check engine LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1786 of 4087

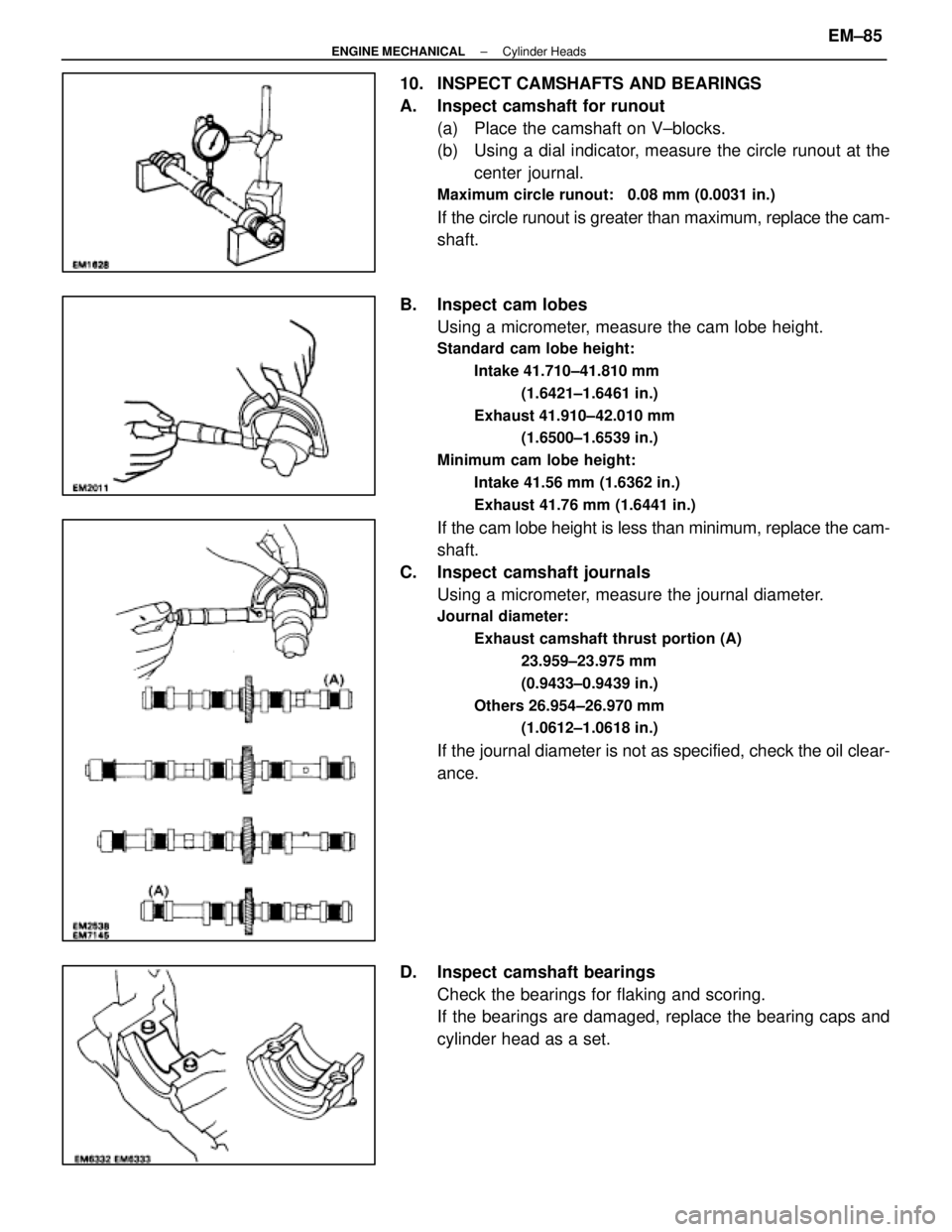

10. INSPECT CAMSHAFTS AND BEARINGS

A. Inspect camshaft for runout(a) Place the camshaft on V±blocks.

(b) Using a dial indicator, measure the circle runout at thecenter journal.

Maximum circle runout: 0.08 mm (0.0031 in.)

If the circle runout is greater than maximum, replace the cam-

shaft.

B. Inspect cam lobes Using a micrometer, measure the cam lobe height.

Standard cam lobe height:

Intake 41.710±41.810 mm (1.6421±1.6461 in.)

Exhaust 41.910±42.010 mm (1.6500±1.6539 in.)

Minimum cam lobe height: Intake 41.56 mm (1.6362 in.)

Exhaust 41.76 mm (1.6441 in.)

If the cam lobe height is less than minimum, replace the cam-

shaft.

C. Inspect camshaft journals Using a micrometer, measure the journal diameter.

Journal diameter:

Exhaust camshaft thrust portion (A) 23.959±23.975 mm

(0.9433±0.9439 in.)

Others 26.954±26.970 mm (1.0612±1.0618 in.)

If the journal diameter is not as specified, check the oil clear-

ance.

D. Inspect camshaft bearings Check the bearings for flaking and scoring.

If the bearings are damaged, replace the bearing caps and

cylinder head as a set.

±

ENGINE MECHANICAL Cylinder HeadsEM±85

WhereEverybodyKnowsYourName

Page 1791 of 4087

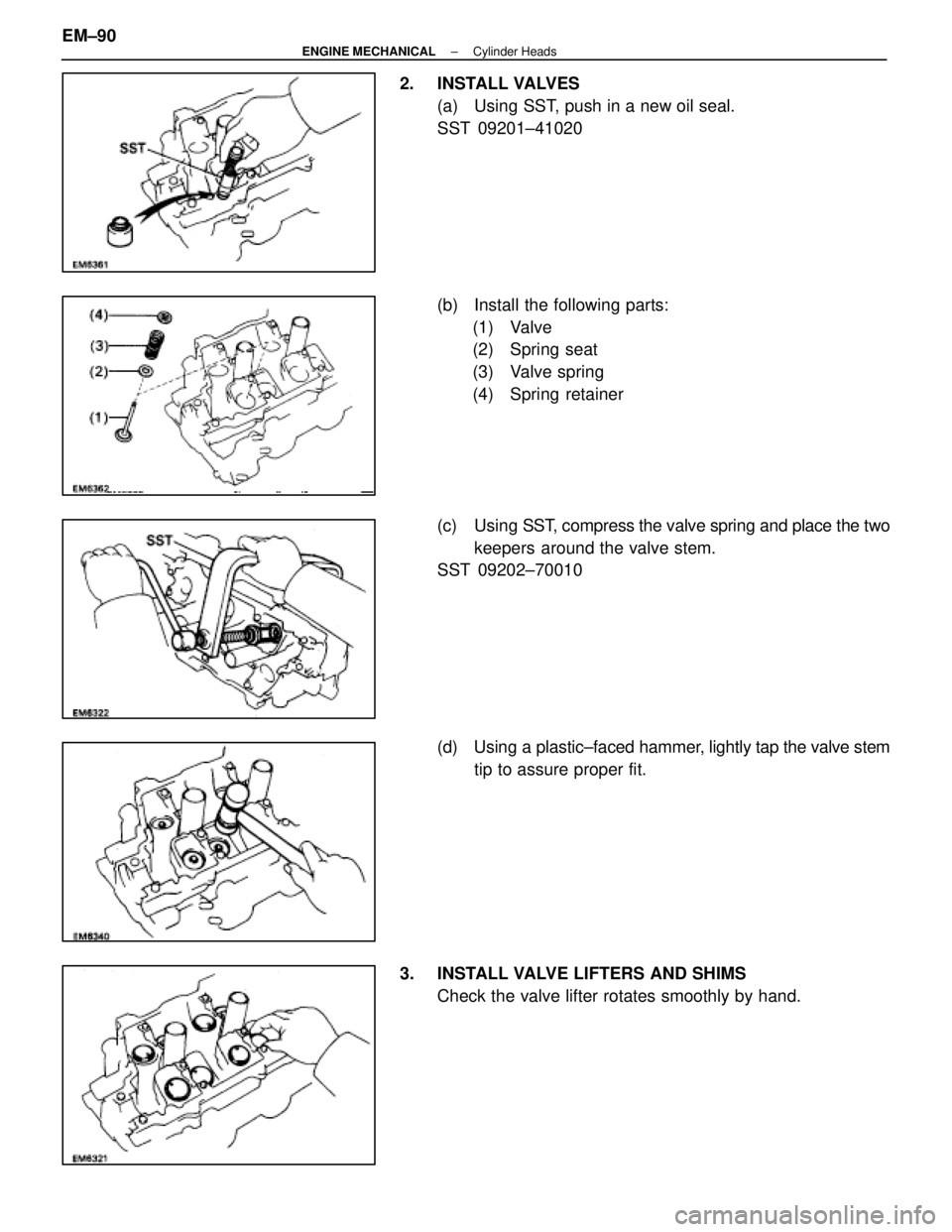

2. INSTALL VALVES(a) Using SST, push in a new oil seal.

SST 09201±41020

(b) Install the following parts:(1) Valve

(2) Spring seat

(3) Valve spring

(4) Spring retainer

(c) Using SST, compress the valve spring and place the two

keepers around the valve stem.

SST 09202±70010

(d) Using a plastic±faced hammer, lightly tap the valve stem

tip to assure proper fit.

3. INSTALL VALVE LIFTERS AND SHIMS Check the valve lifter rotates smoothly by hand.

EM±90

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 1794 of 4087

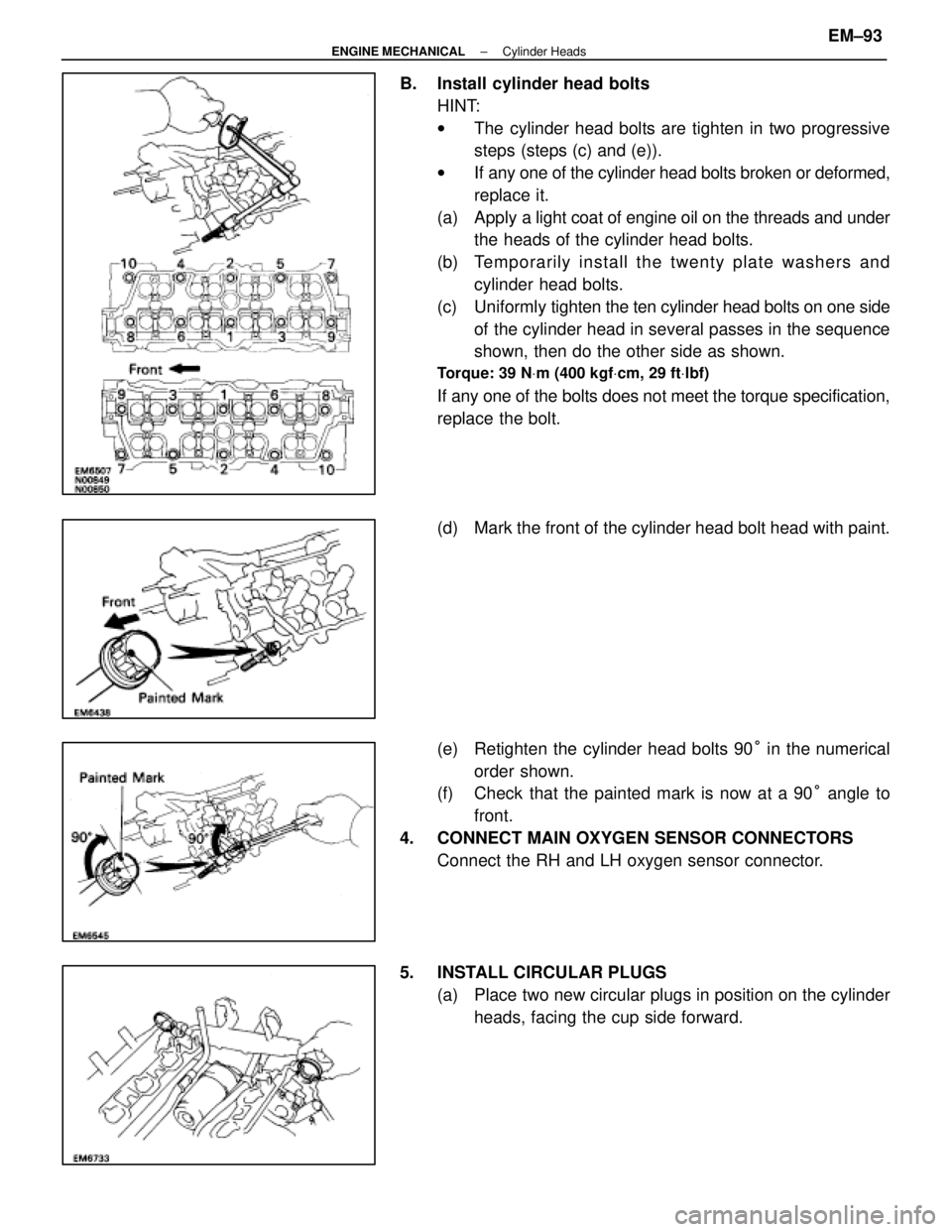

B. Install cylinder head boltsHINT:

wThe cylinder head bolts are tighten in two progressive

steps (steps (c) and (e)).

w If any one of the cylinder head bolts broken or deformed,

replace it.

(a) Apply a light coat of engine oil on the threads and under

the heads of the cylinder head bolts.

(b) Te mp o ra rily in sta ll th e twe n ty pla te wa sh e rs an d cylinder head bolts.

(c) Uniformly tighten the ten cylinder head bolts on one side

of the cylinder head in several passes in the sequence

shown, then do the other side as shown.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

If any one of the bolts does not meet the torque specification,

replace the bolt.

(d) Mark the front of the cylinder head bolt head with paint.

(e) Retighten the cylinder head bolts 90 ° in the numerical

order shown.

(f) Check that the painted mark is now at a 90 ° angle to

front.

4. CONNECT MAIN OXYGEN SENSOR CONNECTORS Connect the RH and LH oxygen sensor connector.

5. INSTALL CIRCULAR PLUGS (a) Place two new circular plugs in position on the cylinderheads, facing the cup side forward.

±

ENGINE MECHANICAL Cylinder HeadsEM±93

WhereEverybodyKnowsYourName

Page 1798 of 4087

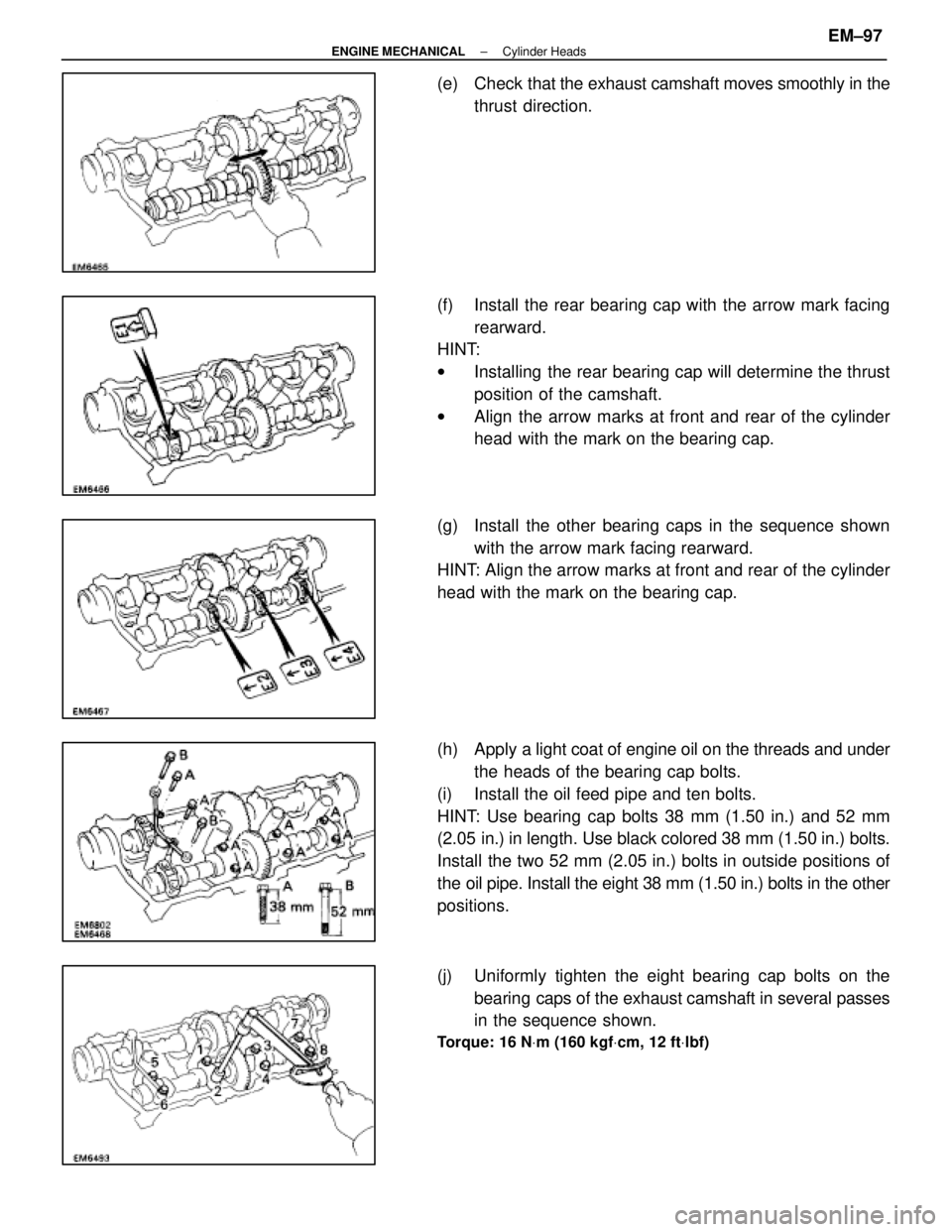

(e) Check that the exhaust camshaft moves smoothly in the

thrust direction.

(f) Install the rear bearing cap with the arrow mark facing rearward.

HINT:

w Installing the rear bearing cap will determine the thrust

position of the camshaft.

w Align the arrow marks at front and rear of the cylinder

head with the mark on the bearing cap.

(g) Install the other bearing caps in the sequence shown with the arrow mark facing rearward.

HINT: Align the arrow marks at front and rear of the cylinder

head with the mark on the bearing cap.

(h) Apply a light coat of engine oil on the threads and under

the heads of the bearing cap bolts.

(i) Install the oil feed pipe and ten bolts.

HINT: Use bearing cap bolts 38 mm (1.50 in.) and 52 mm

(2.05 in.) in length. Use black colored 38 mm (1.50 in.) bolts.

Install the two 52 mm (2.05 in.) bolts in outside positions of

the oil pipe. Install the eight 38 mm (1.50 in.) bolts in the other

positions.

(j) Uniformly tighten the eight bearing cap bolts on the bearing caps of the exhaust camshaft in several passes

in the sequence shown.

Torque: 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

±

ENGINE MECHANICAL Cylinder HeadsEM±97

WhereEverybodyKnowsYourName

Page 1801 of 4087

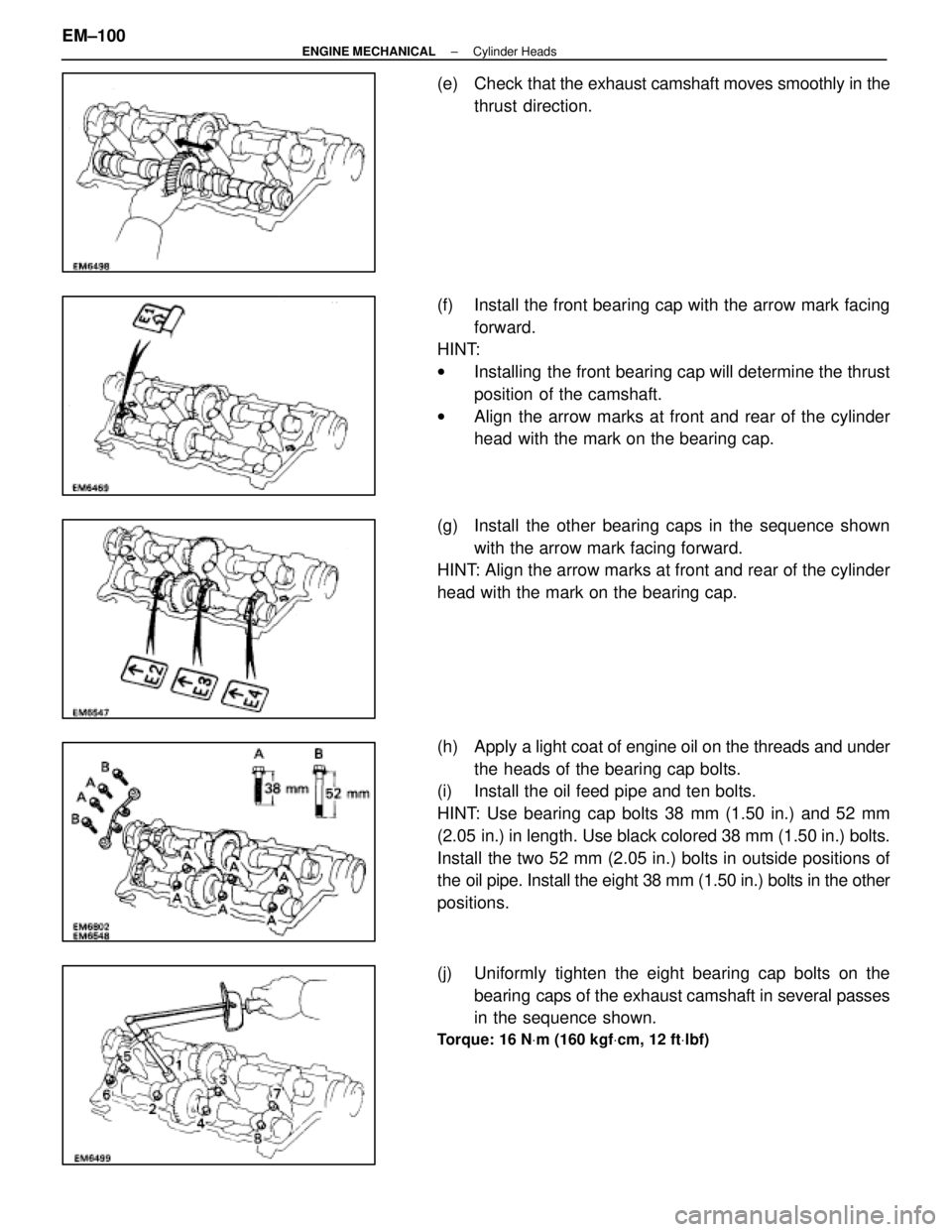

(e) Check that the exhaust camshaft moves smoothly in the

thrust direction.

(f) Install the front bearing cap with the arrow mark facing forward.

HINT:

w Installing the front bearing cap will determine the thrust

position of the camshaft.

w Align the arrow marks at front and rear of the cylinder

head with the mark on the bearing cap.

(g) Install the other bearing caps in the sequence shown with the arrow mark facing forward.

HINT: Align the arrow marks at front and rear of the cylinder

head with the mark on the bearing cap.

(h) Apply a light coat of engine oil on the threads and under

the heads of the bearing cap bolts.

(i) Install the oil feed pipe and ten bolts.

HINT: Use bearing cap bolts 38 mm (1.50 in.) and 52 mm

(2.05 in.) in length. Use black colored 38 mm (1.50 in.) bolts.

Install the two 52 mm (2.05 in.) bolts in outside positions of

the oil pipe. Install the eight 38 mm (1.50 in.) bolts in the other

positions.

(j) Uniformly tighten the eight bearing cap bolts on the

bearing caps of the exhaust camshaft in several passes

in the sequence shown.

Torque: 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

EM±100±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 1802 of 4087

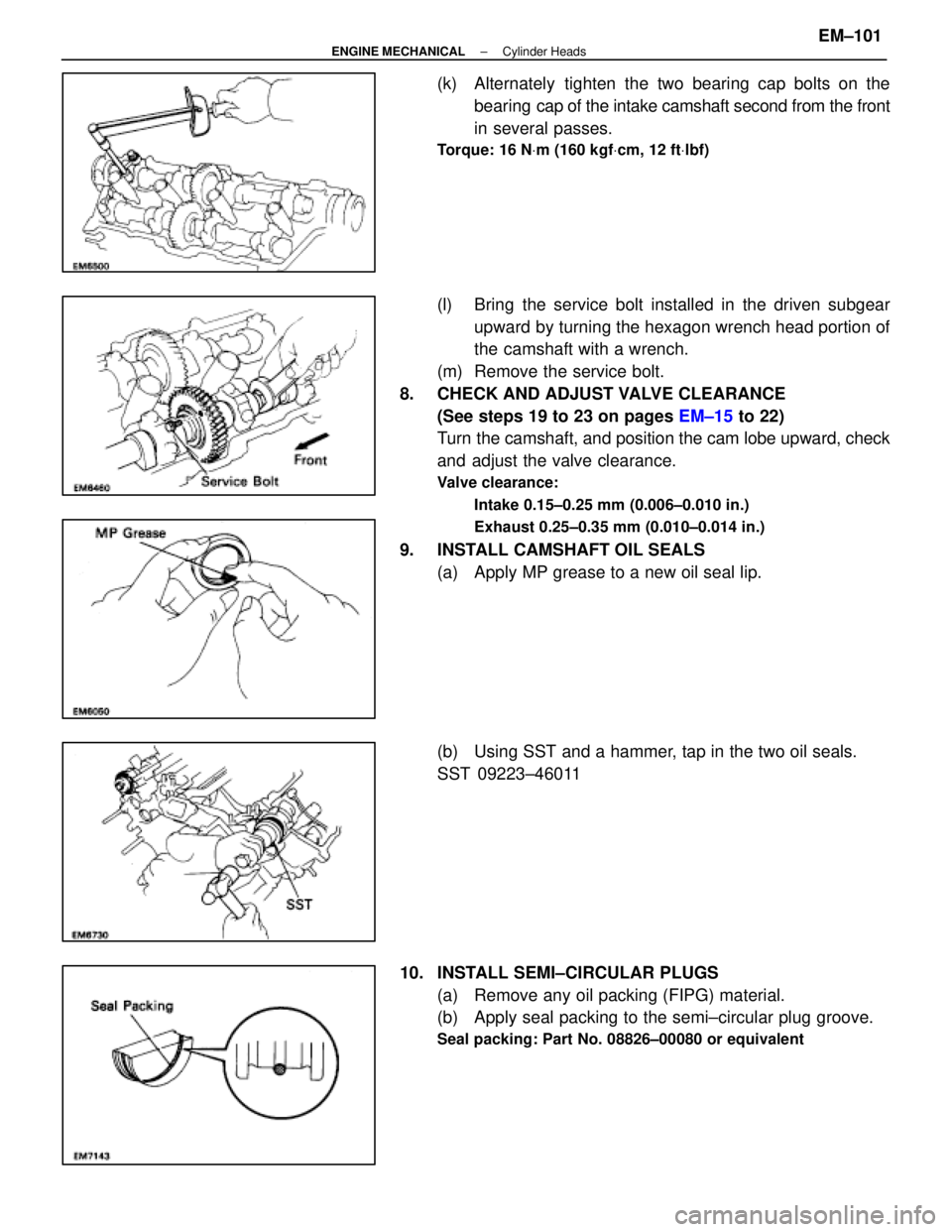

(k) Alternately tighten the two bearing cap bolts on thebearing cap of the intake camshaft second from the front

in several passes.

Torque: 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

(l) Bring the service bolt installed in the driven subgear

upward by turning the hexagon wrench head portion of

the camshaft with a wrench.

(m) Remove the service bolt.

8. CHECK AND ADJUST VALVE CLEARANCE (See steps 19 to 23 on pages EM±15 to 22)

Turn the camshaft, and position the cam lobe upward, check

and adjust the valve clearance.

Valve clearance:

Intake 0.15±0.25 mm (0.006±0.010 in.)

Exhaust 0.25±0.35 mm (0.010±0.014 in.)

9. INSTALL CAMSHAFT OIL SEALS(a) Apply MP grease to a new oil seal lip.

(b) Using SST and a hammer, tap in the two oil seals.

SST 09223±46011

10. INSTALL SEMI±CIRCULAR PLUGS (a) Remove any oil packing (FIPG) material.

(b) Apply seal packing to the semi±circular plug groove.

Seal packing: Part No. 08826±00080 or equivalent

±

ENGINE MECHANICAL Cylinder HeadsEM±101

WhereEverybodyKnowsYourName

Page 1806 of 4087

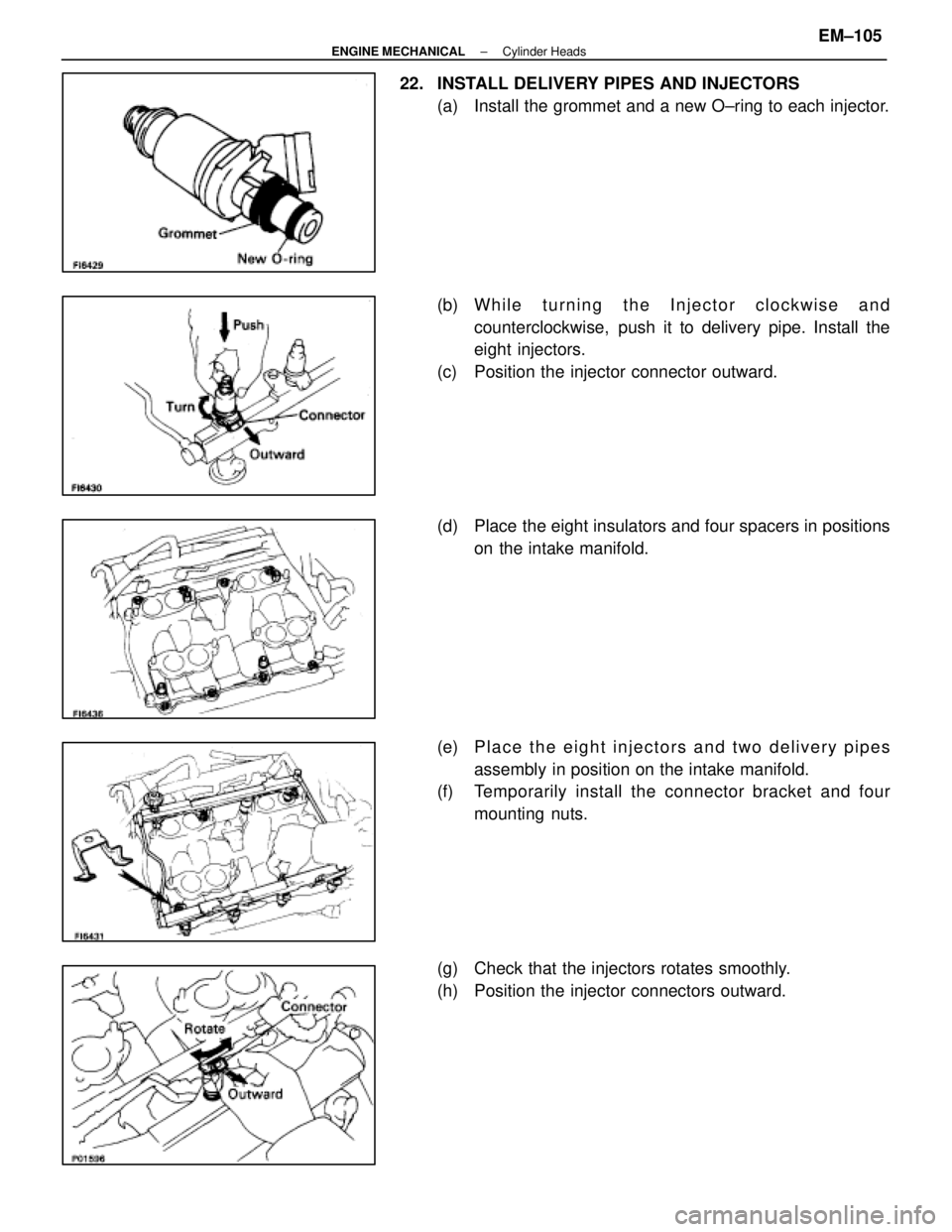

22. INSTALL DELIVERY PIPES AND INJECTORS(a) Install the grommet and a new O±ring to each injector.

(b) W h i l e t u r n i n g t h e I n j e c t o r c l o c k w i s e a n dcounterclockwise, push it to delivery pipe. Install the

eight injectors.

(c) Position the injector connector outward.

(d) Place the eight insulators and four spacers in positions on the intake manifold.

(e) P l a c e t h e e i g h t i n j e c t o r s a n d t w o d e l i v e r y p i p e s assembly in position on the intake manifold.

(f) Temporarily install the c onnector bracket and four

mounting nuts.

(g) Check that the injectors rotates smoothly.

(h) Position the injector connectors outward.

±

ENGINE MECHANICAL Cylinder HeadsEM±105

WhereEverybodyKnowsYourName

Page 1809 of 4087

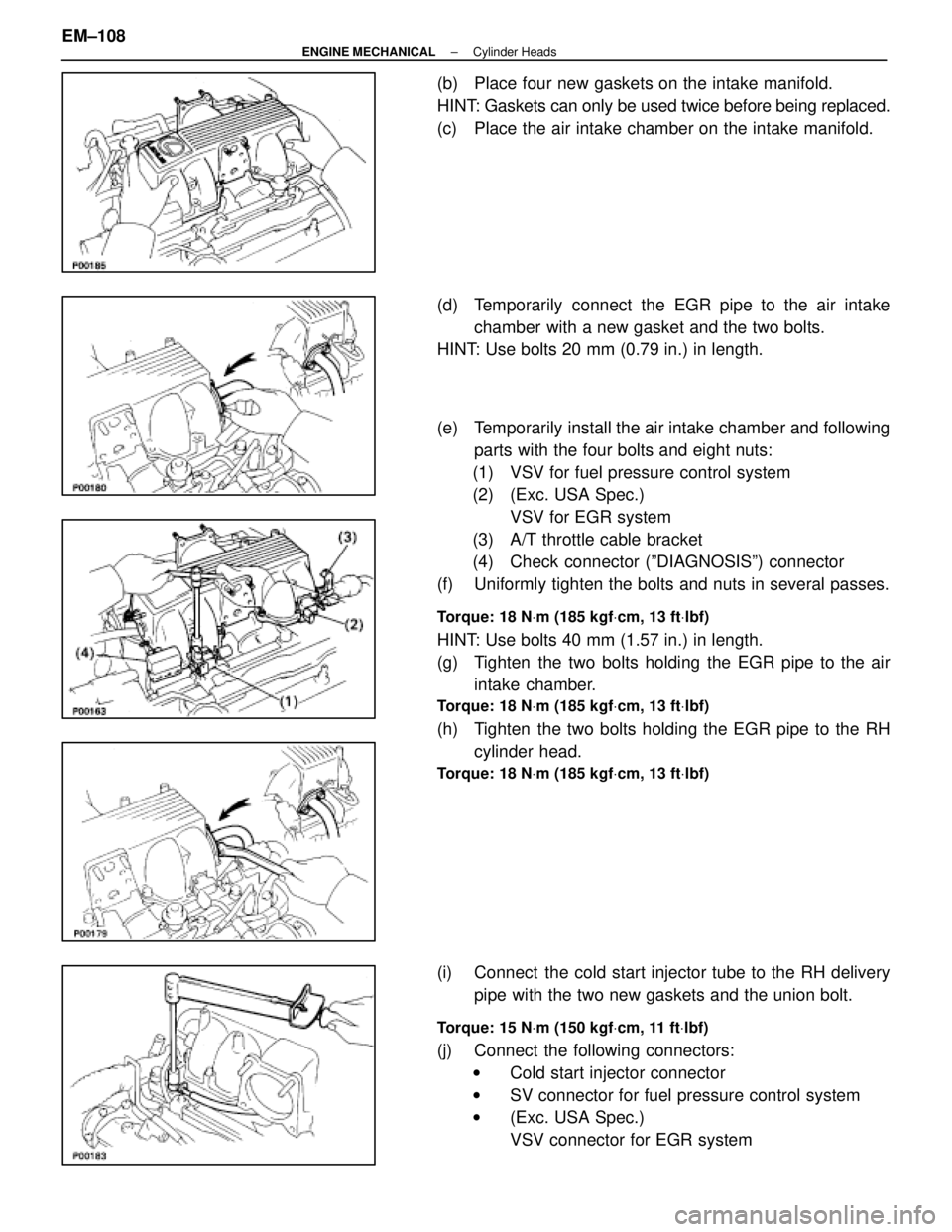

(b) Place four new gaskets on the intake manifold.

HINT: Gaskets can only be used twice before being replaced.

(c) Place the air intake chamber on the intake manifold.

(d) Temporarily connect the EGR pipe to the air intakechamber with a new gasket and the two bolts.

HINT: Use bolts 20 mm (0.79 in.) in length.

(e) Temporarily install the air intake chamber and following

parts with the four bolts and eight nuts:

(1) VSV for fuel pressure control system

(2) (Exc. USA Spec.) VSV for EGR system

(3) A/T throttle cable bracket

(4) Check connector (ºDIAGNOSISº) connector

(f) Uniformly tighten the bolts and nuts in several passes.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT: Use bolts 40 mm (1.57 in.) in length.

(g) Tighten the two bolts holding the EGR pipe to the air

intake chamber.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

(h) Tighten the two bolts holding the EGR pipe to the RH

cylinder head.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

(i) Connect the cold start injector tube to the RH delivery

pipe with the two new gaskets and the union bolt.

Torque: 15 N Vm (150 kgf Vcm, 11 ft Vlbf)

(j) Connect the following connectors:

w Cold start injector connector

w SV connector for fuel pressure control system

w (Exc. USA Spec.)

VSV connector for EGR system

EM±108

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 1816 of 4087

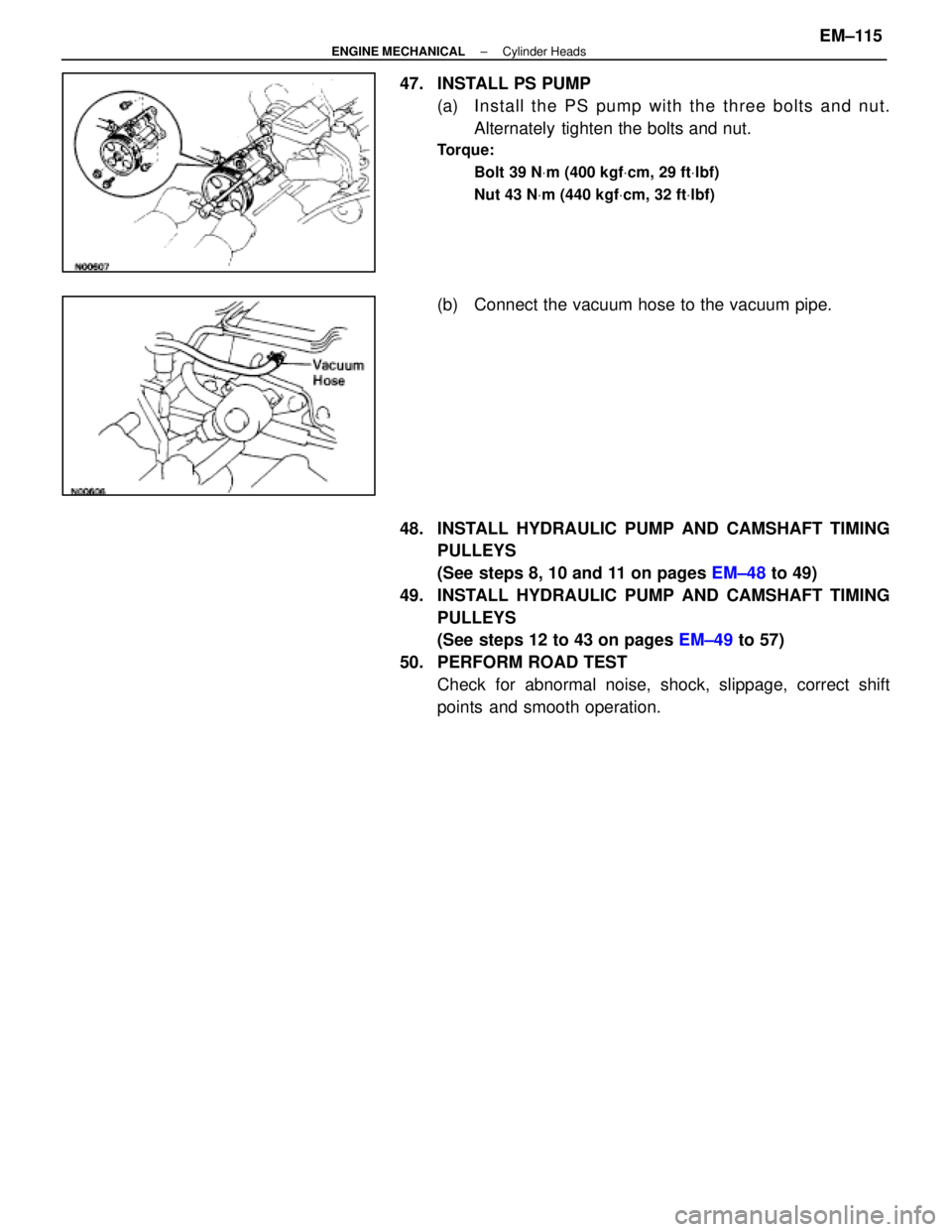

47. INSTALL PS PUMP(a) In sta ll th e PS pu mp with th e th re e bo lts an d nu t.Alternately tighten the bolts and nut.

Torque:

Bolt 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

Nut 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

(b) Connect the vacuum hose to the vacuum pipe.

48. INSTALL HYDRAULIC PUMP AND CAMSHAFT TIMING PULLEYS

(See steps 8, 10 and 11 on pages EM±48 to 49)

49. INSTALL HYDRAULIC PUMP AND CAMSHAFT TIMING PULLEYS

(See steps 12 to 43 on pages EM±49 to 57)

50. PERFORM ROAD TEST Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

±

ENGINE MECHANICAL Cylinder HeadsEM±115

WhereEverybodyKnowsYourName

Page 1822 of 4087

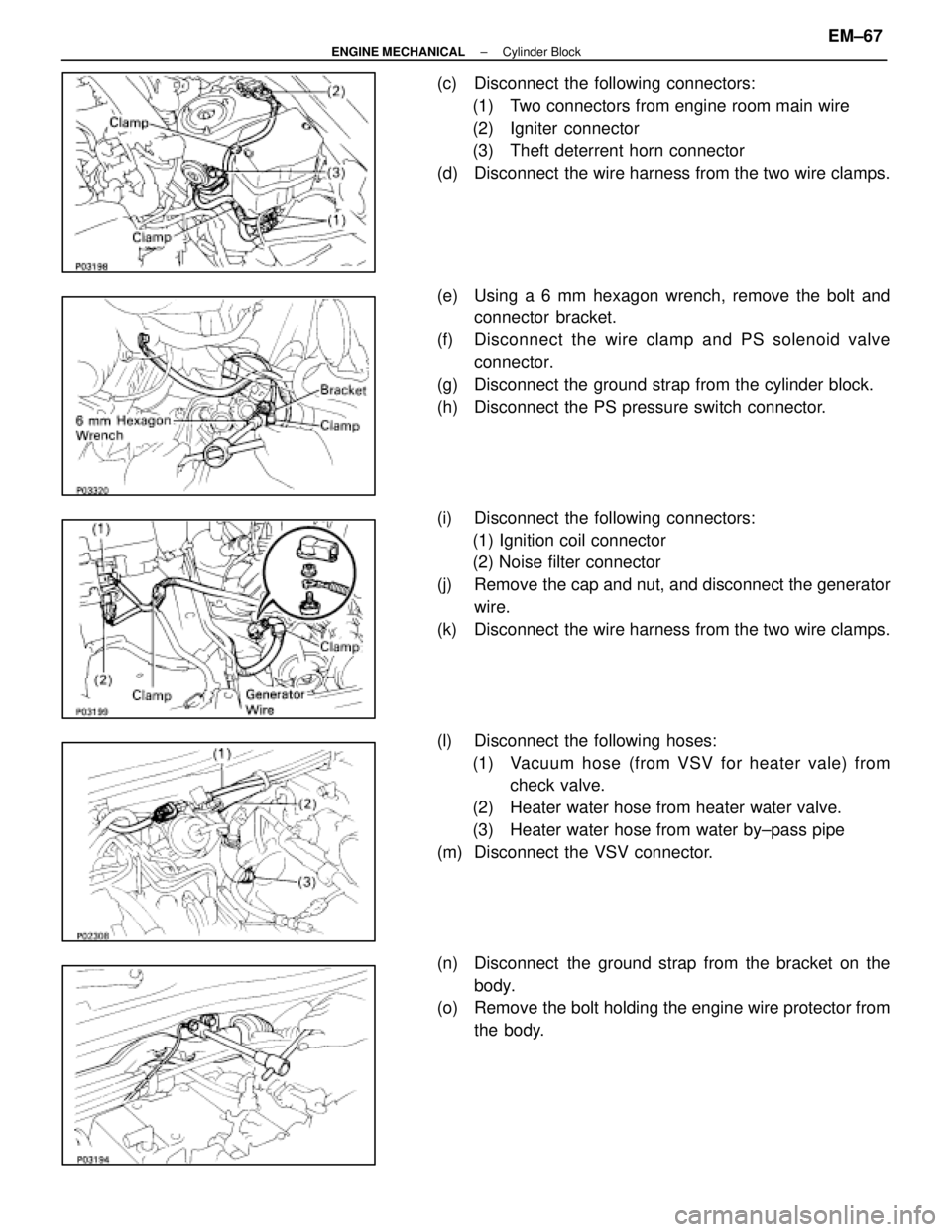

(c) Disconnect the following connectors:(1) Two connectors from engine room main wire

(2) Igniter connector

(3) Theft deterrent horn connector

(d) Disconnect the wire harness from the two wire clamps.

(e) Using a 6 mm hexagon wrench, remove the bolt and connector bracket.

(f) Disc onnect the wire clamp and PS solenoid valve

connector.

(g) Disconnect the ground strap from the cylinder block.

(h) Disconnect the PS pressure switch connector.

(i) Disconnect the following connectors: (1) Ignition coil connector

(2) Noise filter connector

(j) Remove the cap and nut, and disconnect the generator wire.

(k) Disconnect the wire harness from the two wire clamps.

(l) Disconnect the following hoses: (1) Vacuum hose (from VSV for heater vale) from check valve.

(2) Heater water hose from heater water valve.

(3) Heater water hose from water by±pass pipe

(m) Disconnect the VSV connector.

(n) Disconnect the ground strap from the bracket on the body.

(o) Remove the bolt holding the engine wire protector from

the body.

±

ENGINE MECHANICAL Cylinder BlockEM±67

WhereEverybodyKnowsYourName