LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2571 of 4087

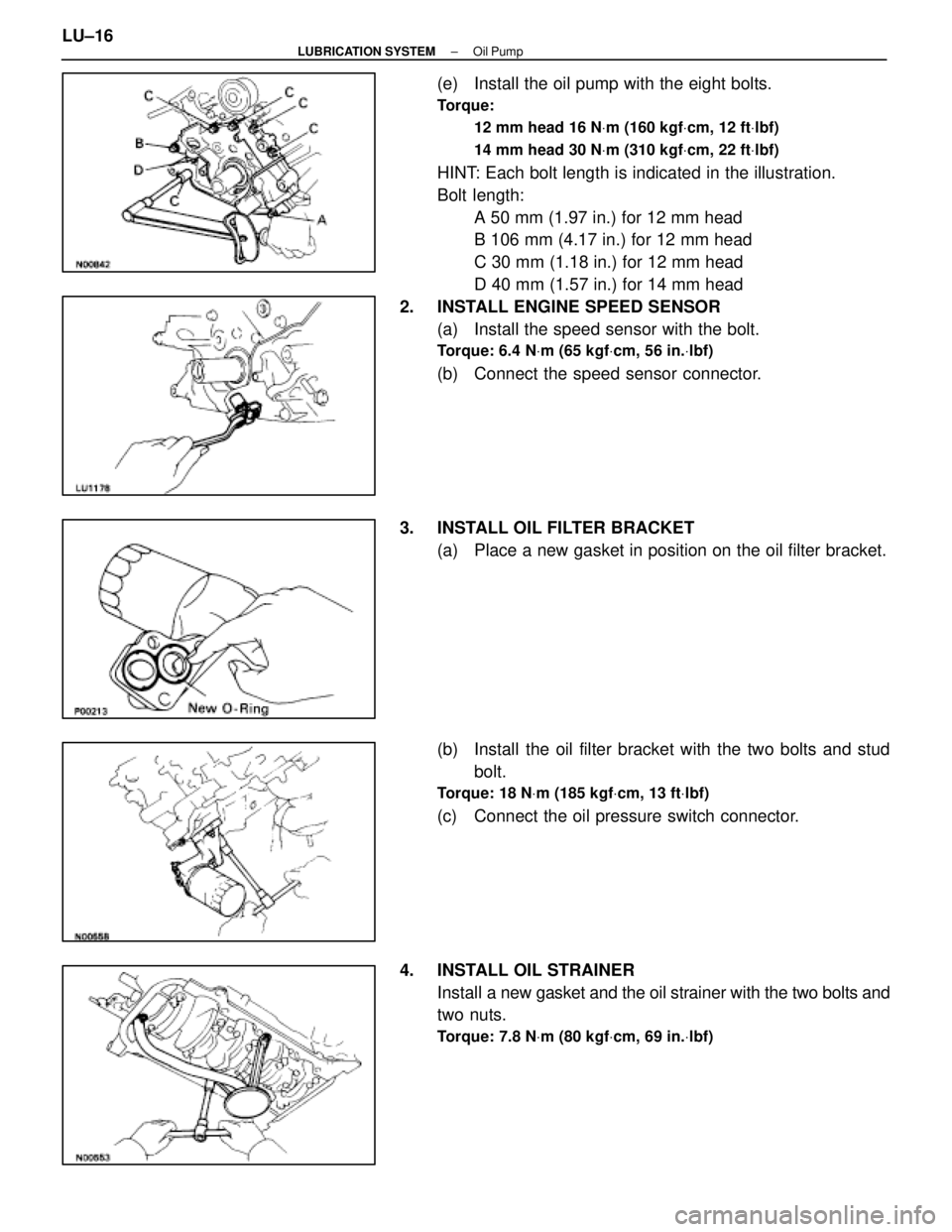

(e) Install the oil pump with the eight bolts.

Torque:12 mm head 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

14 mm head 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Each bolt length is indicated in the illustration.

Bolt length:

A 50 mm (1.97 in.) for 12 mm head

B 106 mm (4.17 in.) for 12 mm head

C 30 mm (1.18 in.) for 12 mm head

D 40 mm (1.57 in.) for 14 mm head

2. INSTALL ENGINE SPEED SENSOR (a) Install the speed sensor with the bolt.

Torque: 6.4 N Vm (65 kgf Vcm, 56 in. Vlbf)

(b) Connect the speed sensor connector.

3. INSTALL OIL FILTER BRACKET (a) Place a new gasket in position on the oil filter bracket.

(b) Install the oil filter bracket with the two bolts and studbolt.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

(c) Connect the oil pressure switch connector.

4. INSTALL OIL STRAINER Install a new gasket and the oil strainer with the two bolts and

two nuts.

Torque: 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

LU±16±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2572 of 4087

5. INSTALL NO.1 OIL PAN(a) Remove any old packing (FIPG) material and be carefulnot to drop any oil on the contact surfaces of the No.1

oil pan and cylinder block.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

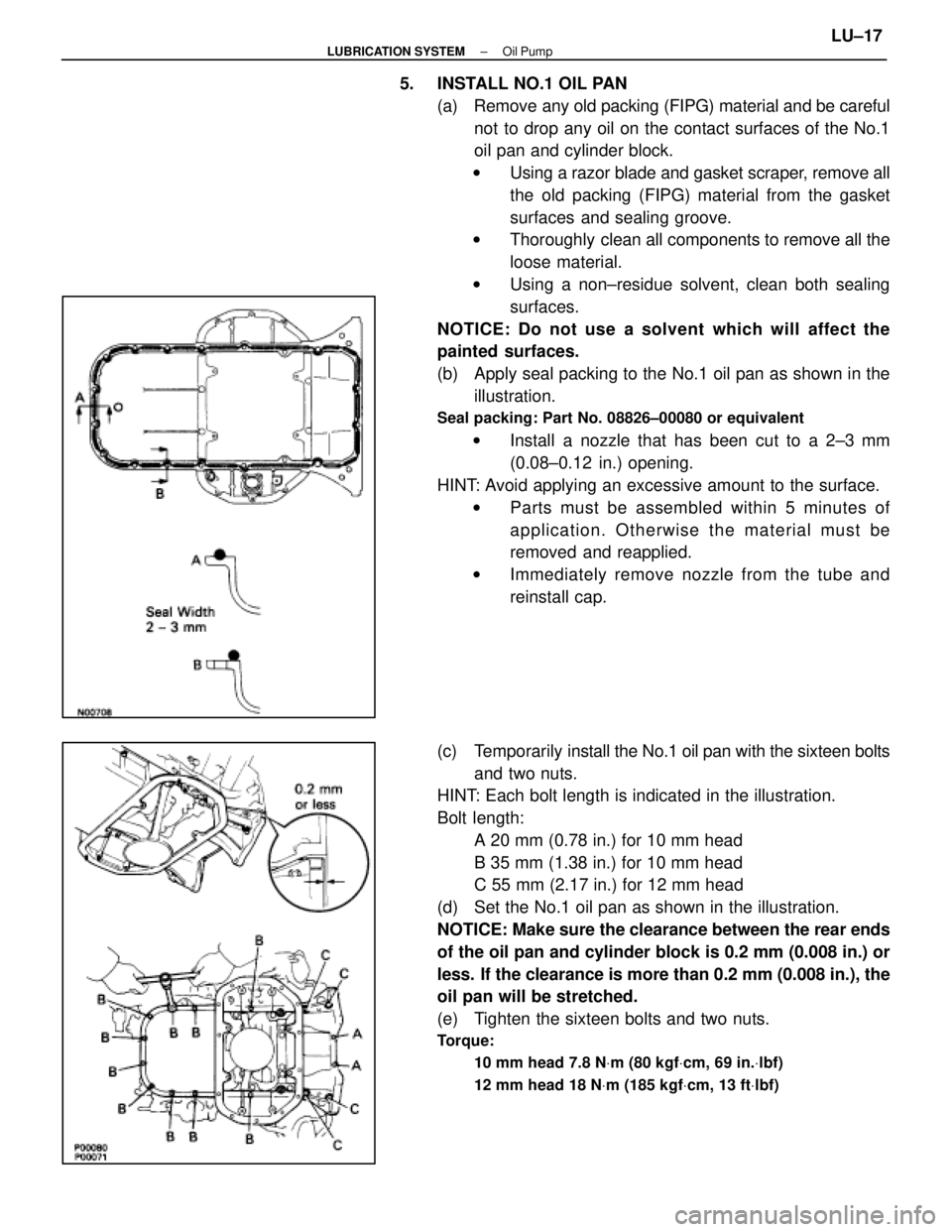

(b) Apply seal packing to the No.1 oil pan as shown in the illustration.

Seal packing: Part No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

HINT: Avoid applying an excessive amount to the surface. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Temporarily install the No.1 oil pan with the sixteen bolts

and two nuts.

HINT: Each bolt length is indicated in the illustration.

Bolt length:

A 20 mm (0.78 in.) for 10 mm head

B 35 mm (1.38 in.) for 10 mm head

C 55 mm (2.17 in.) for 12 mm head

(d) Set the No.1 oil pan as shown in the illustration.

NOTICE: Make sure the clearance between the rear ends

of the oil pan and cylinder block is 0.2 mm (0.008 in.) or

less. If the clearance is more than 0.2 mm (0.008 in.), the

oil pan will be stretched.

(e) Tighten the sixteen bolts and two nuts.

Torque:

10 mm head 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

12 mm head 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

±

LUBRICATION SYSTEM Oil PumpLU±17

WhereEverybodyKnowsYourName

Page 2573 of 4087

6. INSTALL OIL PAN BAFFLE PLATEInstall the baffle plate with the six bolts and two nuts.

Torque: 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

HINT: Use bolts 14 mm (0.55 in.) in length.

7. INSTALL NO.2 OIL PAN (a) Remove any old packing (FIPG) material and be carefulnot to drop any oil on the contact surfaces of the No.1

and No.2 oil pans.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

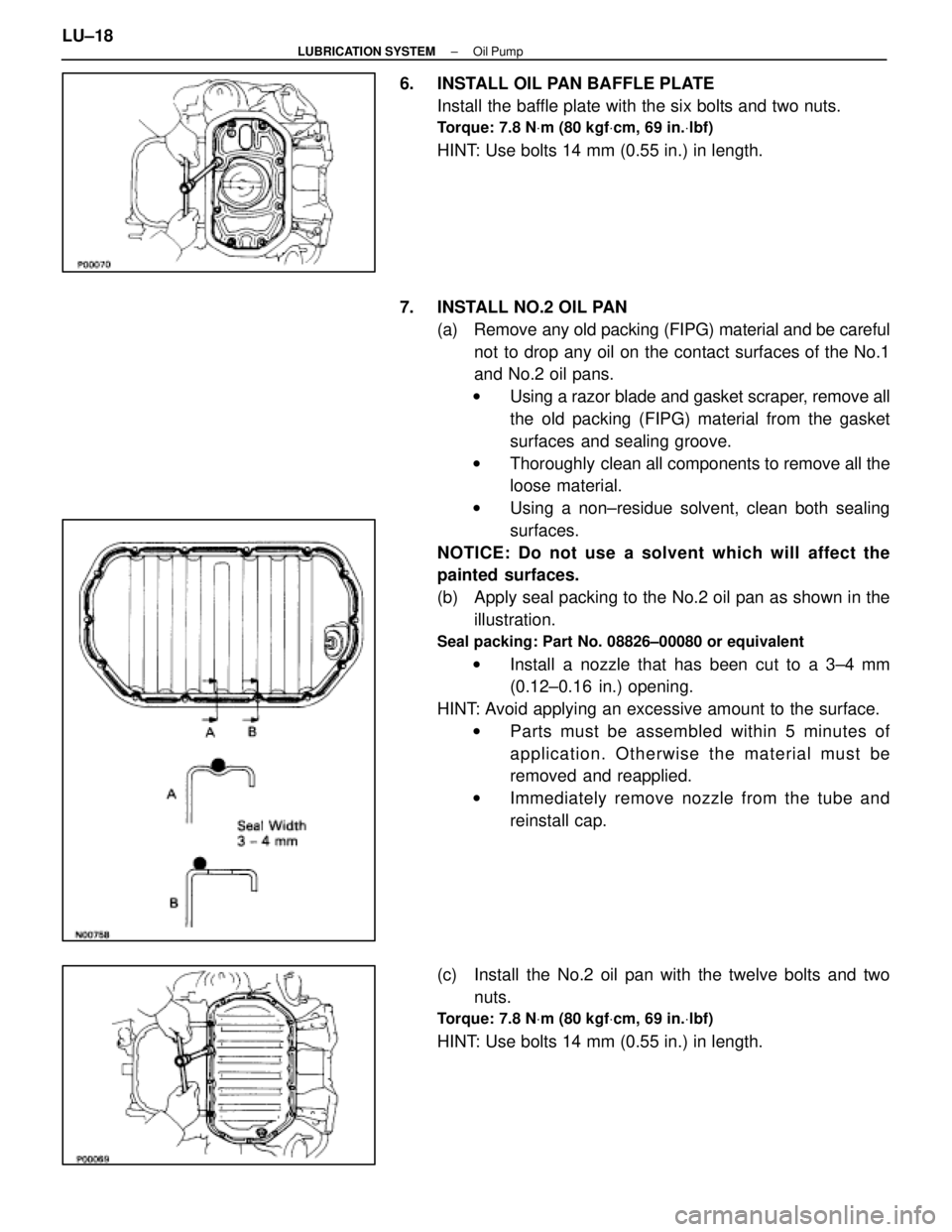

(b) Apply seal packing to the No.2 oil pan as shown in the illustration.

Seal packing: Part No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 3±4 mm

(0.12±0.16 in.) opening.

HINT: Avoid applying an excessive amount to the surface. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Install the No.2 oil pan with the twelve bolts and two nuts.

Torque: 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

HINT: Use bolts 14 mm (0.55 in.) in length.

LU±18

±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2574 of 4087

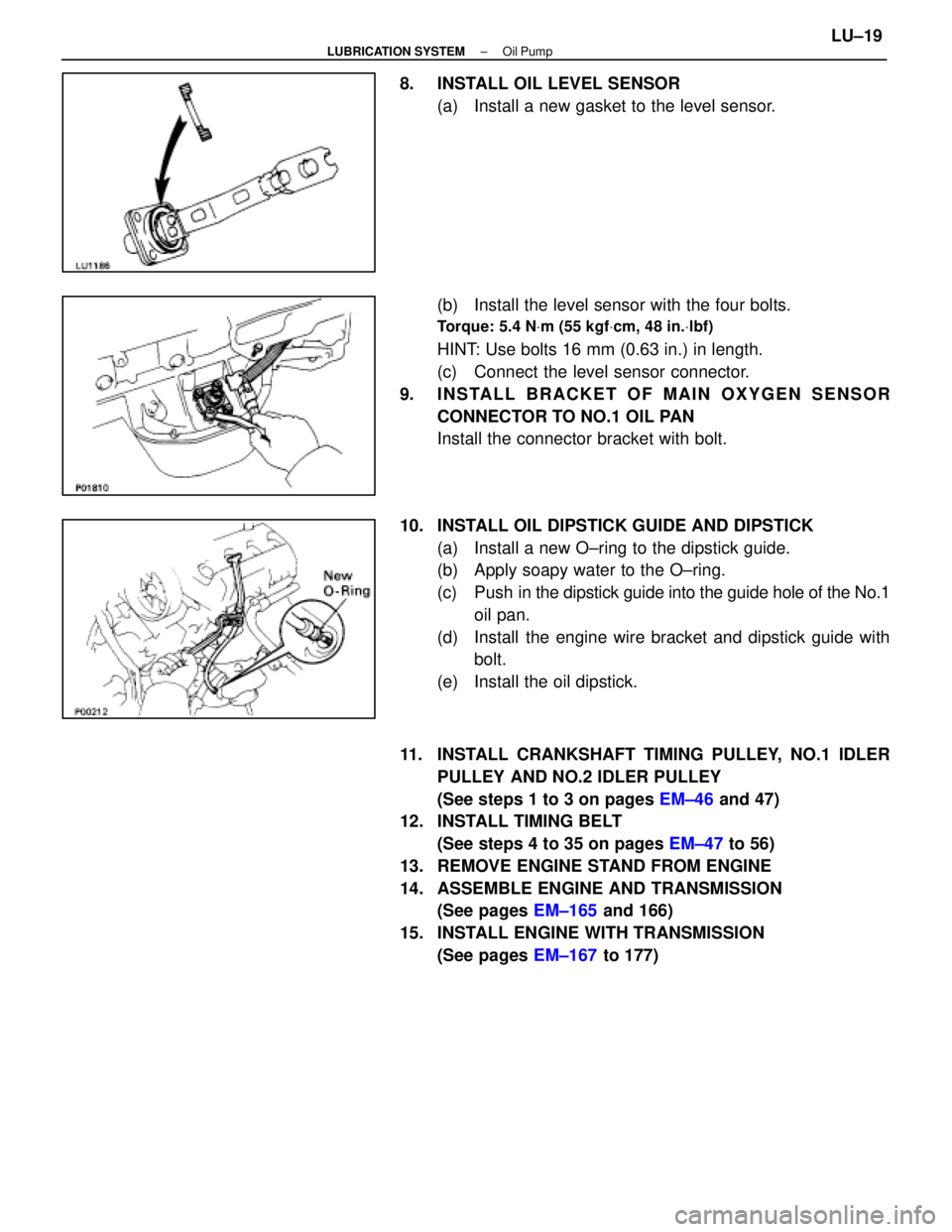

8. INSTALL OIL LEVEL SENSOR(a) Install a new gasket to the level sensor.

(b) Install the level sensor with the four bolts.

Torque: 5.4 N Vm (55 kgf Vcm, 48 in. Vlbf)

HINT: Use bolts 16 mm (0.63 in.) in length.

(c) Connect the level sensor connector.

9. INSTALL BRACKET OF MAIN OXYGEN SENSOR CONNECTOR TO NO.1 OIL PAN

Install the connector bracket with bolt.

10. INSTALL OIL DIPSTICK GUIDE AND DIPSTICK (a) Install a new O±ring to the dipstick guide.

(b) Apply soapy water to the O±ring.

(c) Push in the dipstick guide into the guide hole of the No.1

oil pan.

(d) Install the engine wire bracket and dipstick guide with bolt.

(e) Install the oil dipstick.

11. INSTALL CRANKSHAFT TIMING PULLEY, NO.1 IDLER PULLEY AND NO.2 IDLER PULLEY

(See steps 1 to 3 on pages EM±46 and 47)

12. INSTALL TIMING BELT

(See steps 4 to 35 on pages EM±47 to 56)

13. REMOVE ENGINE STAND FROM ENGINE

14. ASSEMBLE ENGINE AND TRANSMISSION (See pages EM±165 and 166)

15. INSTALL ENGINE WITH TRANSMISSION (See pages EM±167 to 177)

±

LUBRICATION SYSTEM Oil PumpLU±19

WhereEverybodyKnowsYourName

Page 2575 of 4087

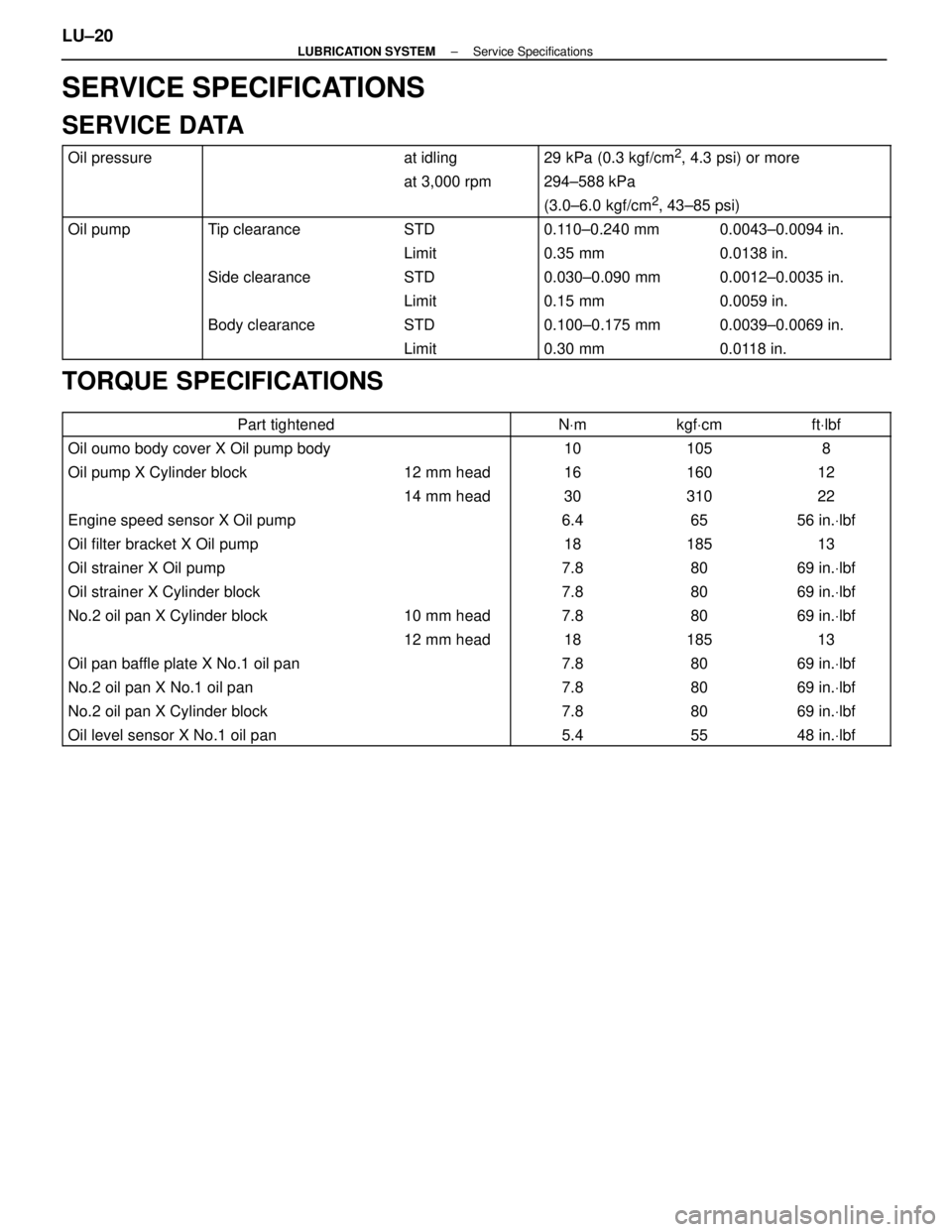

SERVICE SPECIFICATIONS

SERVICE DATA

Oil pressureat idling29 kPa (0.3 kgf/cm2, 4.3 psi) or more

at 3,000 rpm 294±588 kPa

(3.0±6.0 kgf/cm2, 43±85 psi)

Oil pumpTip clearanceSTD0.110±0.240 mm0.0043±0.0094 in.

Limit 0.35 mm0.0138 in.

Side clearanceSTD 0.030±0.090 mm0.0012±0.0035 in.

Limit 0.15 mm0.0059 in.

Body clearanceSTD 0.100±0.175 mm0.0039±0.0069 in.

Limit0.30 mm0.0118 in.

TORQUE SPECIFICATIONS

Part tightenedNVmkgf Vcmft Vlbf

Oil oumo body cover X Oil pump body101058

Oil pump X Cylinder block12 mm head 16160 12

14 mm head 30310 22

Engine speed sensor X Oil pump6.465 56 in. Vlbf

Oil filter bracket X Oil pump18185 13

Oil strainer X Oil pump7.880 69 in. Vlbf

Oil strainer X Cylinder block7.880 69 in. Vlbf

No.2 oil pan X Cylinder block10 mm head 7.880 69 in. Vlbf

12 mm head 18185 13

Oil pan baffle plate X No.1 oil pan7.880 69 in. Vlbf

No.2 oil pan X No.1 oil pan7.880 69 in. Vlbf

No.2 oil pan X Cylinder block7.880 69 in. Vlbf

Oil level sensor X No.1 oil pan5.45548 in. Vlbf

LU±20±

LUBRICATION SYSTEM Service Specifications

WhereEverybodyKnowsYourName

Page 2576 of 4087

STARTING SYSTEM

STARTING SYSTEM

NOTE: The specification descriptions ºUSA Spec.º and

º Exc. USA Spec. º used in this section indicate the following

specifications.

USA Spec .: USA (50 States) Specifications

Exc. USA Spec .: USA (except California) and Canadian

Specifications.

ST±1

WhereEverybodyKnowsYourName

Page 2577 of 4087

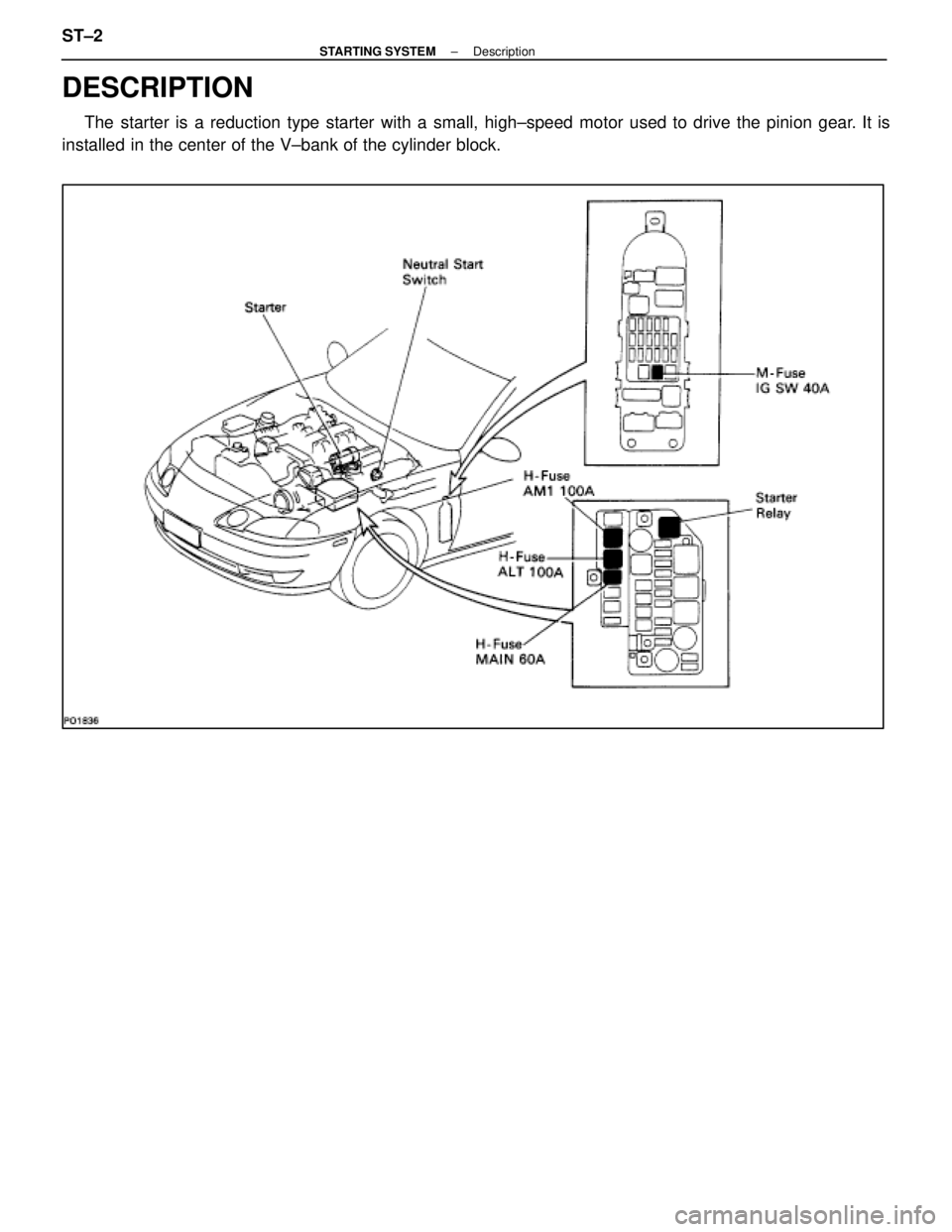

DESCRIPTION

The starter is a reduction type starter with a small, high±speed motor u\

sed to drive the pinion gear. It is

installed in the center of the V±bank of the cylinder block. ST±2

±

STARTING SYSTEM Description

WhereEverybodyKnowsYourName

Page 2578 of 4087

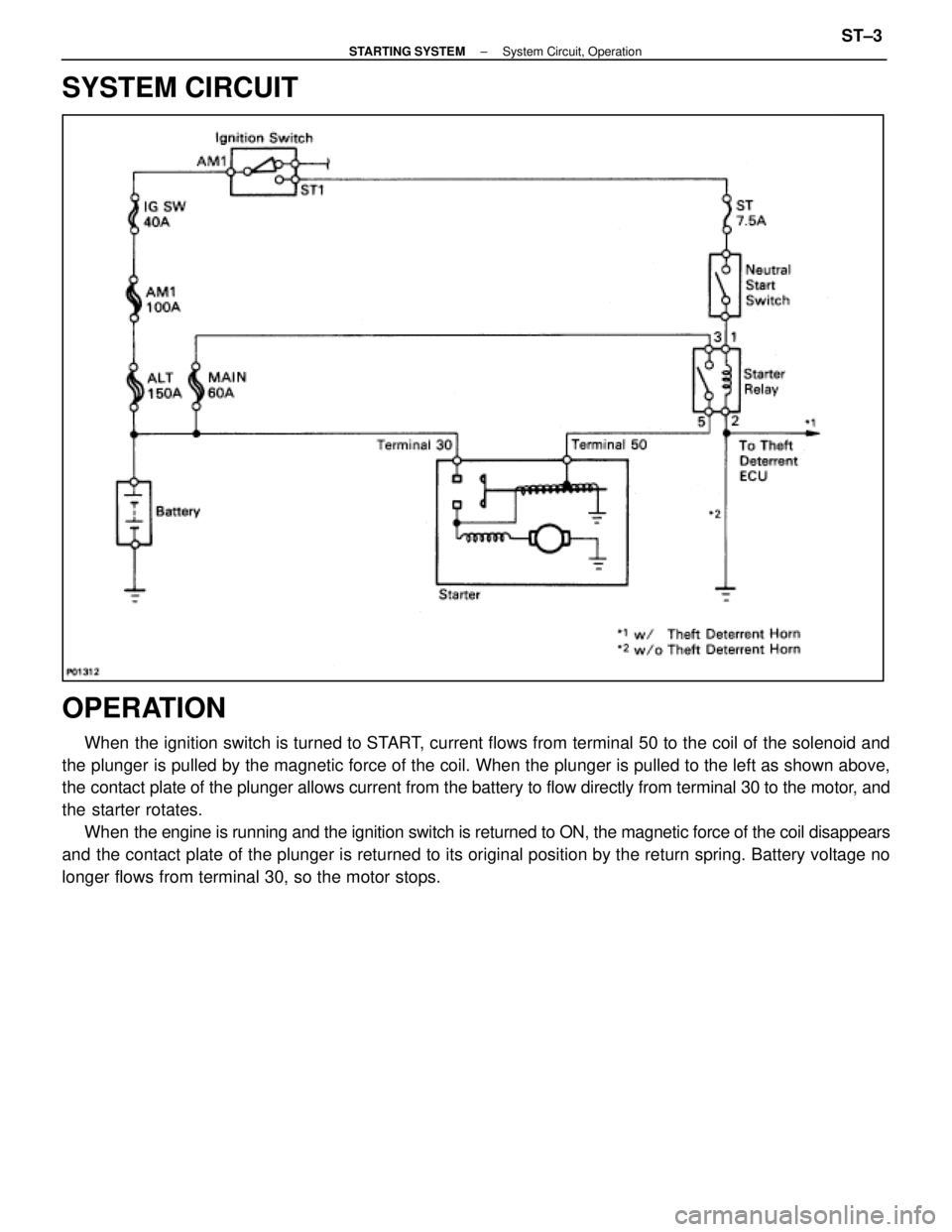

SYSTEM CIRCUIT

OPERATION

When the ignition switch is turned to START, current flows from terminal 50 to the coil of the solenoid and

the plunger is pulled by the magnetic force of the coil. When the plunger is pulled \

to the left as shown above,

the contact plate of the plunger allows current from the battery to flow di\

rectly from terminal 30 to the motor, and

the starter rotates. When the engine is running and the ignition switch is returned to ON, the ma\

gnetic force of the coil disappears

and the contact plate of the plunger is returned to its original position by the return spring. Battery voltage no

longer flows from terminal 30, so the motor stops.

±

STARTING SYSTEM System Circuit, OperationST±3

WhereEverybodyKnowsYourName

Page 2579 of 4087

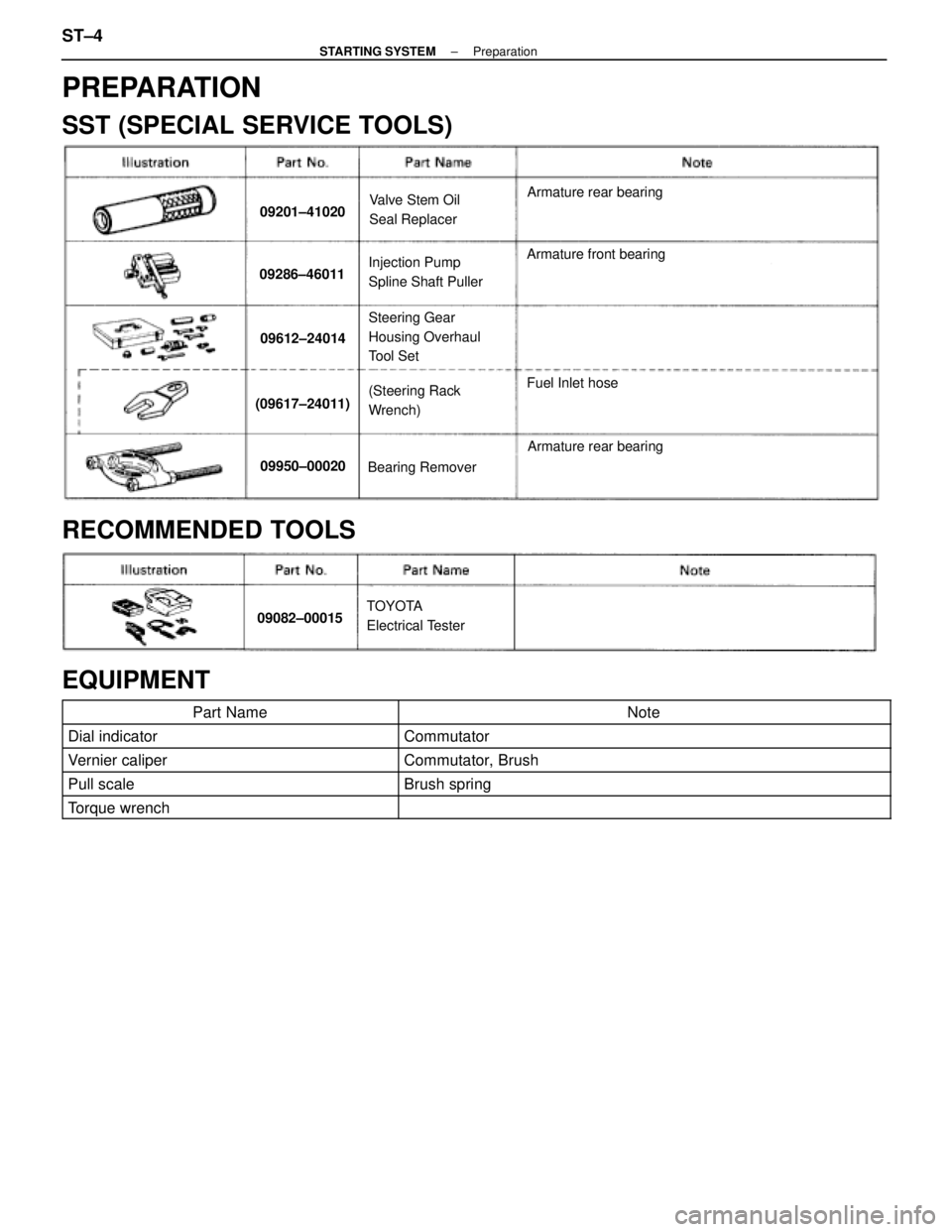

PREPARATION

SST (SPECIAL SERVICE TOOLS)

09201±41020Valve Stem Oil

Seal ReplacerArmature rear bearing

09286±46011Injection Pump

Spline Shaft PullerArmature front bearing

09612±24014

Steering Gear

Housing Overhaul

Tool Set

(09617±24011)(Steering Rack

Wrench)Fuel Inlet hose

09950±00020Bearing Remover

Armature rear bearing

RECOMMENDED TOOLS

09082±00015TOYOTA

Electrical Tester

EQUIPMENT

Part NameNote

Dial indicatorCommutator

Vernier caliperCommutator, Brush

Pull scaleBrush spring

Torque wrench

ST±4±

STARTING SYSTEM Preparation

WhereEverybodyKnowsYourName

Page 2580 of 4087

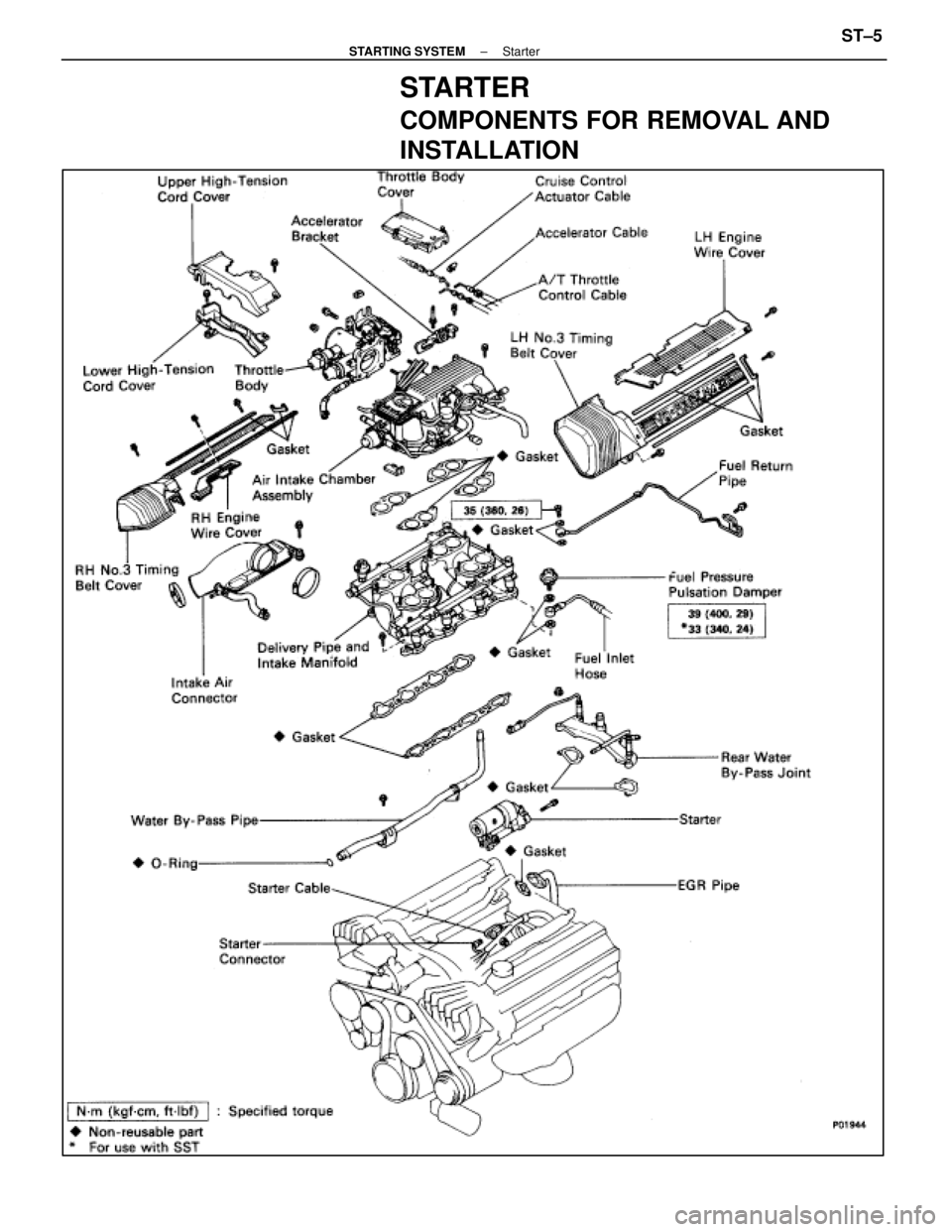

STARTER

COMPONENTS FOR REMOVAL AND

INSTALLATION

±

STARTING SYSTEM StarterST±5

WhereEverybodyKnowsYourName