engine LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2436 of 4087

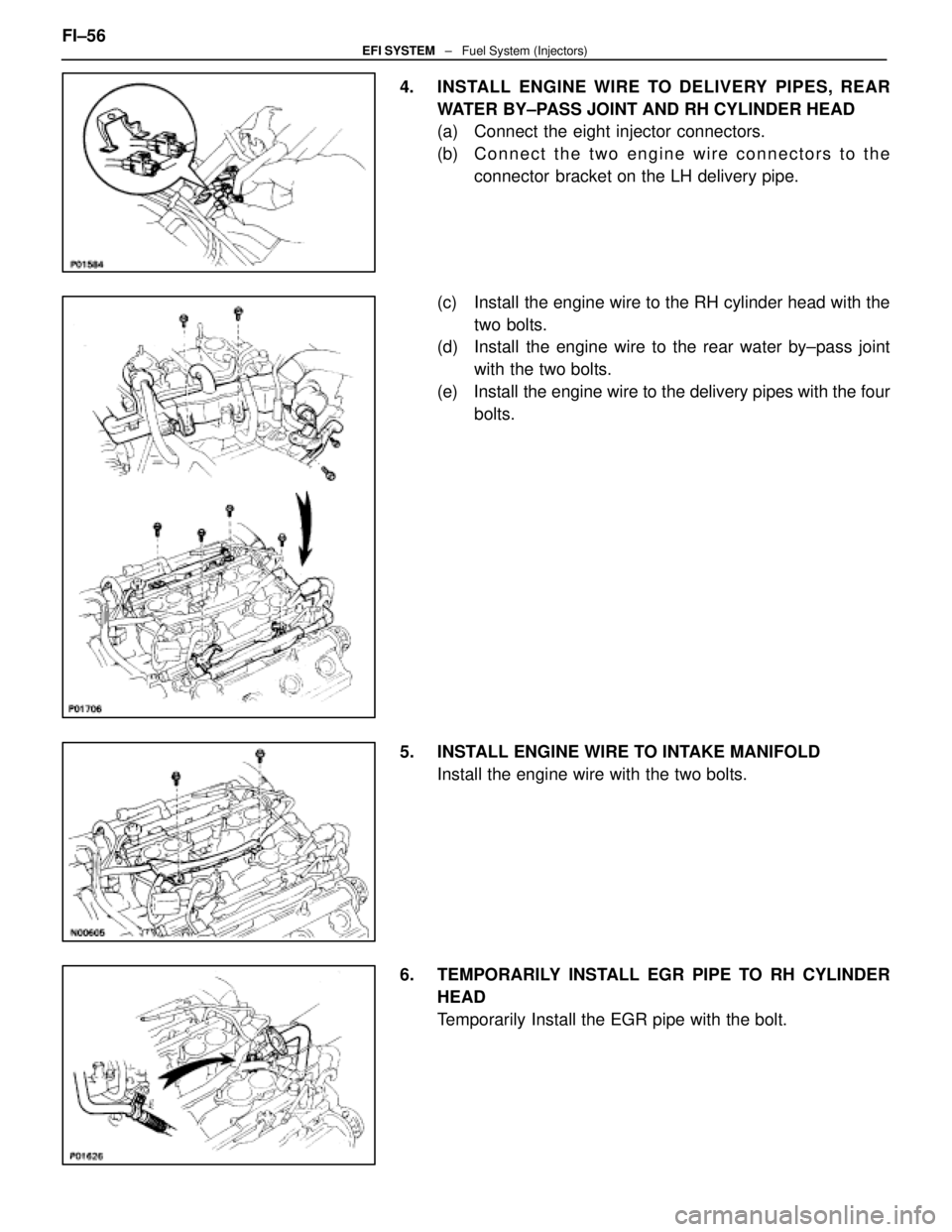

4. INSTALL ENGINE WIRE TO DELIVERY PIPES, REARWATER BY±PASS JOINT AND RH CYLINDER HEAD

(a) Connect the eight injector connectors.

(b) C onnect the two engine wire connectors to the

connector bracket on the LH delivery pipe.

(c) Install the engine wire to the RH cylinder head with the two bolts.

(d) Install the engine wire to the rear water by±pass joint

with the two bolts.

(e) Install the engine wire to the delivery pipes with the four bolts.

5. INSTALL ENGINE WIRE TO INTAKE MANIFOLD Install the engine wire with the two bolts.

6. TEMPORARILY INSTALL EGR PIPE TO RH CYLINDER HEAD

Temporarily Install the EGR pipe with the bolt.

FI±56

EFI SYSTEM

± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 2439 of 4087

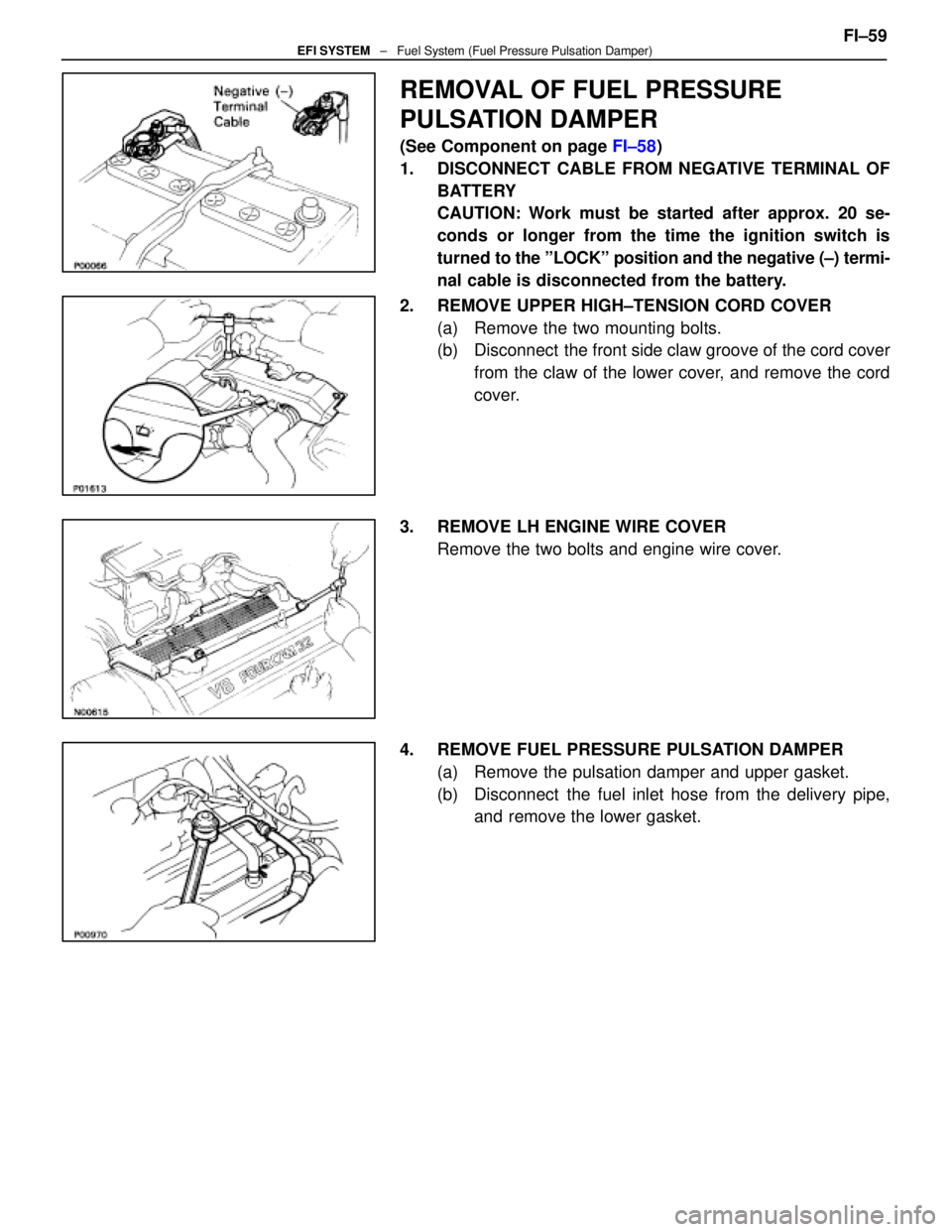

REMOVAL OF FUEL PRESSURE

PULSATION DAMPER

(See Component on page FI±58)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE UPPER HIGH±TENSION CORD COVER (a) Remove the two mounting bolts.

(b) Disconnect the front side claw groove of the cord coverfrom the claw of the lower cover, and remove the cord

cover.

3. REMOVE LH ENGINE WIRE COVER Remove the two bolts and engine wire cover.

4. REMOVE FUEL PRESSURE PULSATION DAMPER (a) Remove the pulsation damper and upper gasket.

(b) Disconnect the fuel inlet hose from the delivery pipe,and remove the lower gasket. FI±59

EFI SYSTEM

± Fuel System (Fuel Pressure Pulsation Damper)

WhereEverybodyKnowsYourName

Page 2440 of 4087

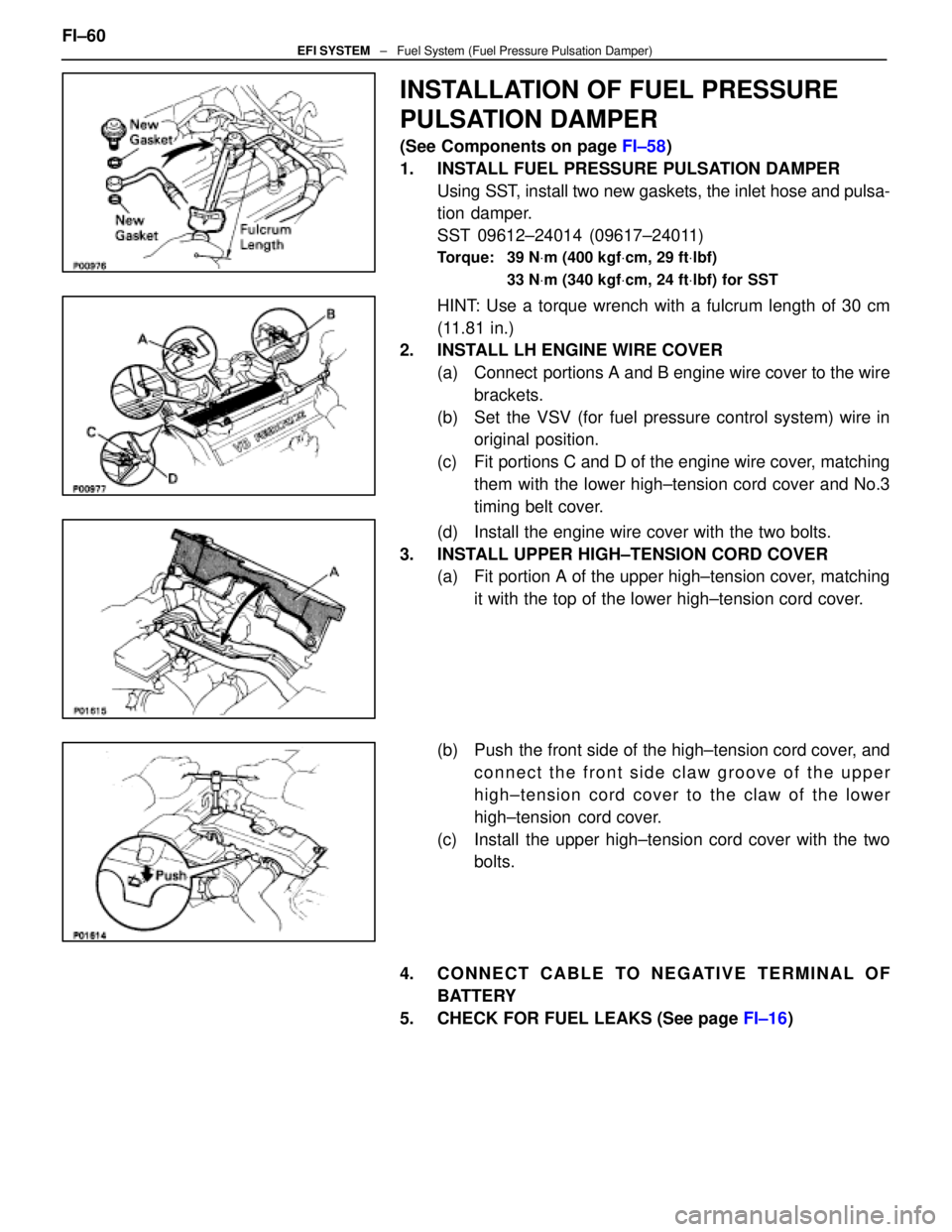

INSTALLATION OF FUEL PRESSURE

PULSATION DAMPER

(See Components on page FI±58)

1. INSTALL FUEL PRESSURE PULSATION DAMPER Using SST, install two new gaskets, the inlet hose and pulsa-

tion damper.

SST 09612±24014 (09617±24011)

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

33 N Vm (340 kgf Vcm, 24 ft Vlbf) for SST

HINT: Use a torque wrench with a fulcrum length of 30 cm

(11.81 in.)

2. INSTALL LH ENGINE WIRE COVER

(a) Connect portions A and B engine wire cover to the wirebrackets.

(b) Set the VSV (for fuel pressure control system) wire in original position.

(c) Fit portions C and D of the engine wire cover, matching them with the lower high±tension cord cover and No.3

timing belt cover.

(d) Install the engine wire cover with the two bolts.

3. INSTALL UPPER HIGH±TENSION CORD COVER (a) Fit portion A of the upper high±tension cover, matching

it with the top of the lower high±tension cord cover.

(b) Push the front side of the high±tension cord cover, and connect the front side claw groove of the upper

high±tension cord cover to the claw of the lower

high±tension cord cover.

(c) Install the upper high±tension cord cover with the two bolts.

4. CONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

5. CHECK FOR FUEL LEAKS (See page FI±16)

FI±60

EFI SYSTEM

± Fuel System (Fuel Pressure Pulsation Damper)

WhereEverybodyKnowsYourName

Page 2447 of 4087

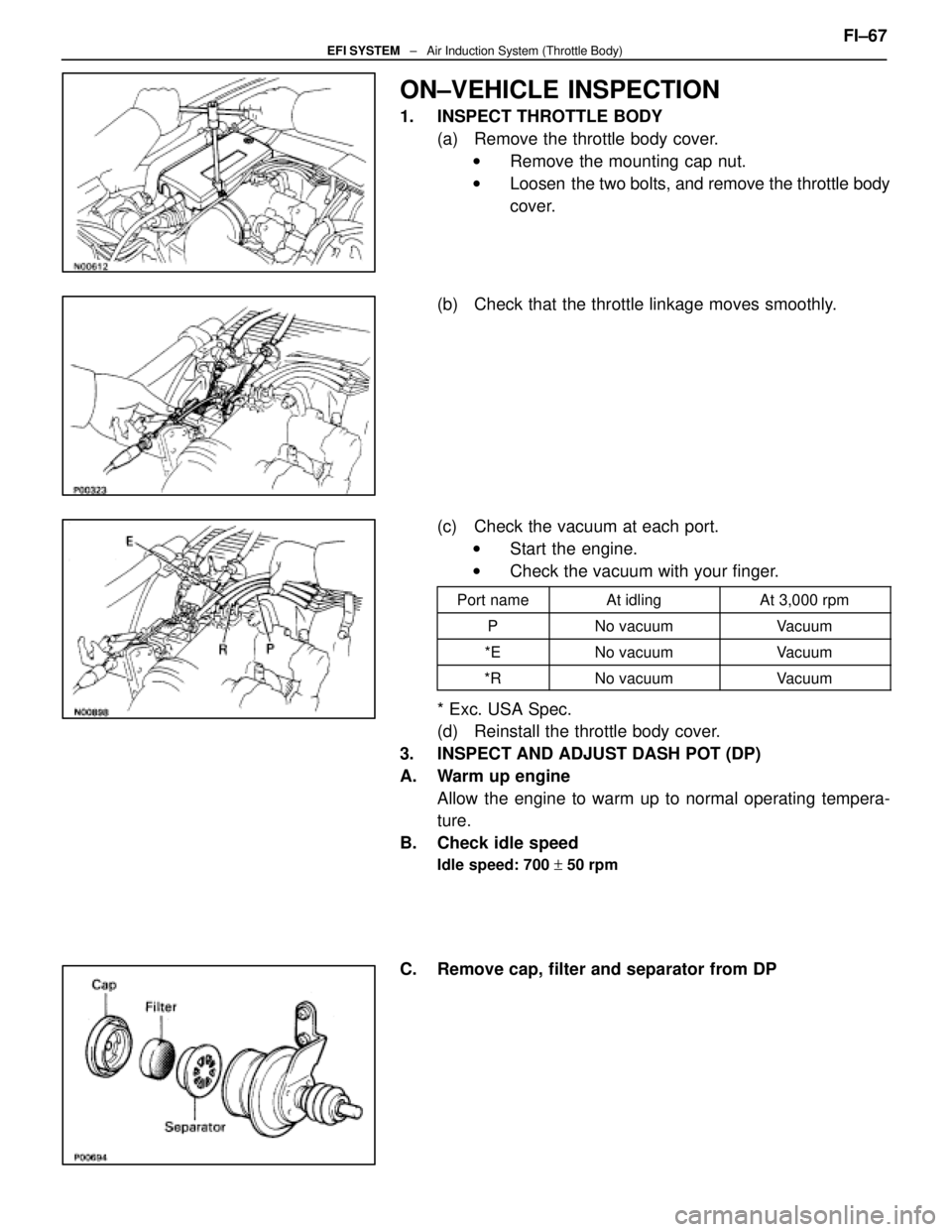

ON±VEHICLE INSPECTION

1. INSPECT THROTTLE BODY(a) Remove the throttle body cover.w Remove the mounting cap nut.

w Loosen the two bolts, and remove the throttle body

cover.

(b) Check that the throttle linkage moves smoothly.

(c) Check the vacuum at each port. w Start the engine.

w Check the vacuum with your finger.

Port nameAt idlingAt 3,000 rpm

PNo vacuumVacuum

*ENo vacuumVacuum

*RNo vacuumVacuum

* Exc. USA Spec.

(d) Reinstall the throttle body cover.

3. INSPECT AND ADJUST DASH POT (DP)

A. Warm up engine Allow the engine to warm up to normal operating tempera-

ture.

B. Check idle speed

Idle speed: 700 + 50 rpm

C. Remove cap, filter and separator from DP FI±67

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 2448 of 4087

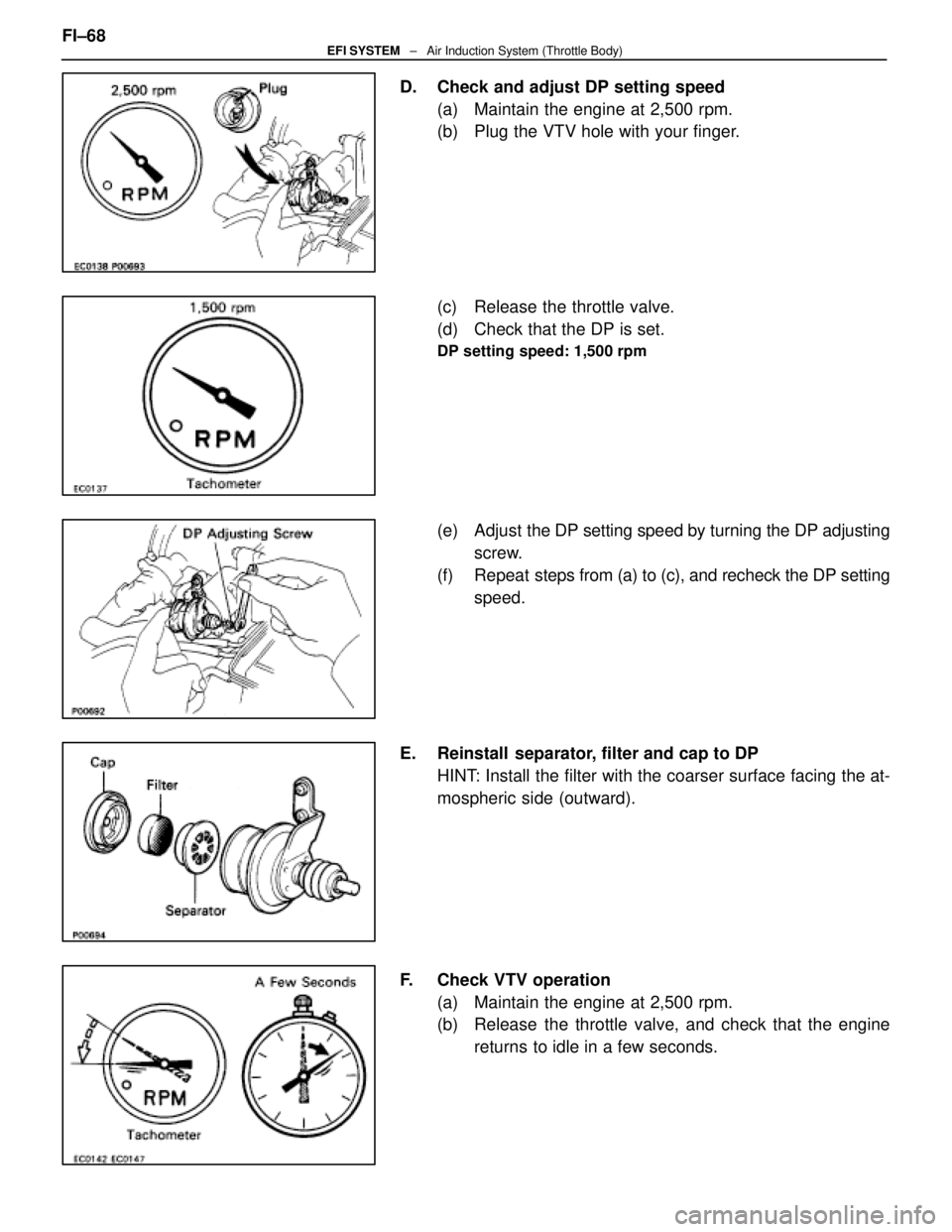

D. Check and adjust DP setting speed(a) Maintain the engine at 2,500 rpm.

(b) Plug the VTV hole with your finger.

(c) Release the throttle valve.

(d) Check that the DP is set.

DP setting speed: 1,500 rpm

(e) Adjust the DP setting speed by turning the DP adjusting

screw.

(f) Repeat steps from (a) to (c), and recheck the DP setting

speed.

E. Reinstall separator, filter and cap to DP HINT: Install the filter with the coarser surface facing the at-

mospheric side (outward).

F. Check VTV operation (a) Maintain the engine at 2,500 rpm.

(b) Release the throttle valve, and check that the enginereturns to idle in a few seconds.

FI±68

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 2450 of 4087

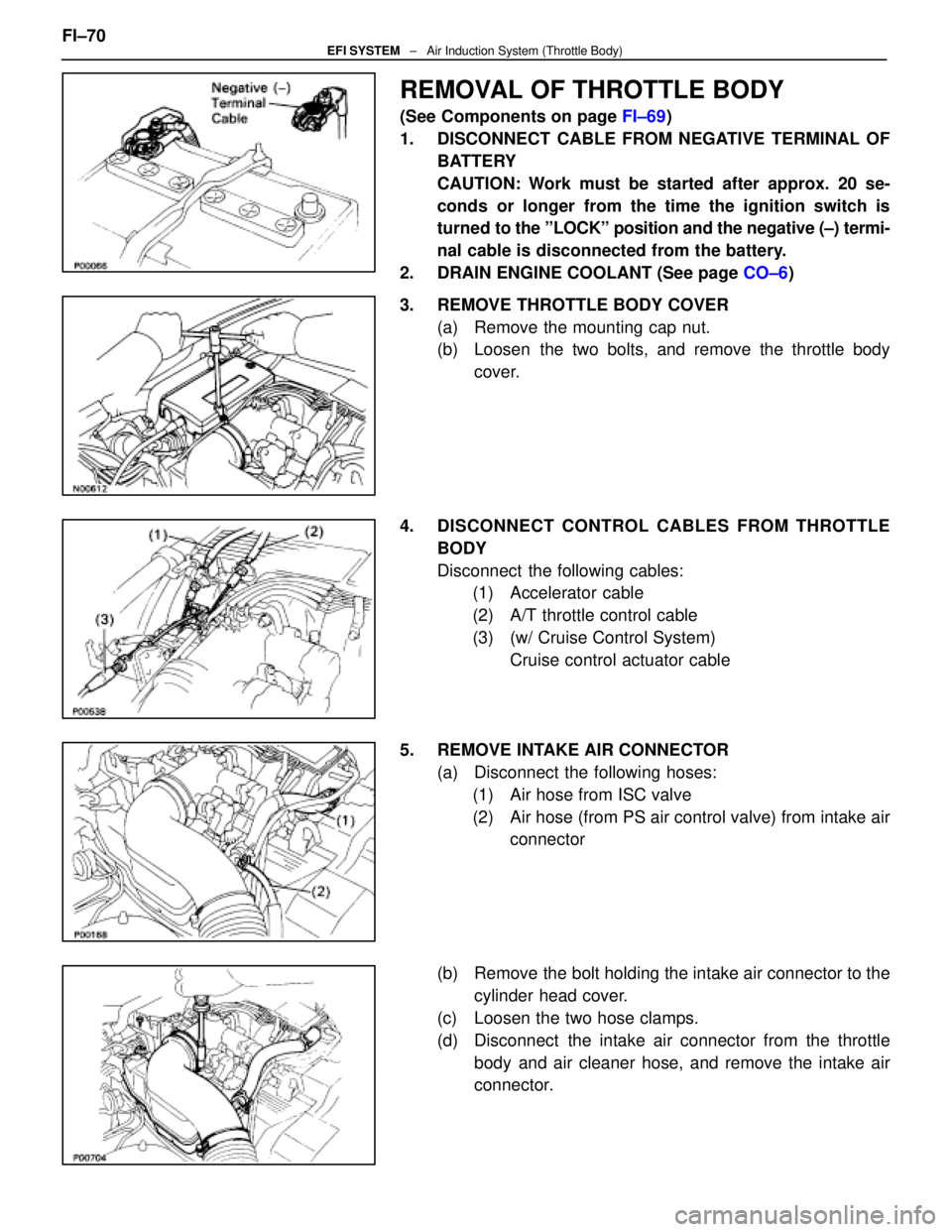

REMOVAL OF THROTTLE BODY

(See Components on page FI±69)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. DRAIN ENGINE COOLANT (See page CO±6)

3. REMOVE THROTTLE BODY COVER (a) Remove the mounting cap nut.

(b) Loosen the two bolts, and remove the throttle bodycover.

4. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System)

Cruise control actuator cable

5. REMOVE INTAKE AIR CONNECTOR (a) Disconnect the following hoses:(1) Air hose from ISC valve

(2) Air hose (from PS air control valve) from intake air connector

(b) Remove the bolt holding the intake air connector to the cylinder head cover.

(c) Loosen the two hose clamps.

(d) Disconnect the intake air connector from the throttle body and air cleaner hose, and remove the intake air

connector.

FI±70

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 2457 of 4087

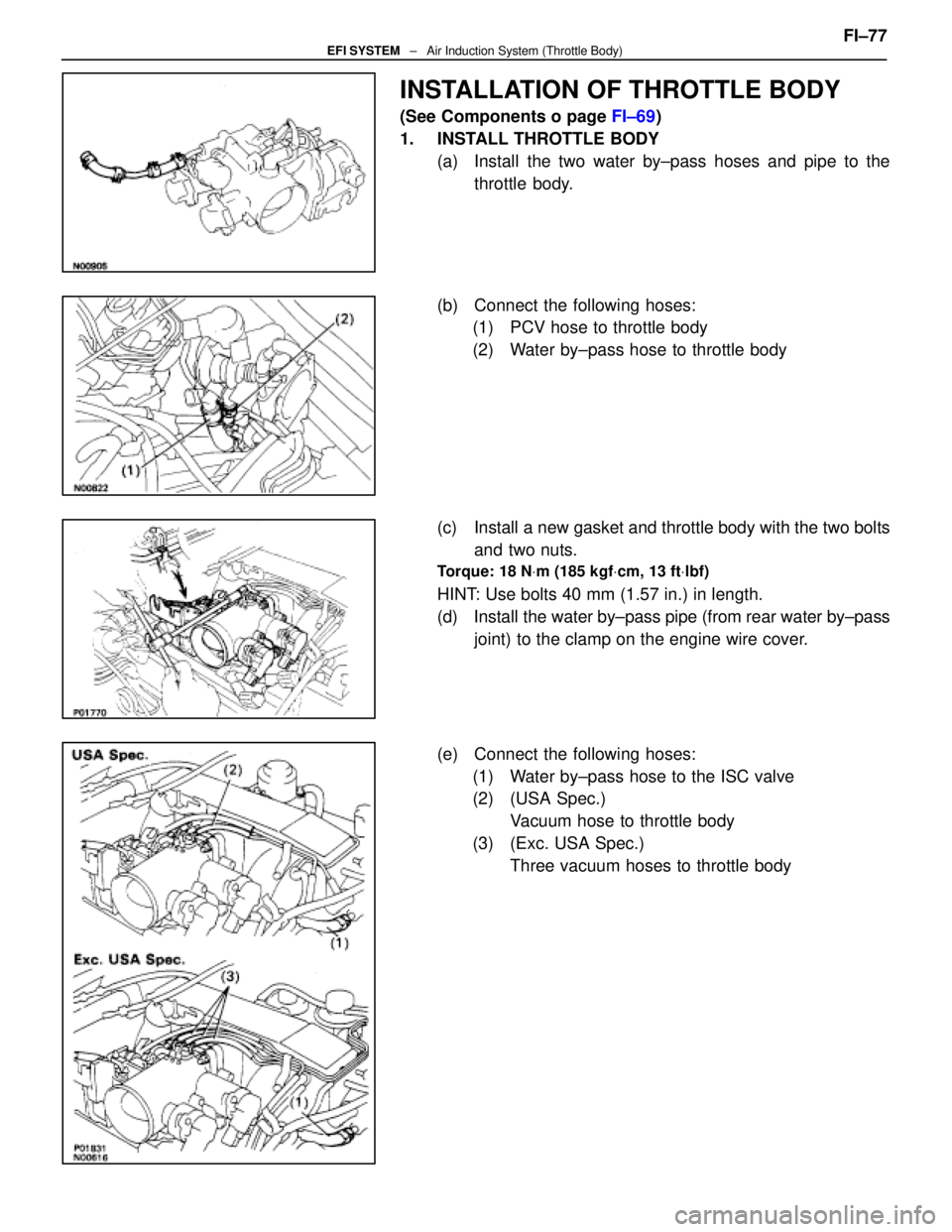

INSTALLATION OF THROTTLE BODY

(See Components o page FI±69)

1. INSTALL THROTTLE BODY (a) Install the two water by±pass hoses and pipe to thethrottle body.

(b) Connect the following hoses: (1) PCV hose to throttle body

(2) Water by±pass hose to throttle body

(c) Install a new gasket and throttle body with the two bolts and two nuts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT: Use bolts 40 mm (1.57 in.) in length.

(d) Install the water by±pass pipe (from rear water by±pass

joint) to the clamp on the engine wire cover.

(e) Connect the following hoses: (1) Water by±pass hose to the ISC valve

(2) (USA Spec.) Vacuum hose to throttle body

(3) (Exc. USA Spec.) Three vacuum hoses to throttle body FI±77

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 2459 of 4087

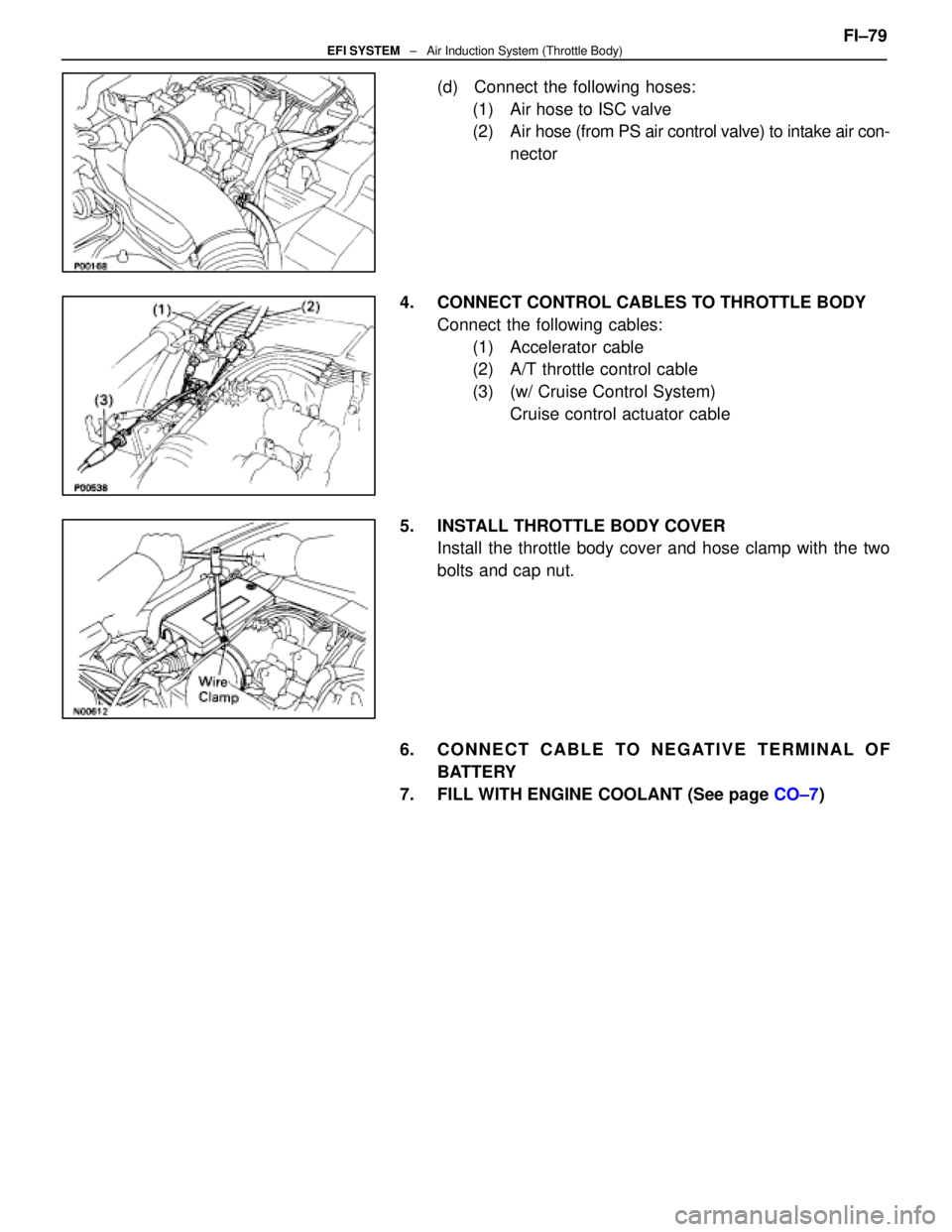

(d) Connect the following hoses:(1) Air hose to ISC valve

(2) Air hose (from PS air control valve) to intake air con-

nector

4. CONNECT CONTROL CABLES TO THROTTLE BODY Connect the following cables:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System) Cruise control actuator cable

5. INSTALL THROTTLE BODY COVER Install the throttle body cover and hose clamp with the two

bolts and cap nut.

6. CONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

7. FILL WITH ENGINE COOLANT (See page CO±7)FI±79

EFI SYSTEM

± Air Induction System (Throttle Body)

WhereEverybodyKnowsYourName

Page 2460 of 4087

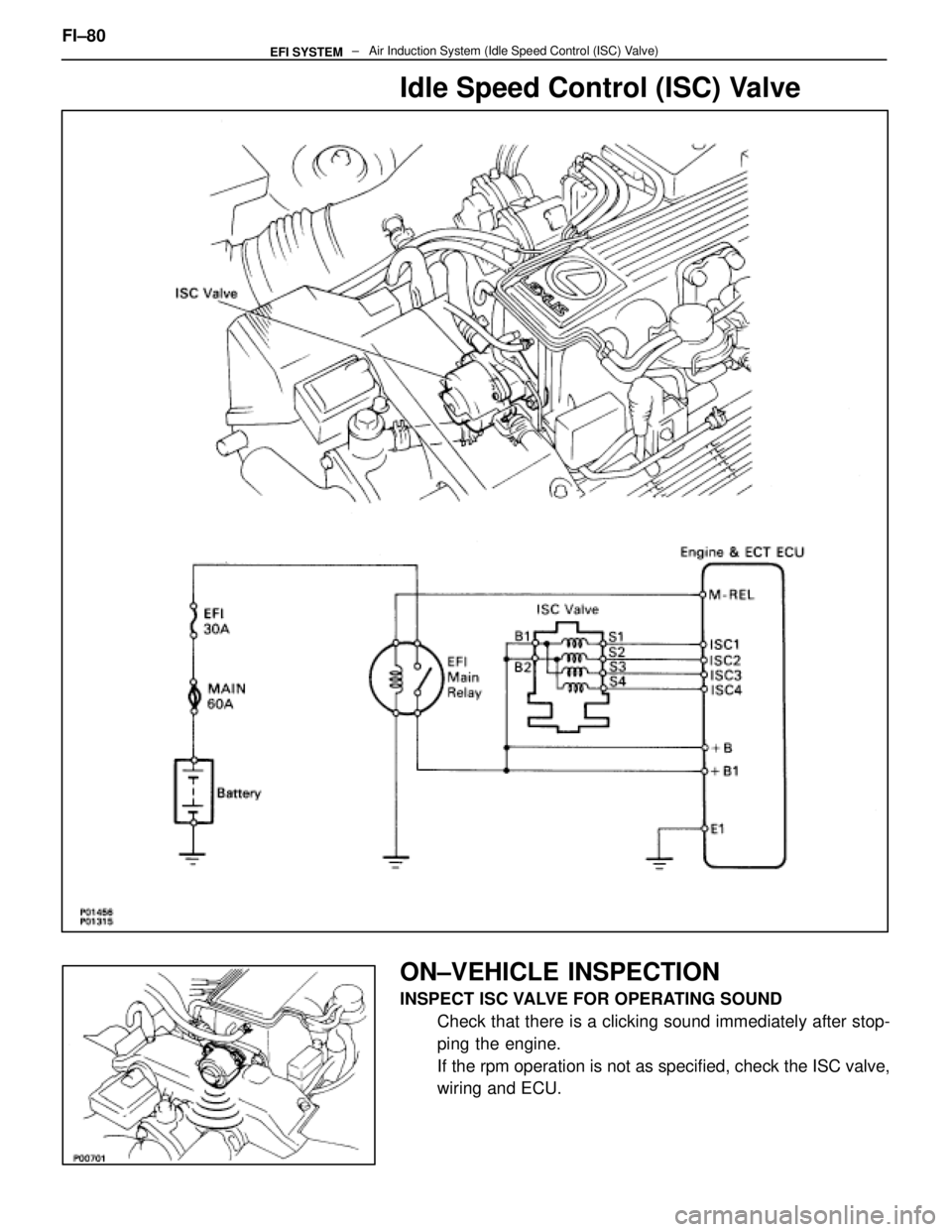

Idle Speed Control (ISC) Valve

ON±VEHICLE INSPECTION

INSPECT ISC VALVE FOR OPERATING SOUNDCheck that there is a clicking sound immediately after stop-

ping the engine.

If the rpm operation is not as specified, check the ISC valve,

wiring and ECU.

FI±80

± Air Induction System (Idle Speed Control (ISC\

) Valve)EFI SYSTEM

WhereEverybodyKnowsYourName

Page 2465 of 4087

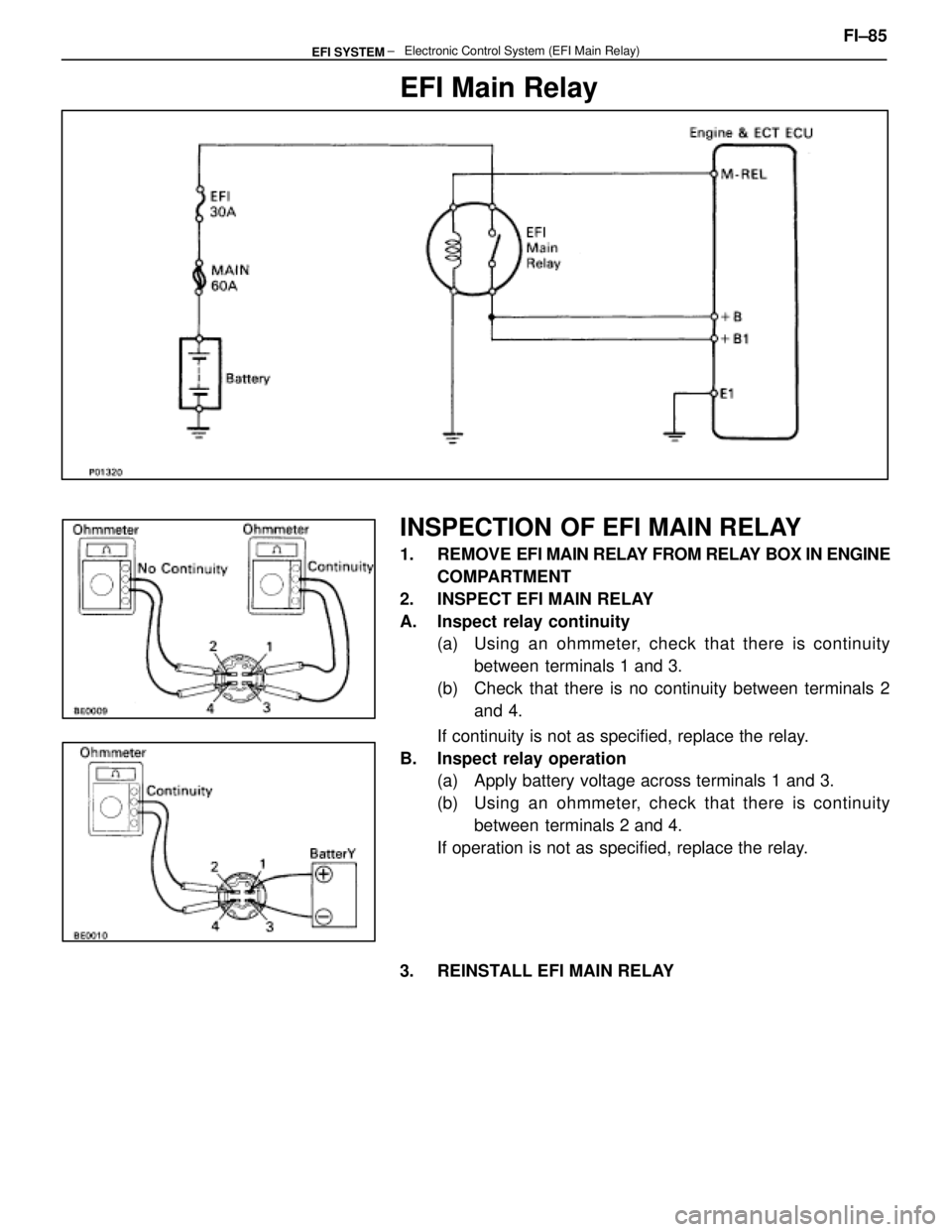

EFI Main Relay

INSPECTION OF EFI MAIN RELAY

1. REMOVE EFI MAIN RELAY FROM RELAY BOX IN ENGINE

COMPARTMENT

2. INSPECT EFI MAIN RELAY

A. Inspect relay continuity (a) Using an ohmmeter, check that there is continuity

between terminals 1 and 3.

(b) Check that there is no continuity between terminals 2 and 4.

If continuity is not as specified, replace the relay.

B. Inspect relay operation (a) Apply battery voltage across terminals 1 and 3.

(b) Using an ohmmeter, check that there is continuity

between terminals 2 and 4.

If operation is not as specified, replace the relay.

3. REINSTALL EFI MAIN RELAY FI±85

± Electronic Control System (EFI Main Relay\

)EFI SYSTEM

WhereEverybodyKnowsYourName