engine coolant LEXUS SC400 1991 Service Owners Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2211 of 4087

INSPECTION AND ADJUSTMENT OF

VALVE CLEARANCE

HINT: Inspect and adjust the valve clearance when the

engine is cold.

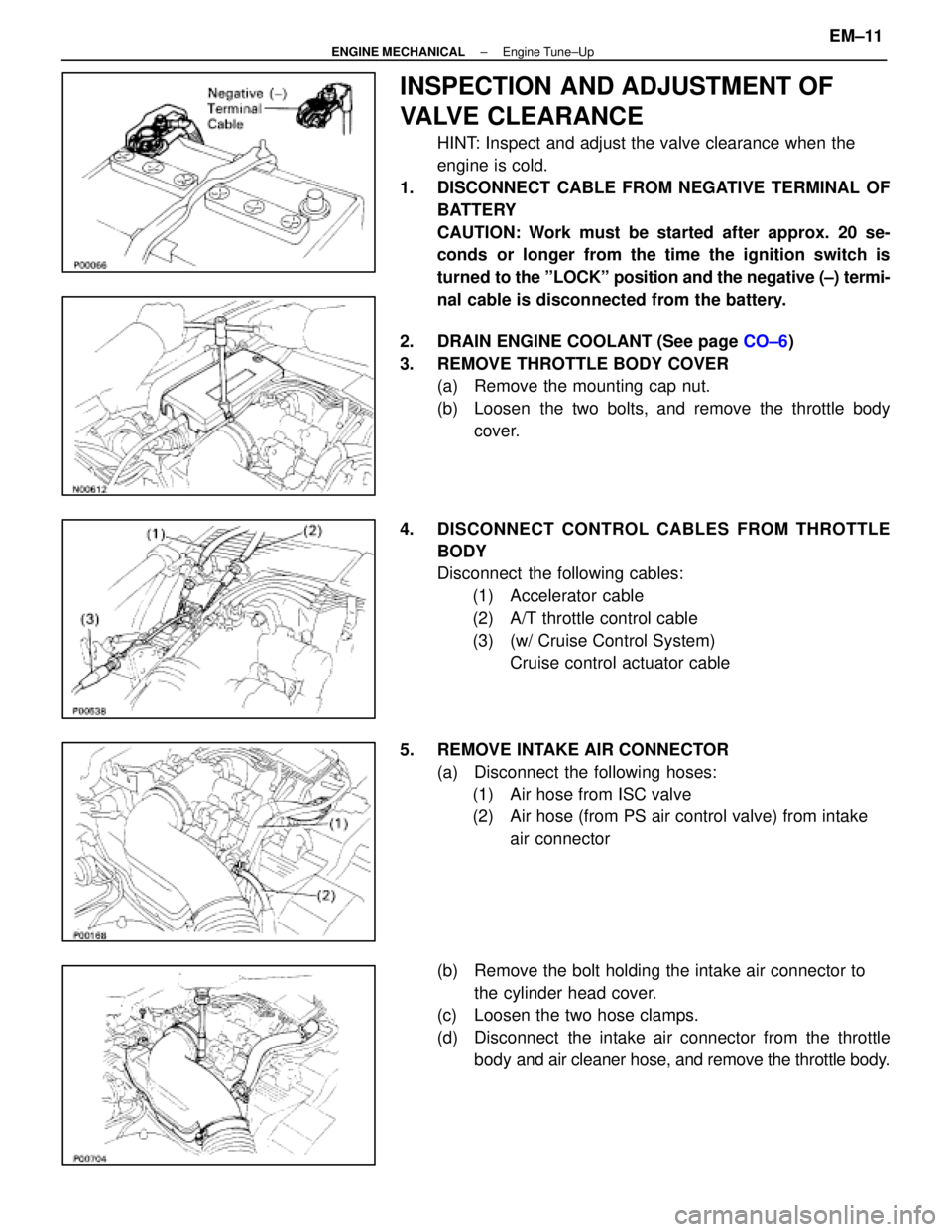

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. DRAIN ENGINE COOLANT (See page CO±6)

3. REMOVE THROTTLE BODY COVER (a) Remove the mounting cap nut.

(b) Loosen the two bolts, and remove the throttle body

cover.

4. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System) Cruise control actuator cable

5. REMOVE INTAKE AIR CONNECTOR (a) Disconnect the following hoses:(1) Air hose from ISC valve

(2) Air hose (from PS air control valve) from intake

air connector

(b) Remove the bolt holding the intake air connector to the cylinder head cover.

(c) Loosen the two hose clamps.

(d) Disconnect the intake air connector from the throttle

body and air cleaner hose, and remove the throttle body.

±

ENGINE MECHANICAL Engine Tune±UpEM±11

WhereEverybodyKnowsYourName

Page 2227 of 4087

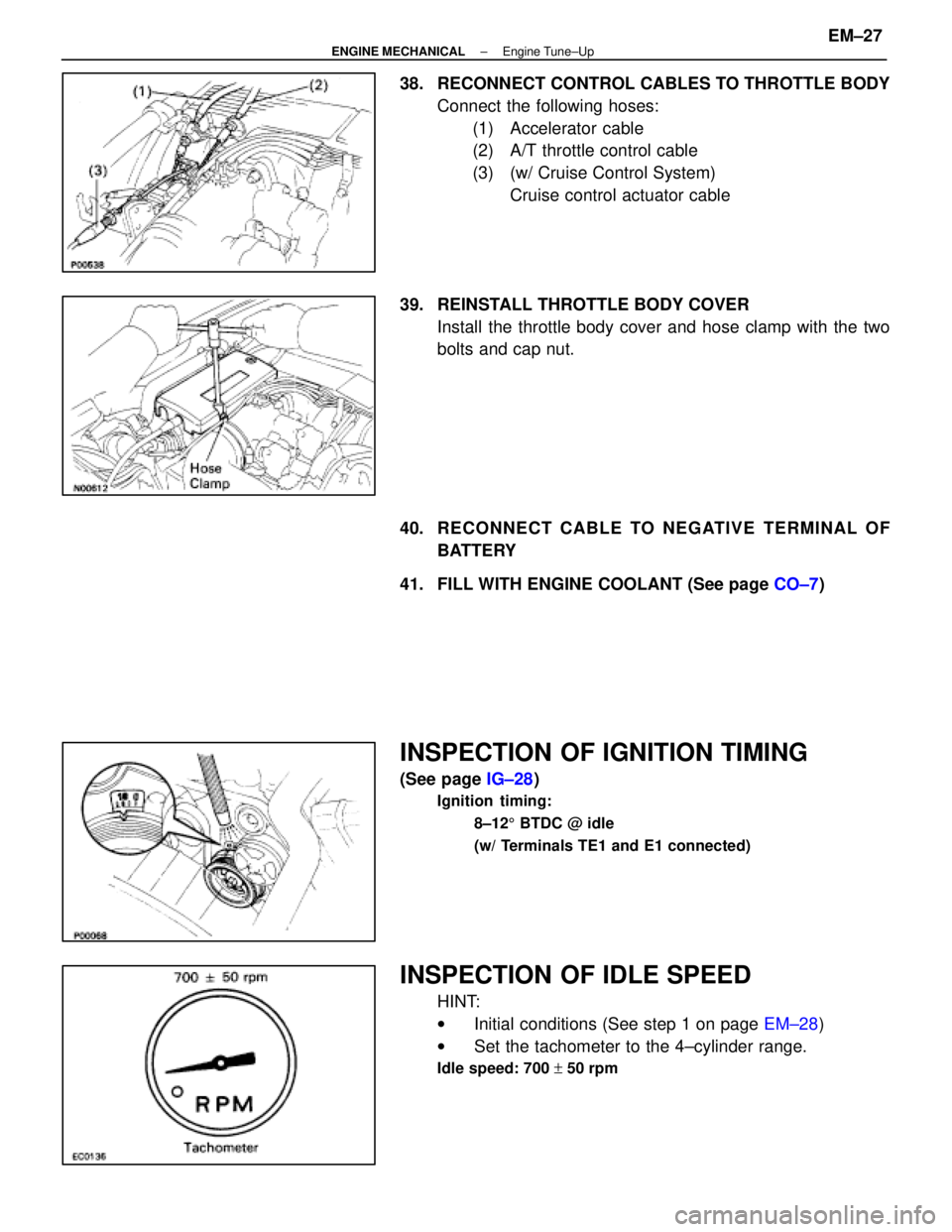

38. RECONNECT CONTROL CABLES TO THROTTLE BODYConnect the following hoses:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System) Cruise control actuator cable

39. REINSTALL THROTTLE BODY COVER Install the throttle body cover and hose clamp with the two

bolts and cap nut.

40. RE CO NNE CT CABLE TO NE G ATIV E TE RMINAL OF BATTERY

41. FILL WITH ENGINE COOLANT (See page CO±7)

INSPECTION OF IGNITION TIMING

(See page IG±28)

Ignition timing:

8±125 BTDC @ idle

(w/ Terminals TE1 and E1 connected)

INSPECTION OF IDLE SPEED

HINT:

w Initial conditions (See step 1 on page EM±28)

w Set the tachometer to the 4±cylinder range.

Idle speed: 700 + 50 rpm

±

ENGINE MECHANICAL Engine Tune±UpEM±27

WhereEverybodyKnowsYourName

Page 2235 of 4087

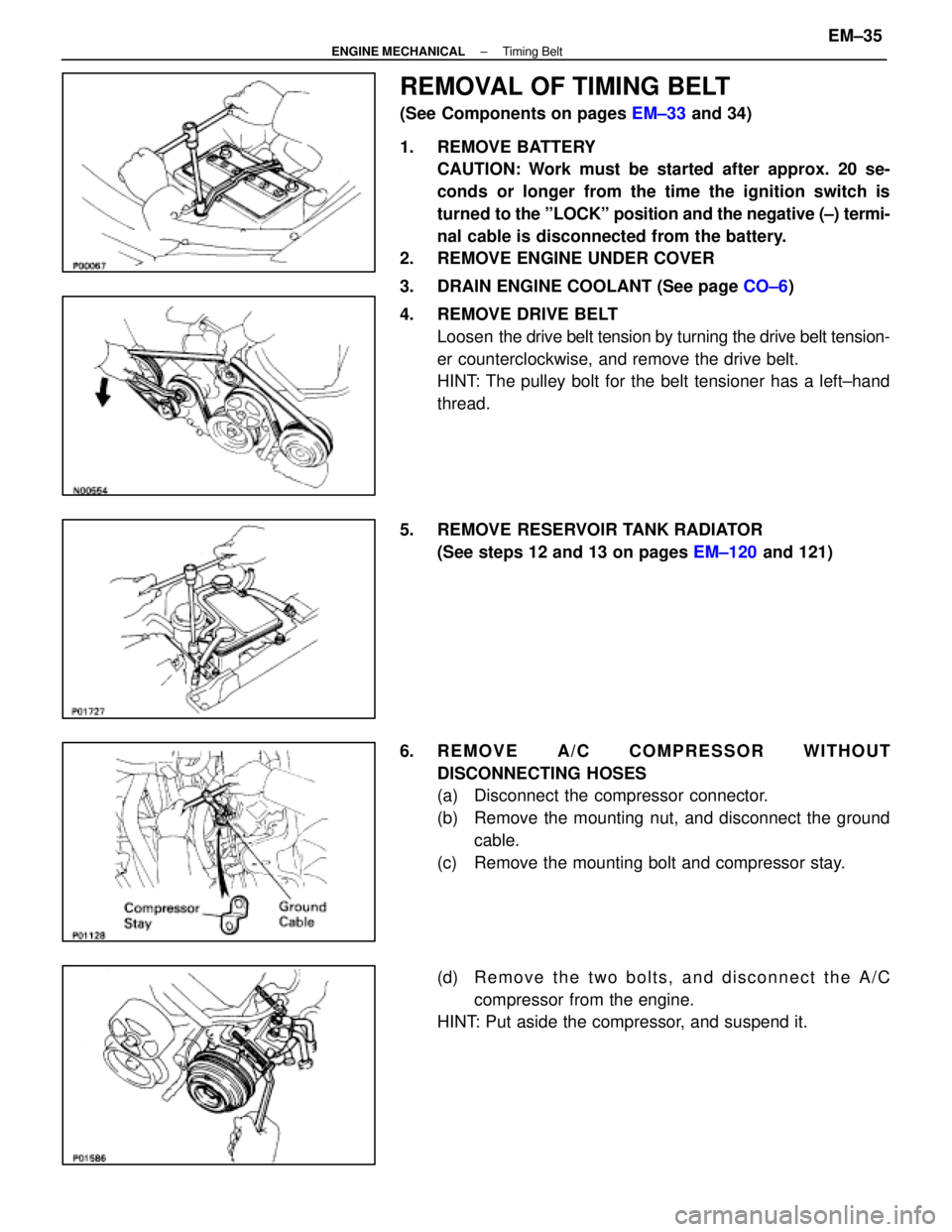

REMOVAL OF TIMING BELT

(See Components on pages EM±33 and 34)

1. REMOVE BATTERY CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE ENGINE UNDER COVER

3. DRAIN ENGINE COOLANT (See page CO±6)

4. REMOVE DRIVE BELT Loosen the drive belt tension by turning the drive belt tension-

er counterclockwise, and remove the drive belt.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

5. REMOVE RESERVOIR TANK RADIATOR (See steps 12 and 13 on pages EM±120 and 121)

6. REMOVE A/C COMPRESSOR WITHOUT DISCONNECTING HOSES

(a) Disconnect the compressor connector.

(b) Remove the mounting nut, and disconnect the groundcable.

(c) Remove the mounting bolt and compressor stay.

(d) R e m o v e t h e t w o b o l t s , a n d d i s c onnect the A/C

compressor from the engine.

HINT: Put aside the compressor, and suspend it.

±

ENGINE MECHANICAL Timing BeltEM±35

WhereEverybodyKnowsYourName

Page 2257 of 4087

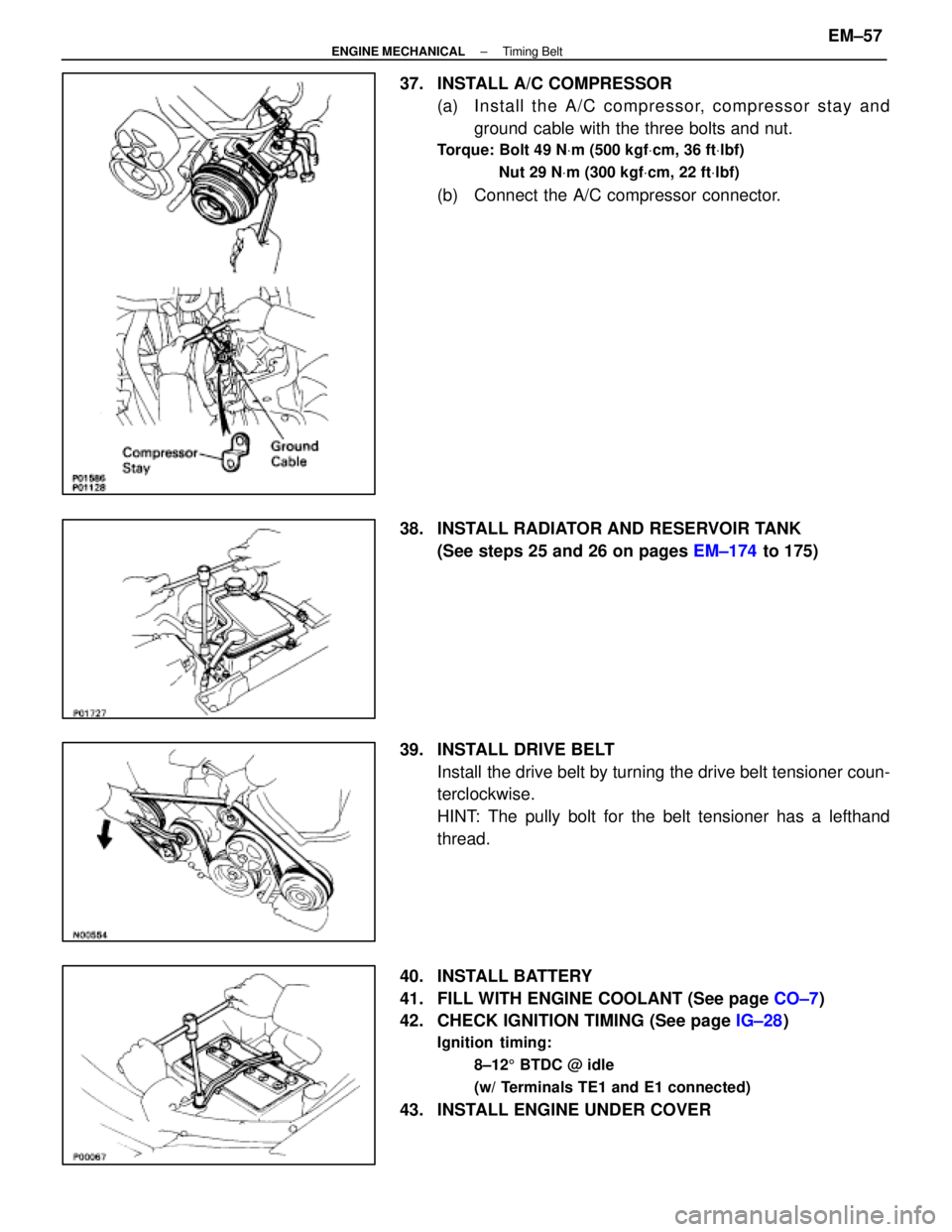

37. INSTALL A/C COMPRESSOR(a) In sta ll th e A/C co mp re sso r, co mp re sso r sta y an dground cable with the three bolts and nut.

Torque: Bolt 49 N Vm (500 kgf Vcm, 36 ft Vlbf)

Nut 29 N Vm (300 kgf Vcm, 22 ft Vlbf)

(b) Connect the A/C compressor connector.

38. INSTALL RADIATOR AND RESERVOIR TANK (See steps 25 and 26 on pages EM±174 to 175)

39. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pully bolt for the belt tensioner has a lefthand

thread.

40. INSTALL BATTERY

41. FILL WITH ENGINE COOLANT (See page CO±7)

42. CHECK IGNITION TIMING (See page IG±28)

Ignition timing:

8±125 BTDC @ idle

(w/ Terminals TE1 and E1 connected)

43. INSTALL ENGINE UNDER COVER

±

ENGINE MECHANICAL Timing BeltEM±57

WhereEverybodyKnowsYourName

Page 2318 of 4087

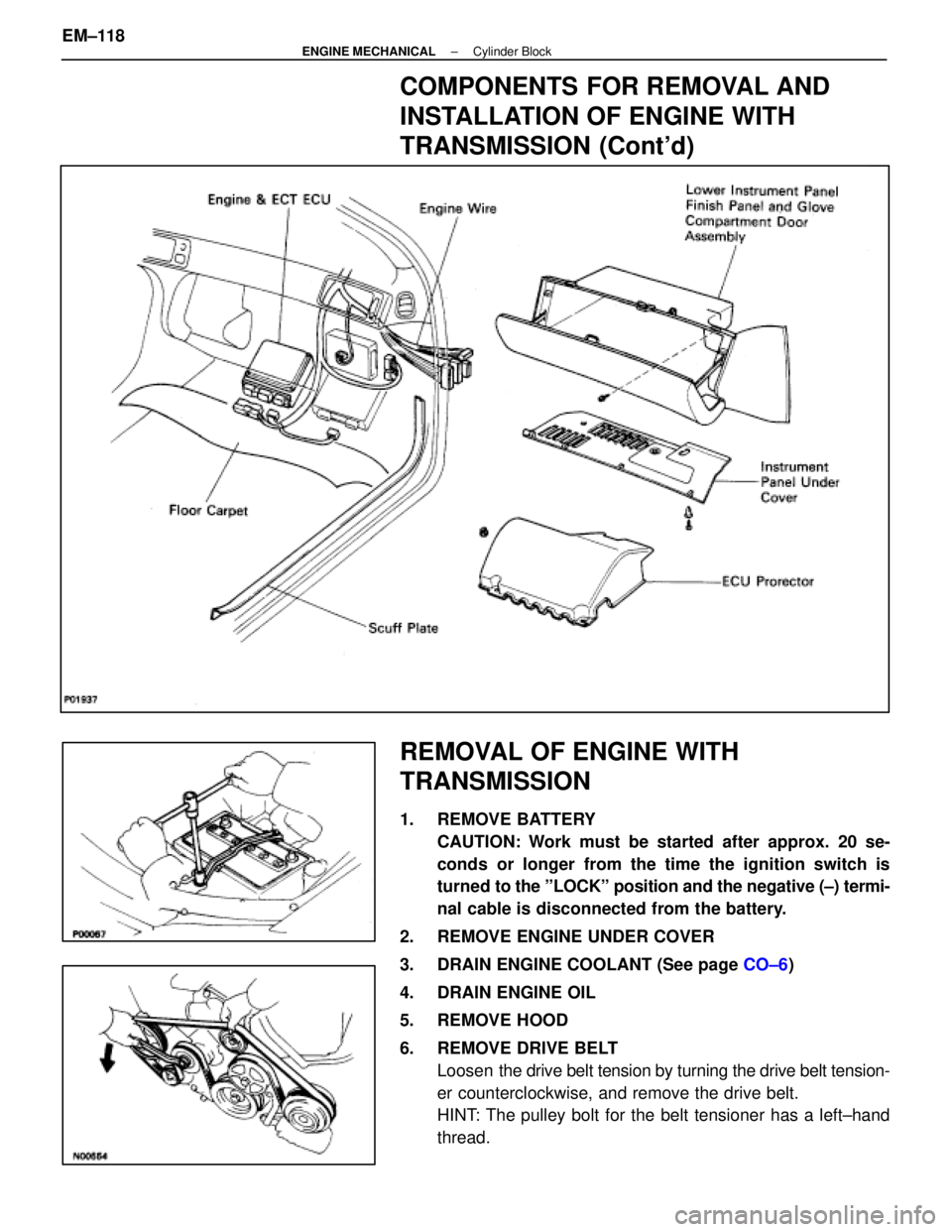

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION (Cont'd)

REMOVAL OF ENGINE WITH

TRANSMISSION

1. REMOVE BATTERYCAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE ENGINE UNDER COVER

3. DRAIN ENGINE COOLANT (See page CO±6)

4. DRAIN ENGINE OIL

5. REMOVE HOOD

6. REMOVE DRIVE BELT Loosen the drive belt tension by turning the drive belt tension-

er counterclockwise, and remove the drive belt.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

EM±118

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 2320 of 4087

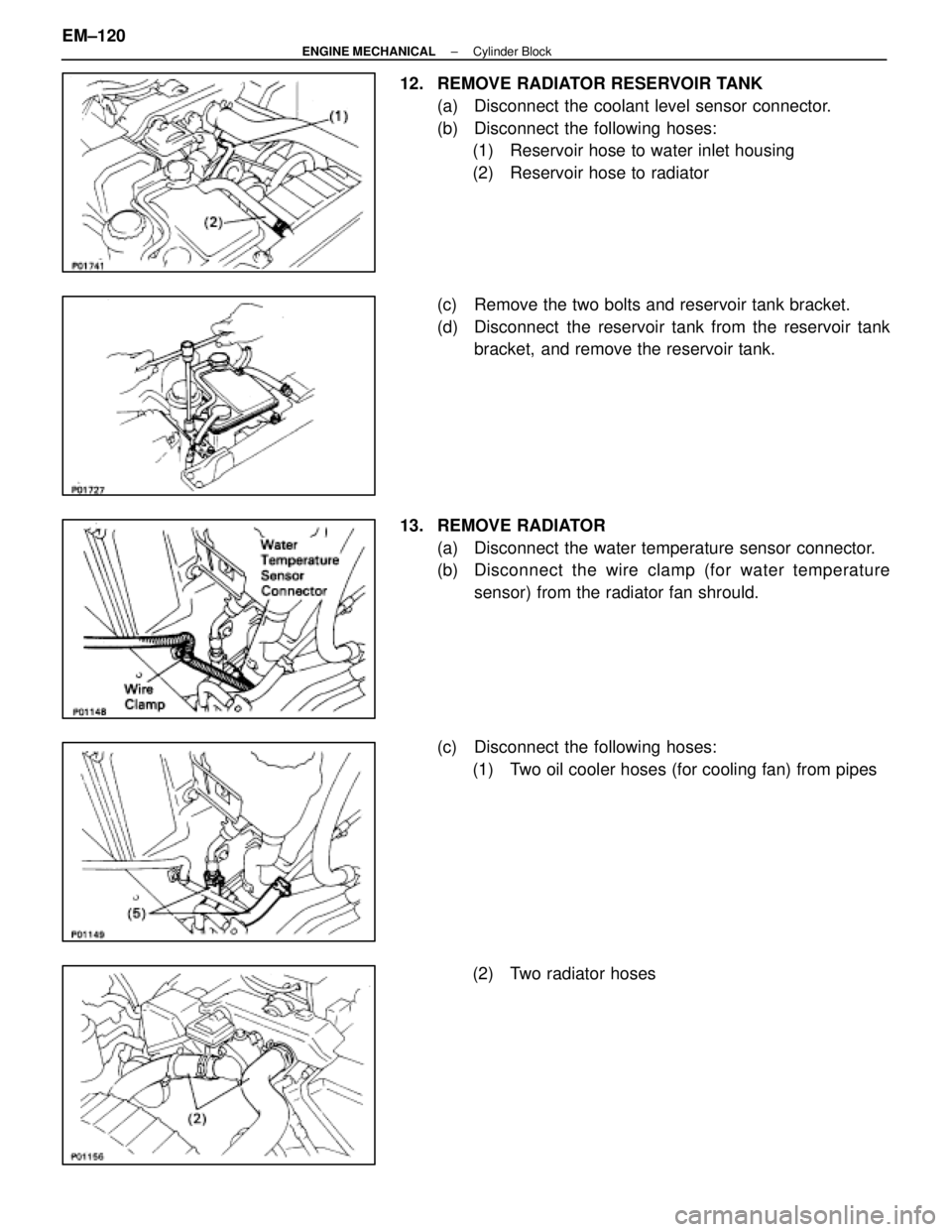

12. REMOVE RADIATOR RESERVOIR TANK(a) Disconnect the coolant level sensor connector.

(b) Disconnect the following hoses:(1) Reservoir hose to water inlet housing

(2) Reservoir hose to radiator

(c) Remove the two bolts and reservoir tank bracket.

(d) Disconnect the reservoir tank from the reservoir tank bracket, and remove the reservoir tank.

13. REMOVE RADIATOR (a) Disconnect the water temperature sensor connector.

(b) Disc onnect the wire clamp (for water temperature

sensor) from the radiator fan shrould.

(c) Disconnect the following hoses: (1) Two oil cooler hoses (for cooling fan) from pipes

(2) Two radiator hoses

EM±120

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 2376 of 4087

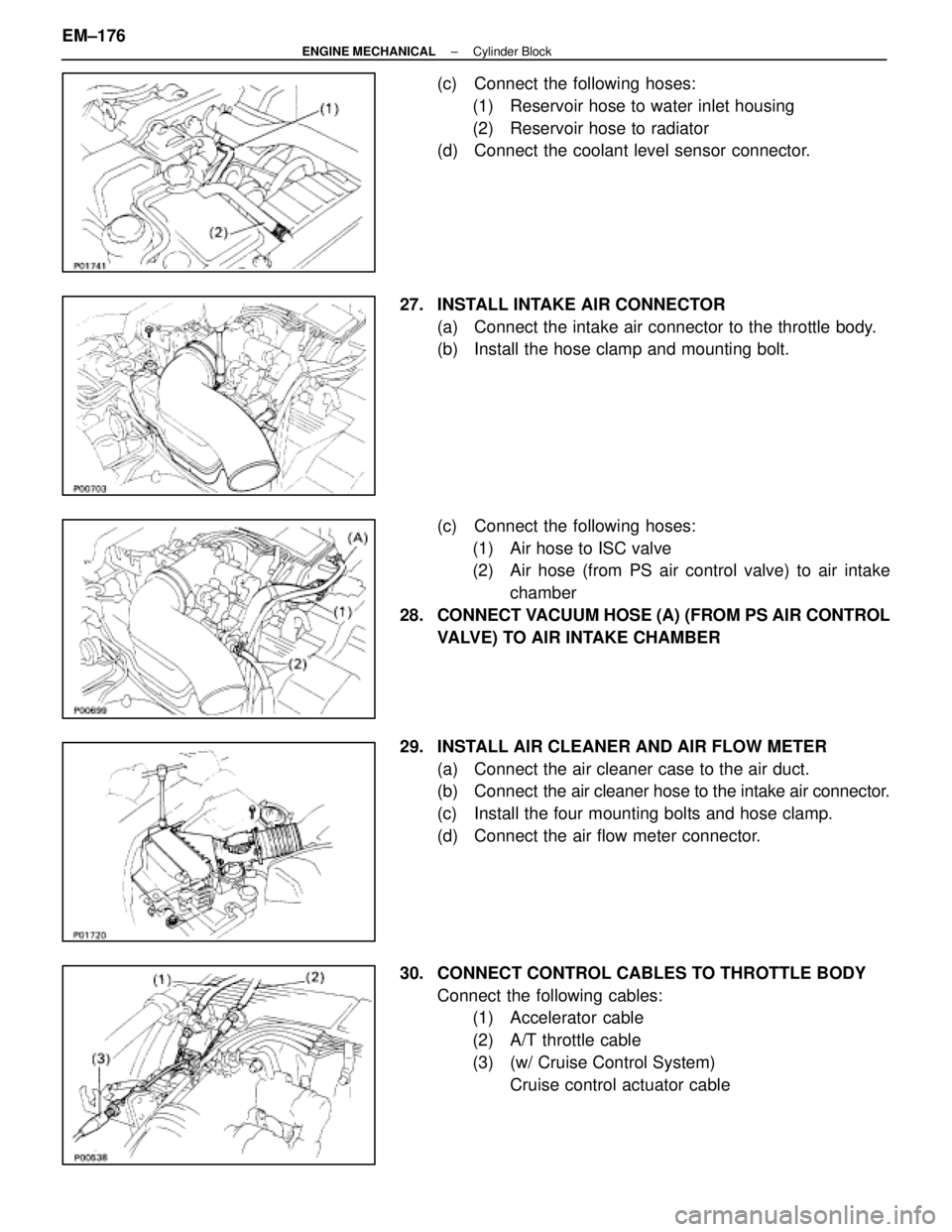

(c) Connect the following hoses:(1) Reservoir hose to water inlet housing

(2) Reservoir hose to radiator

(d) Connect the coolant level sensor connector.

27. INSTALL INTAKE AIR CONNECTOR (a) Connect the intake air connector to the throttle body.

(b) Install the hose clamp and mounting bolt.

(c) Connect the following hoses:(1) Air hose to ISC valve

(2) Air hose (from PS air control valve) to air intake chamber

28. CONNECT VACUUM HOSE (A) (FROM PS AIR CONTROL VALVE) TO AIR INTAKE CHAMBER

29. INSTALL AIR CLEANER AND AIR FLOW METER (a) Connect the air cleaner case to the air duct.

(b) Connect the air cleaner hose to the intake air connector.

(c) Install the four mounting bolts and hose clamp.

(d) Connect the air flow meter connector.

30. CONNECT CONTROL CABLES TO THROTTLE BODY Connect the following cables:(1) Accelerator cable

(2) A/T throttle cable

(3) (w/ Cruise Control System)

Cruise control actuator cable

EM±176

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 2377 of 4087

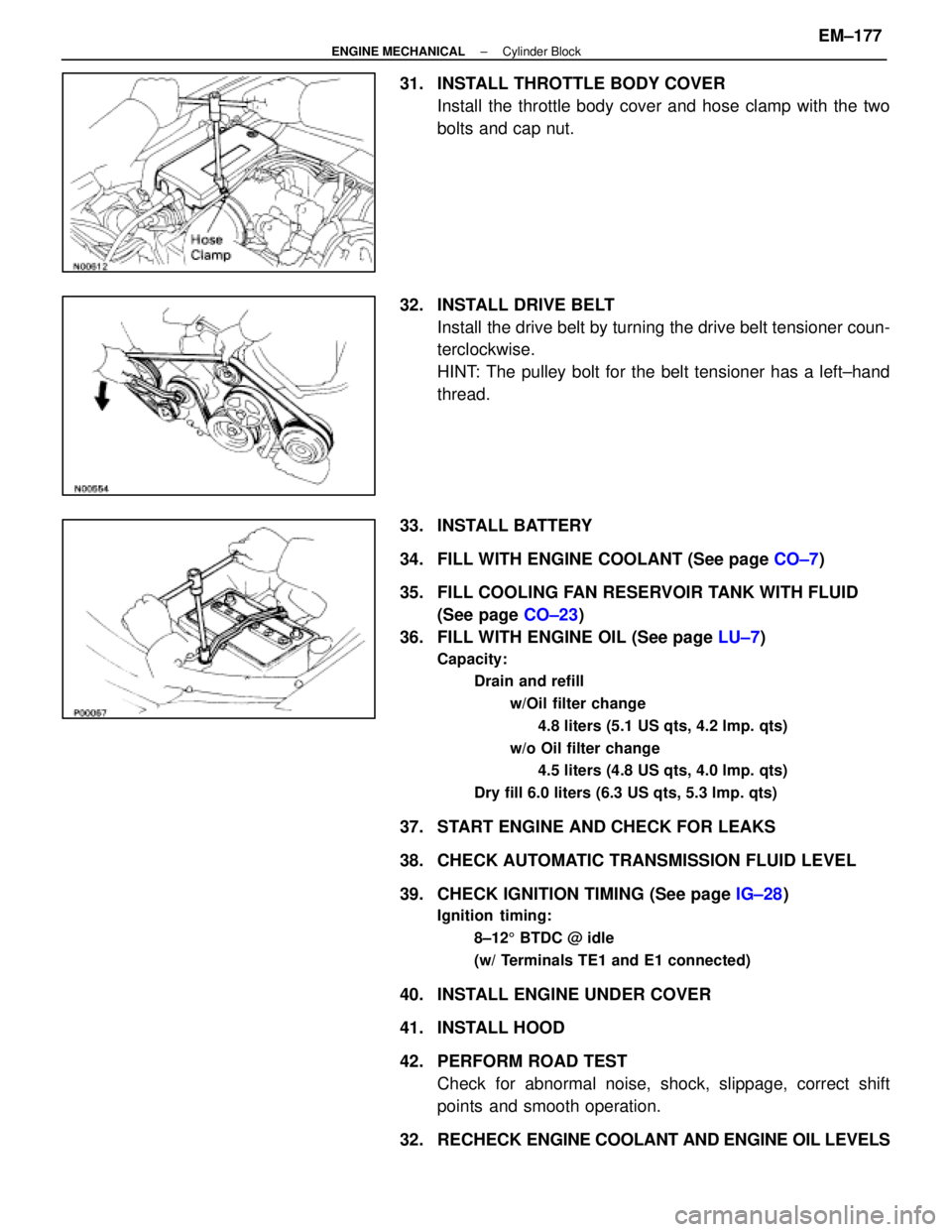

31. INSTALL THROTTLE BODY COVERInstall the throttle body cover and hose clamp with the two

bolts and cap nut.

32. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

33. INSTALL BATTERY

34. FILL WITH ENGINE COOLANT (See page CO±7)

35. FILL COOLING FAN RESERVOIR TANK WITH FLUID (See page CO±23)

36. FILL WITH ENGINE OIL (See page LU±7)

Capacity:

Drain and refill

w/Oil filter change4.8 liters (5.1 US qts, 4.2 lmp. qts)

w/o Oil filter change 4.5 liters (4.8 US qts, 4.0 lmp. qts)

Dry fill 6.0 liters (6.3 US qts, 5.3 lmp. qts)

37. START ENGINE AND CHECK FOR LEAKS

38. CHECK AUTOMATIC TRANSMISSION FLUID LEVEL

39. CHECK IGNITION TIMING (See page IG±28)

Ignition timing:

8±125 BTDC @ idle

(w/ Terminals TE1 and E1 connected)

40. INSTALL ENGINE UNDER COVER

41. INSTALL HOOD

42. PERFORM ROAD TEST Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

32. RECHECK ENGINE COOLANT AND ENGINE OIL LEVELS

±

ENGINE MECHANICAL Cylinder BlockEM±177

WhereEverybodyKnowsYourName

Page 2388 of 4087

The EFI system is composed of three basic sub±systems: Fuel, Air Induction and Elect\

ronic Control

Systems.

FUEL SYSTEM

An electric pump fuel pressure supplies sufficient fuel, under a constant pressure, to the EFI injectors. In

accordance with signals from the ECU (Electronic Control Unit), these \

injectors inject the quantity of fuel most

appropriate for the engine condition into the intake manifold.

AIR INDUCTION SYSTEM

The air induction system provides sufficient air for engine operation.

ELECTRONIC CONTROL SYSTEM

The 1UZ±FE engine (ECU±formerly EFI computer) with a microcomputer \

centrally controls the EFI, ESA,

ISC and Diagnosis system, etc. The ECU controls the following functions:

1. Electronic Fuel Injection (EFI)

The ECU receives signals from various sensors indicating changing engine op\

eration conditions such as:Intake air volume

Intake air temperature

Coolant temperature

Engine rpm

Acceleration/deceleration

Exhaust oxygen content etc.

The signals are utilized by the ECU to determine the injection duration nec\

essary for an optimum air±fuel

ratio.

2. Electronic Spark Advance (ESA) The ECU is programmed with data for optimum ignition timing under any and all opera\

ting conditions. Using

data provided by sensors which monitor various engine functions (rpm, coola\

nt temperature, etc.), the

Electronic Control Unit (ECU) triggers the spark at precisely right instant. (S\

ee IG section)

3. Idle Speed Control (ISC) The ECU is programmed with idle speed data for various engine conditions (\

coolant temperature, air condi-

tioner ON/OFF, etc.).

The air volume flowing through the throttle valve by±pass passage is adj\

usted according to the signal from

each sensor and the idle speed is kept at the set value.

4. Diagnosis Function When the ECU detects any malfunctions or abnormalities in the sensor network\

, it lights the ºCHECKº en-

gine warning light in the combination meter. At the same time, the trouble is identified and a diagnostic code

is recorded by the ECU. The diagnostic code can be read by the number of\

blinks of the ºCHECKº engine

warning light when terminals TE1 and E1 are connected. The diagnostic co\

des are refer to the later page.

(See TR section)

5. Self±Correction Function If any sensor malfunctions, an average value recorded in the back±up ci\

rcuit is substituted to make driving

possible.

If danger is predicted, the engine is stopped and the ºCHECKº engine\

warning light will light up.

6. Fail±Safe Function Even if an abnormality occurs in the ECU, the back±up circuit uses a specifie\

d fuel injection and ignition

timing to provide vehicle driveability, and also lightsup the ºCHECKº engine warning light.

FI±4

EFI SYSTEM

± Description

WhereEverybodyKnowsYourName

Page 2391 of 4087

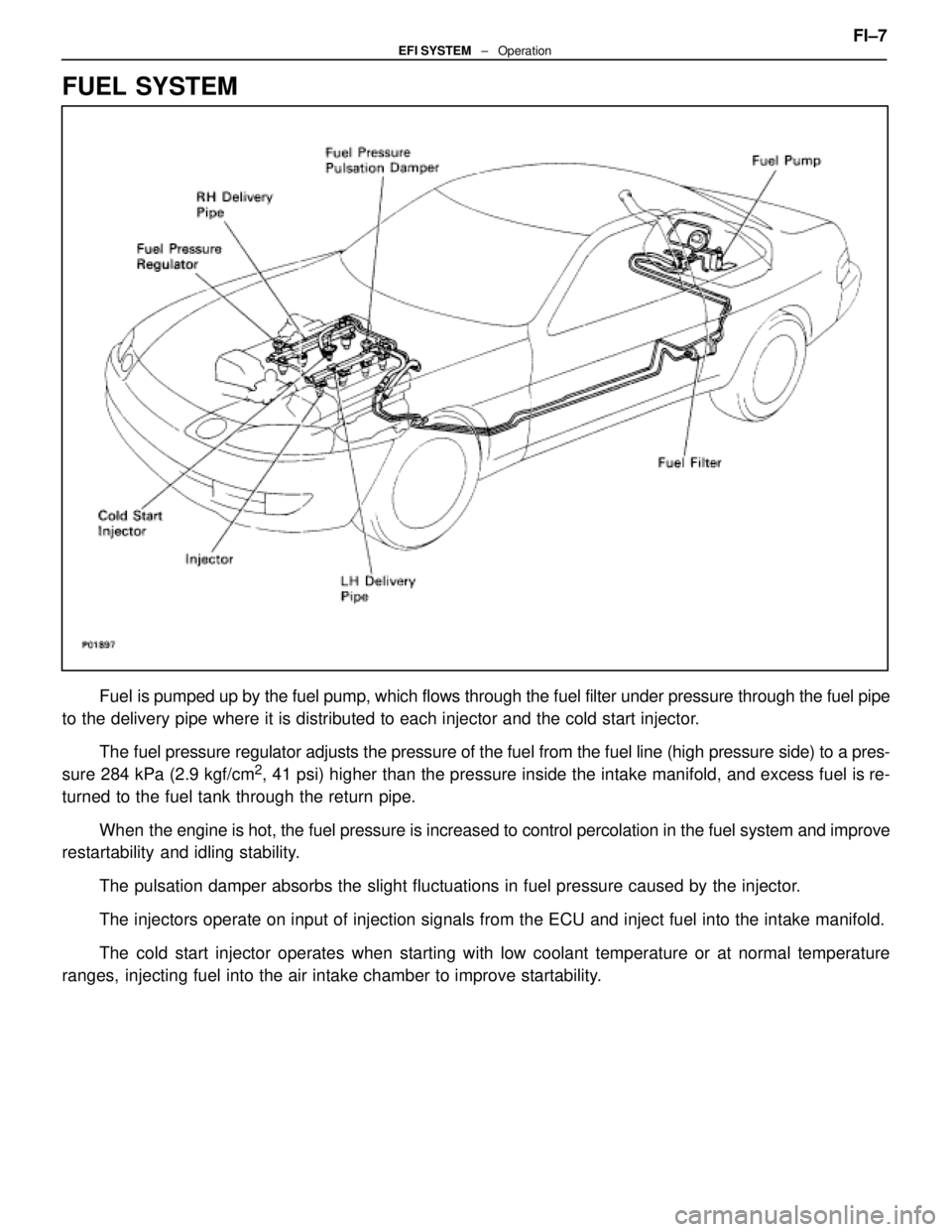

FUEL SYSTEM

Fuel is pumped up by the fuel pump, which flows through the fuel filter under pr\

essure through the fuel pipe

to the delivery pipe where it is distributed to each injector and the cold\

start injector.

The fuel pressure regulator adjusts the pressure of the fuel from the fuel \

line (high pressure side) to a pres-

sure 284 kPa (2.9 kgf/cm

2, 41 psi) higher than the pressure inside the intake manifold, and exce\

ss fuel is re-

turned to the fuel tank through the return pipe.

When the engine is hot, the fuel pressure is increased to control percolatio\

n in the fuel system and improve

restartability and idling stability.

The pulsation damper absorbs the slight fluctuations in fuel pressure ca\

used by the injector.

The injectors operate on input of injection signals from the ECU and inj\

ect fuel into the intake manifold.

The cold start injector operates when starting with low coolant temperature or at normal temperature

ranges, injecting fuel into the air intake chamber to improve startability. FI±7

EFI SYSTEM

± Operation

WhereEverybodyKnowsYourName