engine LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1444 of 4087

30. INSTALL VSV FOR EVAP SYSTEMInstall the VSV with the 2 bolts.

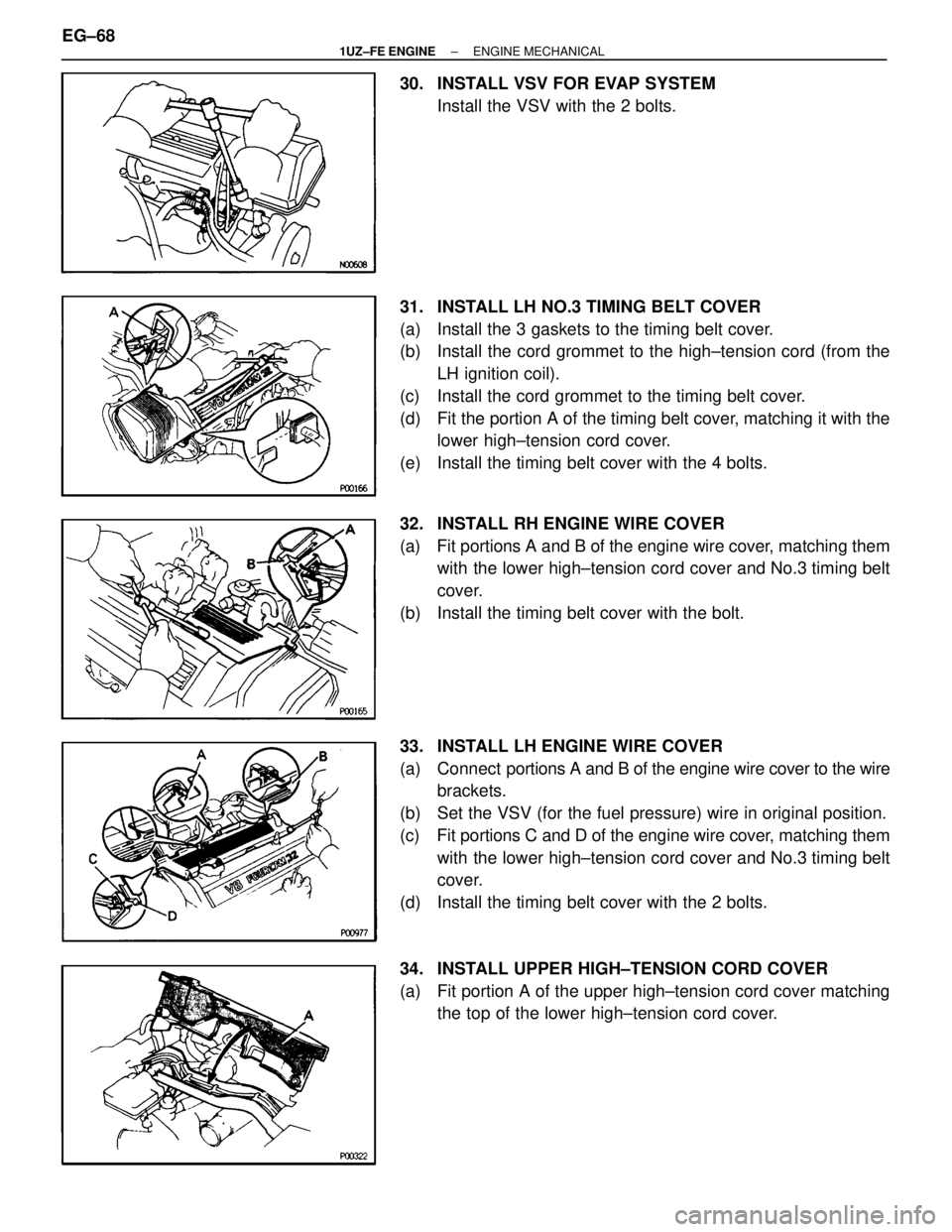

31. INSTALL LH NO.3 TIMING BELT COVER

(a) Install the 3 gaskets to the timing belt cover.

(b) Install the cord grommet to the high±tension cord (from the LH ignition coil).

(c) Install the cord grommet to the timing belt cover.

(d) Fit the portion A of the timing belt cover, matching it with the lower high±tension cord cover.

(e) Install the timing belt cover with the 4 bolts.

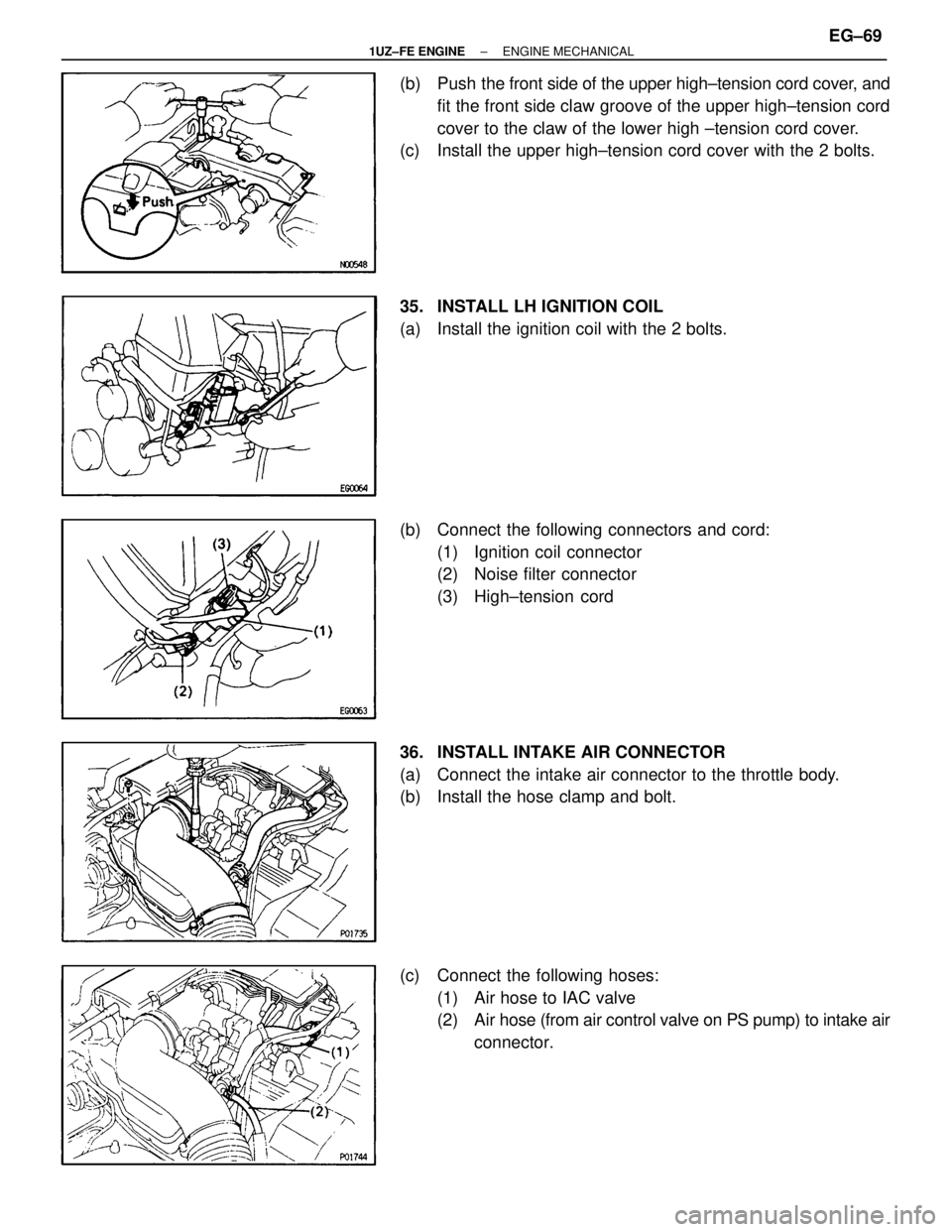

32. INSTALL RH ENGINE WIRE COVER

(a) Fit portions A and B of the engine wire cover, matching them with the lower high±tension cord cover and No.3 timing belt

cover.

(b) Install the timing belt cover with the bolt.

33. INSTALL LH ENGINE WIRE COVER

(a) Connect portions A and B of the engine wire cover to the wire

brackets.

(b) Set the VSV (for the fuel pressure) wire in original position.

(c) Fit portions C and D of the engine wire cover, matching them with the lower high±tension cord cover and No.3 timing belt

cover.

(d) Install the timing belt cover with the 2 bolts.

34. INSTALL UPPER HIGH±TENSION CORD COVER

(a) Fit portion A of the upper high±tension cord cover matching the top of the lower high±tension cord cover.

EG±68

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1445 of 4087

(b) Push the front side of the upper high±tension cord cover, andfit the front side claw groove of the upper high±tension cord

cover to the claw of the lower high ±tension cord cover.

(c) Install the upper high±tension cord cover with the 2 bolts.

35. INSTALL LH IGNITION COIL

(a) Install the ignition coil with the 2 bolts.

(b) Connect the following connectors and cord:

(1) Ignition coil connector

(2) Noise filter connector

(3) High±tension cord

36. INSTALL INTAKE AIR CONNECTOR

(a) Connect the intake air connector to the throttle body.

(b) Install the hose clamp and bolt.

(c) Connect the following hoses: (1) Air hose to IAC valve

(2) Air hose (from air control valve on PS pump) to intake air

connector.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±69

WhereEverybodyKnowsYourName

Page 1446 of 4087

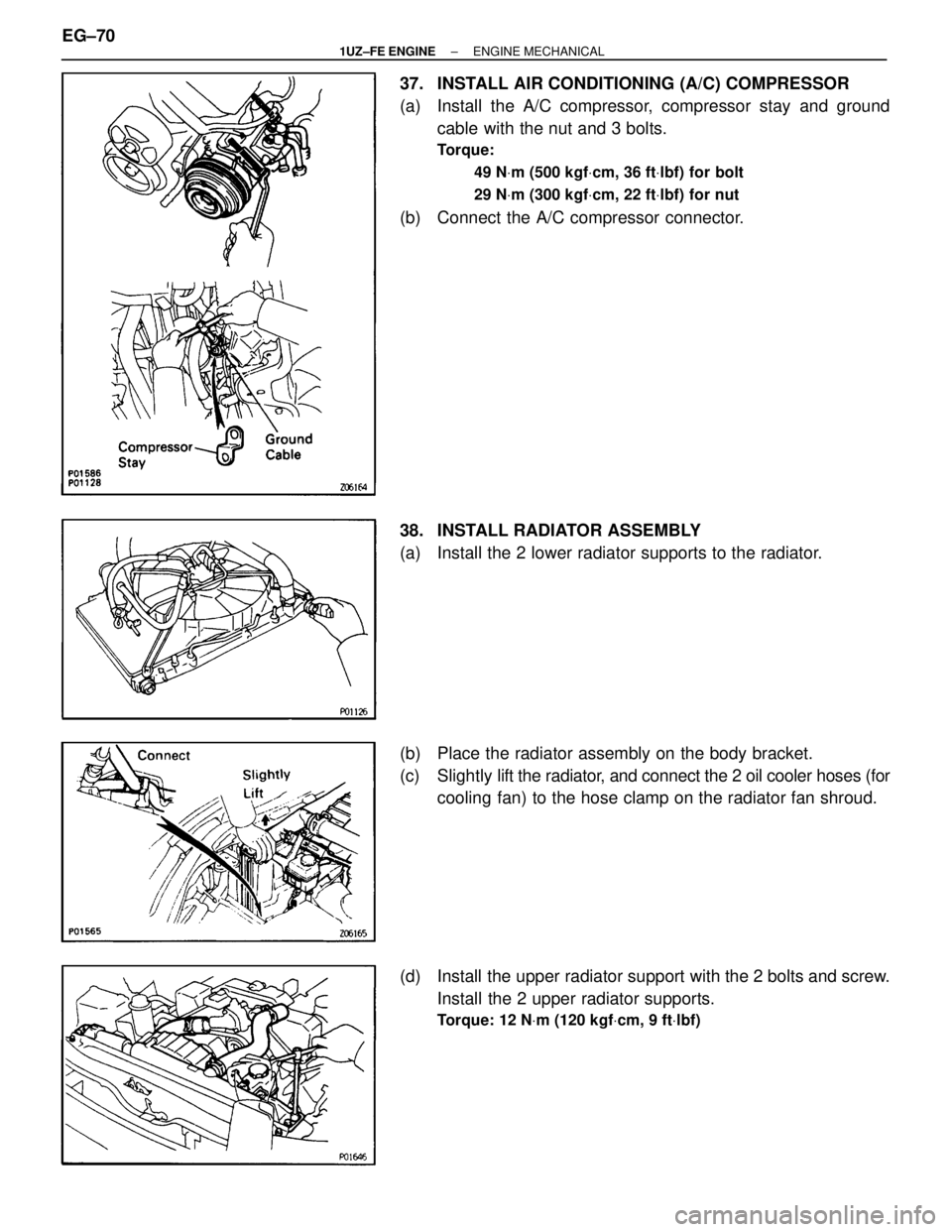

37. INSTALL AIR CONDITIONING (A/C) COMPRESSOR

(a) Install the A/C compressor, compressor stay and groundcable with the nut and 3 bolts.

Torque:

49 NVm (500 kgf Vcm, 36 ft Vlbf) for bolt

29 N Vm (300 kgf Vcm, 22 ft Vlbf) for nut

(b) Connect the A/C compressor connector.

38. INSTALL RADIATOR ASSEMBLY

(a) Install the 2 lower radiator supports to the radiator.

(b) Place the radiator assembly on the body bracket.

(c) Slightly lift the radiator, and connect the 2 oil cooler hoses (for

cooling fan) to the hose clamp on the radiator fan shroud.

(d) Install the upper radiator support with the 2 bolts and screw. Install the 2 upper radiator supports.

Torque: 12 N Vm (120 kgf Vcm, 9 ft Vlbf)

EG±70±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1447 of 4087

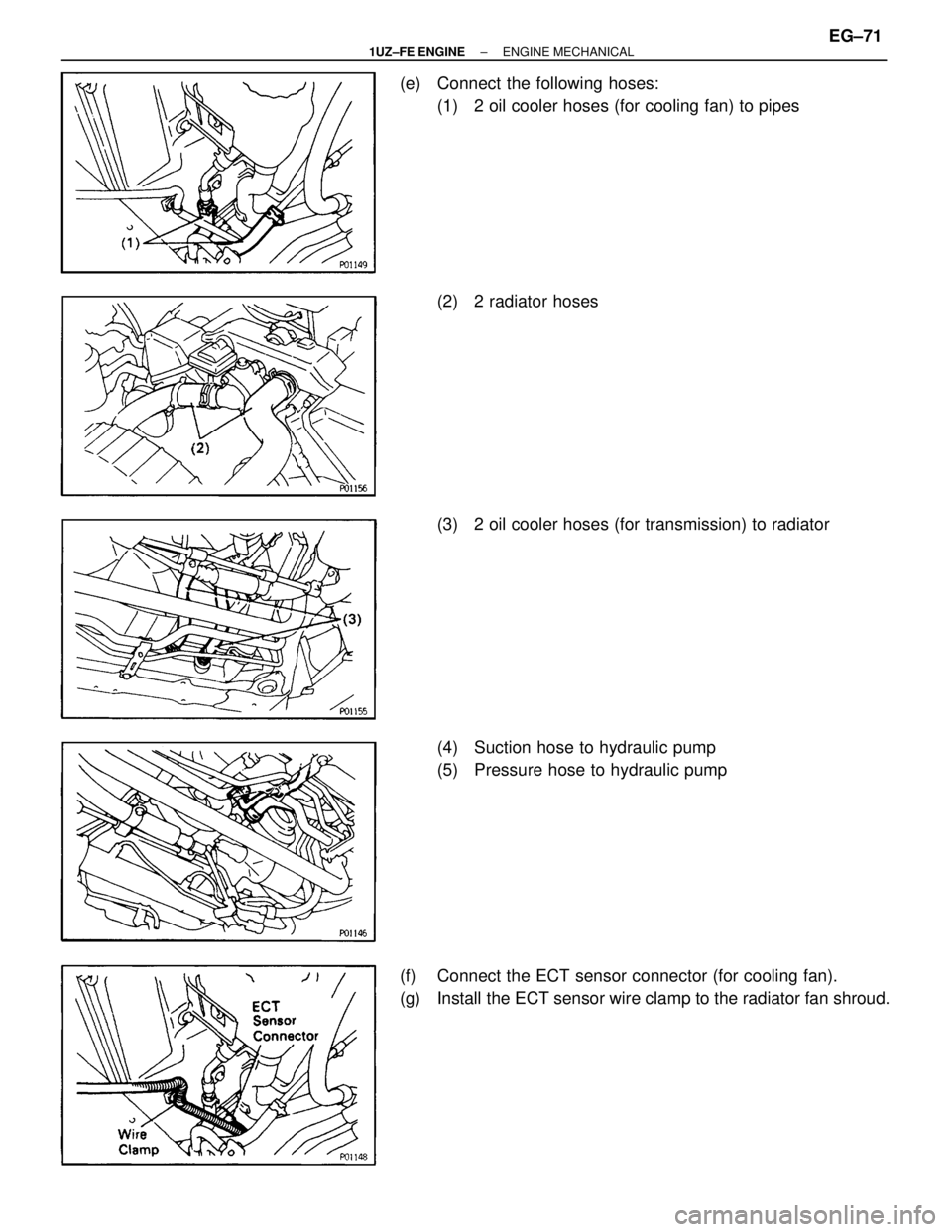

(e) Connect the following hoses:(1) 2 oil cooler hoses (for cooling fan) to pipes

(2) 2 radiator hoses

(3) 2 oil cooler hoses (for transmission) to radiator

(4) Suction hose to hydraulic pump

(5) Pressure hose to hydraulic pump

(f) Connect the ECT sensor connector (for cooling fan).

(g) Install the ECT sensor wire clamp to the radiator fan shroud.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±71

WhereEverybodyKnowsYourName

Page 1448 of 4087

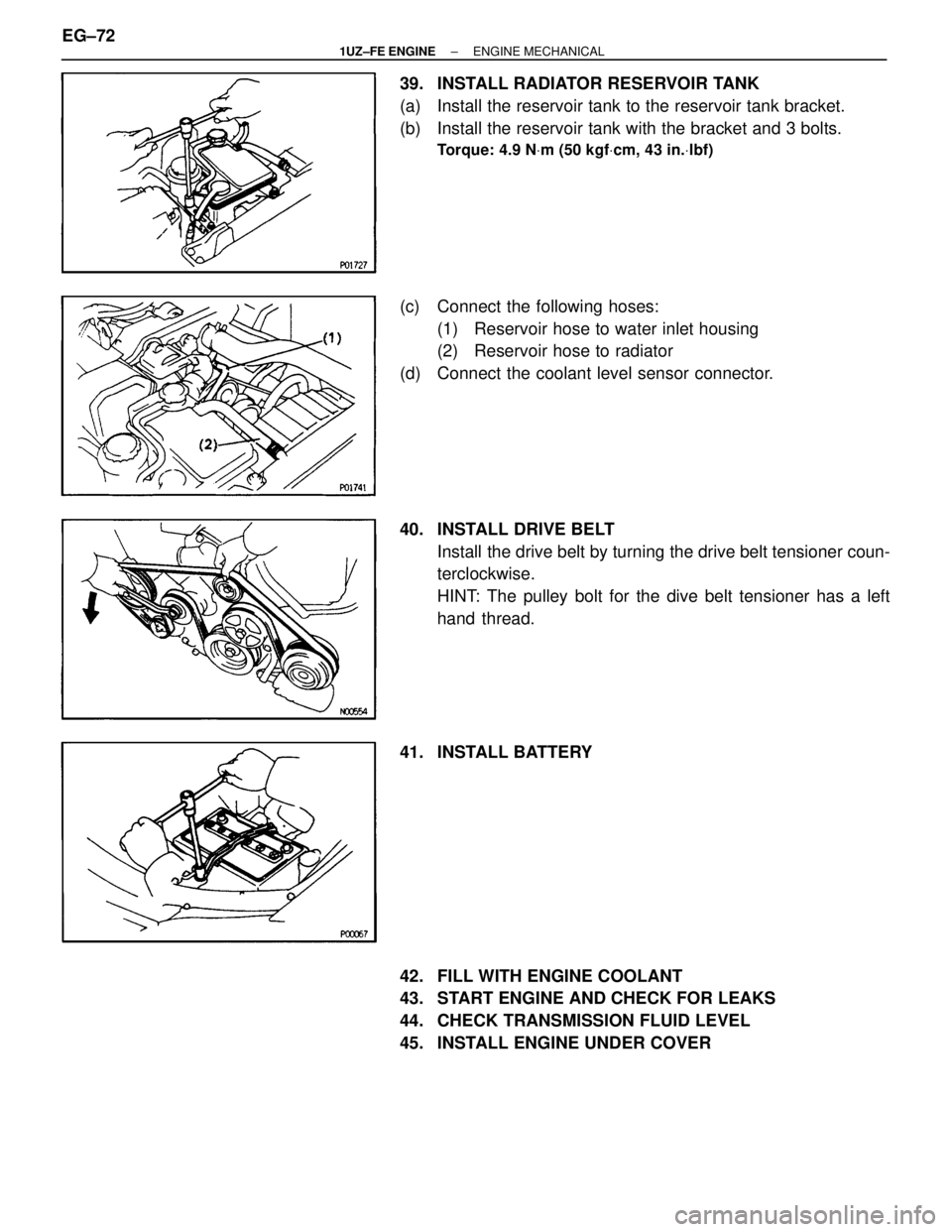

39. INSTALL RADIATOR RESERVOIR TANK

(a) Install the reservoir tank to the reservoir tank bracket.

(b) Install the reservoir tank with the bracket and 3 bolts.

Torque: 4.9 NVm (50 kgf Vcm, 43 in. Vlbf)

(c) Connect the following hoses:

(1) Reservoir hose to water inlet housing

(2) Reservoir hose to radiator

(d) Connect the coolant level sensor connector.

40. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pulley bolt for the dive belt tensioner has a left

hand thread.

41. INSTALL BATTERY

42. FILL WITH ENGINE COOLANT

43. START ENGINE AND CHECK FOR LEAKS

44. CHECK TRANSMISSION FLUID LEVEL

45. INSTALL ENGINE UNDER COVER

EG±72

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1449 of 4087

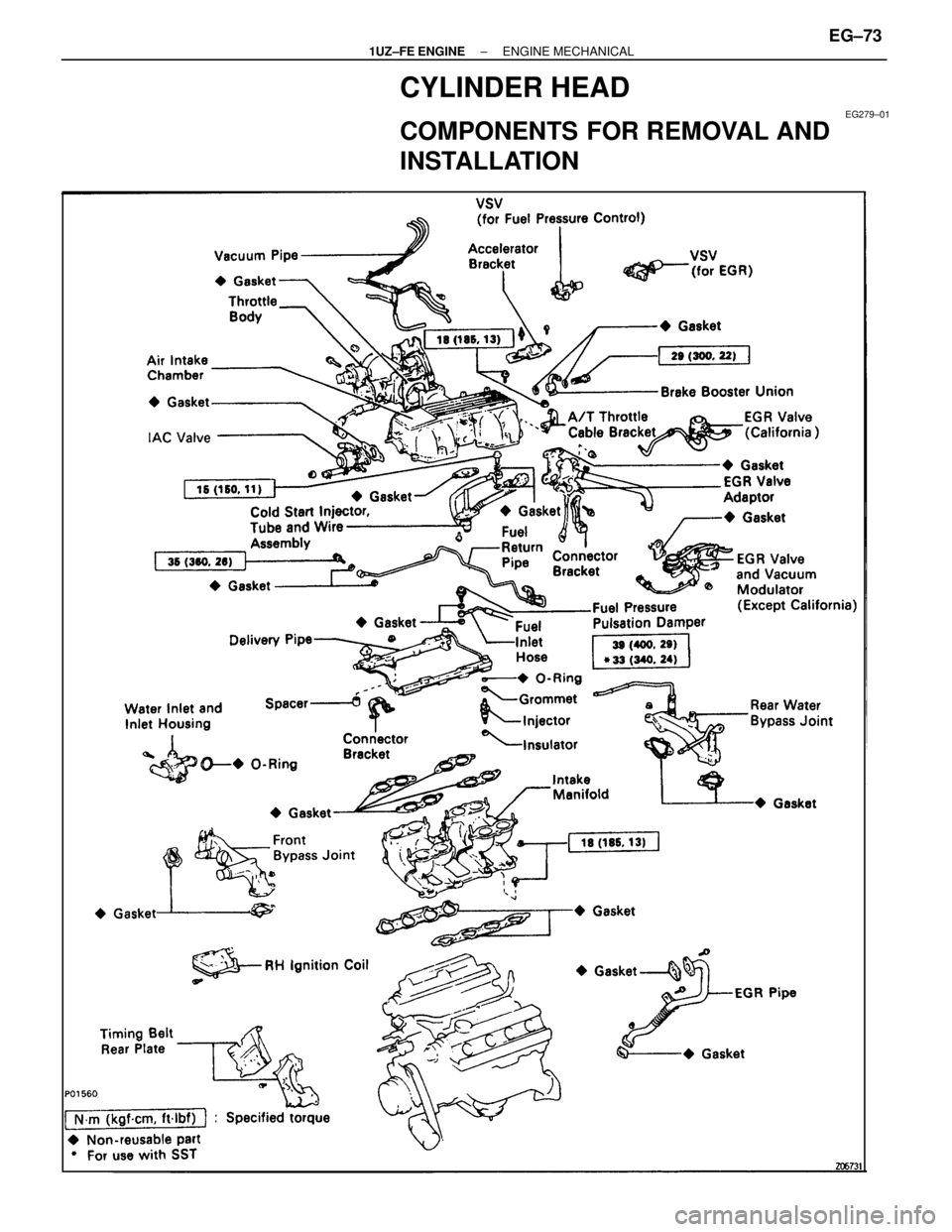

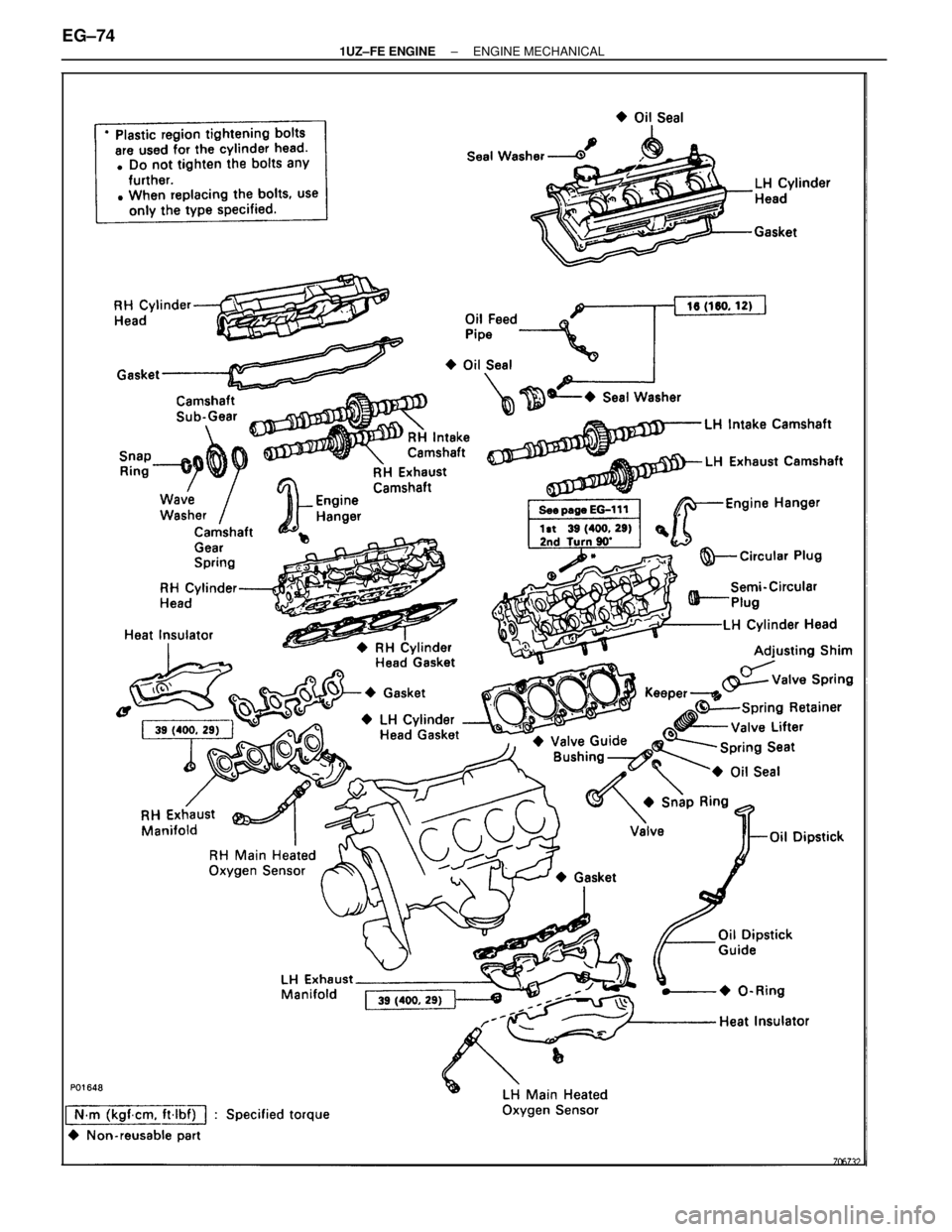

CYLINDER HEAD

EG279±01

COMPONENTS FOR REMOVAL AND

INSTALLATION

±

1UZ±FE ENGINE ENGINE MECHANICALEG±73

WhereEverybodyKnowsYourName

Page 1450 of 4087

EG±74±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1451 of 4087

EG24R±02

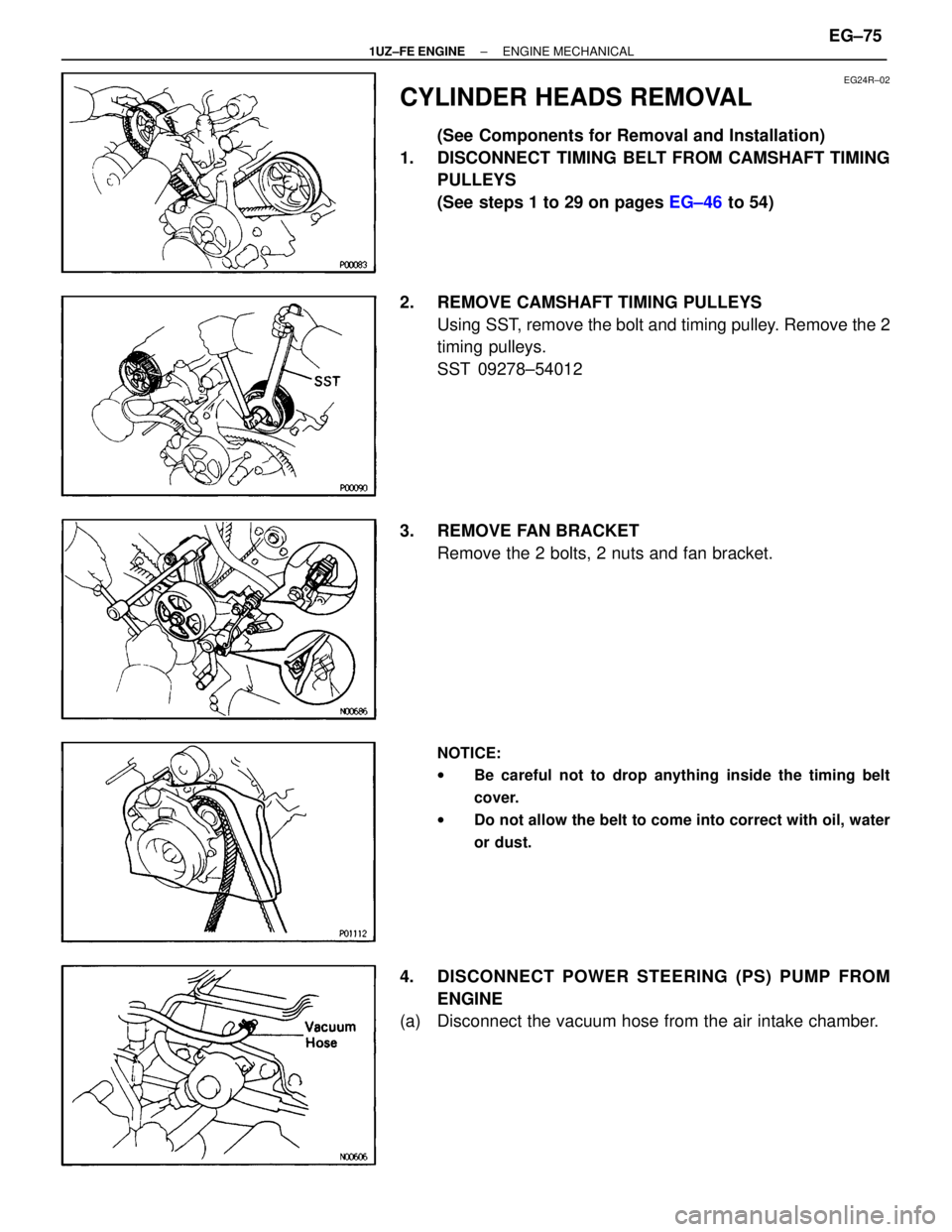

CYLINDER HEADS REMOVAL

(See Components for Removal and Installation)

1. DISCONNECT TIMING BELT FROM CAMSHAFT TIMING PULLEYS

(See steps 1 to 29 on pages EG±46 to 54)

2. REMOVE CAMSHAFT TIMING PULLEYS Using SST, remove the bolt and timing pulley. Remove the 2

timing pulleys.

SST 09278±54012

3. REMOVE FAN BRACKET Remove the 2 bolts, 2 nuts and fan bracket.

NOTICE:

w Be careful not to drop anything inside the timing belt

cover.

w Do not allow the belt to come into correct with oil, water

or dust.

4. DISCONNECT POWER STEERING (PS) PUMP FROM

ENGINE

(a) Disconnect the vacuum hose from the air intake chamber.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±75

WhereEverybodyKnowsYourName

Page 1452 of 4087

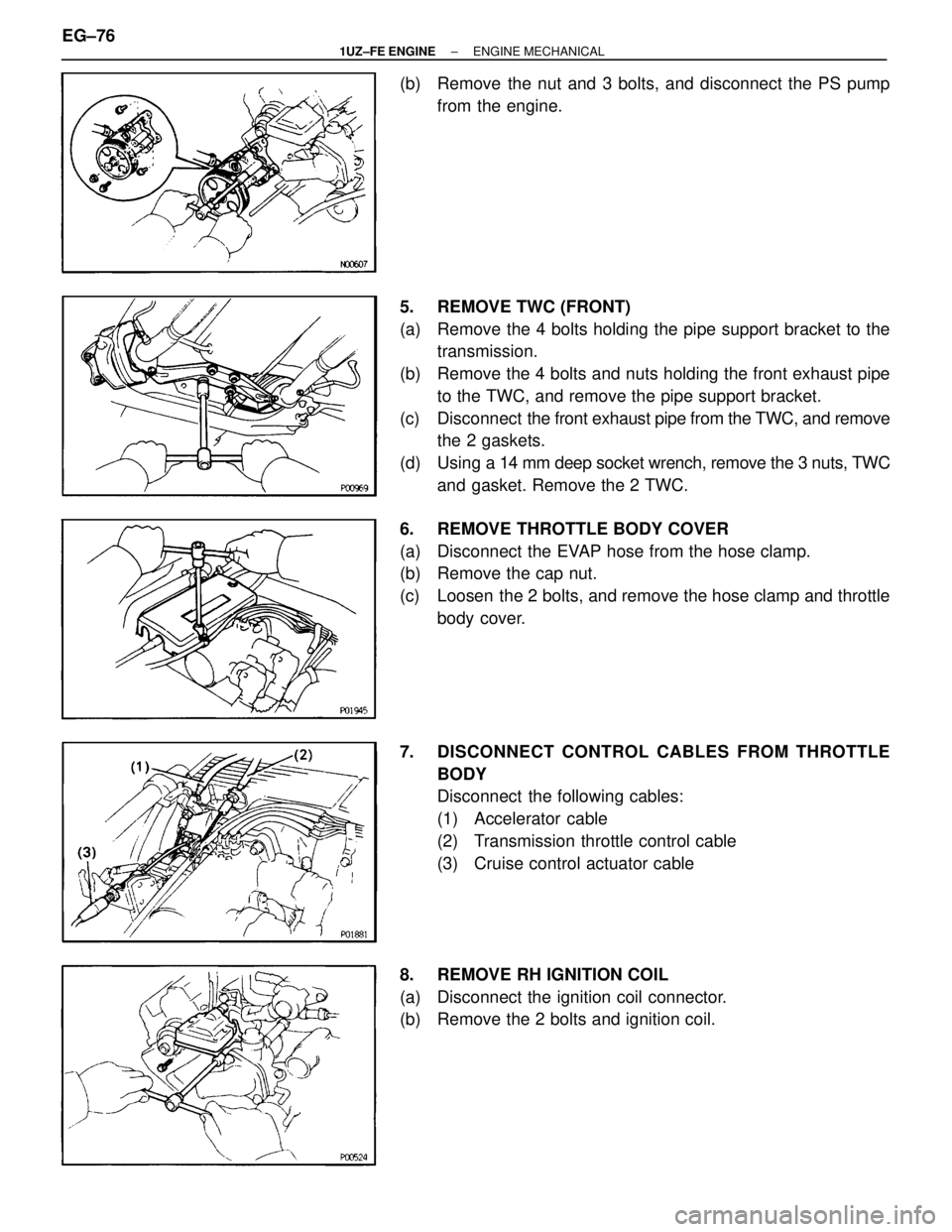

(b) Remove the nut and 3 bolts, and disconnect the PS pumpfrom the engine.

5. REMOVE TWC (FRONT)

(a) Remove the 4 bolts holding the pipe support bracket to the transmission.

(b) Remove the 4 bolts and nuts holding the front exhaust pipe to the TWC, and remove the pipe support bracket.

(c) Disconnect the front exhaust pipe from the TWC, and remove

the 2 gaskets.

(d) Using a 14 mm deep socket wrench, remove the 3 nuts, TWC

and gasket. Remove the 2 TWC.

6. REMOVE THROTTLE BODY COVER

(a) Disconnect the EVAP hose from the hose clamp.

(b) Remove the cap nut.

(c) Loosen the 2 bolts, and remove the hose clamp and throttle body cover.

7. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:

(1) Accelerator cable

(2) Transmission throttle control cable

(3) Cruise control actuator cable

8. REMOVE RH IGNITION COIL

(a) Disconnect the ignition coil connector.

(b) Remove the 2 bolts and ignition coil.

EG±76

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1453 of 4087

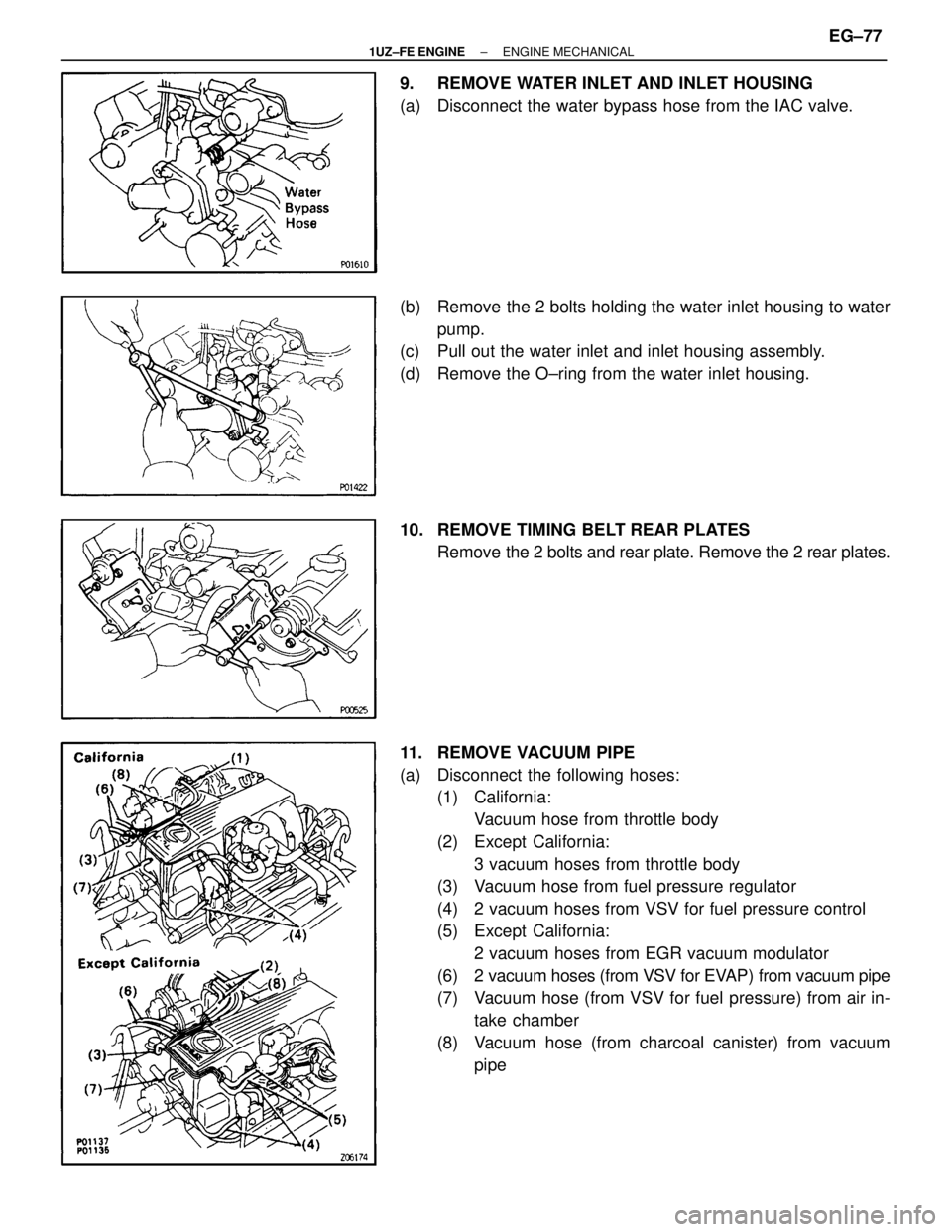

9. REMOVE WATER INLET AND INLET HOUSING

(a) Disconnect the water bypass hose from the IAC valve.

(b) Remove the 2 bolts holding the water inlet housing to waterpump.

(c) Pull out the water inlet and inlet housing assembly.

(d) Remove the O±ring from the water inlet housing.

10. REMOVE TIMING BELT REAR PLATES

Remove the 2 bolts and rear plate. Remove the 2 rear plates.

11. REMOVE VACUUM PIPE

(a) Disconnect the following hoses: (1) California:

Vacuum hose from throttle body

(2) Except California: 3 vacuum hoses from throttle body

(3) Vacuum hose from fuel pressure regulator

(4) 2 vacuum hoses from VSV for fuel pressure control

(5) Except California:

2 vacuum hoses from EGR vacuum modulator

(6) 2 vacuum hoses (from VSV for EVAP) from vacuum pipe

(7) Vacuum hose (from VSV for fuel pressure) from air in-

take chamber

(8) Vacuum hose (from charcoal canister) from vacuum pipe

±

1UZ±FE ENGINE ENGINE MECHANICALEG±77

WhereEverybodyKnowsYourName