Cylinder BlockEM±65

WhereEverybodyKnowsYourName

Page 1822 of 4087

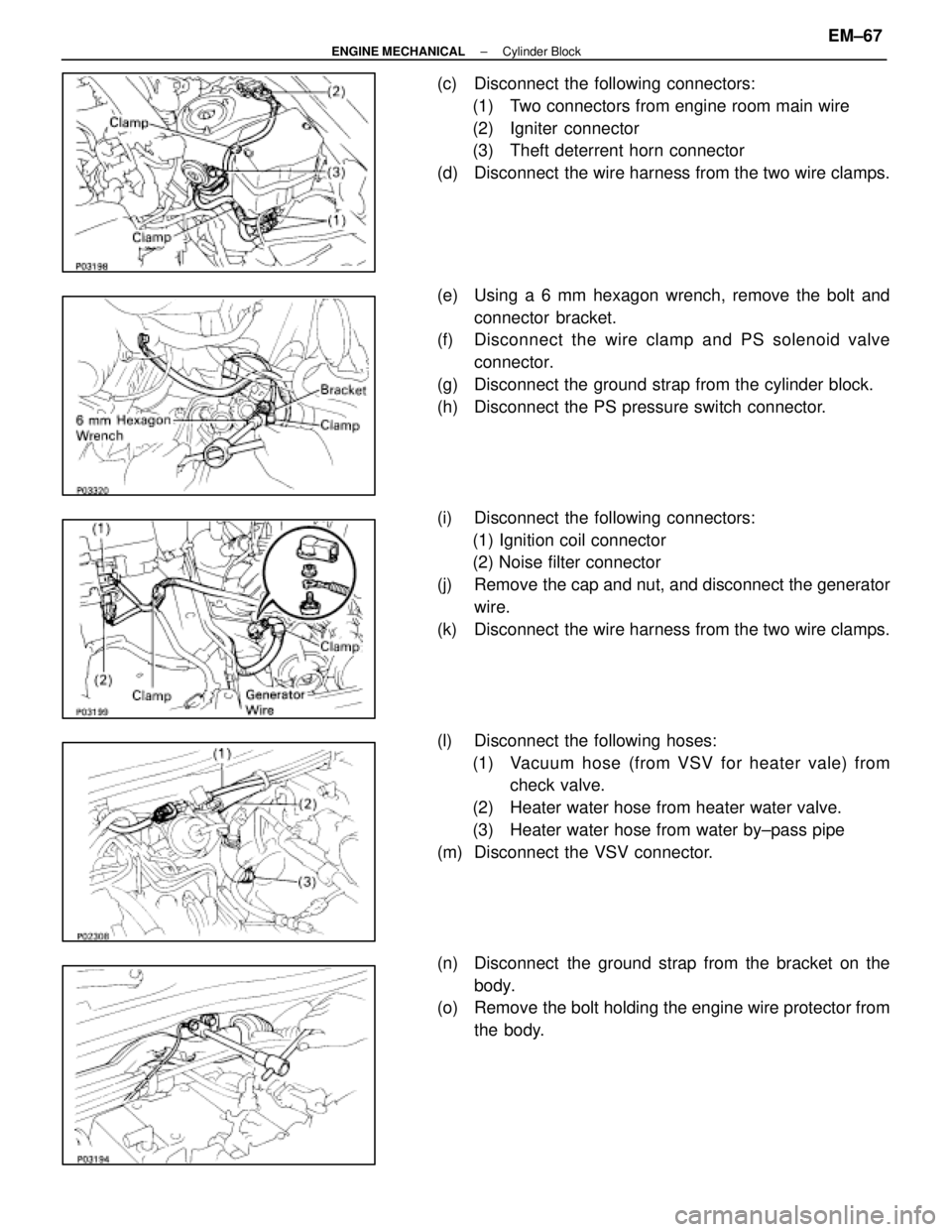

(c) Disconnect the following connectors:(1) Two connectors from engine room main wire

(2) Igniter connector

(3) Theft deterrent horn connector

(d) Disconnect the wire harness from the two wire clamps.

(e) Using a 6 mm hexagon wrench, remove the bolt and connector bracket.

(f) Disc onnect the wire clamp and PS solenoid valve

connector.

(g) Disconnect the ground strap from the cylinder block.

(h) Disconnect the PS pressure switch connector.

(i) Disconnect the following connectors: (1) Ignition coil connector

(2) Noise filter connector

(j) Remove the cap and nut, and disconnect the generator wire.

(k) Disconnect the wire harness from the two wire clamps.

(l) Disconnect the following hoses: (1) Vacuum hose (from VSV for heater vale) from check valve.

(2) Heater water hose from heater water valve.

(3) Heater water hose from water by±pass pipe

(m) Disconnect the VSV connector.

(n) Disconnect the ground strap from the bracket on the body.

(o) Remove the bolt holding the engine wire protector from

the body.

±

ENGINE MECHANICAL Cylinder BlockEM±67

WhereEverybodyKnowsYourName

Page 1864 of 4087

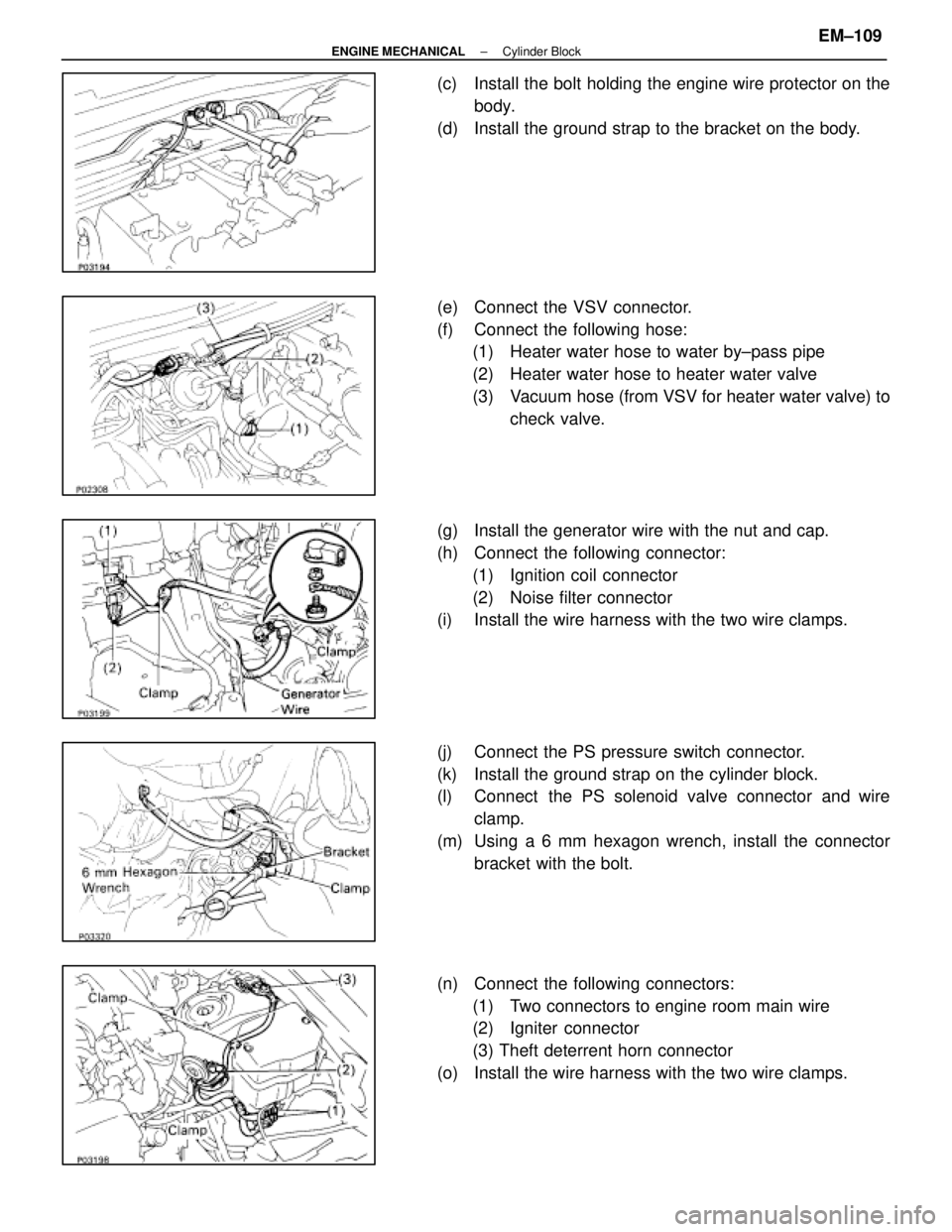

(c) Install the bolt holding the engine wire protector on thebody.

(d) Install the ground strap to the bracket on the body.

(e) Connect the VSV connector.

(f) Connect the following hose: (1) Heater water hose to water by±pass pipe

(2) Heater water hose to heater water valve

(3) Vacuum hose (from VSV for heater water valve) to

check valve.

(g) Install the generator wire with the nut and cap.

(h) Connect the following connector: (1) Ignition coil connector

(2) Noise filter connector

(i) Install the wire harness with the two wire clamps.

(j) Connect the PS pressure switch connector.

(k) Install the ground strap on the cylinder block.

(l) Connect the PS solenoid valve connector and wire

clamp.

(m) Using a 6 mm hexagon wrench, install the connector bracket with the bolt.

(n) Connect the following connectors: (1) Two connectors to engine room main wire

(2) Igniter connector

(3) Theft deterrent horn connector

(o) Install the wire harness with the two wire clamps.

±

ENGINE MECHANICAL Cylinder BlockEM±109

WhereEverybodyKnowsYourName

Page 1867 of 4087

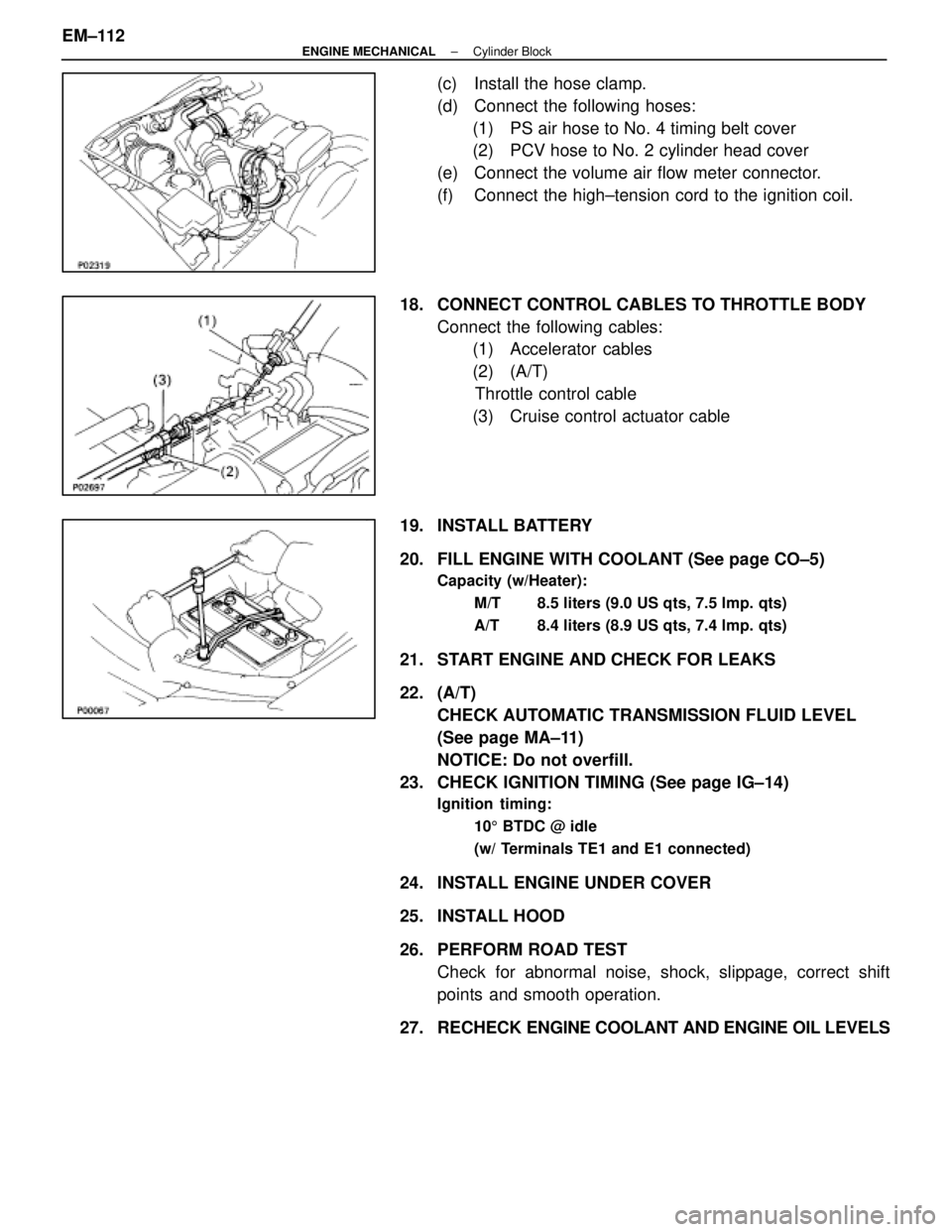

(c) Install the hose clamp.

(d) Connect the following hoses:(1) PS air hose to No. 4 timing belt cover

(2) PCV hose to No. 2 cylinder head cover

(e) Connect the volume air flow meter connector.

(f) Connect the high±tension cord to the ignition coil.

18. CONNECT CONTROL CABLES TO THROTTLE BODY Connect the following cables:(1) Accelerator cables

(2) (A/T)

Throttle control cable

(3) Cruise control actuator cable

19. INSTALL BATTERY

20. FILL ENGINE WITH COOLANT (See page CO±5)

Capacity (w/Heater): M/T 8.5 liters (9.0 US qts, 7.5 lmp. qts)

A/T 8.4 liters (8.9 US qts, 7.4 lmp. qts)

21. START ENGINE AND CHECK FOR LEAKS

22. (A/T)CHECK AUTOMATIC TRANSMISSION FLUID LEVEL

(See page MA±11)

NOTICE: Do not overfill.

23. CHECK IGNITION TIMING (See page IG±14)

Ignition timing:

105 BTDC @ idle

(w/ Terminals TE1 and E1 connected)

24. INSTALL ENGINE UNDER COVER

25. INSTALL HOOD

26. PERFORM ROAD TEST Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

27. RECHECK ENGINE COOLANT AND ENGINE OIL LEVELS

EM±112

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1880 of 4087

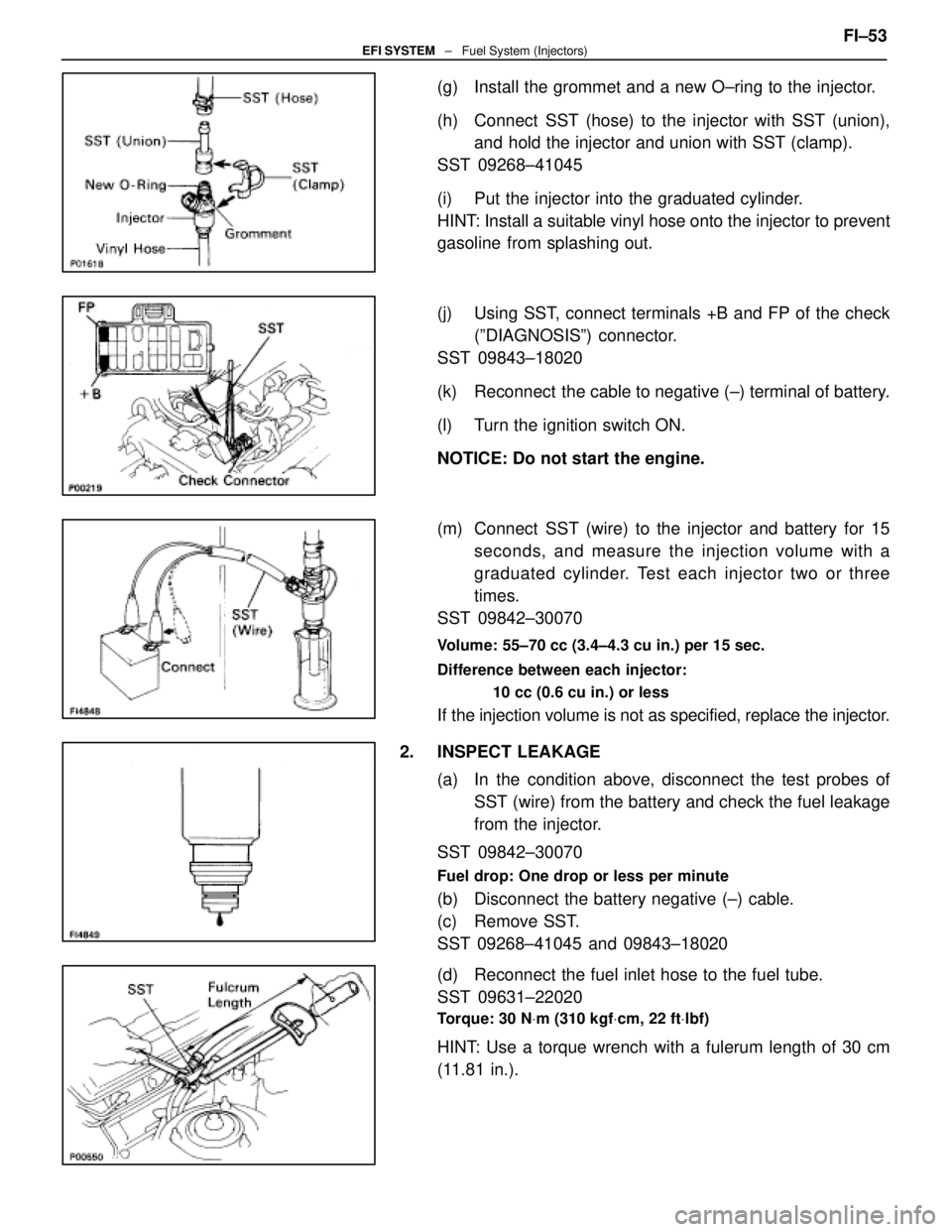

(g) Install the grommet and a new O±ring to the injector.

(h) Connect SST (hose) to the injector with SST (union),and hold the injector and union with SST (clamp).

SST 09268±41045

(i) Put the injector into the graduated cylinder.

HINT: Install a suitable vinyl hose onto the injector to prevent

gasoline from splashing out.

(j) Using SST, connect terminals +B and FP of the check (ºDIAGNOSISº) connector.

SST 09843±18020

(k) Reconnect the cable to negative (±) terminal of battery.

(l) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(m) Connect SST (wire) to the injector and battery for 15 seconds, and measure the injection volume with a

graduated cylinder. Test each injector two or three

times.

SST 09842±30070

Volume: 55±70 cc (3.4±4.3 cu in.) per 15 sec.

Difference between each injector:

10 cc (0.6 cu in.) or less

If the injection volume is not as specified, replace the injector.

2. INSPECT LEAKAGE (a) In the condition above, disconnect the test probes ofSST (wire) from the battery and check the fuel leakage

from the injector.

SST 09842±30070

Fuel drop: One drop or less per minute

(b) Disconnect the battery negative (±) cable.

(c) Remove SST.

SST 09268±41045 and 09843±18020

(d) Reconnect the fuel inlet hose to the fuel tube.

SST 09631±22020

Torque: 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Use a torque wrench with a fulerum length of 30 cm

(11.81 in.). FI±53

EFI SYSTEM

± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 1889 of 4087

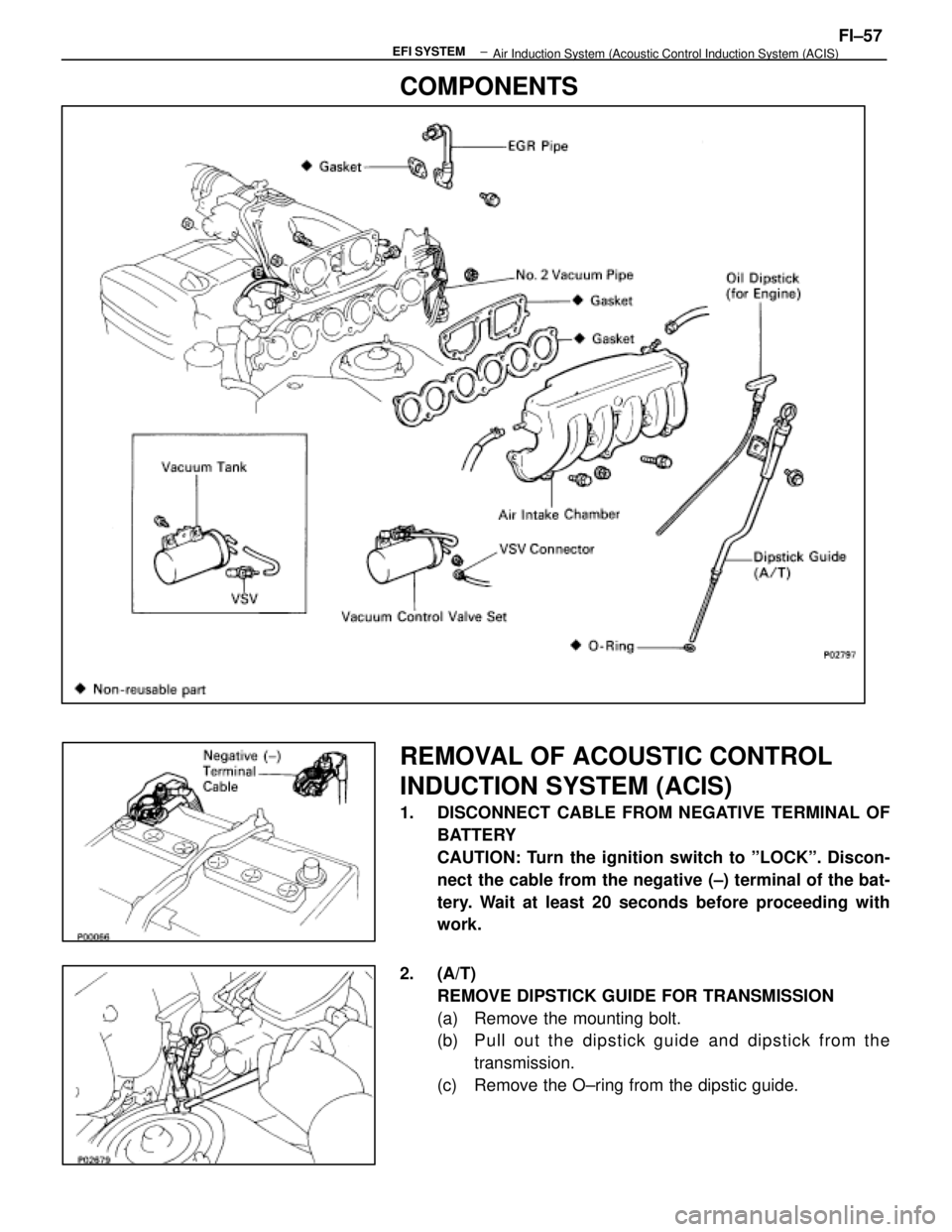

COMPONENTS

REMOVAL OF ACOUSTIC CONTROL

INDUCTION SYSTEM (ACIS)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Turn the ignition switch to ºLOCKº. Discon-

nect the cable from the negative (±) terminal of the bat-

tery. Wait at least 20 seconds before proceeding with

work.

2. (A/T) REMOVE DIPSTICK GUIDE FOR TRANSMISSION

(a) Remove the mounting bolt.

(b) P u ll ou t th e dip stick gu id e an d dip stick fro m th etransmission.

(c) Remove the O±ring from the dipstic guide.

±

EFI SYSTEMFI±57

Air Induction System (Acoustic Control Induction System (ACIS)

WhereEverybodyKnowsYourName

Page 1896 of 4087

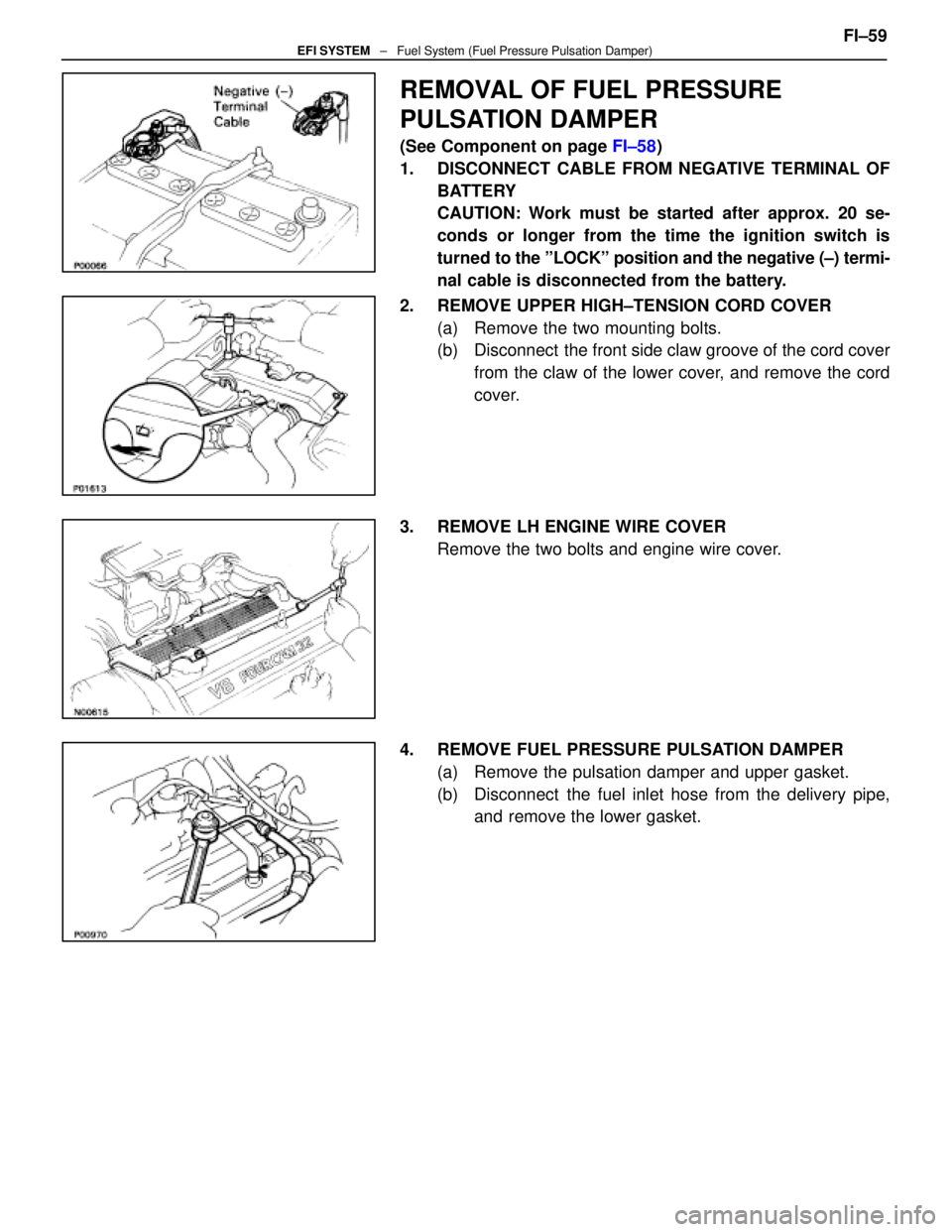

REMOVAL OF FUEL PRESSURE

PULSATION DAMPER

(See Component on page FI±58)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE UPPER HIGH±TENSION CORD COVER (a) Remove the two mounting bolts.

(b) Disconnect the front side claw groove of the cord coverfrom the claw of the lower cover, and remove the cord

cover.

3. REMOVE LH ENGINE WIRE COVER Remove the two bolts and engine wire cover.

4. REMOVE FUEL PRESSURE PULSATION DAMPER (a) Remove the pulsation damper and upper gasket.

(b) Disconnect the fuel inlet hose from the delivery pipe,and remove the lower gasket. FI±59

EFI SYSTEM

± Fuel System (Fuel Pressure Pulsation Damper)

WhereEverybodyKnowsYourName