torque LEXUS SC400 1991 Service User Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 153 of 4087

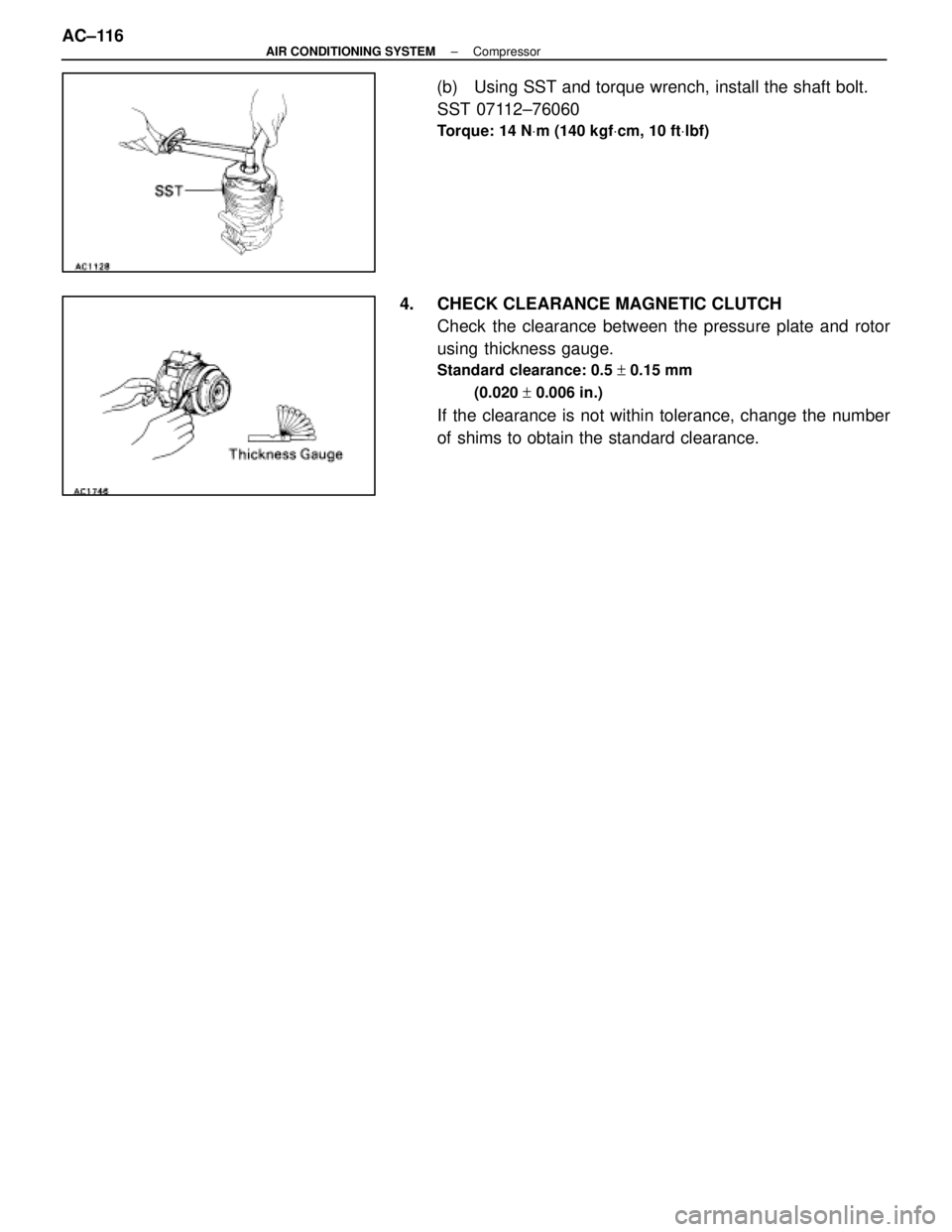

(b) Using SST and torque wrench, install the shaft bolt.SST 07112±76060

Torque: 14 N Vm (140 kgf Vcm, 10 ft Vlbf)

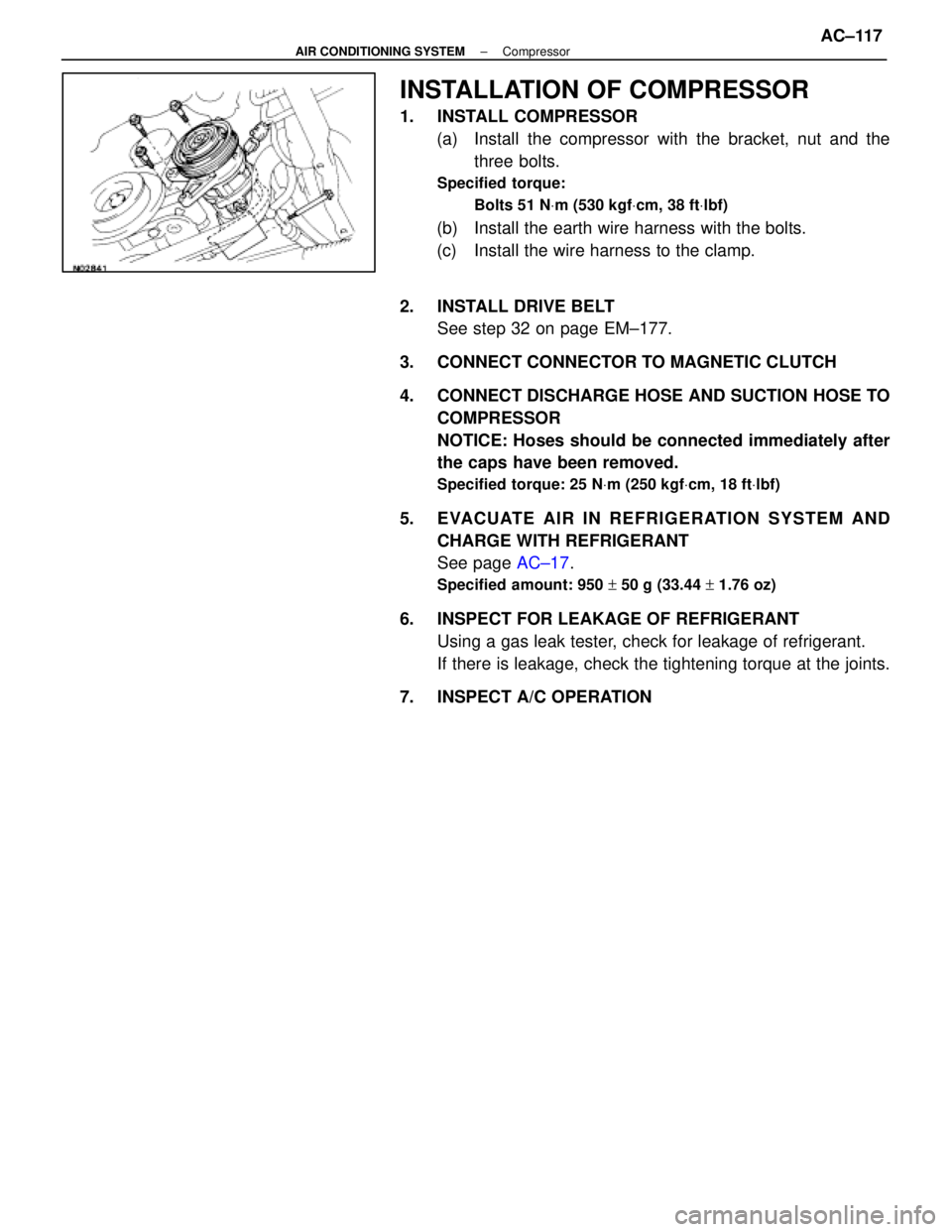

4. CHECK CLEARANCE MAGNETIC CLUTCH

Check the clearance between the pressure plate and rotor

using thickness gauge.

Standard clearance: 0.5 + 0.15 mm

(0.020 + 0.006 in.)

If the clearance is not within tolerance, change the number

of shims to obtain the standard clearance.

AC±116

±

AIR CONDITIONING SYSTEM Compressor

WhereEverybodyKnowsYourName

Page 154 of 4087

INSTALLATION OF COMPRESSOR

1. INSTALL COMPRESSOR(a) Install the compressor with the bracket, nut and the three bolts.

Specified torque:

Bolts 51 N Vm (530 kgf Vcm, 38 ft Vlbf)

(b) Install the earth wire harness with the bolts.

(c) Install the wire harness to the clamp.

2. INSTALL DRIVE BELT See step 32 on page EM±177.

3. CONNECT CONNECTOR TO MAGNETIC CLUTCH

4. CONNECT DISCHARGE HOSE AND SUCTION HOSE TO COMPRESSOR

NOTICE: Hoses should be connected immediately after

the caps have been removed.

Specified torque: 25 N Vm (250 kgf Vcm, 18 ft Vlbf)

5. EVACUATE AIR IN REFRIGERATION SYSTEM AND

CHARGE WITH REFRIGERANT

See page AC±17.

Specified amount: 950 + 50 g (33.44 + 1.76 oz)

6. INSPECT FOR LEAKAGE OF REFRIGERANT

Using a gas leak tester, check for leakage of refrigerant.

If there is leakage, check the tightening torque at the joints.

7. INSPECT A/C OPERATION

±

AIR CONDITIONING SYSTEM CompressorAC±117

WhereEverybodyKnowsYourName

Page 155 of 4087

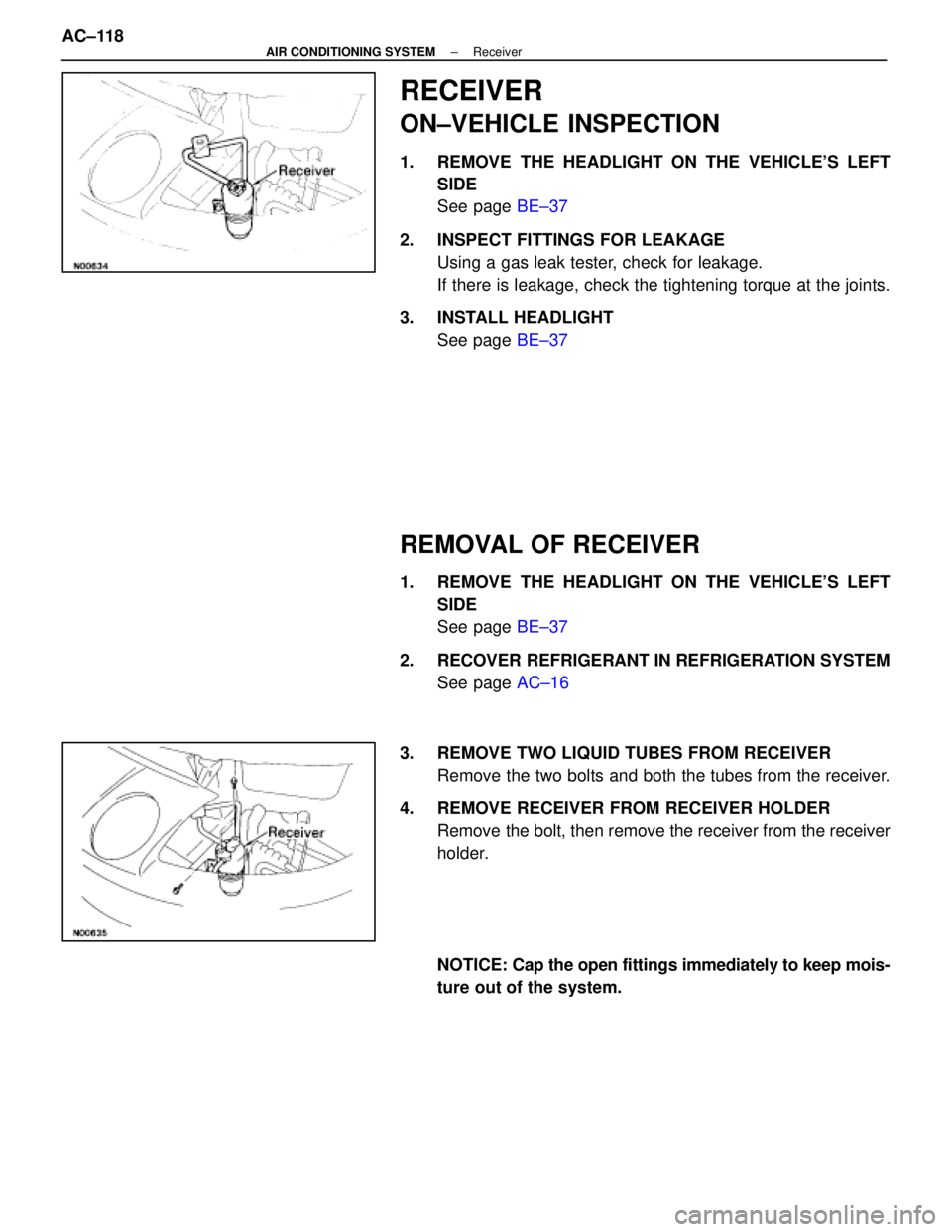

RECEIVER

ON±VEHICLE INSPECTION

1. REMOVE THE HEADLIGHT ON THE VEHICLE'S LEFTSIDE

See page BE±37

2. INSPECT FITTINGS FOR LEAKAGE Using a gas leak tester, check for leakage.

If there is leakage, check the tightening torque at the joints.

3. INSTALL HEADLIGHT See page BE±37

REMOVAL OF RECEIVER

1. REMOVE THE HEADLIGHT ON THE VEHICLE'S LEFT

SIDE

See page BE±37

2. RECOVER REFRIGERANT IN REFRIGERATION SYSTEM See page AC±16

3. REMOVE TWO LIQUID TUBES FROM RECEIVER Remove the two bolts and both the tubes from the receiver.

4. REMOVE RECEIVER FROM RECEIVER HOLDER Remove the bolt, then remove the receiver from the receiver

holder.

NOTICE: Cap the open fittings immediately to keep mois-

ture out of the system.

AC±118

±

AIR CONDITIONING SYSTEM Receiver

WhereEverybodyKnowsYourName

Page 156 of 4087

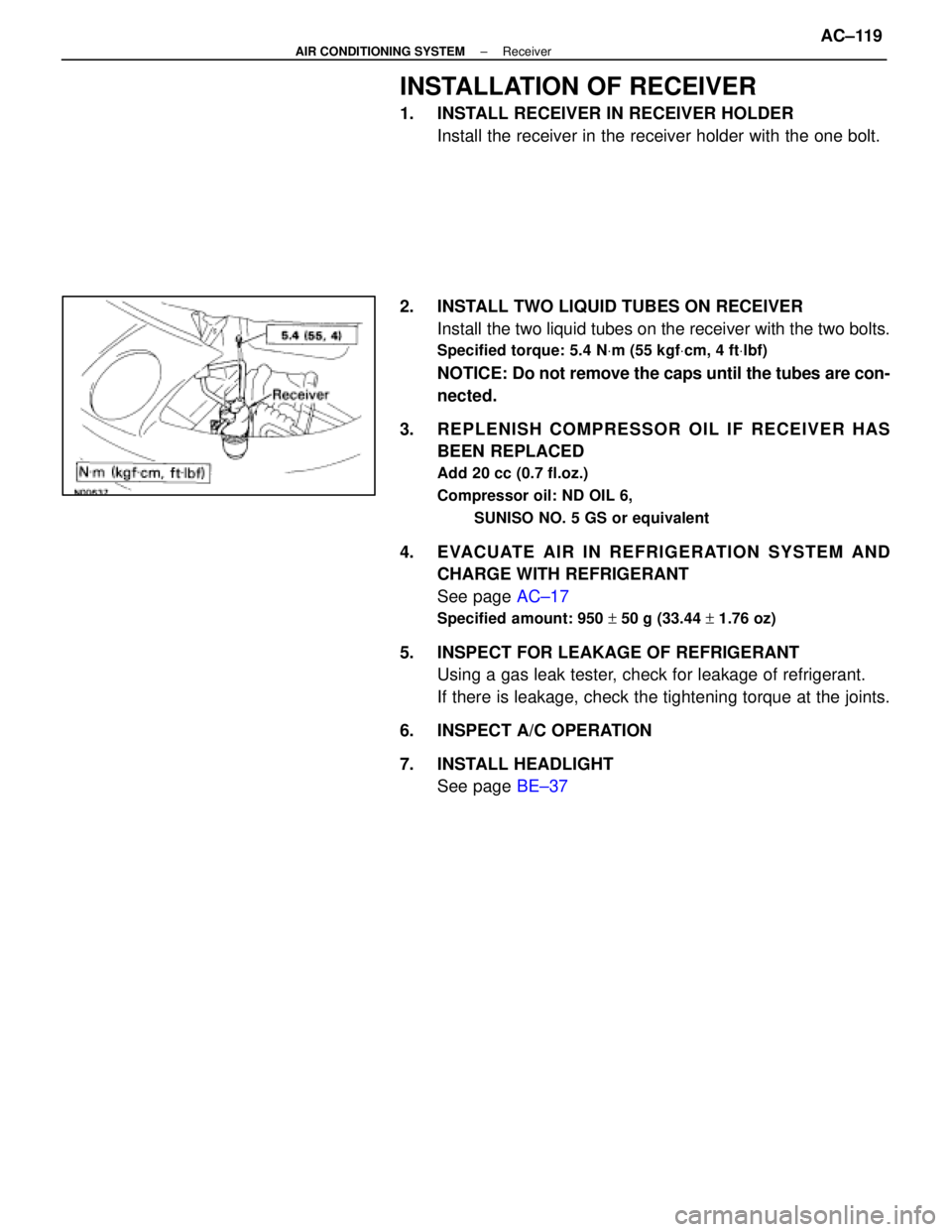

INSTALLATION OF RECEIVER

1. INSTALL RECEIVER IN RECEIVER HOLDERInstall the receiver in the receiver holder with the one bolt.

2. INSTALL TWO LIQUID TUBES ON RECEIVER Install the two liquid tubes on the receiver with the two bolts.

Specified torque: 5.4 N Vm (55 kgf Vcm, 4 ft Vlbf)

NOTICE: Do not remove the caps until the tubes are con-

nected.

3. REPLENISH COMPRESSOR OIL IF RECEIVER HAS BEEN REPLACED

Add 20 cc (0.7 fl.oz.)

Compressor oil: ND OIL 6,

SUNISO NO. 5 GS or equivalent

4. EVACUATE AIR IN REFRIGERATION SYSTEM ANDCHARGE WITH REFRIGERANT

See page AC±17

Specified amount: 950 + 50 g (33.44 + 1.76 oz)

5. INSPECT FOR LEAKAGE OF REFRIGERANT

Using a gas leak tester, check for leakage of refrigerant.

If there is leakage, check the tightening torque at the joints.

6. INSPECT A/C OPERATION

7. INSTALL HEADLIGHT See page BE±37

±

AIR CONDITIONING SYSTEM ReceiverAC±119

WhereEverybodyKnowsYourName

Page 157 of 4087

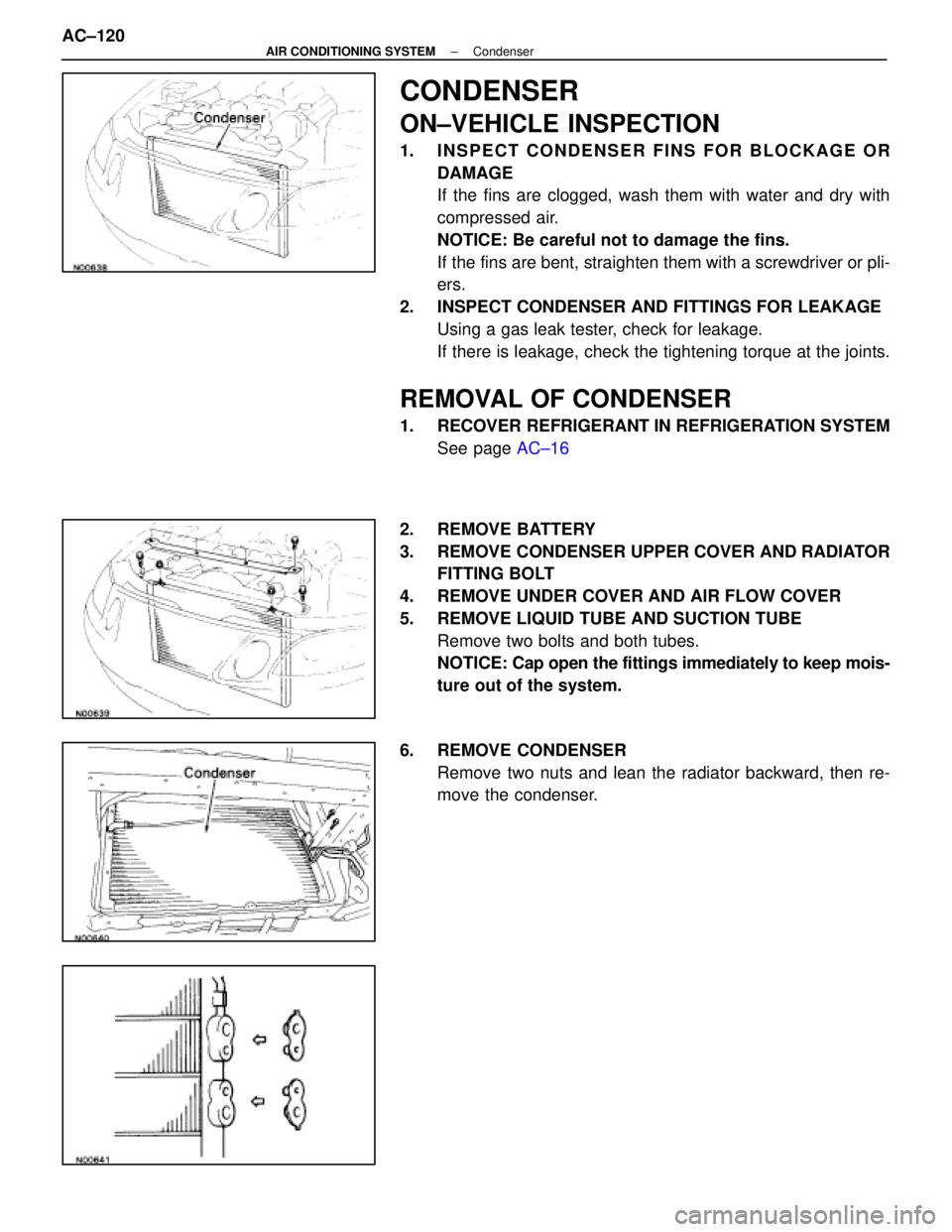

CONDENSER

ON±VEHICLE INSPECTION

1. INSPECT CONDENSER FINS FOR BLOCKAGE OR

DAMAGE

If the fins are clogged, wash them with water and dry with

compressed air.

NOTICE: Be careful not to damage the fins.

If the fins are bent, straighten them with a screwdriver or pli-

ers.

2. INSPECT CONDENSER AND FITTINGS FOR LEAKAGE Using a gas leak tester, check for leakage.

If there is leakage, check the tightening torque at the joints.

REMOVAL OF CONDENSER

1. RECOVER REFRIGERANT IN REFRIGERATION SYSTEMSee page AC±16

2. REMOVE BATTERY

3. REMOVE CONDENSER UPPER COVER AND RADIATOR FITTING BOLT

4. REMOVE UNDER COVER AND AIR FLOW COVER

5. REMOVE LIQUID TUBE AND SUCTION TUBE Remove two bolts and both tubes.

NOTICE: Cap open the fittings immediately to keep mois-

ture out of the system.

6. REMOVE CONDENSER Remove two nuts and lean the radiator backward, then re-

move the condenser.

AC±120

±

AIR CONDITIONING SYSTEM Condenser

WhereEverybodyKnowsYourName

Page 158 of 4087

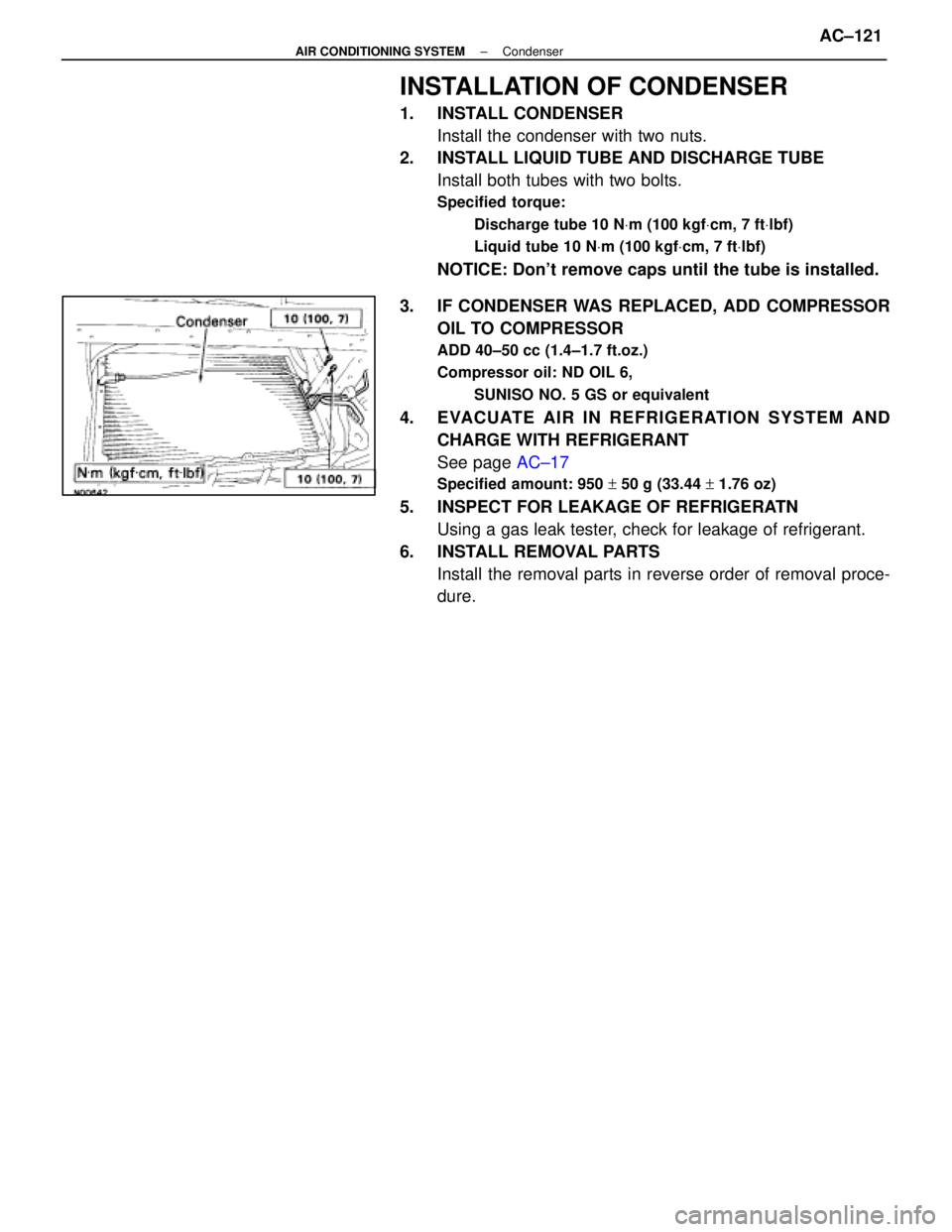

INSTALLATION OF CONDENSER

1. INSTALL CONDENSERInstall the condenser with two nuts.

2. INSTALL LIQUID TUBE AND DISCHARGE TUBE

Install both tubes with two bolts.

Specified torque:

Discharge tube 10 N Vm (100 kgf Vcm, 7 ft Vlbf)

Liquid tube 10 N Vm (100 kgf Vcm, 7 ft Vlbf)

NOTICE: Don't remove caps until the tube is installed.

3. IF CONDENSER WAS REPLACED, ADD COMPRESSOR OIL TO COMPRESSOR

ADD 40±50 cc (1.4±1.7 ft.oz.)

Compressor oil: ND OIL 6,

SUNISO NO. 5 GS or equivalent

4. EVACUATE AIR IN REFRIGERATION SYSTEM ANDCHARGE WITH REFRIGERANT

See page AC±17

Specified amount: 950 + 50 g (33.44 + 1.76 oz)

5. INSPECT FOR LEAKAGE OF REFRIGERATN

Using a gas leak tester, check for leakage of refrigerant.

6. INSTALL REMOVAL PARTS Install the removal parts in reverse order of removal proce-

dure.

±

AIR CONDITIONING SYSTEM CondenserAC±121

WhereEverybodyKnowsYourName

Page 161 of 4087

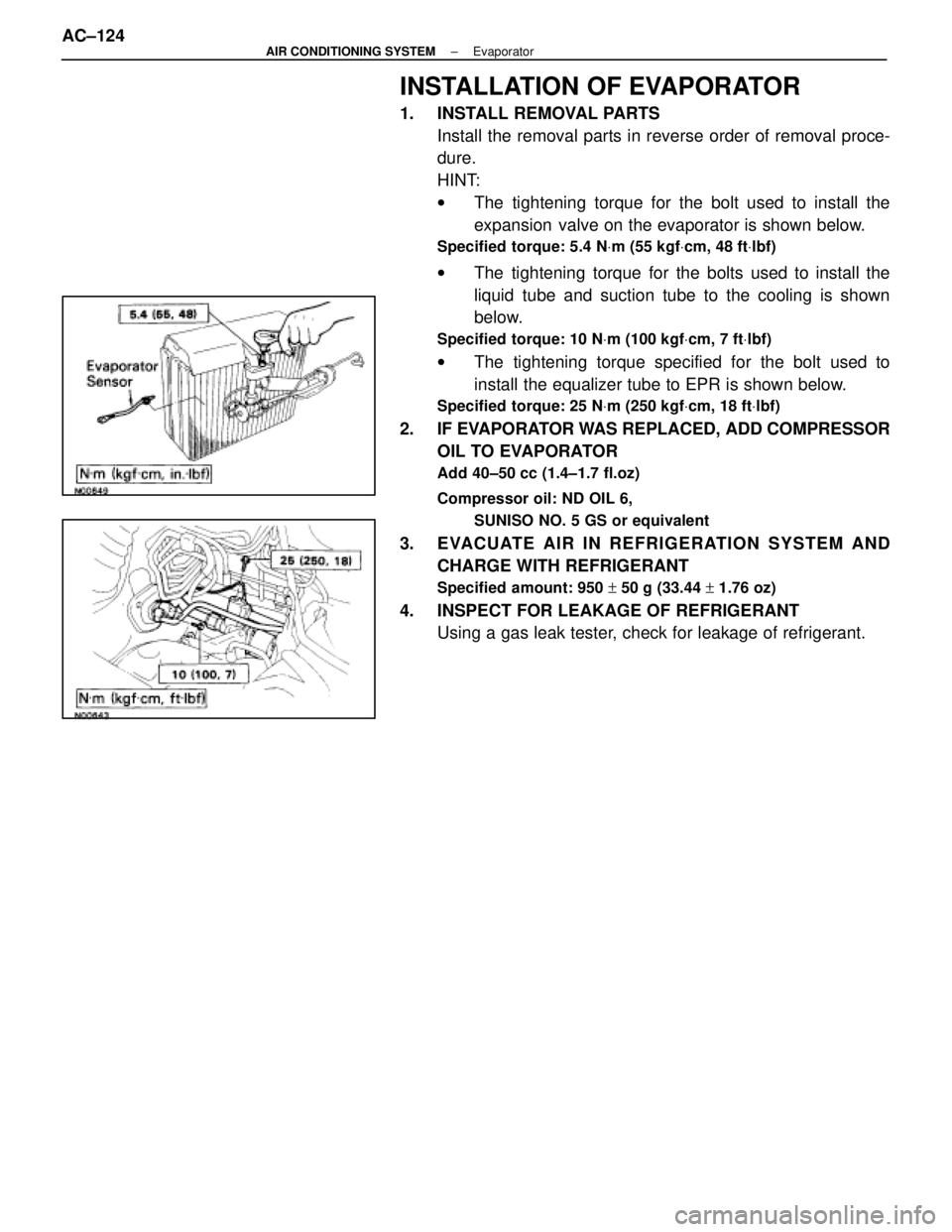

INSTALLATION OF EVAPORATOR

1. INSTALL REMOVAL PARTSInstall the removal parts in reverse order of removal proce-

dure.

HINT:

wThe tightening torque for the bolt used to install the

expansion valve on the evaporator is shown below.

Specified torque: 5.4 N Vm (55 kgf Vcm, 48 ft Vlbf)

w The tightening torque for the bolts used to install the

liquid tube and suction tube to the cooling is shown

below.

Specified torque: 10 N Vm (100 kgf Vcm, 7 ft Vlbf)

w The tightening torque specified for the bolt used to

install the equalizer tube to EPR is shown below.

Specified torque: 25 N Vm (250 kgf Vcm, 18 ft Vlbf)

2. IF EVAPORATOR WAS REPLACED, ADD COMPRESSOR

OIL TO EVAPORATOR

Add 40±50 cc (1.4±1.7 fl.oz)

Compressor oil: ND OIL 6,

SUNISO NO. 5 GS or equivalent

3. EVACUATE AIR IN REFRIGERATION SYSTEM ANDCHARGE WITH REFRIGERANT

Specified amount: 950 + 50 g (33.44 + 1.76 oz)

4. INSPECT FOR LEAKAGE OF REFRIGERANT

Using a gas leak tester, check for leakage of refrigerant.

AC±124

±

AIR CONDITIONING SYSTEM Evaporator

WhereEverybodyKnowsYourName

Page 163 of 4087

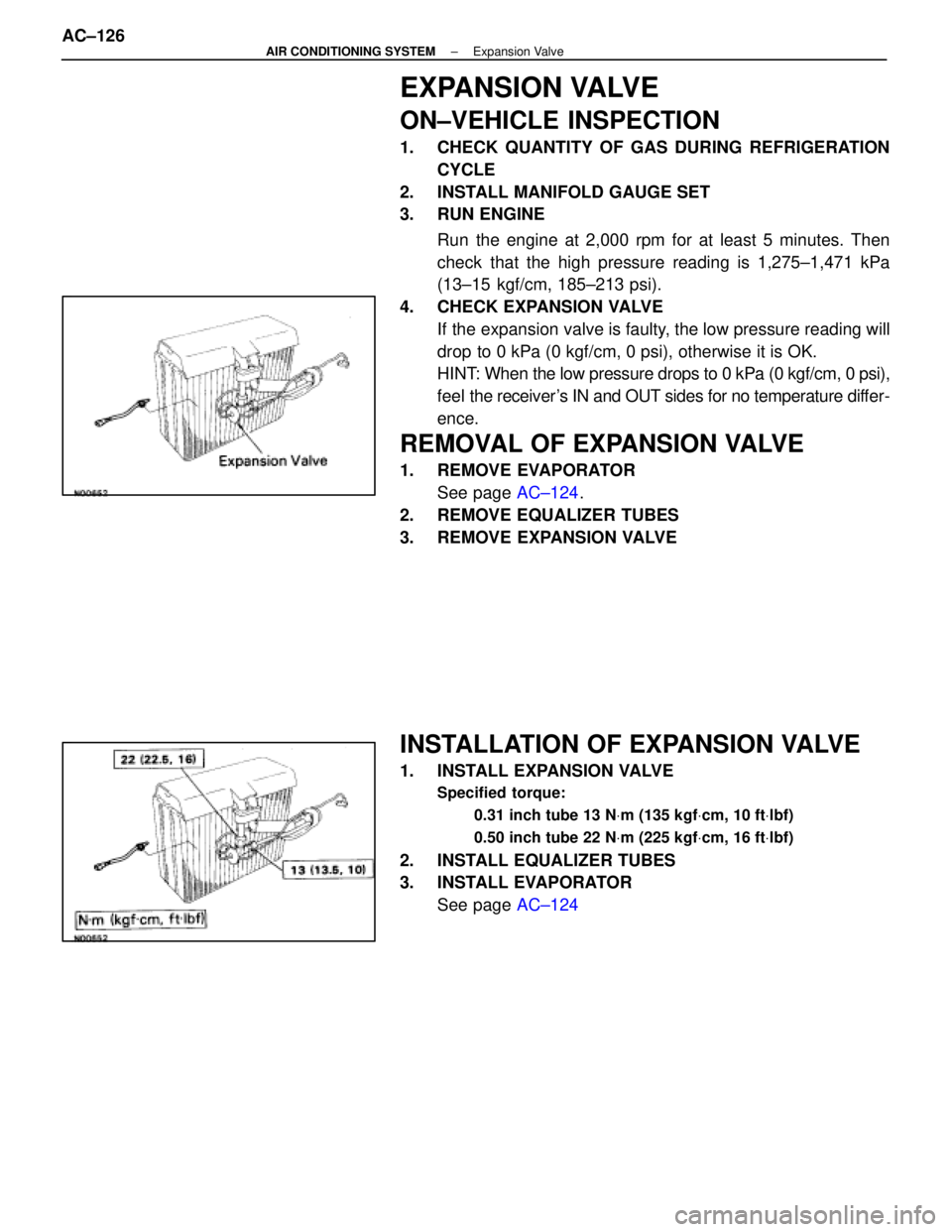

EXPANSION VALVE

ON±VEHICLE INSPECTION

1. CHECK QUANTITY OF GAS DURING REFRIGERATIONCYCLE

2. INSTALL MANIFOLD GAUGE SET

3. RUN ENGINE

Run the engine at 2,000 rpm for at least 5 minutes. Then

check that the high pressure reading is 1,275±1,471 kPa

(13±15 kgf/cm, 185±213 psi).

4. CHECK EXPANSION VALVE If the expansion valve is faulty, the low pressure reading will

drop to 0 kPa (0 kgf/cm, 0 psi), otherwise it is OK.

HINT: When the low pressure drops to 0 kPa (0 kgf/cm, 0 psi),

feel the receiver's IN and OUT sides for no temperature differ-

ence.

REMOVAL OF EXPANSION VALVE

1. REMOVE EVAPORATOR See page AC±124.

2. REMOVE EQUALIZER TUBES

3. REMOVE EXPANSION VALVE

INSTALLATION OF EXPANSION VALVE

1. INSTALL EXPANSION VALVE

Specified torque:

0.31 inch tube 13 N Vm (135 kgf Vcm, 10 ft Vlbf)

0.50 inch tube 22 N Vm (225 kgf Vcm, 16 ft Vlbf)

2. INSTALL EQUALIZER TUBES

3. INSTALL EVAPORATOR

See page AC±124

AC±126

±

AIR CONDITIONING SYSTEM Expansion Valve

WhereEverybodyKnowsYourName

Page 172 of 4087

REVOLUTION DETECTING SENSOR

INSPECTION OF REVOLUTION

DETECTING SENSOR

See page AC±55

REMOVAL OF REVOLUTION DETECTING

SENSOR

1. REMOVE COMPRESSOR

See page AC±111

2. REMOVE SENSOR Remove the two bolts and the sensor.

INSTALLATION OF REVOLUTION

DETECTING SENSOR

1. INSTALL SENSORUsing a torque wrench, tighten the bolts.

Specified Torque: 6 N Vm (60 kgf Vcm, 4 ft Vlbf)

2. INSTALL COMPRESSOR

See page AC±117

±

AIR CONDITIONING SYSTEM Revolution Detecting SensorAC±135

WhereEverybodyKnowsYourName

Page 174 of 4087

INSTALLATION OF PRESSURE SWITCH

1. INSTALL PRESSURE SWITCH

(a) Install the pressure switch to the liquid tube.

Specified torque: 10 NVm (100 kgf Vcm, 7 ft Vlbf)

HINT: Lock the switch mount on the tube with an open end

wrench, being careful not to deform the tube, and install the

switch.

(b) Connect the connector.

2. EVACUATE AIR IN REFRIGERATION SYSTEM AND CHARGE WITH REFRIGERANT

See page AC±17

Specified amount: 950 + 50 g (33.44 + 1.76 oz)

3. INSPECTION FOR LEAKAGE OF REFRIGERANT

Using a gas lead tester, check for leakage of refrigerant from

the pressure switch mount.

4. INSPECT A/C OPERATION

POWER TRANSISTOR

REMOVAL OF POWER TRANSISTOR

1. REMOVE GLOVE BOX

2. REMOVE POWER TRANSISTOR

(a) Disconnect connectors.

(b) Remove the two screws and the power transistor.

INSPECTION OF POWER TRANSISTOR

See page AC±79

INSTALLATION OF POWER

TRANSISTOR

1. INSTALL POWER TRANSISTOR

(a) Install power transistor with two screws.

(b) Connect connectors.

2. INSTALL GLOVE BOX

See page BO±112

±

AIR CONDITIONING SYSTEM Pressure Switch, Power TransistorAC±137

WhereEverybodyKnowsYourName