change wheel LEXUS SC300 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC300, Model: LEXUS SC300 1991Pages: 4087, PDF Size: 75.75 MB

Page 16 of 4087

PRECAUTIONS FOR VEHICLES

EQUIPPED WITH TRACTION

CONTROL (TRAC) SYSTEM

When using a rear wheel two±wheel drum tester such as a

speedometer tester or chassis dynamometer, etc., or jacking up

the rear wheels and driving the wheels, always push in the TRAC

cut (ºTRAC OFFº) switch and turn the TRAC system OFF.

CONFIRM TRAC SYSTEM IS OFF

1. Press the TRAC cut (ºTRAC OFFº) switch.

2. Check that the TRAC OFF indicator light comes on when the

TRAC system is turned off by the TRAC cut switch.

HINT: The TRAC indicator light should always operate right after

the engine is restarted.

3. Begin measurements.

4. Press the TRAC cut switch again to change the TRAC to operative and check that the TRAC OFF indicator light goes

off.

HINT: The TRAC indicator light blinks when the TRAC system is

operative.

±

INTRODUCTION Precautions for V

ehicles Equipped with Traction Cotnrol

(TRAC)SystemIN±13

WhereEverybodyKnowsYourName

Page 936 of 4087

The speed sensor detects the wheel speed and sends the ap-

propriate signals to the ECU. These signals are used for control

of both the ABS and TRAC control systems. The front and rear

rotors each have 48 serrations. When the rotors rotate, the mag-

netic field emitted by the permanent magnet in the speed sensor

generates an AC voltage. Since the frequency of this AC voltage

changes in proportion to the speed of the rotors (wheels), the

frequency is used by the ECU to detect the speed of each wheel.

BR3583

BR3582

DTC31, 32,

33, 34Speed Sensor Circuit

CIRCUIT DESCRIPTION

DTC No.DTC Detecting ConditionTrouble Area

31, 32,

33, 34

Detection of any of conditions (1) through (3):

(1) At vehicle speed of 10 km/h (6 mph) or more, pulses are not input for 5 sec.

(2) Momentary interruption of the vehicle speed sen- sor signal occurs at least 7 times in the time be-

tween switching the ignition switch ON and switch-

ing it OFF.

(3) Abnormal fluctuation of speed sensor signals with the vehicle speed 20 km/h (12 mph) or more.

Right front, left front, right rear and left rear

speed sensor.

Open or short in each speed sensor circuit.

ECU

Hint: DTC No. 31 is for the right front wheel speed sensor.

DTC No. 32 is for the left front wheel speed sensor.

DTC No. 33 is for the right rear wheel speed sensor.

DTC No. 34 is for the left rear wheel speed sensor.

Fail safe function: If trouble occurs in the speed sensor circuit, the E\

CU prohibits TRAC control.

BR±190

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Page 1087 of 4087

DTC

31, 32,

33, 34,35, 36

Speed Sensor Circuit

CIRCUIT DESCRIPTION

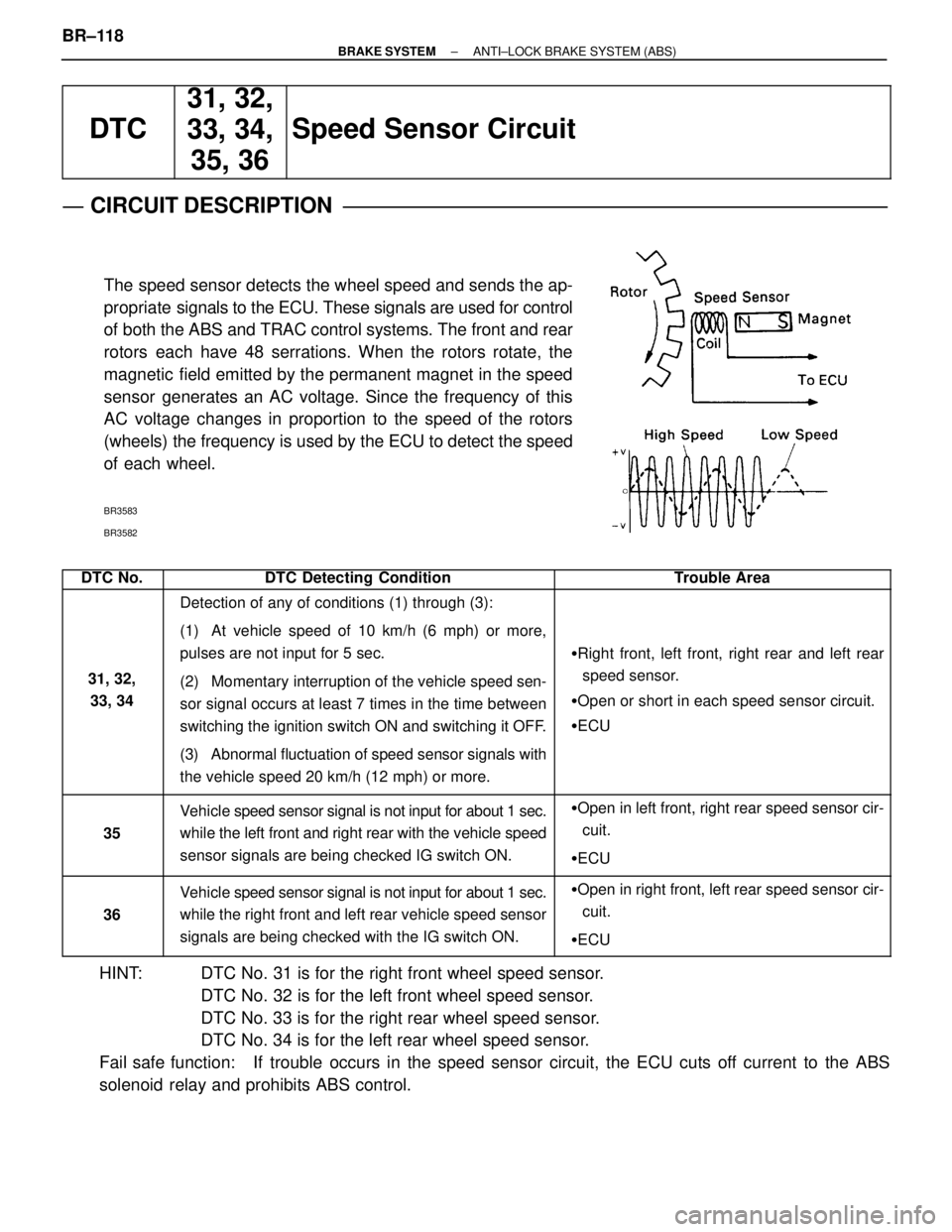

The speed sensor detects the wheel speed and sends the ap-

propriate signals to the ECU. These signals are used for control

of both the ABS and TRAC control systems. The front and rear

rotors each have 48 serrations. When the rotors rotate, the

magnetic field emitted by the permanent magnet in the speed

sensor generates an AC voltage. Since the frequency of this

AC voltage changes in proportion to the speed of the rotors

(wheels) the frequency is used by the ECU to detect the speed

of each wheel.

BR3583

BR3582

DTC No.DTC Detecting ConditionTrouble Area

31, 32,

33, 34

Detection of any of conditions (1) through (3):

(1) At vehicle speed of 10 km/h (6 mph) or more,

pulses are not input for 5 sec.

(2) Momentary interruption of the vehicle speed sen-

sor signal occurs at least 7 times in the time between

switching the ignition switch ON and switching it OFF.

(3) Abnormal fluctuation of speed sensor signals with

the vehicle speed 20 km/h (12 mph) or more.

Right front, left front, right rear and left rear

speed sensor.

Open or short in each speed sensor circuit.

ECU

35

Vehicle speed sensor signal is not input for about 1 sec.

while the left front and right rear with the vehicle speed

sensor signals are being checked IG switch ON.

Open in left front, right rear speed sensor cir-

cuit.

ECU

36

Vehicle speed sensor signal is not input for about 1 sec.

while the right front and left rear vehicle speed sensor

signals are being checked with the IG switch ON.

Open in right front, left rear speed sensor cir-

cuit.

ECU

HINT: DTC No. 31 is for the right front wheel speed sensor.

DTC No. 32 is for the left front wheel speed sensor.

DTC No. 33 is for the right rear wheel speed sensor.

DTC No. 34 is for the left rear wheel speed sensor.

Fail safe function: If trouble occurs in the speed sensor circuit, the ECU cuts off current to the ABS

solenoid relay and prohibits ABS control.

BR±118

±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)

WhereEverybodyKnowsYourName

Page 2164 of 4087

(b) Check the brake drums for scoring or wear.

Maximum drum inside diameter:191 mm (7.520 in.)

(c) Clean the brake parts with a damp cloth.NOTICE: Do not use compressed air to clean the brake

parts.

(d) Seat the parking brake shoes during the road test (item 25) in do the following:

wDrive the vehicle at approx. 50 km/h (30 mph) on a safe,

level and dry road.

w With the parking brake release buttom pushed in, pull on

the lever with 88 N (9 kgf, 20 lbf) of force.

w Drive the vehicle for approx. 400 meters (1/4 mile) in this

condition.

w Repeat this procedure 2 or 3 times.

w Check parking pedal travel.

If necessary, adjust the parking brake.

16. INSPECT AND CHANGE BRAKE FLUID

(a) Visually inspect the master cylinder for leaks.

(b) Change brake fluid (See BR section)

Fluid: SAE J1703 or FMVSS No.116 DOT3

MA04F±01

CHASSIS

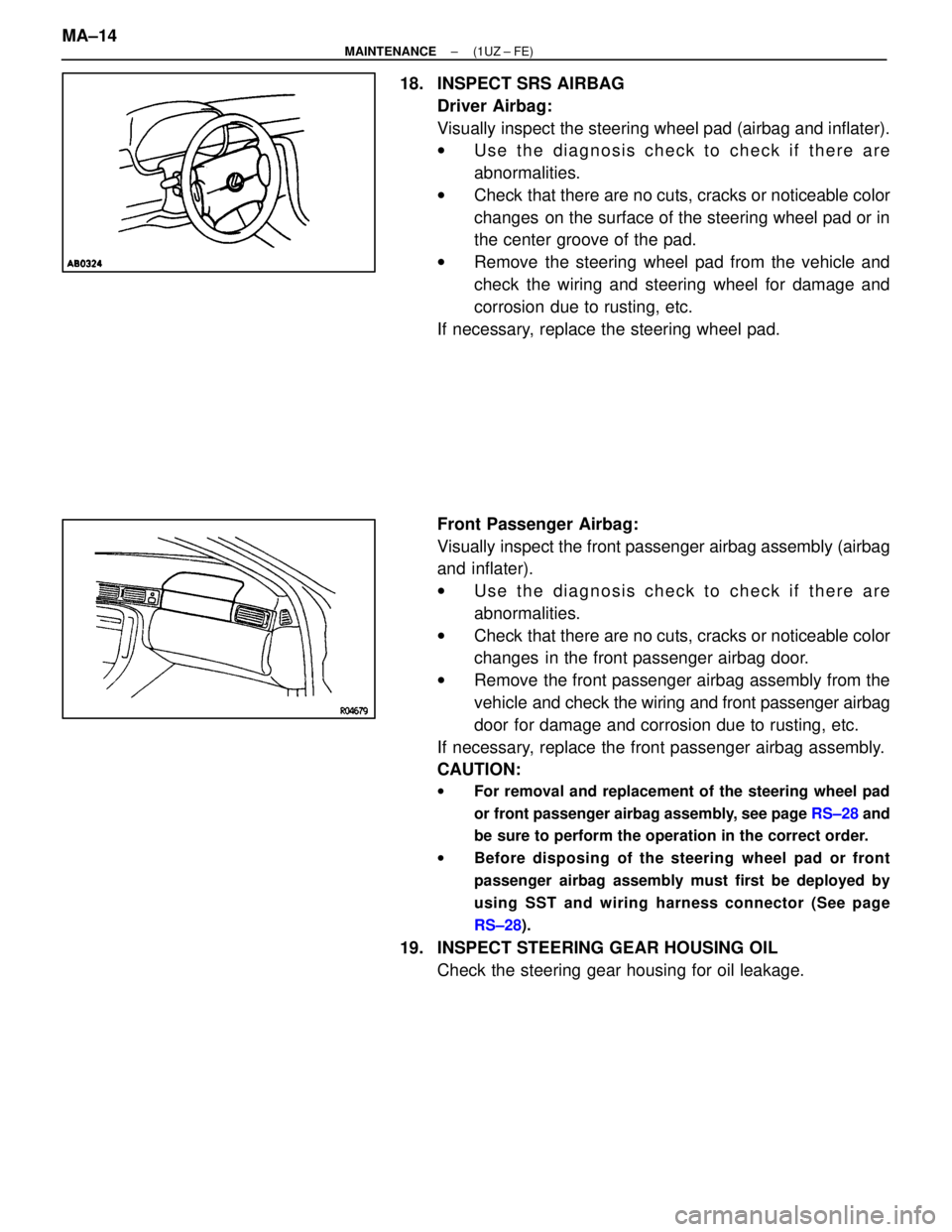

17. INSPECT STEERING LINKAGE

(a) Check the steering wheel freeplay.

Maximum freeplay:30 mm (1.18 in.)

With the vehicle stopped and pointed straight ahead, rock the

steering wheel gently back and forth with light finger pres-

sure.

(b) Check the steering linkage for looseness or damage. Check that:

wTie rod ends do not have excessive play.

w Dust seals and boots are not damaged.

w Boot clamps are not loose.

±

MAINTENANCE (1UZ ± FE)MA±13

WhereEverybodyKnowsYourName

Page 2165 of 4087

18. INSPECT SRS AIRBAGDriver Airbag:

Visually inspect the steering wheel pad (airbag and inflater).

wUse the diagnosis check to check if there are

abnormalities.

w Check that there are no cuts, cracks or noticeable color

changes on the surface of the steering wheel pad or in

the center groove of the pad.

w Remove the steering wheel pad from the vehicle and

check the wiring and steering wheel for damage and

corrosion due to rusting, etc.

If necessary, replace the steering wheel pad.

Front Passenger Airbag:

Visually inspect the front passenger airbag assembly (airbag

and inflater).

w Use the diagnosis check to check if there are

abnormalities.

w Check that there are no cuts, cracks or noticeable color

changes in the front passenger airbag door.

w Remove the front passenger airbag assembly from the

vehicle and check the wiring and front passenger airbag

door for damage and corrosion due to rusting, etc.

If necessary, replace the front passenger airbag assembly.

CAUTION:

w For removal and replacement of the steering wheel pad

or front passenger airbag assembly, see page RS±28 and

be sure to perform the operation in the correct order.

w Before disposing of the steering wheel pad or front

passenger airbag assembly must first be deployed by

using SST and wiring harness connector (See page

RS±28 ).

19. INSPECT STEERING GEAR HOUSING OIL

Check the steering gear housing for oil leakage.

MA±14

±

MAINTENANCE (1UZ ± FE)

WhereEverybodyKnowsYourName

Page 2170 of 4087

GENERAL MAINTENANCE

MA00M±03

There are the maintenance and inspection

items which are considered to be the owner's

responsibility. They can be performed by the

owner or be can have them done at a service

shop. These items include those which should

be checked on a daily basis, those which, in

most cases, do not require (special) tools and

those which are considered to be reasonable

for the owner to perform. Items and procedures

for general maintanance are as follows:

MA00P±04

OUTSIDE VEHICLE

1. TIRES

(a) Check the pressure with a gauge. Adjust ifnecessary.

(b) Check for cuts, damage or excessive wear.

2. WHEEL NUTS Wheel checking the tires, check the nuts for

looseness or for missing nuts. If necessary,

tighten them.

3. TIRE ROTATION It is recommended that tires be rotated every

12,000 km (7,500 miles).

4. WINDSHIELD WIPER BLADES Check for wear or cracks whenever they do not

wipe clean. Replace if necessary.

5. FLUID LEAKS

(a) Check underneath for leaking fuel, oil, water or

other fluid.

(b) If you smell gasoline fumes or notice any leak, have the cause found and corrected.

6. DOORS AND ENGINE HOOD

(a) Check that all doors including the trunk lid operate smoothly, and that all latches lock

securely.

(b) Check that the engine hood secondary latch secures the hood from opening when the

primary latch is released.

MA00R±05

INSIDE VEHICLE

7. LIGHTS

(a) C h e c k t h a t t h e h eadlights, stop lights,

tail±lights, turn signal lights, and other lights

are all working. (b) Check the headlight aiming.

8. WARNING LIGHT AND BUZZERS

Check that all warning lights and buzzers func-

tion properly.

9. HORN Check that it is working.

10. WINDSHIELD GLASS

Check for scratches, pits or abrasions.

11. WINDSHIELD WIPER AND WASHER

(a) Check operation of the wipers and washer.

(b) Check that the wipers do not streak.

12. WINDSHIELD DEFROSTER Check that the air comes out from the defroster

outlet when operating the heater air condition-

er at defroster mode.

13. REAR VIEW MIRROR

Check that it is mounted securely.

14. SUN VISORS Check that they move freely and are mounted

securely.

15. STEERING WHEEL Check that it has the specified freeplay. Be

alert for changes in steering condition, such as

hard steering, excessive freeplay or strange

noise.

16. SEATS

(a) Check that all front seat controls such as seat adjusters, seatback recliner, etc. operate

smoothly.

(b) Check that all latches lock securely in any position.

(c) Check that the locks hold securely in any latched position.

(d) Check that the head restraints move up and

down smoothly and that the locks hold securely

in ay latches position.

(e) For folding±down rear seat backs, check that the latches lock securely.

17. SEAT BELTS

(a) Ch e ck th a t th e se a t be lt syste m su ch as buckles, retractors and anchors operate

properly and smoothly.

(b) Check that the belt webbing is not cut, frayed,

worn or damaged.

18. ACCELERATOR PEDAL Check the pedal for smooth operation and un-

even pedal effort or catching.

±

MAINTENANCE (1UZ ± FE)MA±19

WhereEverybodyKnowsYourName

Page 2964 of 4087

SERVICE HINT

Troubles with the power steering system are usually concerned with hard steering due to the fact that there

is no assistance. In such cases, before attempting to make repairs, it i\

s necessary to determine whether

the trouble lies with the pump or with the gear housing. To do this, an on±vehicle inspection, can be made

by using a pressure gauge.

ON±VEHICLE INSPECTION Power steering is a hydraulic device and problems are normally due to insufficient fluid pressure acting on

the piston. This could be caused by either the pump not producing the speci\

fied fluid pressure or the control

valve in the gear housing not functioning properly so that the proper fluid p\

ressure can not be obtained.

If the fault lies with the pump, the same symptoms will generally occur wh\

ether the steering wheel is turned

fully to the right or left. On the other hand, if the fault lies with the con\

trol valve, there will generally be a

difference between the amount of assistance when the steering wheel is turned to th\

e left and right, causing

harder steering. However, if the piston seal of the power cylinder is worn, there will be a loss of f\

luid pressure

whether the steering wheel is turned to the right or left and the symptoms will\

be the same for both.

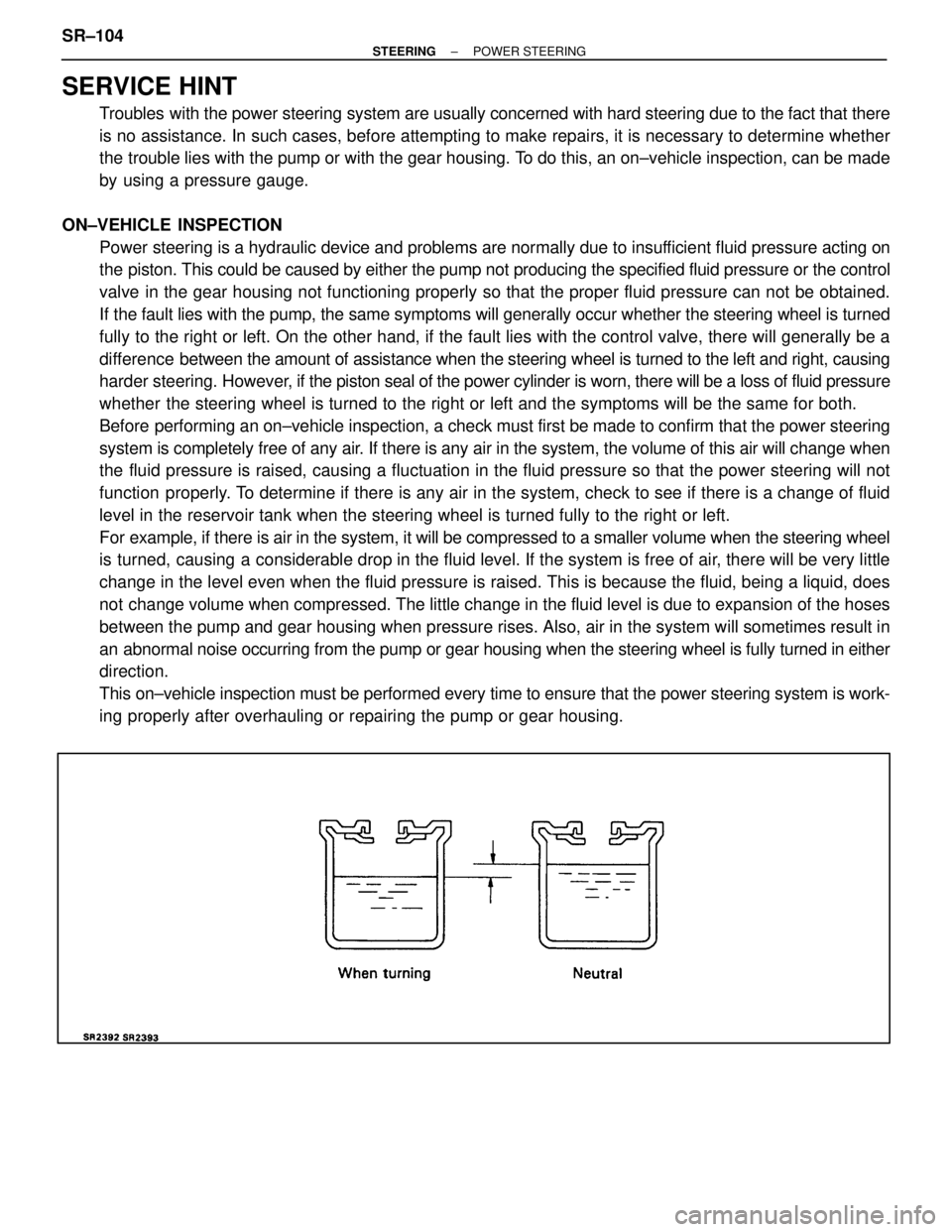

Before performing an on±vehicle inspection, a check must first be made to c\

onfirm that the power steering

system is completely free of any air. If there is any air in the system, the volume of this air will change \

when

the fluid pressure is raised, causing a fluctuation in the fluid pressure s\

o that the power steering will not

function properly. To determine if there is any air in the system, check to see if there is \

a change of fluid

level in the reservoir tank when the steering wheel is turned fully to t\

he right or left.

For example, if there is air in the system, it will be compressed to a smal\

ler volume when the steering wheel

is turned, causing a considerable drop in the fluid level. If the system is free of air, there will be very little

change in the level even when the fluid pressure is raised. This is beca\

use the fluid, being a liquid, does

not change volume when compressed. The little change in the fluid level is d\

ue to expansion of the hoses

between the pump and gear housing when pressure rises. Also, air in the system will sometimes result in

an abnormal noise occurring from the pump or gear housing when the steerin\

g wheel is fully turned in either

direction.

This on±vehicle inspection must be performed every time to ensure tha\

t the power steering system is work-

ing properly after overhauling or repairing the pump or gear housing.

SR±104±

STEERING POWER STEERING

WhereEverybodyKnowsYourName

Page 3011 of 4087

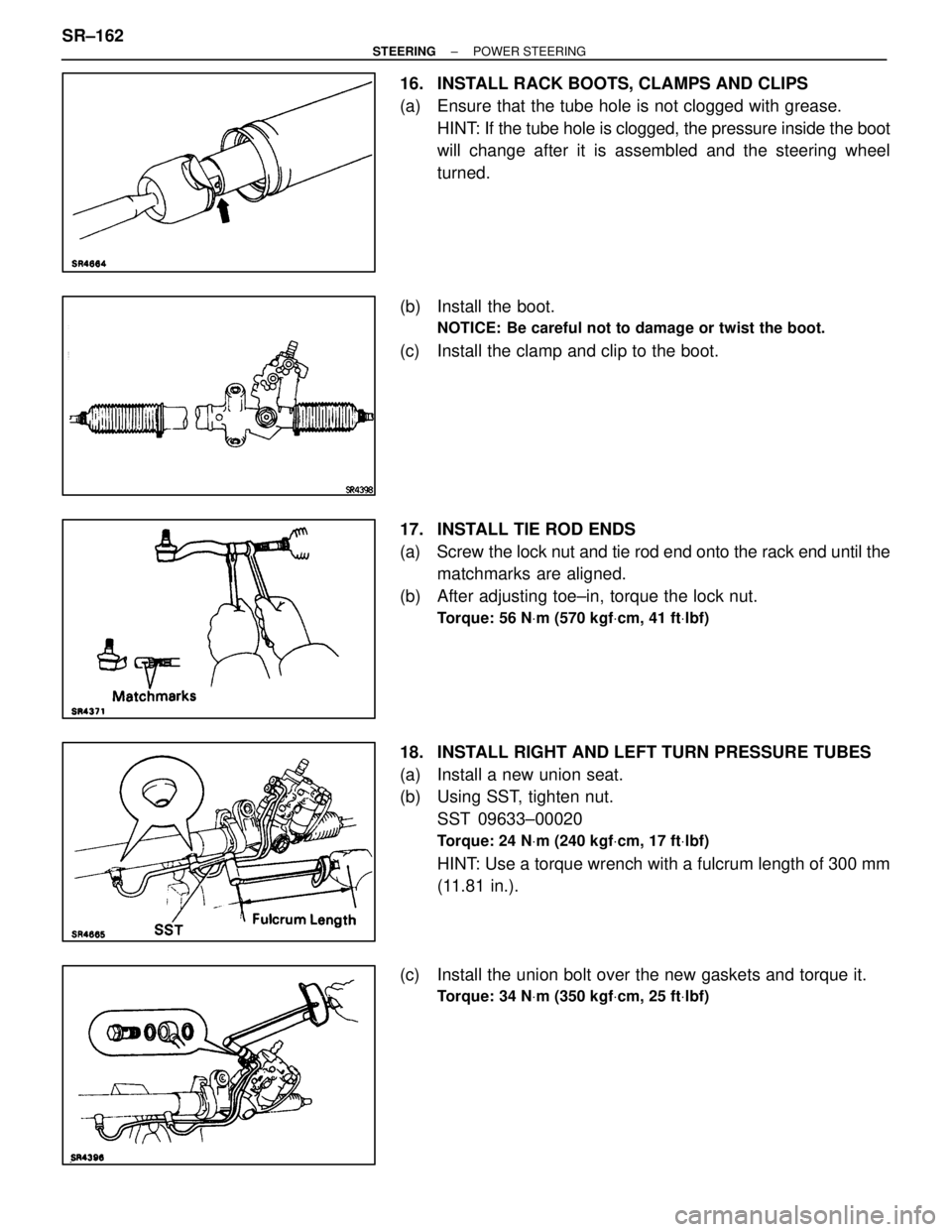

16. INSTALL RACK BOOTS, CLAMPS AND CLIPS

(a) Ensure that the tube hole is not clogged with grease.HINT: If the tube hole is clogged, the pressure inside the boot

will change after it is assembled and the steering wheel

turned.

(b) Install the boot.

NOTICE: Be careful not to damage or twist the boot.

(c) Install the clamp and clip to the boot.

17. INSTALL TIE ROD ENDS

(a) Screw the lock nut and tie rod end onto the rack end until the matchmarks are aligned.

(b) After adjusting toe±in, torque the lock nut.

Torque: 56 N Vm (570 kgf Vcm, 41 ft Vlbf)

18. INSTALL RIGHT AND LEFT TURN PRESSURE TUBES

(a) Install a new union seat.

(b) Using SST, tighten nut.

SST 09633±00020

Torque: 24 N Vm (240 kgf Vcm, 17 ft Vlbf)

HINT: Use a torque wrench with a fulcrum length of 300 mm

(11.81 in.).

(c) Install the union bolt over the new gaskets and torque it.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

SR±162±

STEERING POWER STEERING

WhereEverybodyKnowsYourName