oxygen sensor LEXUS SC400 1991 Service Owner's Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1775 of 4087

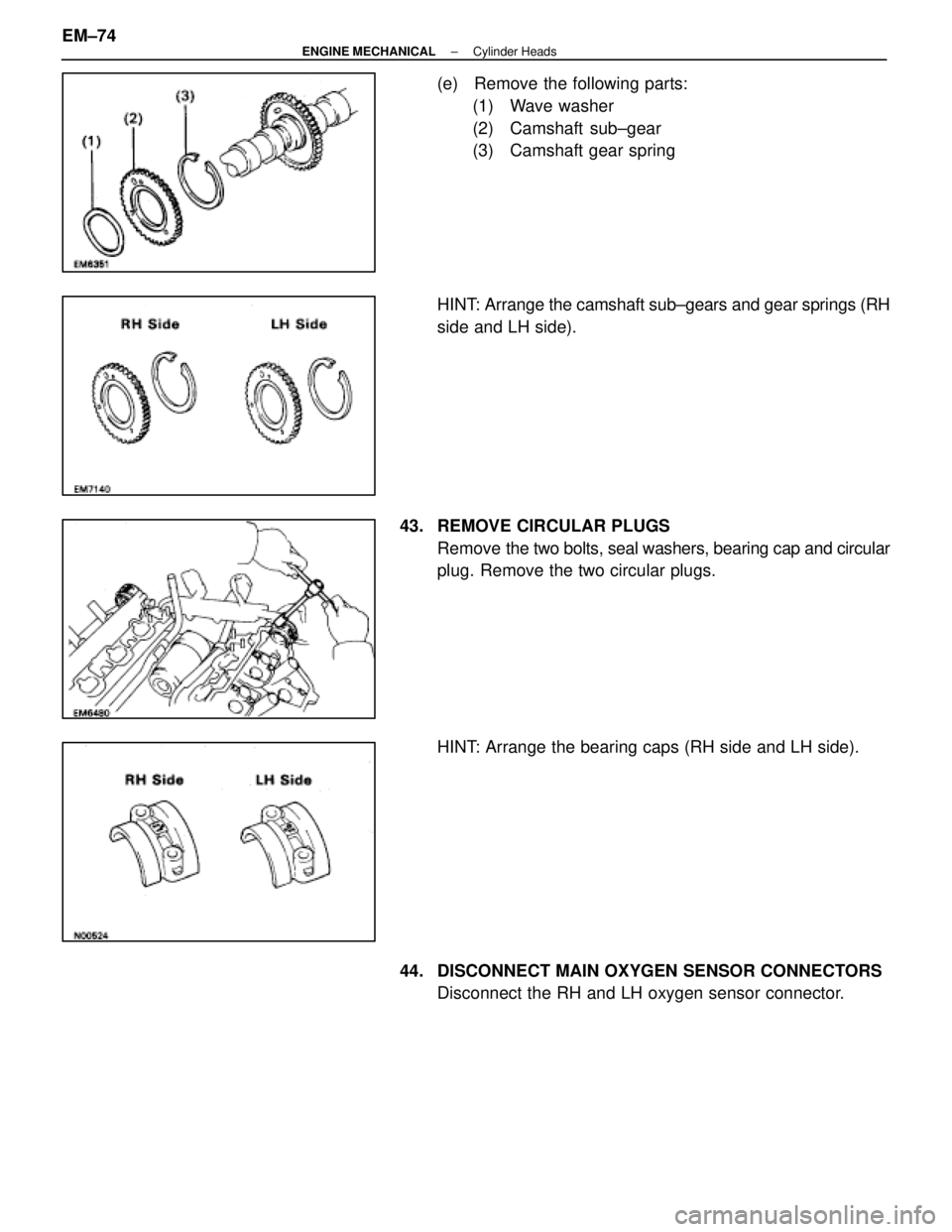

(e) Remove the following parts:(1) Wave washer

(2) Camshaft sub±gear

(3) Camshaft gear spring

HINT: Arrange the camshaft sub±gears and gear springs (RH

side and LH side).

43. REMOVE CIRCULAR PLUGS Remove the two bolts, seal washers, bearing cap and circular

plug. Remove the two circular plugs.

HINT: Arrange the bearing caps (RH side and LH side).

44. DISCONNECT MAIN OXYGEN SENSOR CONNECTORS Disconnect the RH and LH oxygen sensor connector.

EM±74

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 1776 of 4087

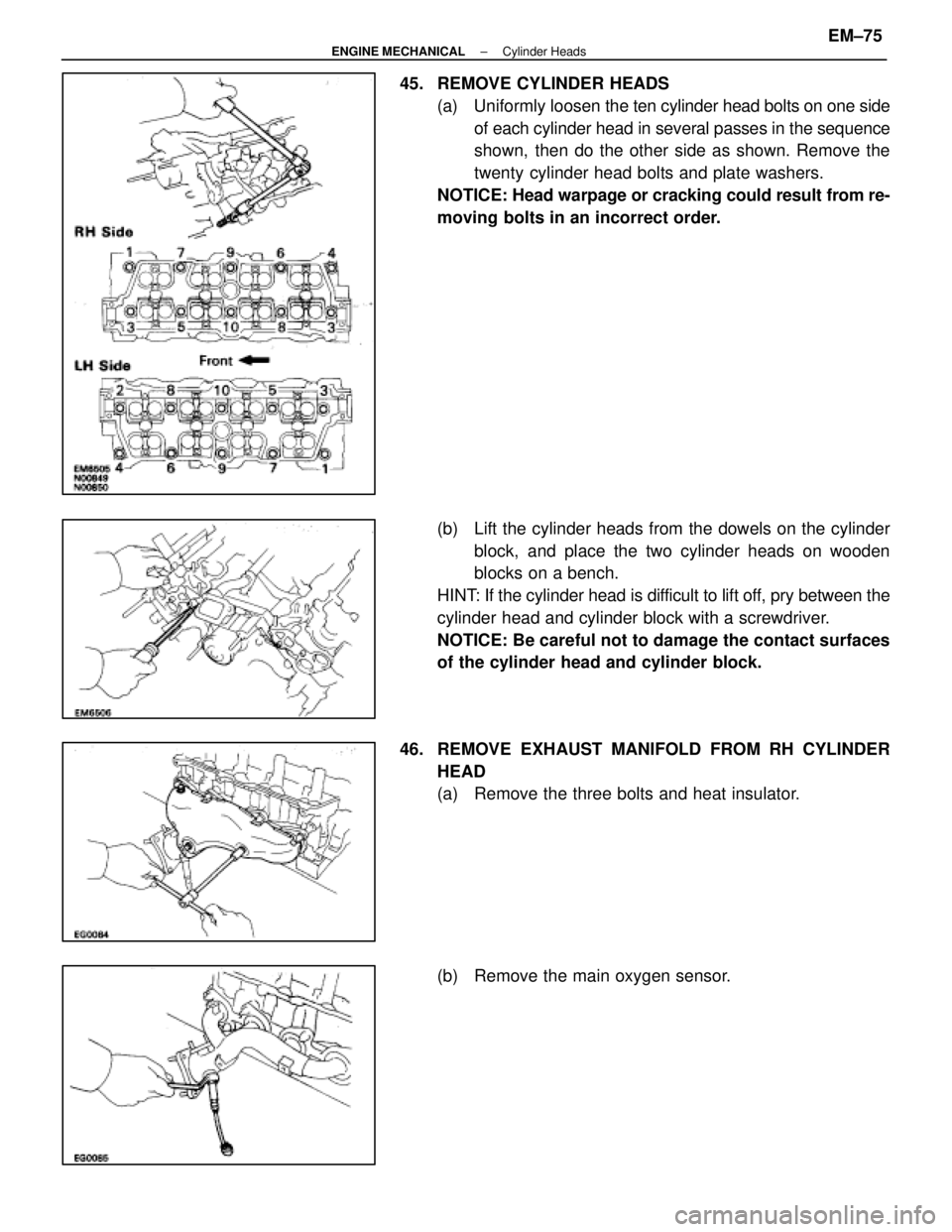

45. REMOVE CYLINDER HEADS(a) Uniformly loosen the ten cylinder head bolts on one side

of each cylinder head in several passes in the sequence

shown, then do the other side as shown. Remove the

twenty cylinder head bolts and plate washers.

NOTICE: Head warpage or cracking could result from re-

moving bolts in an incorrect order.

(b) Lift the cylinder heads from the dowels on the cylinder block, and place the two cylinder heads on wooden

blocks on a bench.

HINT: If the cylinder head is difficult to lift off, pry between the

cylinder head and cylinder block with a screwdriver.

NOTICE: Be careful not to damage the contact surfaces

of the cylinder head and cylinder block.

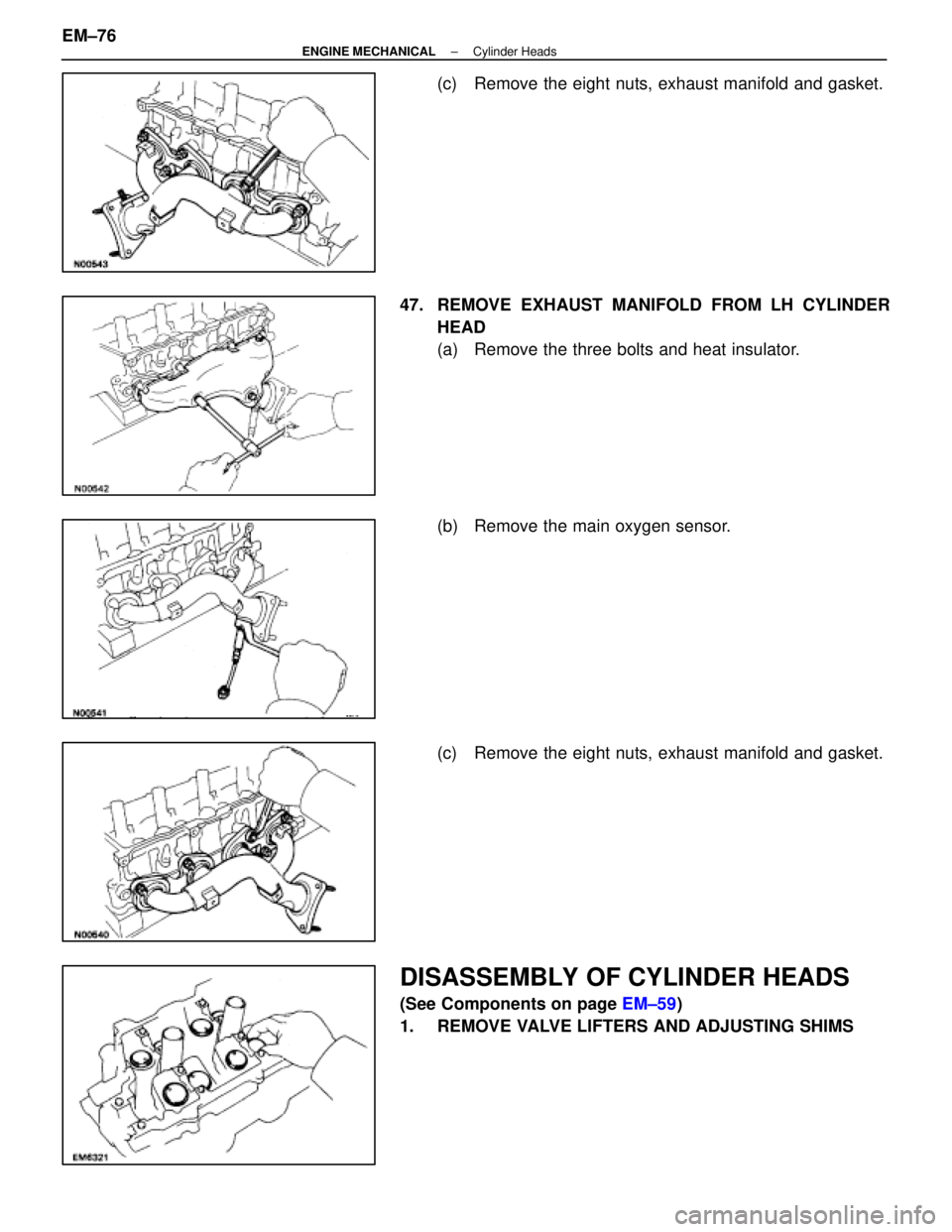

46. REMOVE EXHAUST MANIFOLD FROM RH CYLINDER HEAD

(a) Remove the three bolts and heat insulator.

(b) Remove the main oxygen sensor.

±

ENGINE MECHANICAL Cylinder HeadsEM±75

WhereEverybodyKnowsYourName

Page 1777 of 4087

(c) Remove the eight nuts, exhaust manifold and gasket.

47. REMOVE EXHAUST MANIFOLD FROM LH CYLINDER HEAD

(a) Remove the three bolts and heat insulator.

(b) Remove the main oxygen sensor.

(c) Remove the eight nuts, exhaust manifold and gasket.

DISASSEMBLY OF CYLINDER HEADS

(See Components on page EM±59)

1. REMOVE VALVE LIFTERS AND ADJUSTING SHIMS

EM±76

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 1792 of 4087

INSTALLATION OF CYLINDER HEADS

(See Components on pages EM±58 and 59)

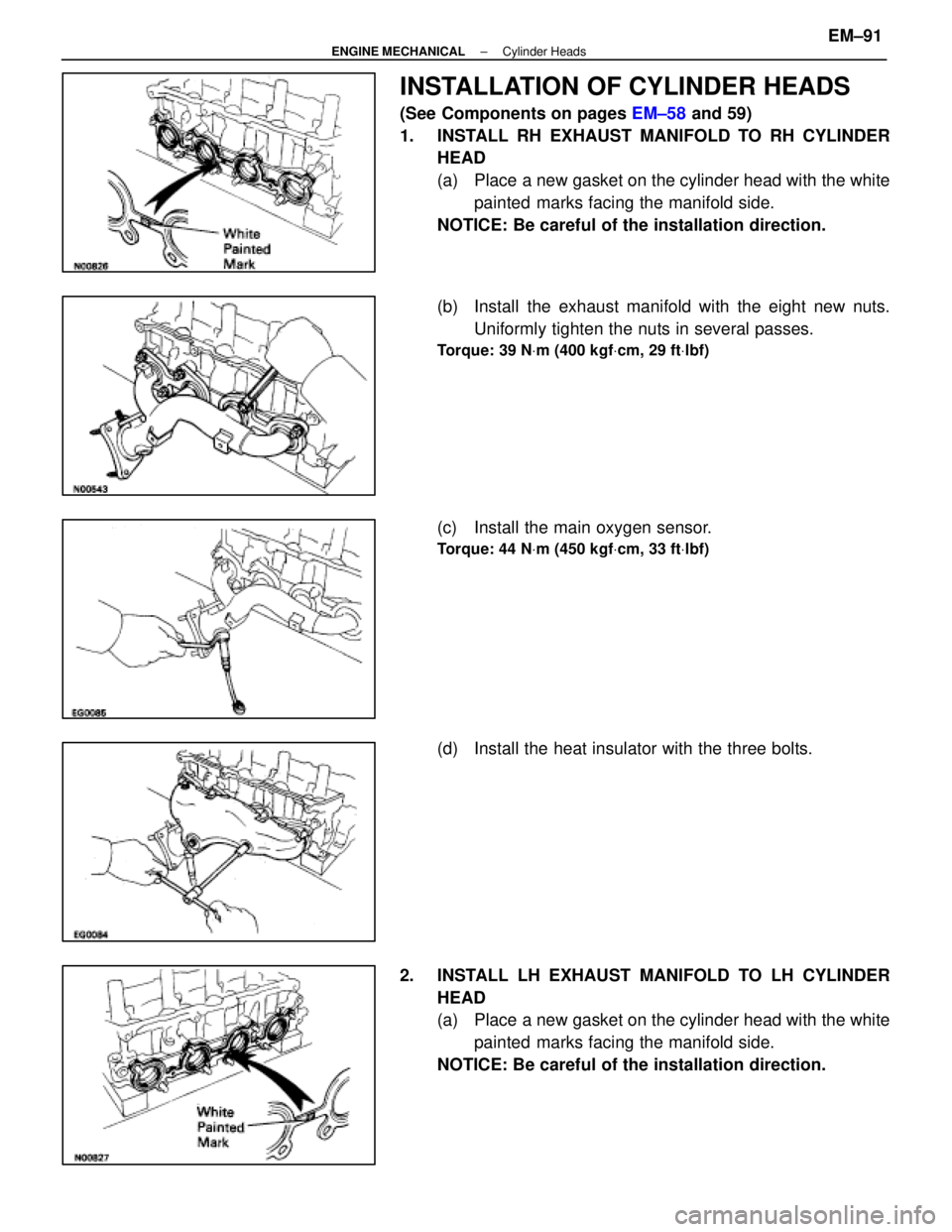

1. INSTALL RH EXHAUST MANIFOLD TO RH CYLINDER HEAD

(a) Place a new gasket on the cylinder head with the white

painted marks facing the manifold side.

NOTICE: Be careful of the installation direction.

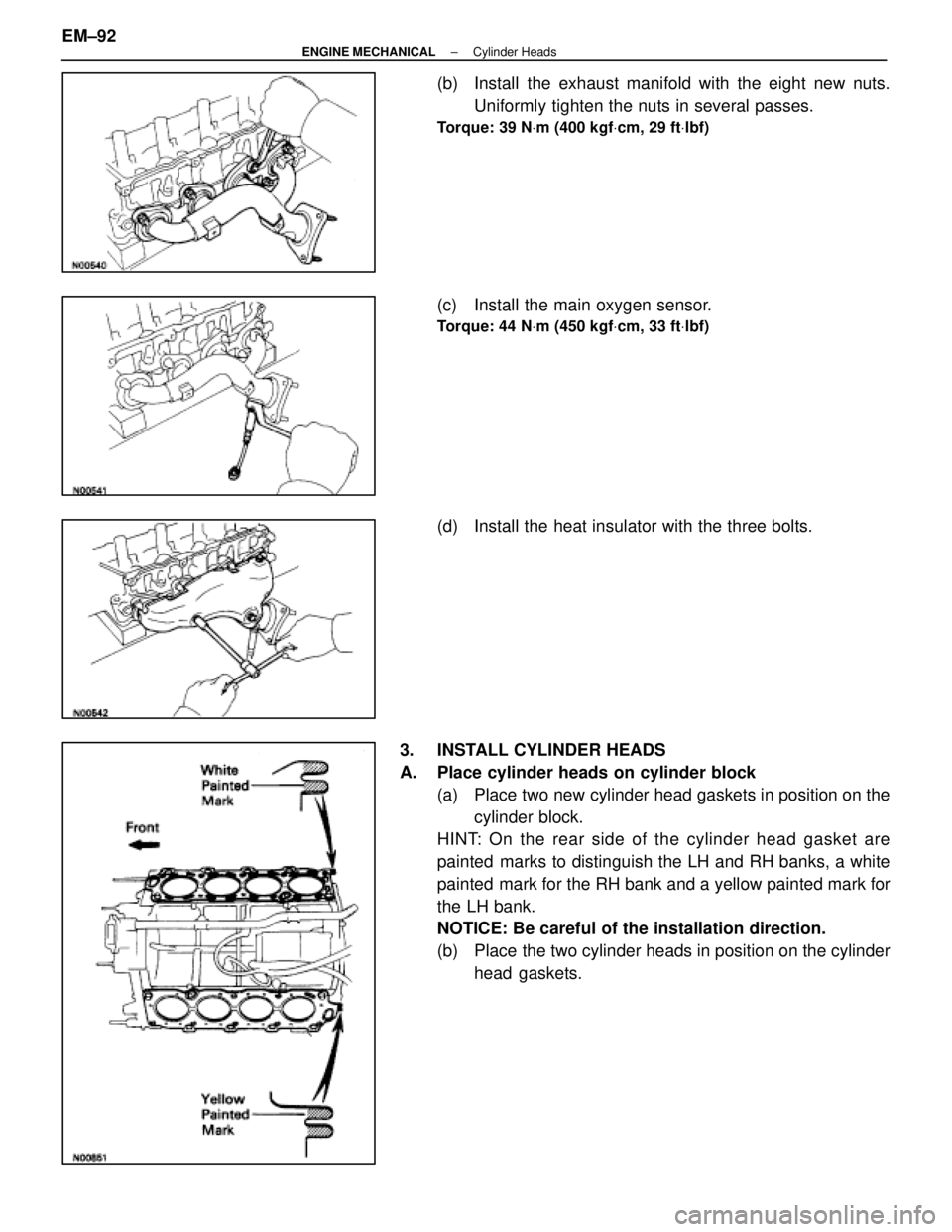

(b) Install the exhaust manifold with the eight new nuts. Uniformly tighten the nuts in several passes.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(c) Install the main oxygen sensor.

Torque: 44 N Vm (450 kgf Vcm, 33 ft Vlbf)

(d) Install the heat insulator with the three bolts.

2. INSTALL LH EXHAUST MANIFOLD TO LH CYLINDER HEAD

(a) Place a new gasket on the cylinder head with the whitepainted marks facing the manifold side.

NOTICE: Be careful of the installation direction.

±

ENGINE MECHANICAL Cylinder HeadsEM±91

WhereEverybodyKnowsYourName

Page 1793 of 4087

(b) Install the exhaust manifold with the eight new nuts.Uniformly tighten the nuts in several passes.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(c) Install the main oxygen sensor.

Torque: 44 N Vm (450 kgf Vcm, 33 ft Vlbf)

(d) Install the heat insulator with the three bolts.

3. INSTALL CYLINDER HEADS

A. Place cylinder heads on cylinder block (a) Place two new cylinder head gaskets in position on thecylinder block.

HINT: On the rear side of the cylinder head gasket are

painted marks to distinguish the LH and RH banks, a white

painted mark for the RH bank and a yellow painted mark for

the LH bank.

NOTICE: Be careful of the installation direction.

(b) Place the two cylinder heads in position on the cylinder

head gaskets.

EM±92

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 1794 of 4087

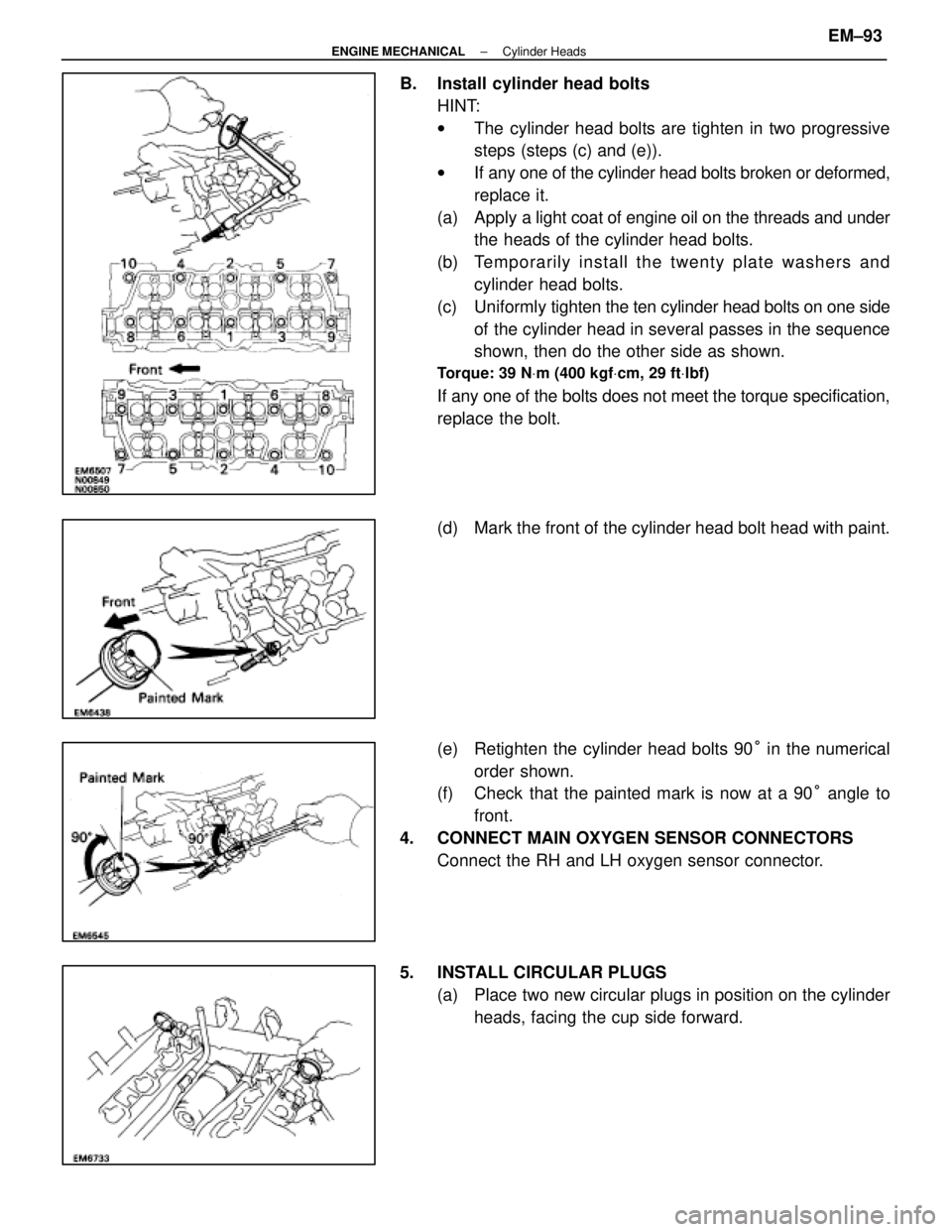

B. Install cylinder head boltsHINT:

wThe cylinder head bolts are tighten in two progressive

steps (steps (c) and (e)).

w If any one of the cylinder head bolts broken or deformed,

replace it.

(a) Apply a light coat of engine oil on the threads and under

the heads of the cylinder head bolts.

(b) Te mp o ra rily in sta ll th e twe n ty pla te wa sh e rs an d cylinder head bolts.

(c) Uniformly tighten the ten cylinder head bolts on one side

of the cylinder head in several passes in the sequence

shown, then do the other side as shown.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

If any one of the bolts does not meet the torque specification,

replace the bolt.

(d) Mark the front of the cylinder head bolt head with paint.

(e) Retighten the cylinder head bolts 90 ° in the numerical

order shown.

(f) Check that the painted mark is now at a 90 ° angle to

front.

4. CONNECT MAIN OXYGEN SENSOR CONNECTORS Connect the RH and LH oxygen sensor connector.

5. INSTALL CIRCULAR PLUGS (a) Place two new circular plugs in position on the cylinderheads, facing the cup side forward.

±

ENGINE MECHANICAL Cylinder HeadsEM±93

WhereEverybodyKnowsYourName

Page 1923 of 4087

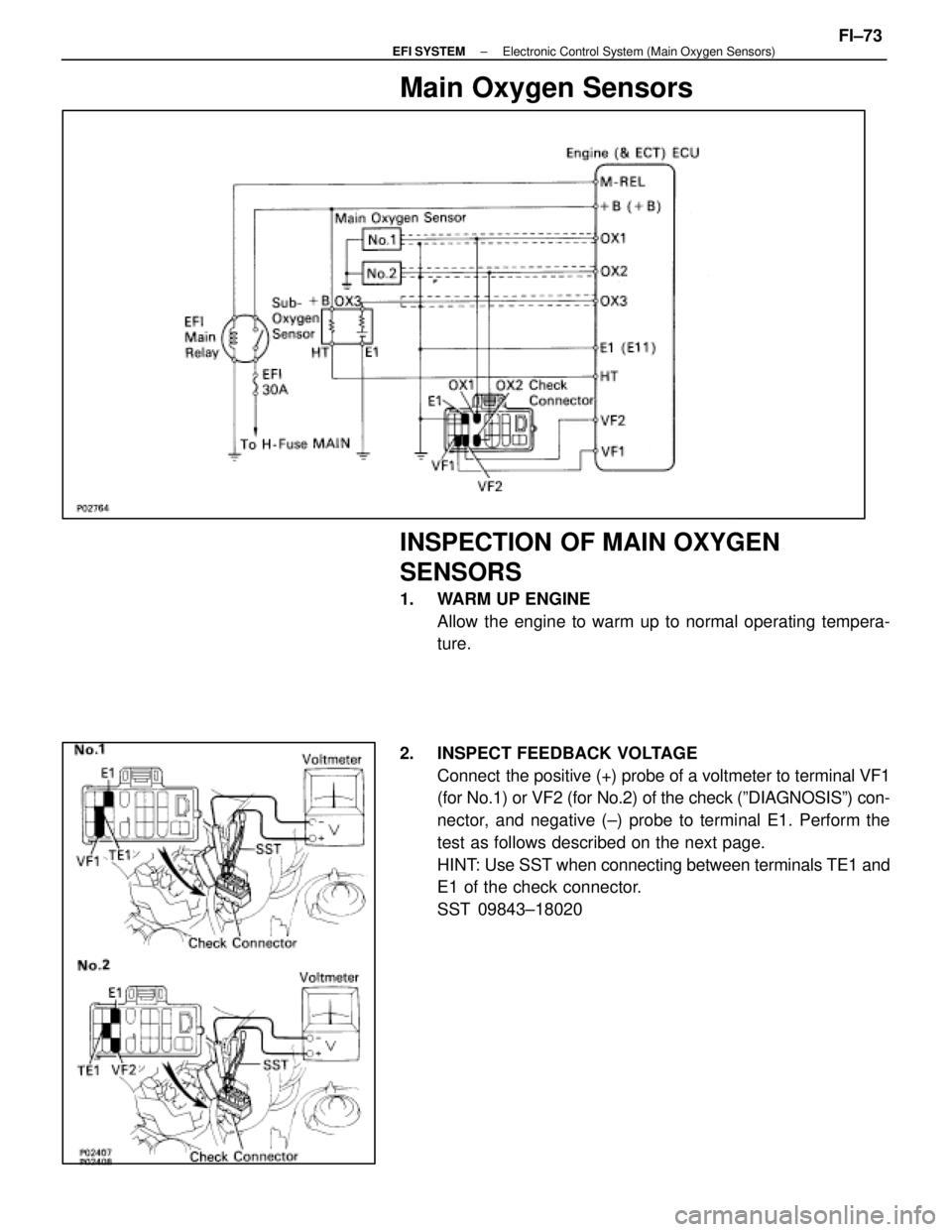

Main Oxygen Sensors

INSPECTION OF MAIN OXYGEN

SENSORS

1. WARM UP ENGINEAllow the engine to warm up to normal operating tempera-

ture.

2. INSPECT FEEDBACK VOLTAGE Connect the positive (+) probe of a voltmeter to terminal VF1

(for No.1) or VF2 (for No.2) of the check (ºDIAGNOSISº) con-\

nector, and negative (±) probe to terminal E1. Perform the

test as follows described on the next page.

HINT: Use SST when connecting between terminals TE1 and

E1 of the check connector.

SST 09843±18020

±

EFI SYSTEM Electronic Control System (Main Oxygen Sensors)FI±73

WhereEverybodyKnowsYourName

Page 1924 of 4087

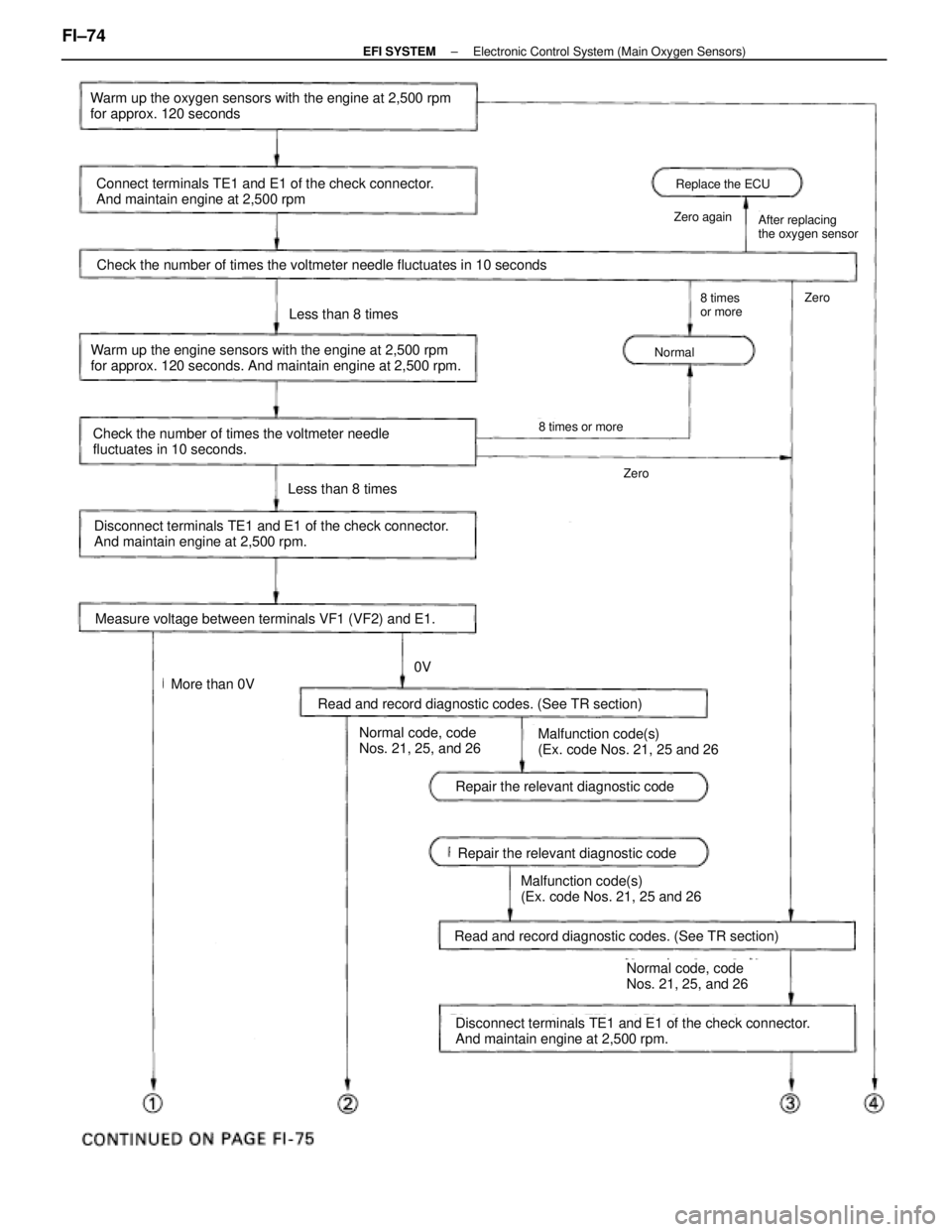

Replace the ECU

Zero againAfter replacing

the oxygen sensor

Normal

8 times

or moreZero

Check the number of times the voltmeter needle fluctuates in 10 seconds

Zero

8 times or more

Warm up the oxygen sensors with the engine at 2,500 rpm

for approx. 120 seconds

Connect terminals TE1 and E1 of the check connector.

And maintain engine at 2,500 rpm

Warm up the engine sensors with the engine at 2,500 rpm

for approx. 120 seconds. And maintain engine at 2,500 rpm.

Check the number of times the voltmeter needle

fluctuates in 10 seconds.

Less than 8 times

Disconnect terminals TE1 and E1 of the check connector.

And maintain engine at 2,500 rpm.

Measure voltage between terminals VF1 (VF2) and E1.

Less than 8 times

More than 0V

0V

Normal code, code

Nos. 21, 25, and 26Malfunction code(s)

(Ex. code Nos. 21, 25 and 26

Read and record diagnostic codes. (See TR section)

Repair the relevant diagnostic code

Disconnect terminals TE1 and E1 of the check connector.

And maintain engine at 2,500 rpm.

Read and record diagnostic codes. (See TR section)

Malfunction code(s)

(Ex. code Nos. 21, 25 and 26

Normal code, code

Nos. 21, 25, and 26

Repair the relevant diagnostic code

FI±74±

EFI SYSTEM Electronic Control System (Main Oxygen Sensors)

WhereEverybodyKnowsYourName

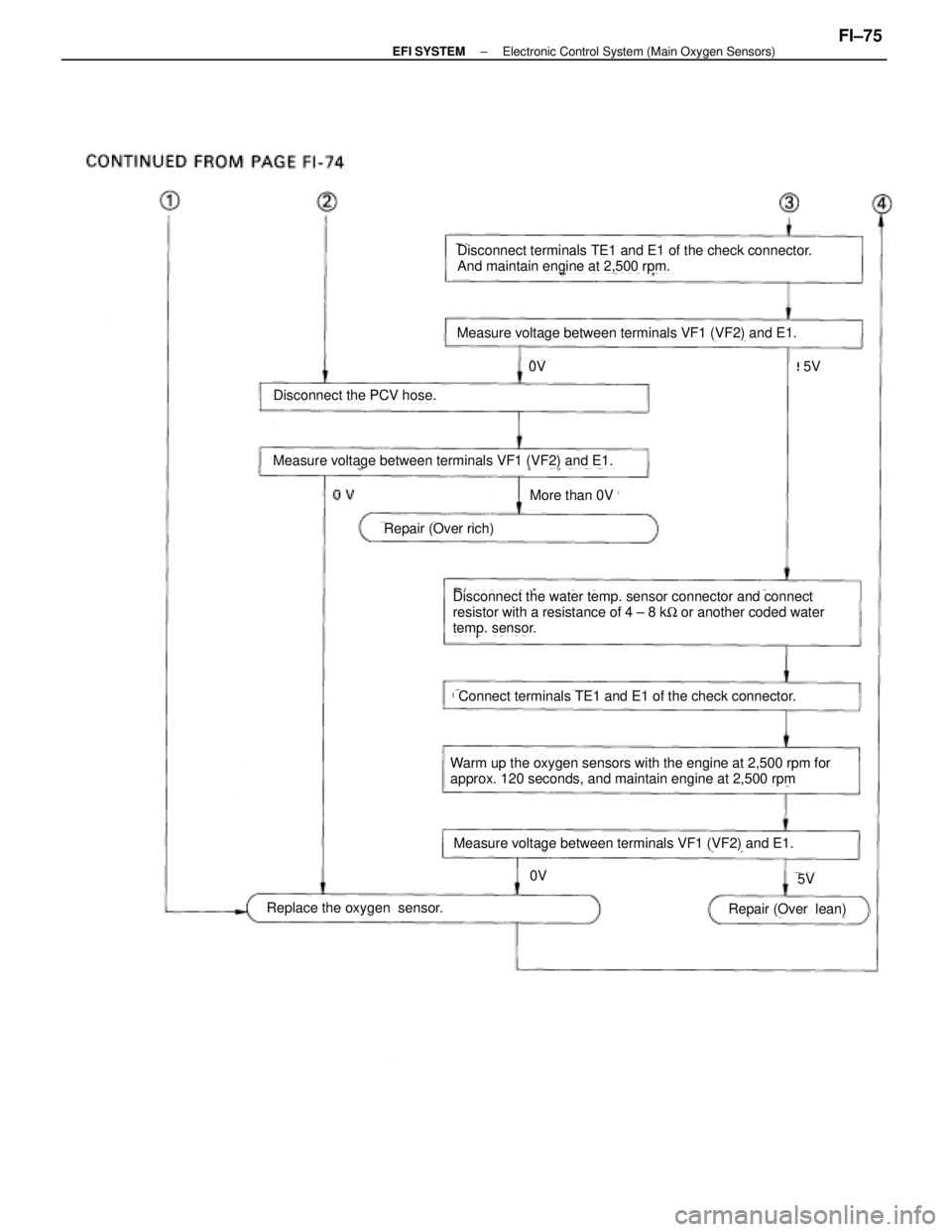

Page 1925 of 4087

Measure voltage between terminals VF1 (VF2) and E1.

Disconnect terminals TE1 and E1 of the check connector.

And maintain engine at 2,500 rpm.

Measure voltage between terminals VF1 (VF2) and E1.

Disconnect the PCV hose.

0V

5V

More than 0V

Repair (Over rich)

Disconnect the water temp. sensor connector and connect

resistor with a resistance of 4 ± 8 kW or another coded water

temp. sensor.

Connect terminals TE1 and E1 of the check connector.

Warm up the oxygen sensors with the engine at 2,500 rpm for

approx. 120 seconds, and maintain engine at 2,500 rpm

Measure voltage between terminals VF1 (VF2) and E1.

Replace the oxygen sensor.Repair (Over lean)

5V

0V

±

EFI SYSTEM Electronic Control System (Main Oxygen Sensors)FI±75

WhereEverybodyKnowsYourName

Page 1926 of 4087

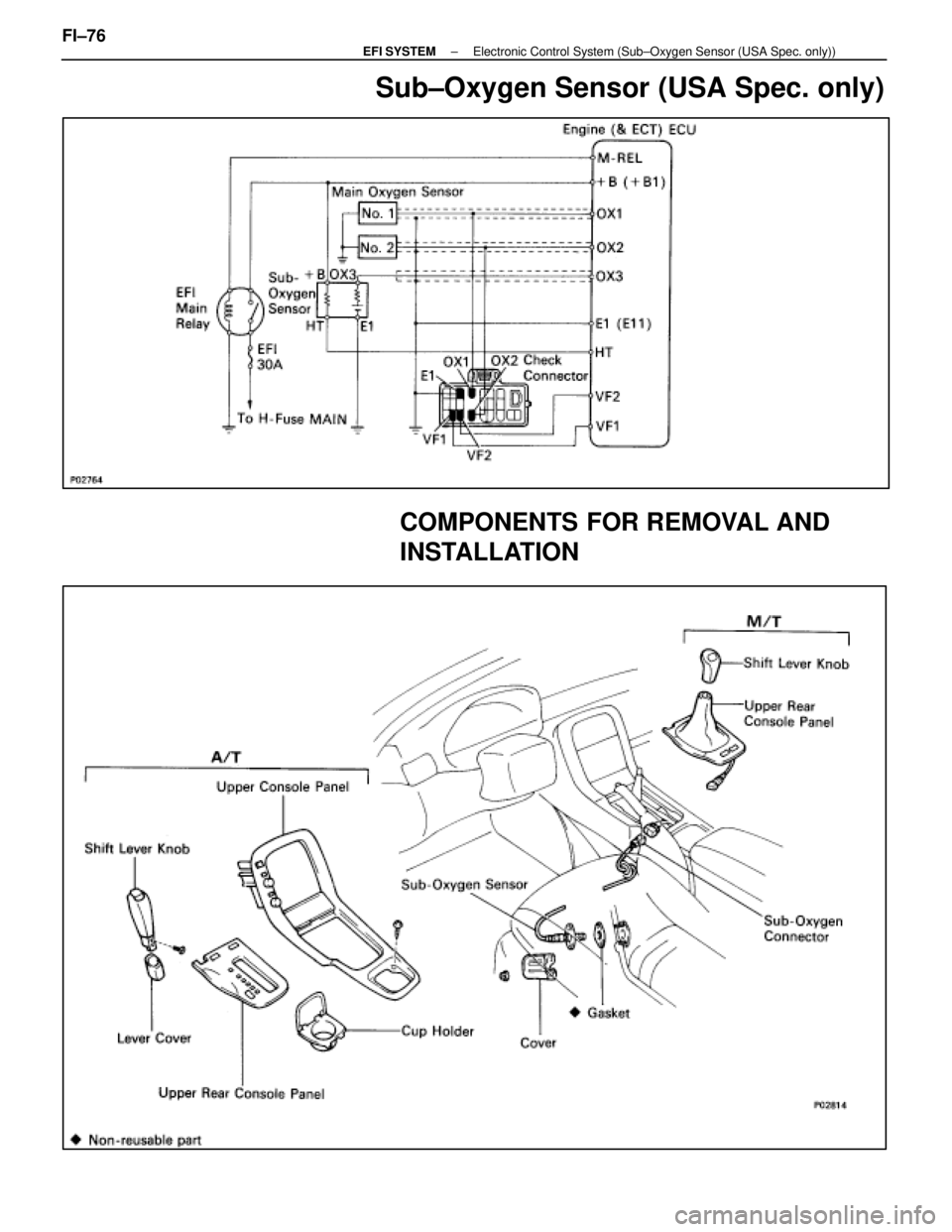

Sub±Oxygen Sensor (USA Spec. only)

COMPONENTS FOR REMOVAL AND

INSTALLATION

FI±76±

EFI SYSTEM Electronic Control System (Sub±Oxygen Sensor (USA Spec. only))

WhereEverybodyKnowsYourName