LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1431 of 4087

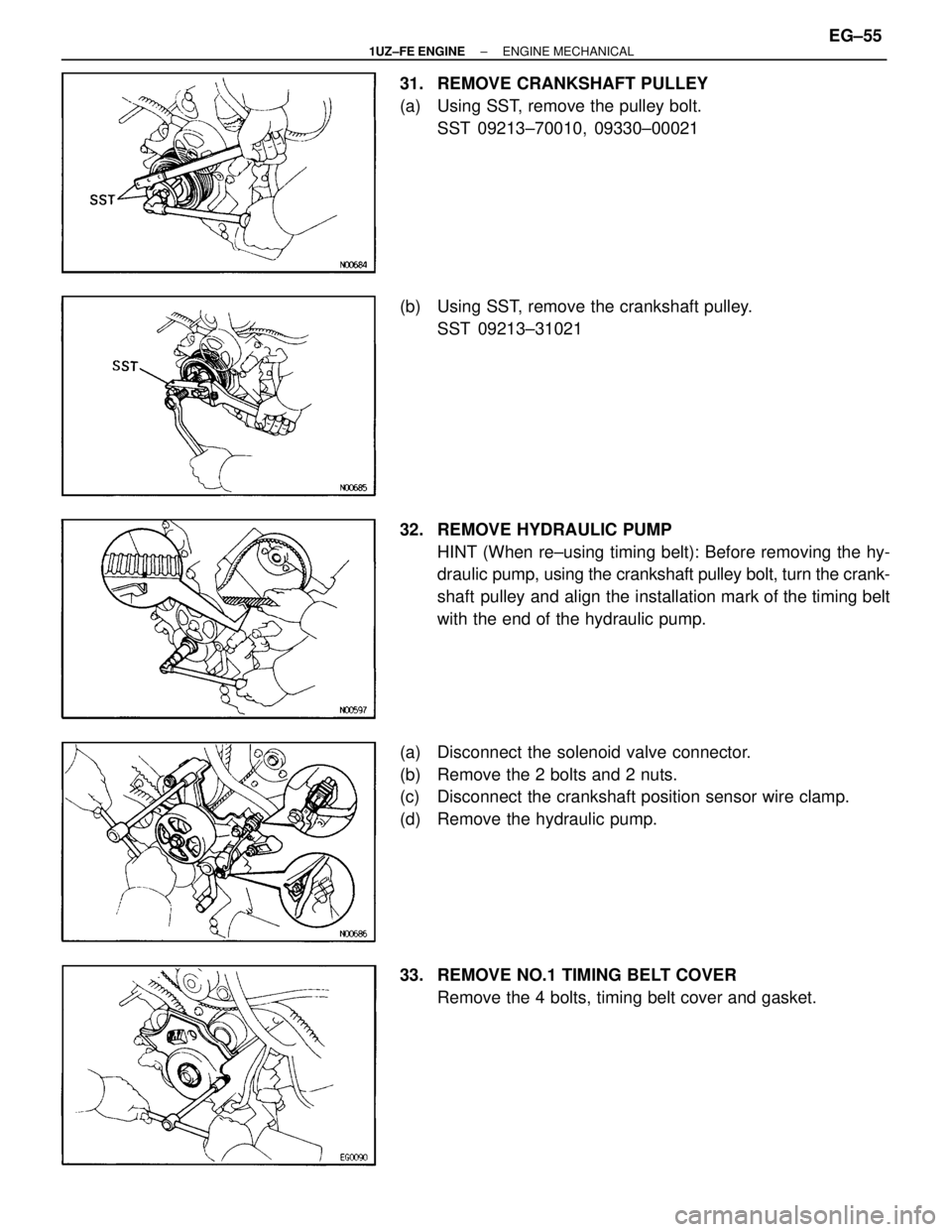

31. REMOVE CRANKSHAFT PULLEY

(a) Using SST, remove the pulley bolt.SST 09213±70010, 09330±00021

(b) Using SST, remove the crankshaft pulley. SST 09213±31021

32. REMOVE HYDRAULIC PUMP HINT (When re±using timing belt): Before removing the hy-

draulic pump, using the crankshaft pulley bolt, turn the crank-

shaft pulley and align the installation mark of the timing belt

with the end of the hydraulic pump.

(a) Disconnect the solenoid valve connector.

(b) Remove the 2 bolts and 2 nuts.

(c) Disconnect the crankshaft position sensor wire clamp.

(d) Remove the hydraulic pump.

33. REMOVE NO.1 TIMING BELT COVER Remove the 4 bolts, timing belt cover and gasket.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±55

WhereEverybodyKnowsYourName

Page 1432 of 4087

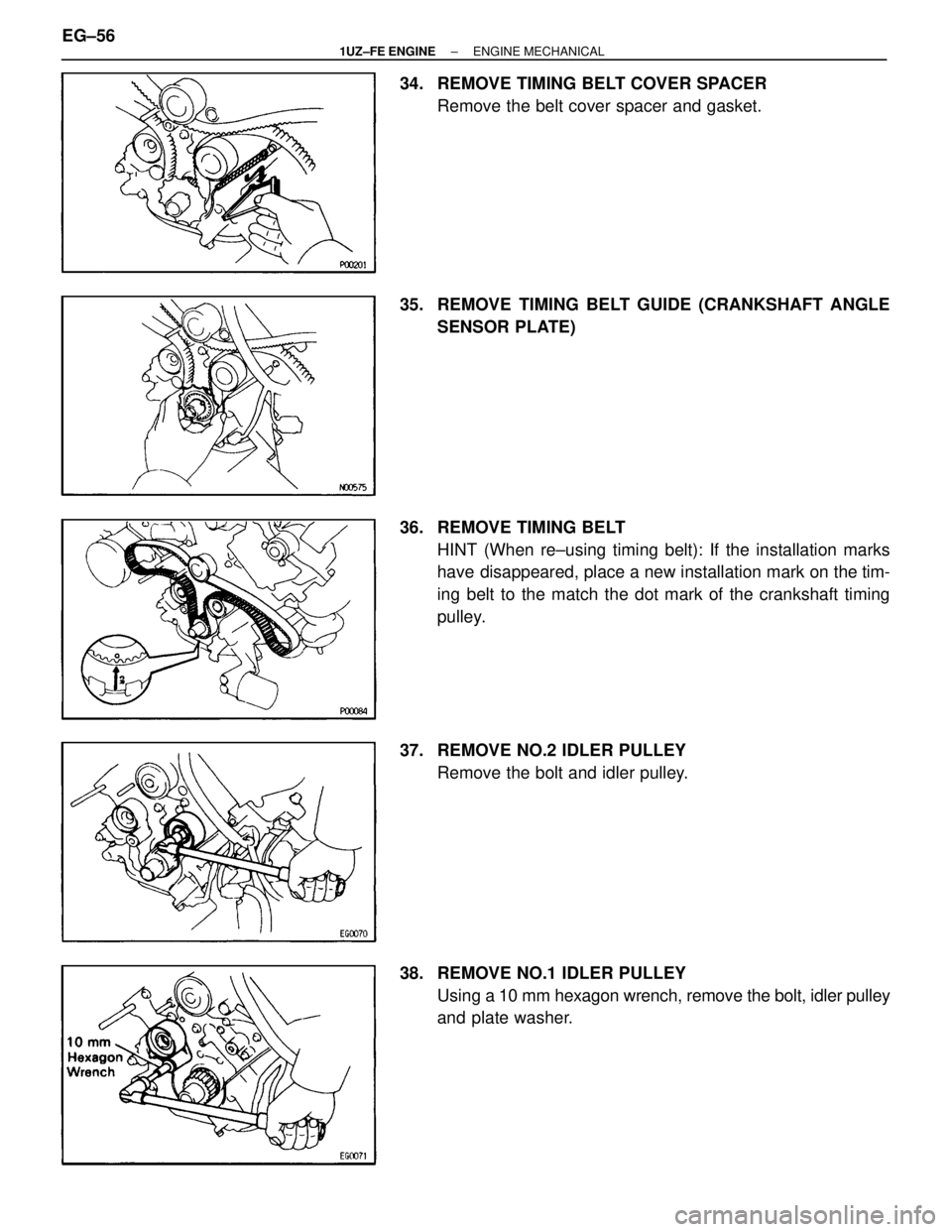

34. REMOVE TIMING BELT COVER SPACERRemove the belt cover spacer and gasket.

35. REMOVE TIMING BELT GUIDE (CRANKSHAFT ANGLE SENSOR PLATE)

36. REMOVE TIMING BELT HINT (When re±using timing belt): If the installation marks

have disappeared, place a new installation mark on the tim-

ing belt to the match the dot mark of the crankshaft timing

pulley.

37. REMOVE NO.2 IDLER PULLEY Remove the bolt and idler pulley.

38. REMOVE NO.1 IDLER PULLEY Using a 10 mm hexagon wrench, remove the bolt, idler pulley

and plate washer.

EG±56

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1433 of 4087

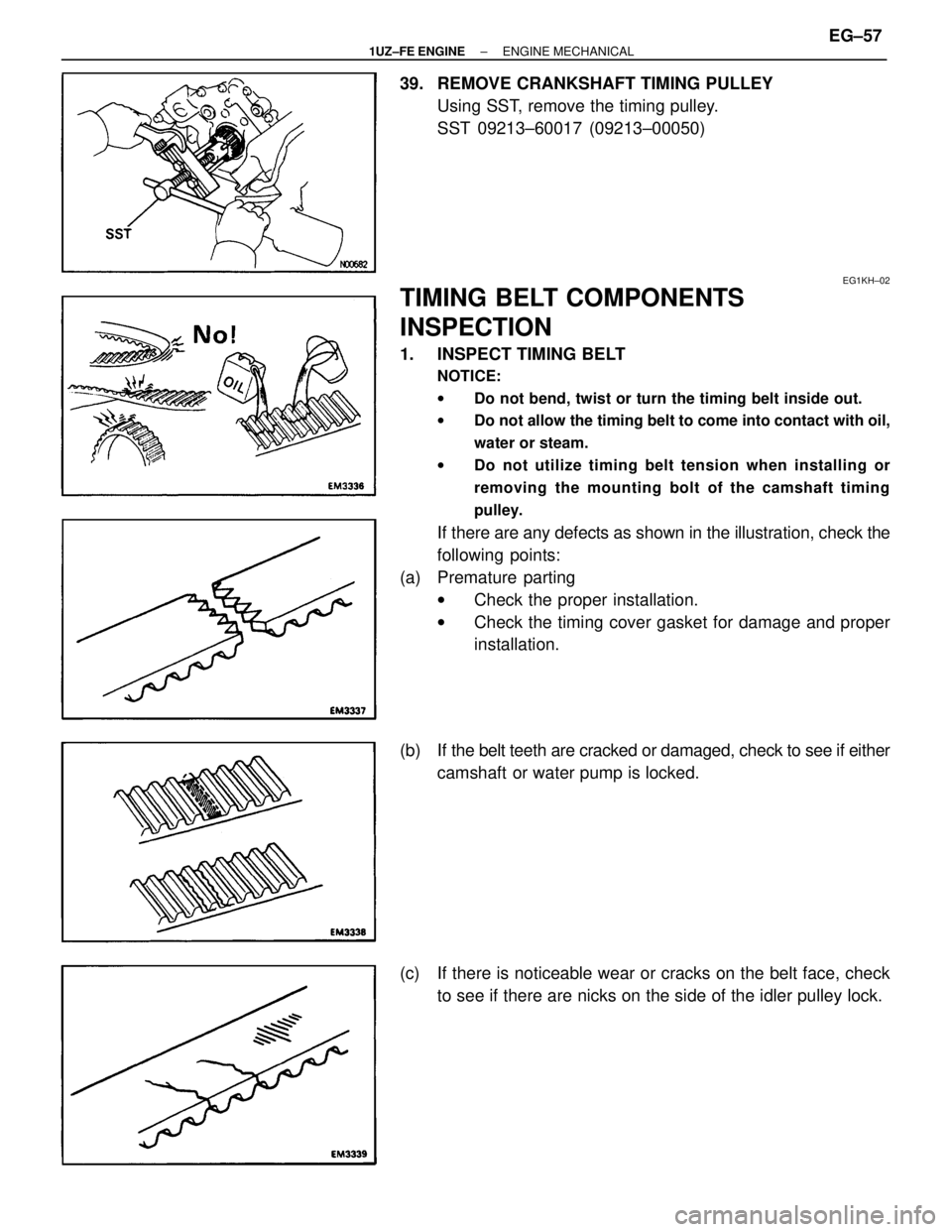

39. REMOVE CRANKSHAFT TIMING PULLEYUsing SST, remove the timing pulley.

SST 09213±60017 (09213±00050)

EG1KH±02

TIMING BELT COMPONENTS

INSPECTION

1. INSPECT TIMING BELT

NOTICE:

w Do not bend, twist or turn the timing belt inside out.

w Do not allow the timing belt to come into contact with oil,

water or steam.

w Do not utilize timing belt tension when installing or

removing the mounting bolt of the camshaft timing

pulley.

If there are any defects as shown in the illustration, check the

following points:

(a) Premature parting wCheck the proper installation.

w Check the timing cover gasket for damage and proper

installation.

(b) If the belt teeth are cracked or damaged, check to see if either

camshaft or water pump is locked.

(c) If there is noticeable wear or cracks on the belt face, check to see if there are nicks on the side of the idler pulley lock.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±57

WhereEverybodyKnowsYourName

Page 1434 of 4087

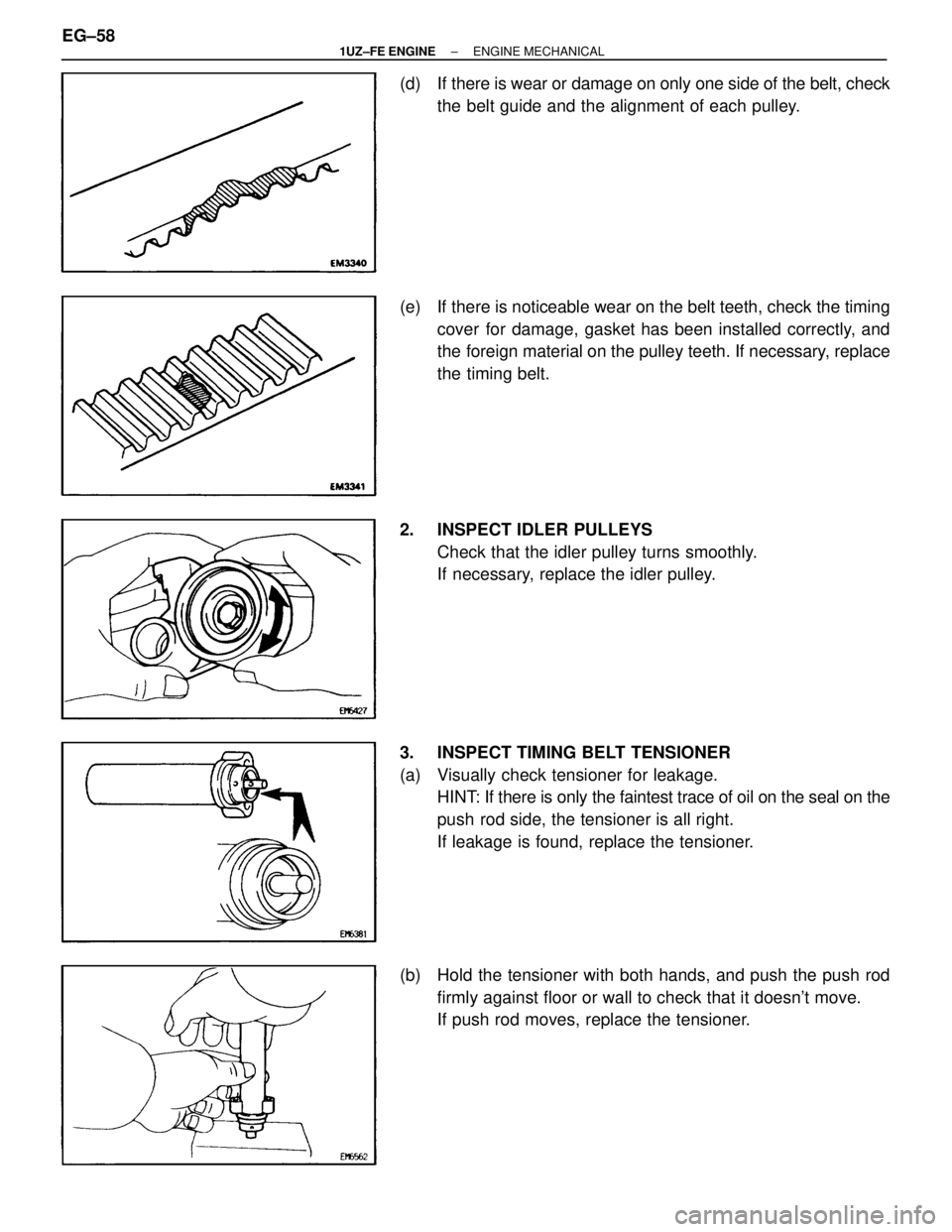

(d) If there is wear or damage on only one side of the belt, checkthe belt guide and the alignment of each pulley.

(e) If there is noticeable wear on the belt teeth, check the timing cover for damage, gasket has been installed correctly, and

the foreign material on the pulley teeth. If necessary, replace

the timing belt.

2. INSPECT IDLER PULLEYS Check that the idler pulley turns smoothly.

If necessary, replace the idler pulley.

3. INSPECT TIMING BELT TENSIONER

(a) Visually check tensioner for leakage. HINT: If there is only the faintest trace of oil on the seal on the

push rod side, the tensioner is all right.

If leakage is found, replace the tensioner.

(b) Hold the tensioner with both hands, and push the push rod firmly against floor or wall to check that it doesn't move.

If push rod moves, replace the tensioner.

EG±58

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1435 of 4087

(c) Measure the protrusion of the push rod from the housing end.

Protrusion:

10.5 ± 11.5 mm (0.413 ± 0.453 in.)

If the protrusion is not as specified, replace the tensioner.

EG21R±02

TIMING BELT INSTALLATION

See Components for Removal and Installation:

1. INSTALL CRANKSHAFT TIMING PULLEY

(a) Align the timing pulley set key with the key groove of thepulley.

(b) Using SST and a hammer, tap in the timing pulley, facing the flange side inward.

SST 09223±46011

2. INSTALL NO.1 IDLER PULLEY

(a) Apply adhesive 2 or 3 threads of the pivot bolt.

Adhesive: Part No. 08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Using a 10 mm hexagon wrench, install the plate washer and

idler pulley with the pivot bolt.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

(c) Check that the pulley bracket moves smoothly.

3. INSTALL NO.2 IDLER PULLEY

(a) Install the idler pulley with the bolt.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

(b) Check that the idler pulley moves smoothly.

4. TEMPORARILY INSTALL TIMING BELT

NOTICE: The engine should be cold.

(a) Using the crankshaft pulley bolt, turn the crankshaft and align

the timing marks of the crankshaft timing pulley and oil pump

body.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±59

WhereEverybodyKnowsYourName

Page 1436 of 4087

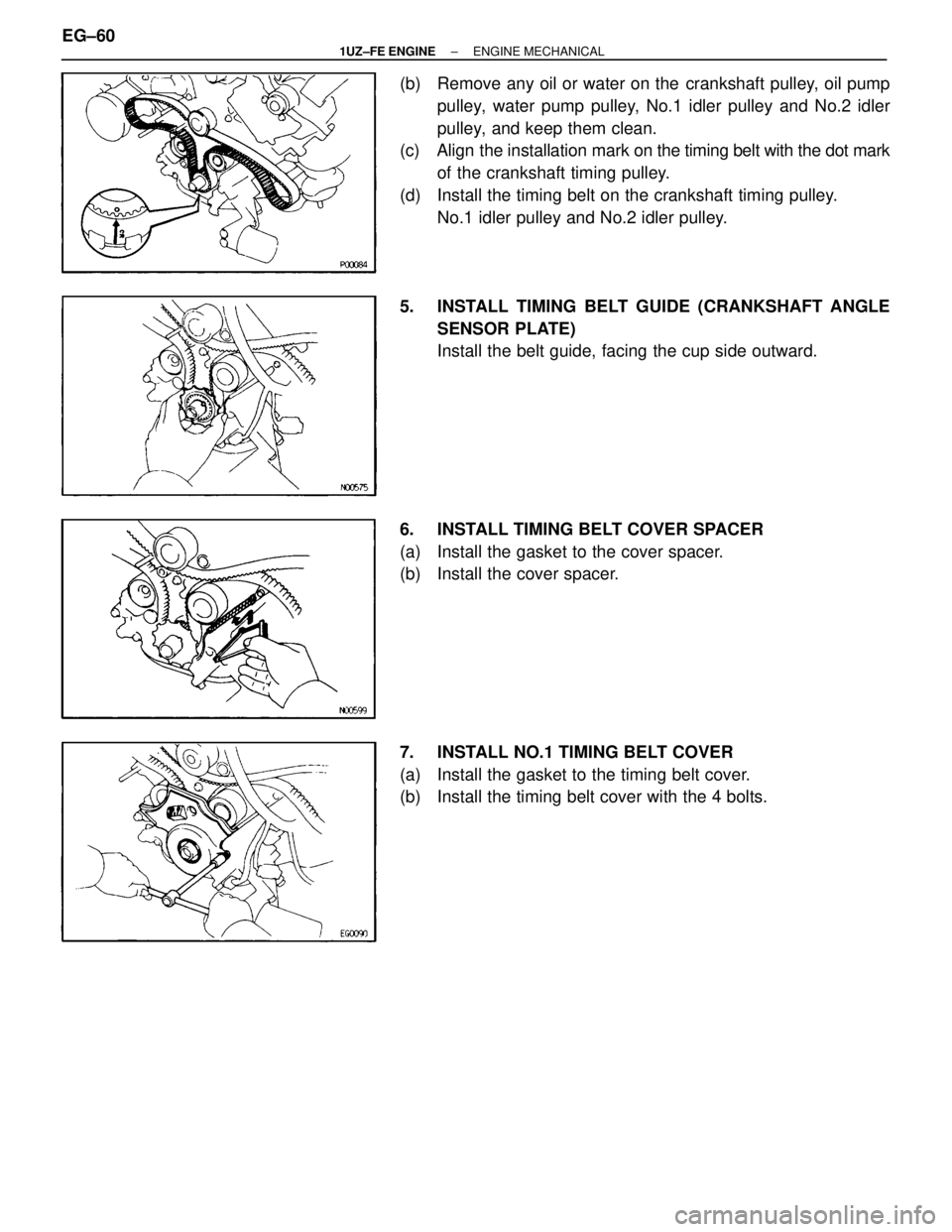

(b) Remove any oil or water on the crankshaft pulley, oil pumppulley, water pump pulley, No.1 idler pulley and No.2 idler

pulley, and keep them clean.

(c) Align the installation mark on the timing belt with the dot mark

of the crankshaft timing pulley.

(d) Install the timing belt on the crankshaft timing pulley. No.1 idler pulley and No.2 idler pulley.

5. INSTALL TIMING BELT GUIDE (CRANKSHAFT ANGLE SENSOR PLATE)

Install the belt guide, facing the cup side outward.

6. INSTALL TIMING BELT COVER SPACER

(a) Install the gasket to the cover spacer.

(b) Install the cover spacer.

7. INSTALL NO.1 TIMING BELT COVER

(a) Install the gasket to the timing belt cover.

(b) Install the timing belt cover with the 4 bolts.

EG±60

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1437 of 4087

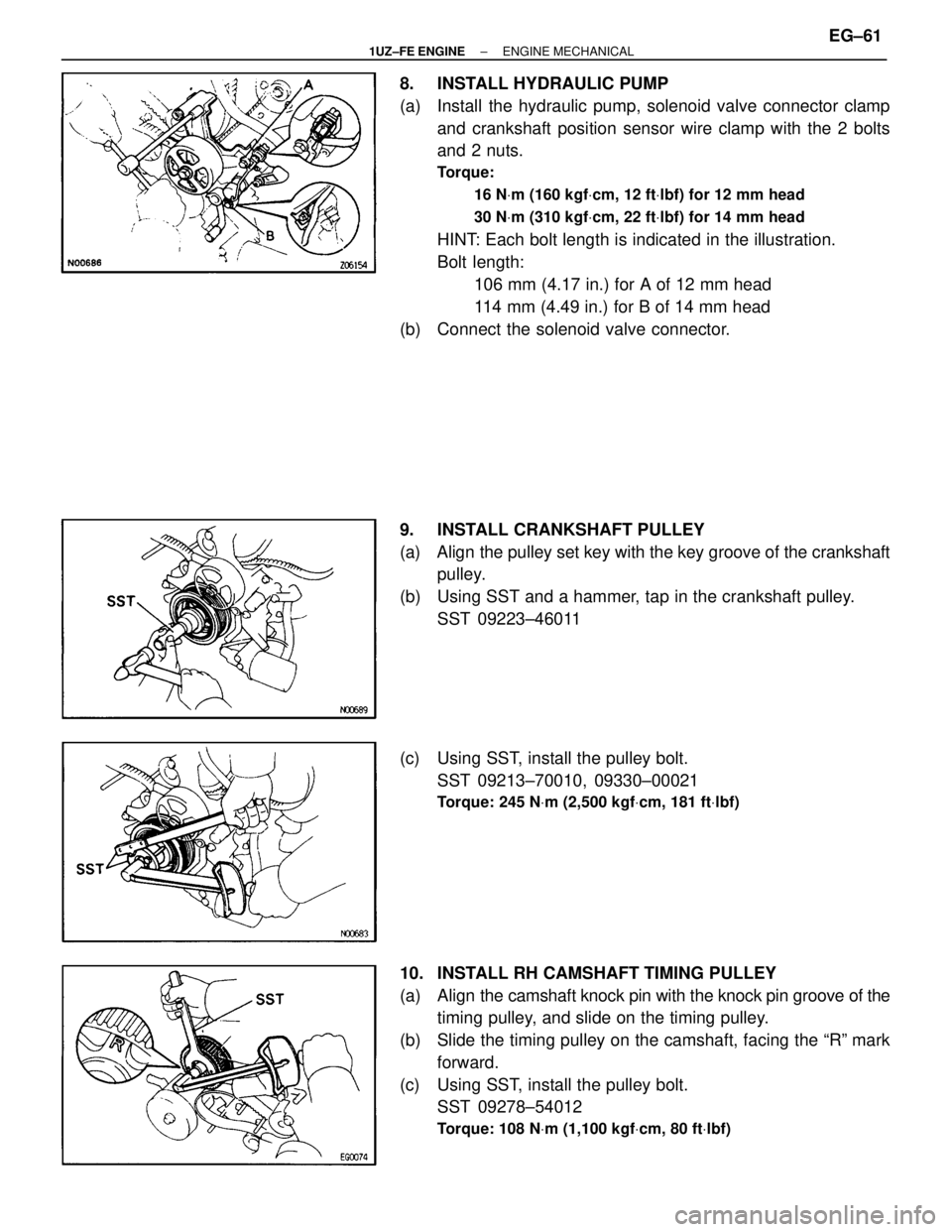

8. INSTALL HYDRAULIC PUMP

(a) Install the hydraulic pump, solenoid valve connector clampand crankshaft position sensor wire clamp with the 2 bolts

and 2 nuts.

Torque:

16 NVm (160 kgf Vcm, 12 ft Vlbf) for 12 mm head

30 N Vm (310 kgf Vcm, 22 ft Vlbf) for 14 mm head

HINT: Each bolt length is indicated in the illustration.

Bolt length:

106 mm (4.17 in.) for A of 12 mm head

114 mm (4.49 in.) for B of 14 mm head

(b) Connect the solenoid valve connector.

9. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the crankshaft pulley.

(b) Using SST and a hammer, tap in the crankshaft pulley. SST 09223±46011

(c) Using SST, install the pulley bolt. SST 09213±70010, 09330±00021

Torque: 245 N Vm (2,500 kgf Vcm, 181 ft Vlbf)

10. INSTALL RH CAMSHAFT TIMING PULLEY

(a) Align the camshaft knock pin with the knock pin groove of the

timing pulley, and slide on the timing pulley.

(b) Slide the timing pulley on the camshaft, facing the ªRº mark forward.

(c) Using SST, install the pulley bolt. SST 09278±54012

Torque: 108 N Vm (1,100 kgf Vcm, 80 ft Vlbf)

±

1UZ±FE ENGINE ENGINE MECHANICALEG±61

WhereEverybodyKnowsYourName

Page 1438 of 4087

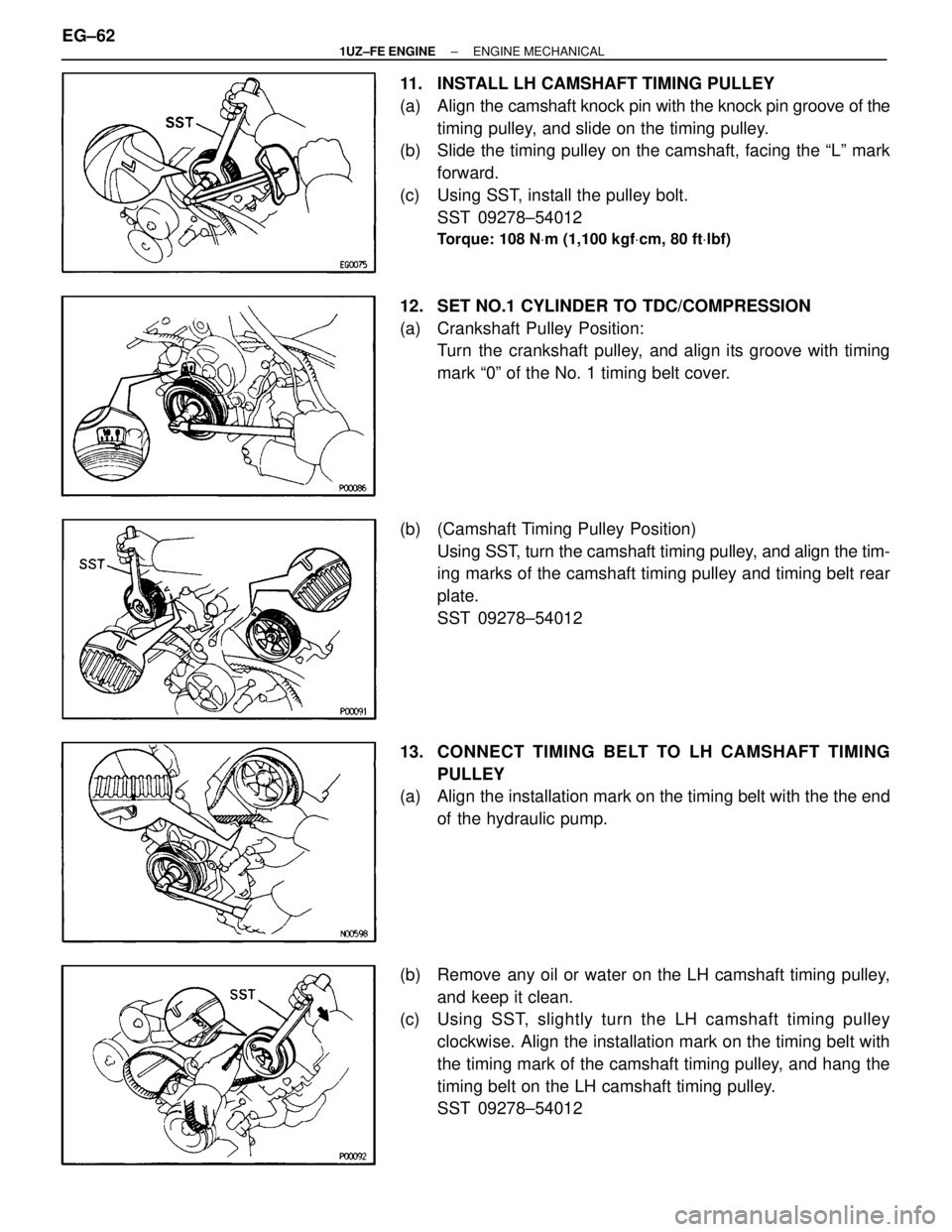

11. INSTALL LH CAMSHAFT TIMING PULLEY

(a) Align the camshaft knock pin with the knock pin groove of the

timing pulley, and slide on the timing pulley.

(b) Slide the timing pulley on the camshaft, facing the ªLº mark

forward.

(c) Using SST, install the pulley bolt. SST 09278±54012

Torque: 108 N Vm (1,100 kgf Vcm, 80 ft Vlbf)

12. SET NO.1 CYLINDER TO TDC/COMPRESSION

(a) Crankshaft Pulley Position:

Turn the crankshaft pulley, and align its groove with timing

mark ª0º of the No. 1 timing belt cover.

(b) (Camshaft Timing Pulley Position) Using SST, turn the camshaft timing pulley, and align the tim-

ing marks of the camshaft timing pulley and timing belt rear

plate.

SST 09278±54012

13. CONNECT TIMING BELT TO LH CAMSHAFT TIMING PULLEY

(a) Align the installation mark on the timing belt with the the end

of the hydraulic pump.

(b) Remove any oil or water on the LH camshaft timing pulley, and keep it clean.

(c) Using SST, slightly turn the LH camshaft timing pulley

clockwise. Align the installation mark on the timing belt with

the timing mark of the camshaft timing pulley, and hang the

timing belt on the LH camshaft timing pulley.

SST 09278±54012

EG±62

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1439 of 4087

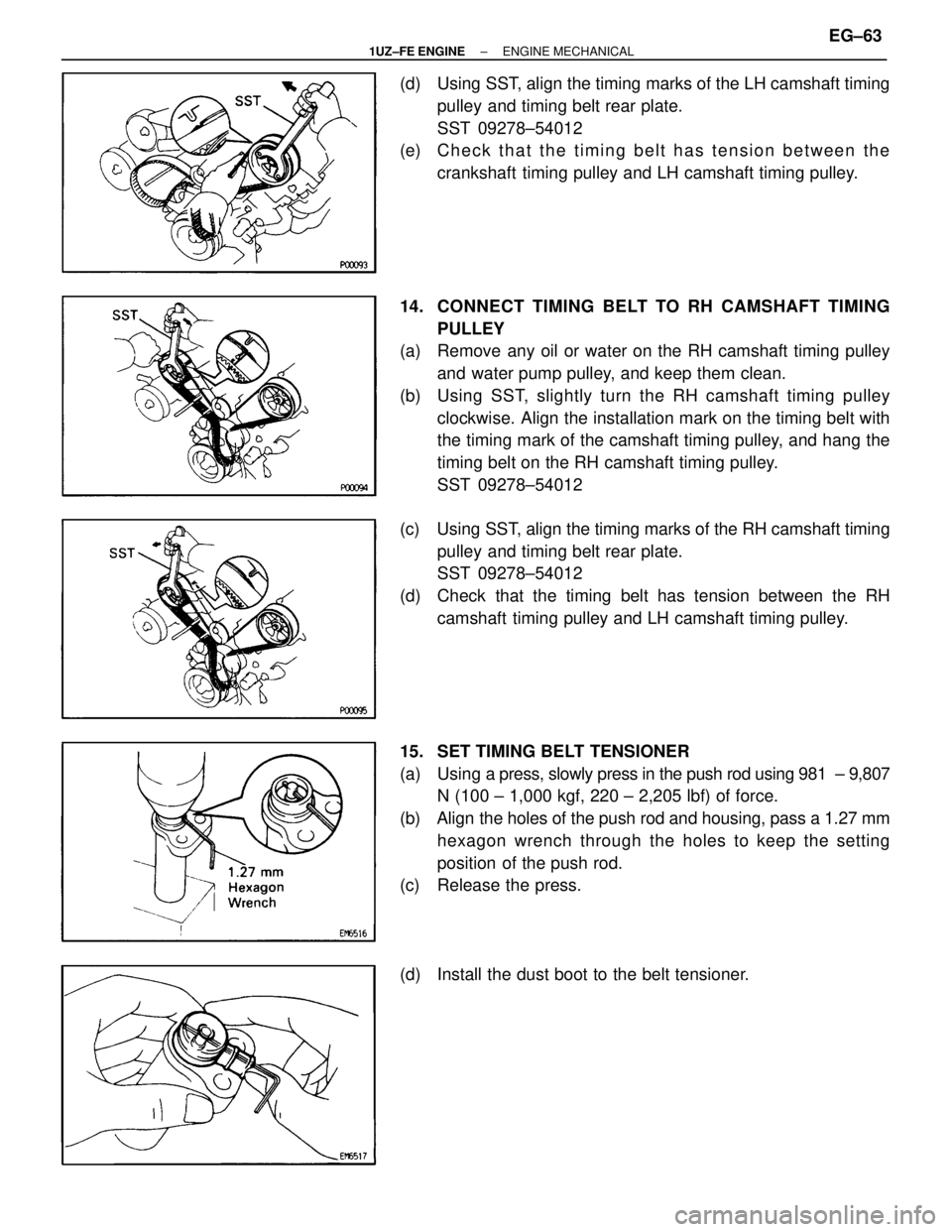

(d) Using SST, align the timing marks of the LH camshaft timingpulley and timing belt rear plate.

SST 09278±54012

(e) C h e c k t h a t t h e t i m i n g b e l t h a s t e n s i o n b e t w e e n t h e

crankshaft timing pulley and LH camshaft timing pulley.

14. CONNECT TIMING BELT TO RH CAMSHAFT TIMING PULLEY

(a) Remove any oil or water on the RH camshaft timing pulley

and water pump pulley, and keep them clean.

(b) Using SST, slightly turn the RH camshaft timing pulley clockwise. Align the installation mark on the timing belt with

the timing mark of the camshaft timing pulley, and hang the

timing belt on the RH camshaft timing pulley.

SST 09278±54012

(c) Using SST, align the timing marks of the RH camshaft timing pulley and timing belt rear plate.

SST 09278±54012

(d) Check that the timing belt has tension between the RH camshaft timing pulley and LH camshaft timing pulley.

15. SET TIMING BELT TENSIONER

(a) Using a press, slowly press in the push rod using 981 ± 9,807

N (100 ± 1,000 kgf, 220 ± 2,205 lbf) of force.

(b) Align the holes of the push rod and housing, pass a 1.27 mm hexagon wrench through the holes to keep the setting

position of the push rod.

(c) Release the press.

(d) Install the dust boot to the belt tensioner.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±63

WhereEverybodyKnowsYourName

Page 1440 of 4087

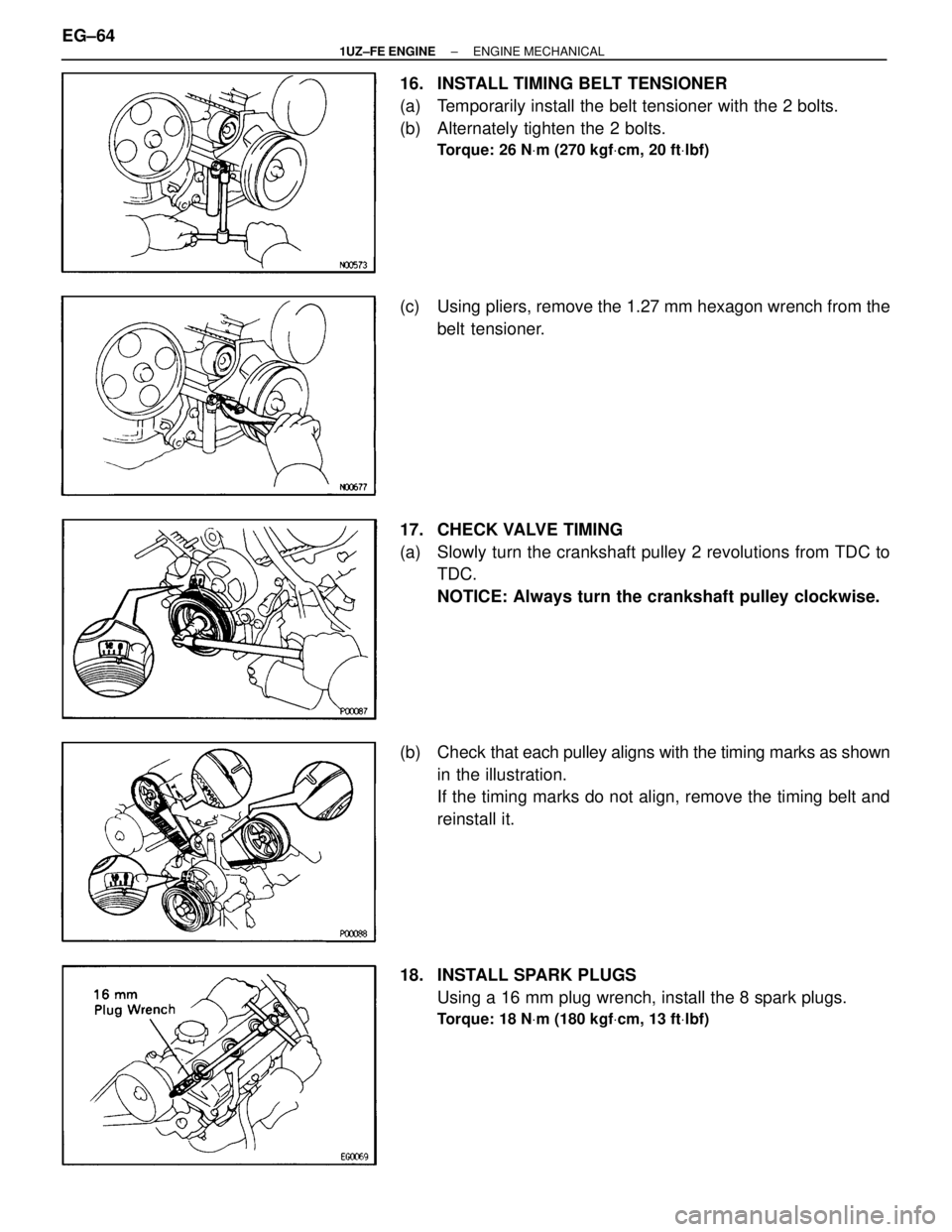

16. INSTALL TIMING BELT TENSIONER

(a) Temporarily install the belt tensioner with the 2 bolts.

(b) Alternately tighten the 2 bolts.

Torque: 26 NVm (270 kgf Vcm, 20 ft Vlbf)

(c) Using pliers, remove the 1.27 mm hexagon wrench from the

belt tensioner.

17. CHECK VALVE TIMING

(a) Slowly turn the crankshaft pulley 2 revolutions from TDC to TDC.

NOTICE: Always turn the crankshaft pulley clockwise.

(b) Check that each pulley aligns with the timing marks as shown

in the illustration.

If the timing marks do not align, remove the timing belt and

reinstall it.

18. INSTALL SPARK PLUGS Using a 16 mm plug wrench, install the 8 spark plugs.

Torque: 18 N Vm (180 kgf Vcm, 13 ft Vlbf)

EG±64±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName