LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: transmission oil, trunk release, check oil, spark plugs replace, clock reset, alternator belt, air filter

Page 3211 of 4087

YESNo

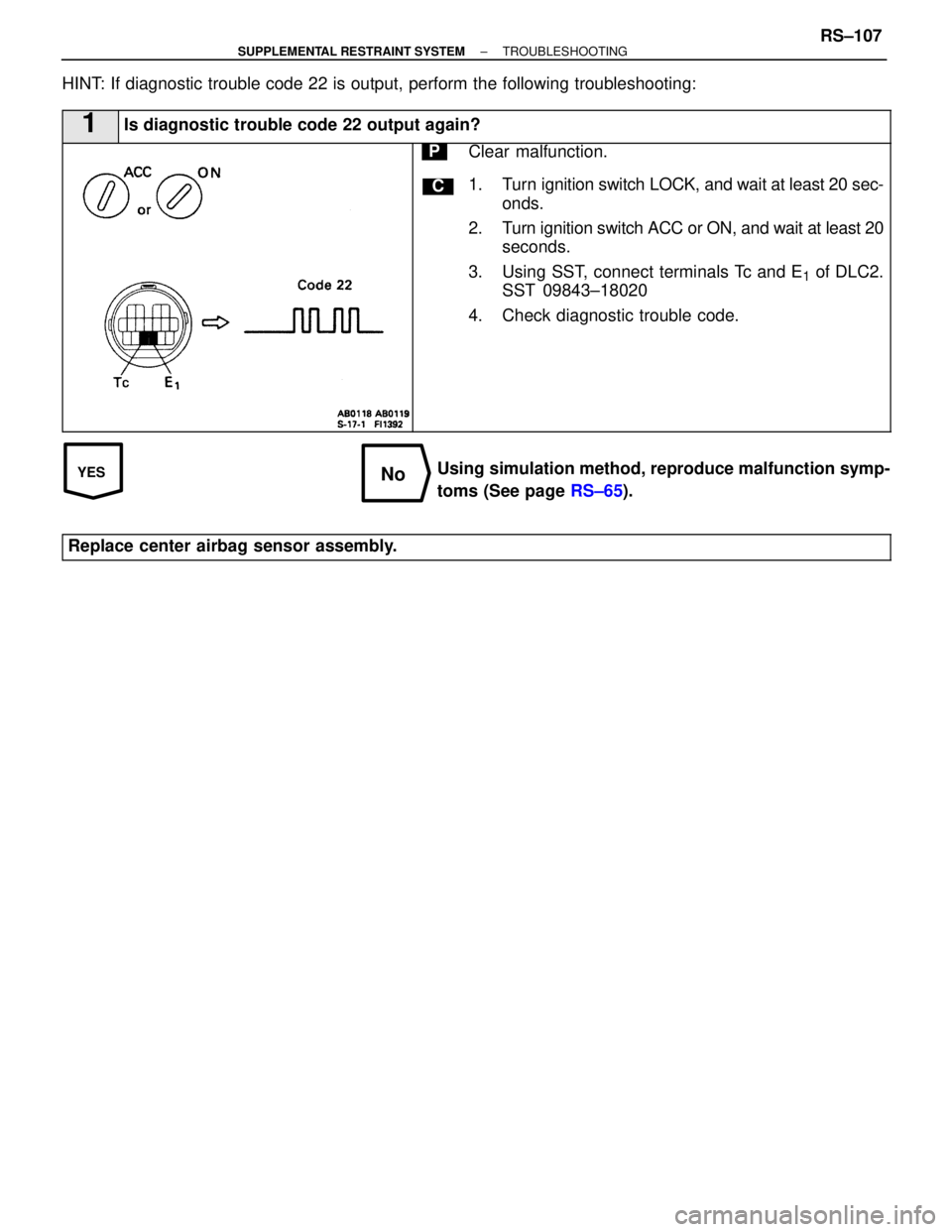

HINT: If diagnostic trouble code 22 is output, perform the following troubles\

hooting:

1Is diagnostic trouble code 22 output again?

C

PClear malfunction.

1. Turn ignition switch LOCK, and wait at least 20 sec-onds.

2. Turn ignition switch ACC or ON, and wait at least 20 seconds.

3. Using SST, connect terminals Tc and E

1 of DLC2.

SST 09843±18020

4. Check diagnostic trouble code.

Using simulation method, reproduce malfunction symp-

toms (See page RS±65).

Replace center airbag sensor assembly.

±

SUPPLEMENTAL RESTRAINT SYSTEM TROUBLESHOOTINGRS±107

WhereEverybodyKnowsYourName

Page 3212 of 4087

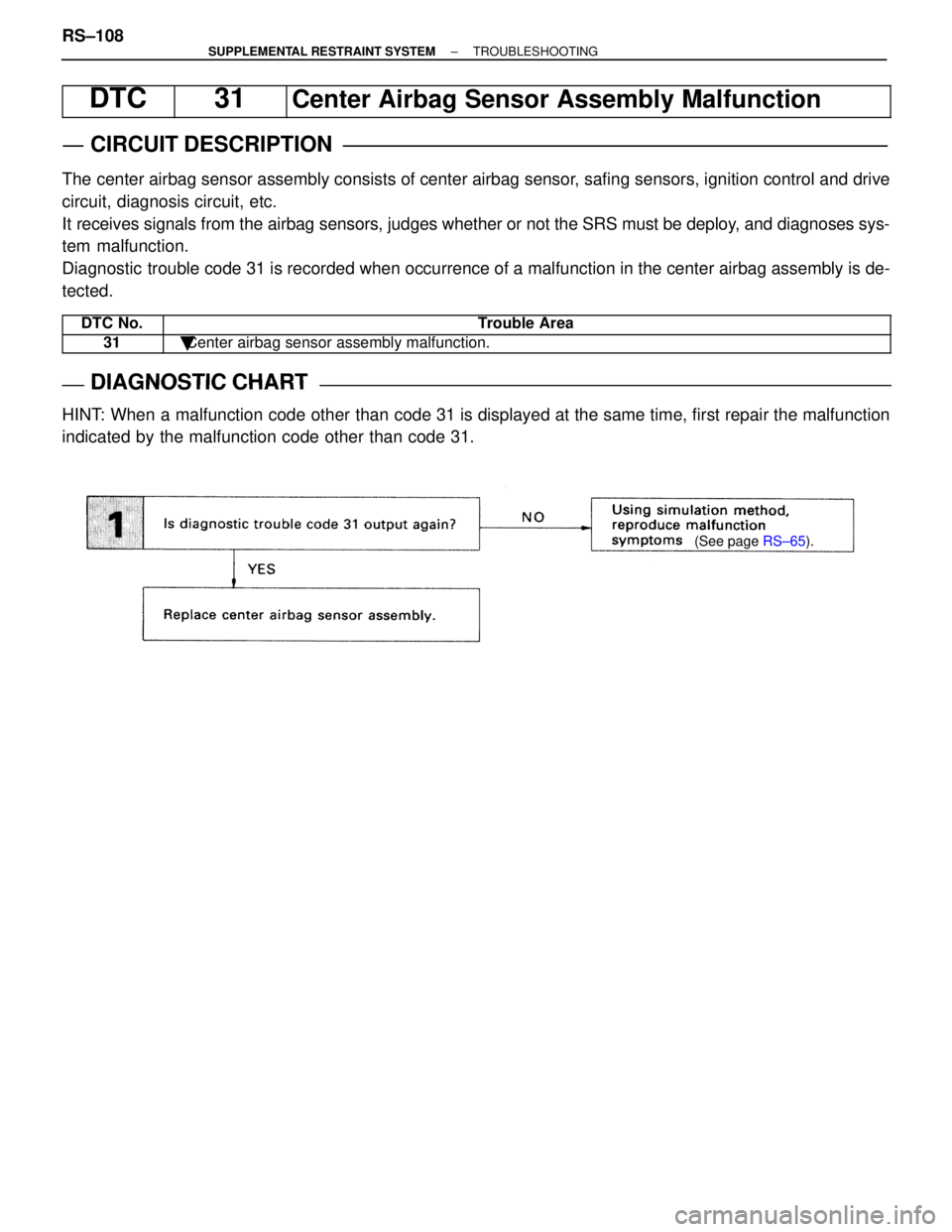

DTC31Center Airbag Sensor Assembly Malfunction

CIRCUIT DESCRIPTION

The center airbag sensor assembly consists of center airbag sensor, safing sensors, ignition control and drive

circuit, diagnosis circuit, etc.

It receives signals from the airbag sensors, judges whether or not the SRS must be deploy, and diagnoses sys-

tem malfunction.

Diagnostic trouble code 31 is recorded when occurrence of a malfunction in the cen\

ter airbag assembly is de-

tected.

DTC No.Trouble Area

31�Center airbag sensor assembly malfunction.

DIAGNOSTIC CHARTDIAGNOSTIC CHART

HINT: When a malfunction code other than code 31 is displayed at the same time, first repair the malfunction

indicated by the malfunction code other than code 31.

(See page RS±65).

RS±108±

SUPPLEMENTAL RESTRAINT SYSTEM TROUBLESHOOTING

WhereEverybodyKnowsYourName

Page 3213 of 4087

YESNO

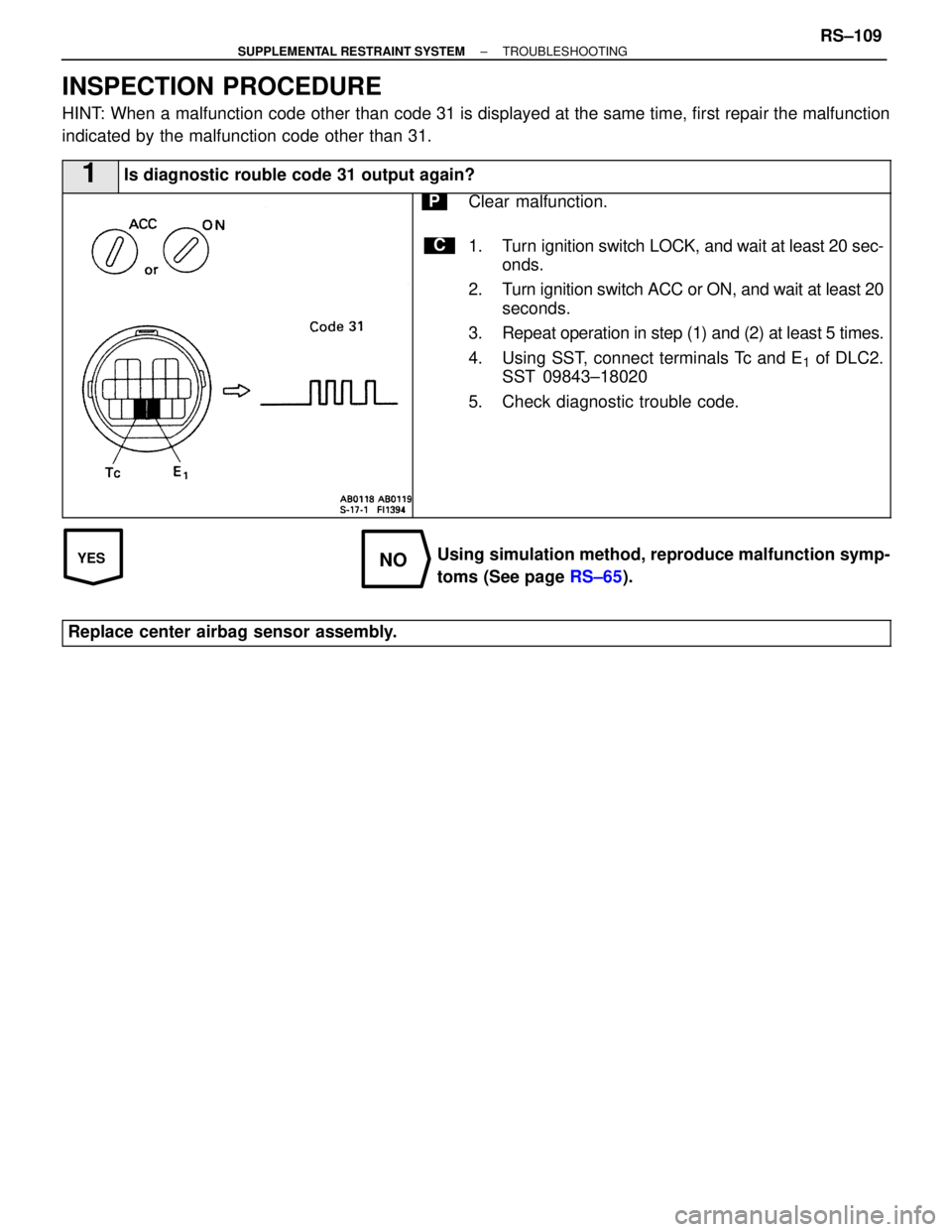

INSPECTION PROCEDURE

HINT: When a malfunction code other than code 31 is displayed at the same time, first repair the malfunction

indicated by the malfunction code other than 31.

1Is diagnostic rouble code 31 output again?

C

PClear malfunction.

1. Turn ignition switch LOCK, and wait at least 20 sec-onds.

2. Turn ignition switch ACC or ON, and wait at least 20 seconds.

3. Repeat operation in step (1) and (2) at least 5 times.

4. Using SST, connect terminals Tc and E

1 of DLC2.

SST 09843±18020

5. Check diagnostic trouble code.

Using simulation method, reproduce malfunction symp-

toms (See page RS±65).

Replace center airbag sensor assembly.

±

SUPPLEMENTAL RESTRAINT SYSTEM TROUBLESHOOTINGRS±109

WhereEverybodyKnowsYourName

Page 3214 of 4087

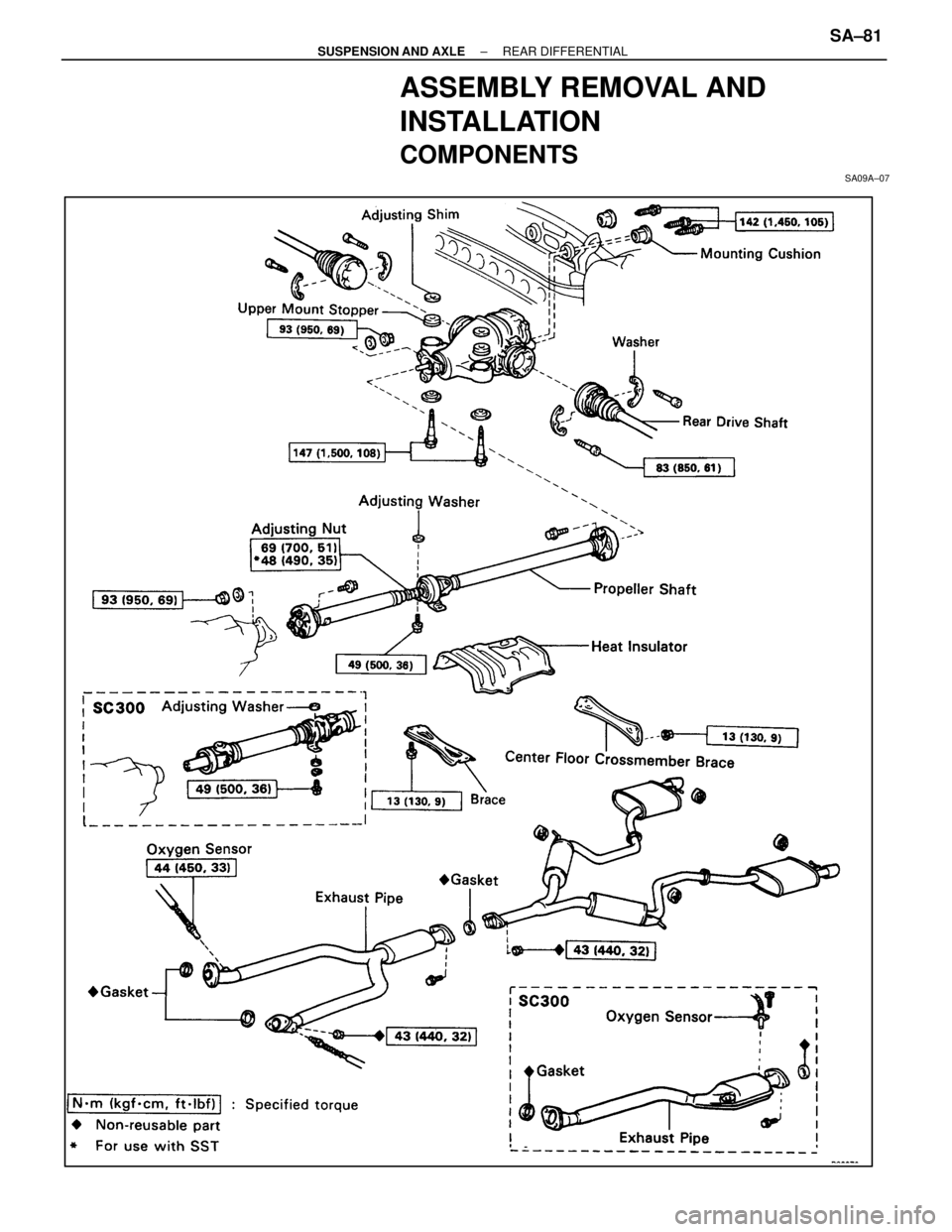

ASSEMBLY REMOVAL AND

INSTALLATION

COMPONENTS

SA09A±07

±

SUSPENSION AND AXLE REAR DIFFERENTIALSA±81

WhereEverybodyKnowsYourName

Page 3215 of 4087

DIFFERENTIAL REMOVAL

SA0S6±05

1. REMOVE PROPELLER SHAFT(See page PR±6 or 24)

2. DRAIN DIFFERENTIAL OIL

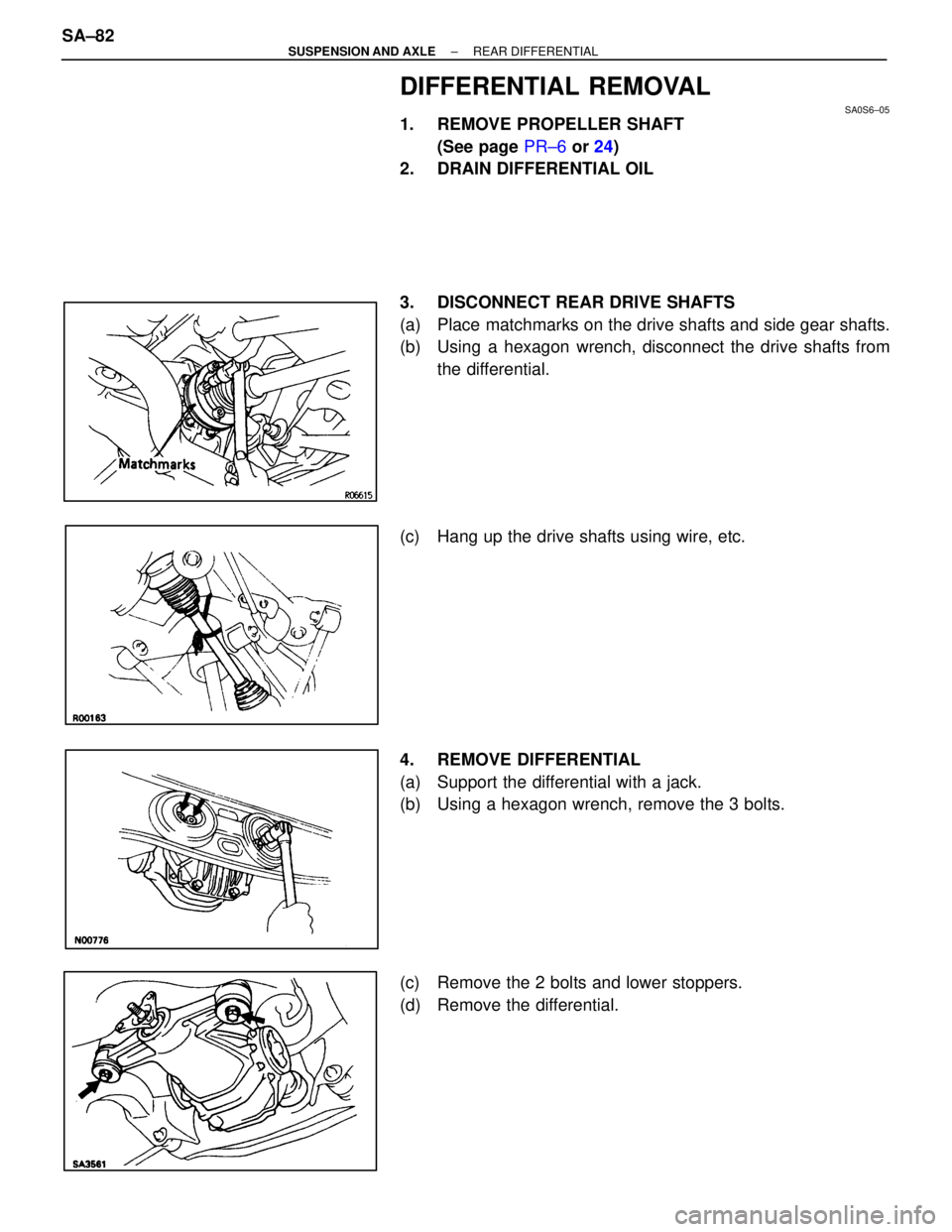

3. DISCONNECT REAR DRIVE SHAFTS

(a) Place matchmarks on the drive shafts and side gear shafts.

(b) Using a hexagon wrench, disconnect the drive shafts from

the differential.

(c) Hang up the drive shafts using wire, etc.

4. REMOVE DIFFERENTIAL

(a) Support the differential with a jack.

(b) Using a hexagon wrench, remove the 3 bolts.

(c) Remove the 2 bolts and lower stoppers.

(d) Remove the differential.

SA±82

±

SUSPENSION AND AXLE REAR DIFFERENTIAL

WhereEverybodyKnowsYourName

Page 3216 of 4087

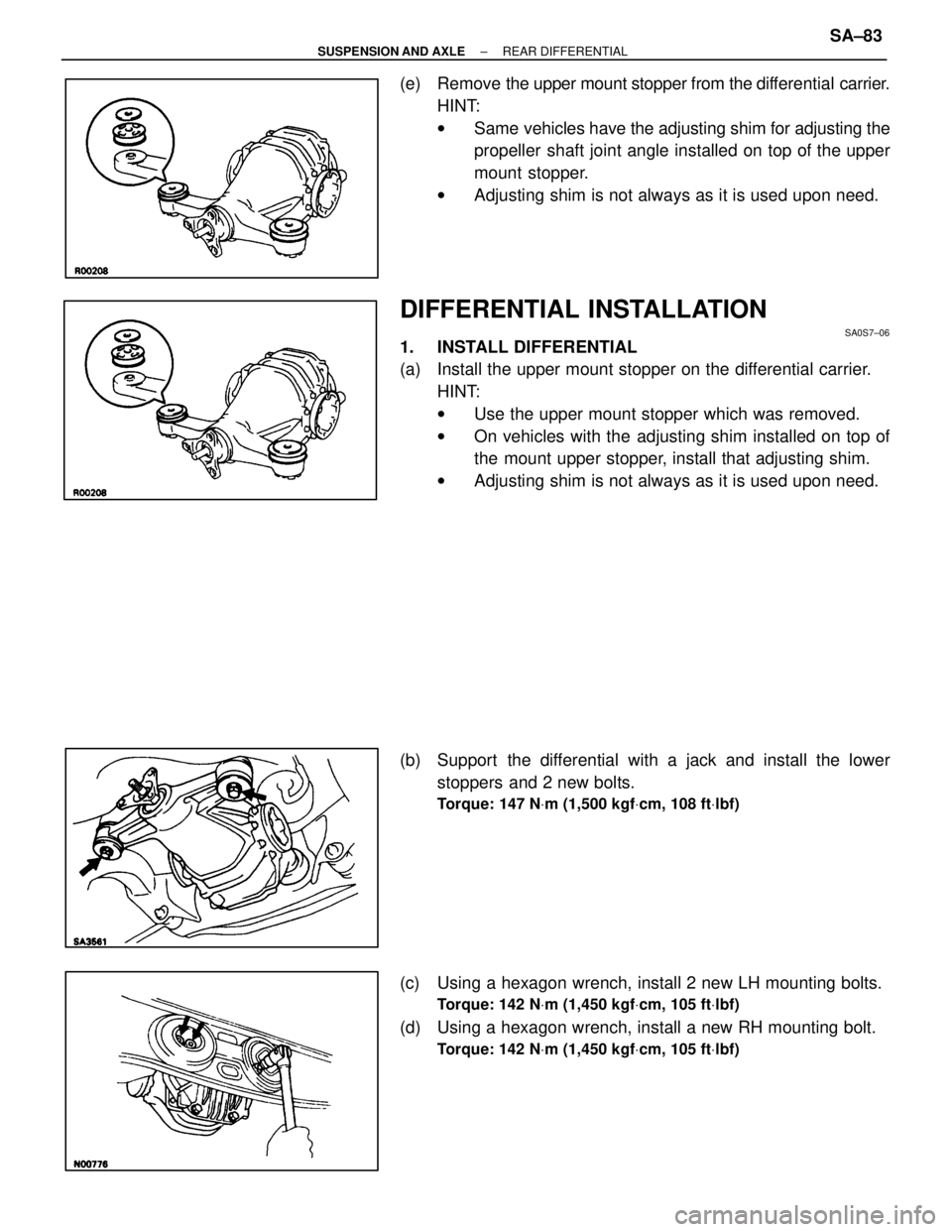

(e) Remove the upper mount stopper from the differential carrier.

HINT:

w Same vehicles have the adjusting shim for adjusting the

propeller shaft joint angle installed on top of the upper

mount stopper.

w Adjusting shim is not always as it is used upon need.

DIFFERENTIAL INSTALLATION

SA0S7±06

1. INSTALL DIFFERENTIAL

(a) Install the upper mount stopper on the differential carrier.

HINT:

wUse the upper mount stopper which was removed.

w On vehicles with the adjusting shim installed on top of

the mount upper stopper, install that adjusting shim.

w Adjusting shim is not always as it is used upon need.

(b) Support the differential with a jack and install the lower stoppers and 2 new bolts.

Torque: 147 N Vm (1,500 kgf Vcm, 108 ft Vlbf)

(c) Using a hexagon wrench, install 2 new LH mounting bolts.

Torque: 142 N Vm (1,450 kgf Vcm, 105 ft Vlbf)

(d) Using a hexagon wrench, install a new RH mounting bolt.

Torque: 142 N Vm (1,450 kgf Vcm, 105 ft Vlbf)

±

SUSPENSION AND AXLE REAR DIFFERENTIALSA±83

WhereEverybodyKnowsYourName

Page 3217 of 4087

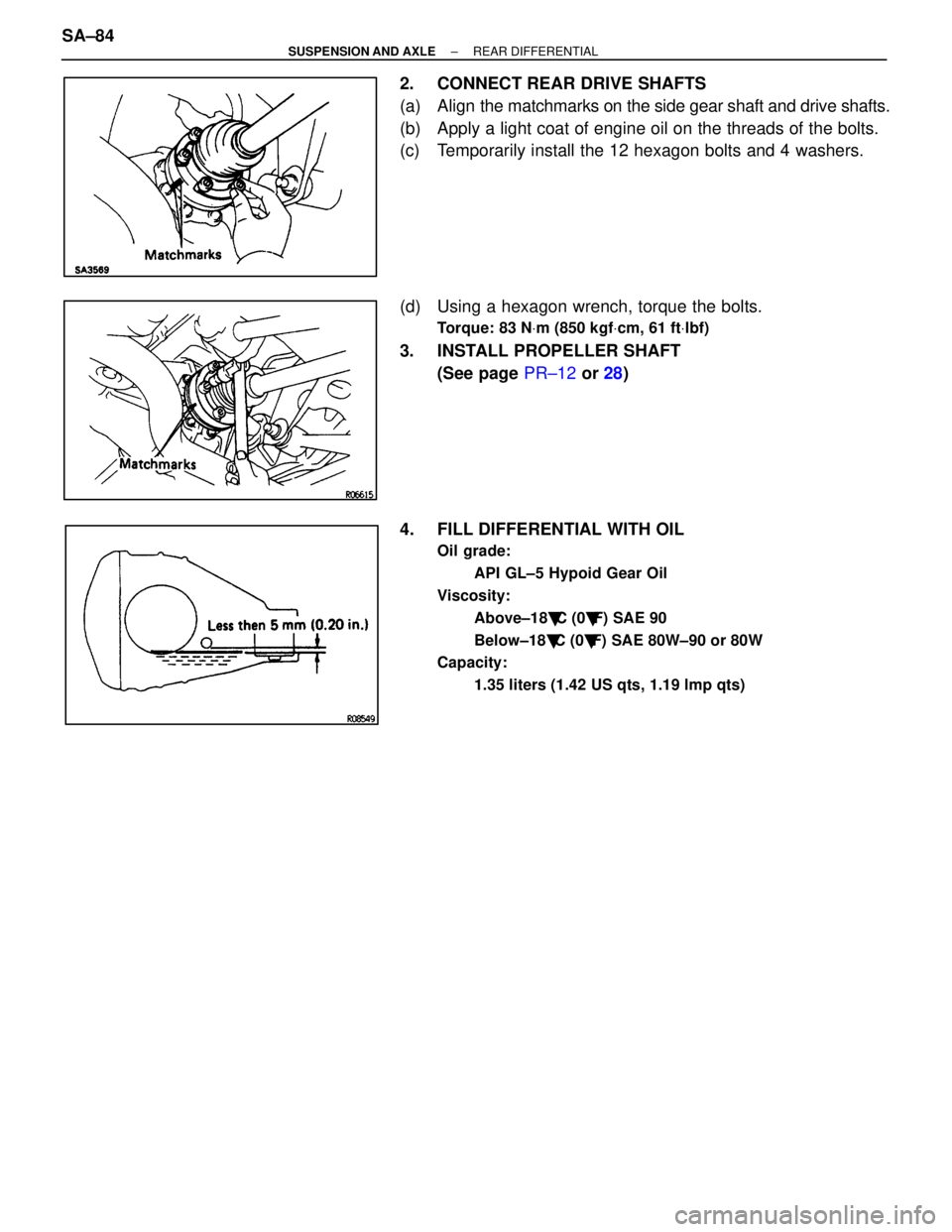

2. CONNECT REAR DRIVE SHAFTS

(a) Align the matchmarks on the side gear shaft and drive shafts.

(b) Apply a light coat of engine oil on the threads of the bolts.

(c) Temporarily install the 12 hexagon bolts and 4 washers.

(d) Using a hexagon wrench, torque the bolts.

Torque: 83 N Vm (850 kgf Vcm, 61 ft Vlbf)

3. INSTALL PROPELLER SHAFT

(See page PR±12 or 28)

4. FILL DIFFERENTIAL WITH OIL

Oil grade: API GL±5 Hypoid Gear Oil

Viscosity: Above±18 �C (0 �F) SAE 90

Below±18 �C (0 �F) SAE 80W±90 or 80W

Capacity:

1.35 liters (1.42 US qts, 1.19 lmp qts)

SA±84±

SUSPENSION AND AXLE REAR DIFFERENTIAL

WhereEverybodyKnowsYourName

Page 3218 of 4087

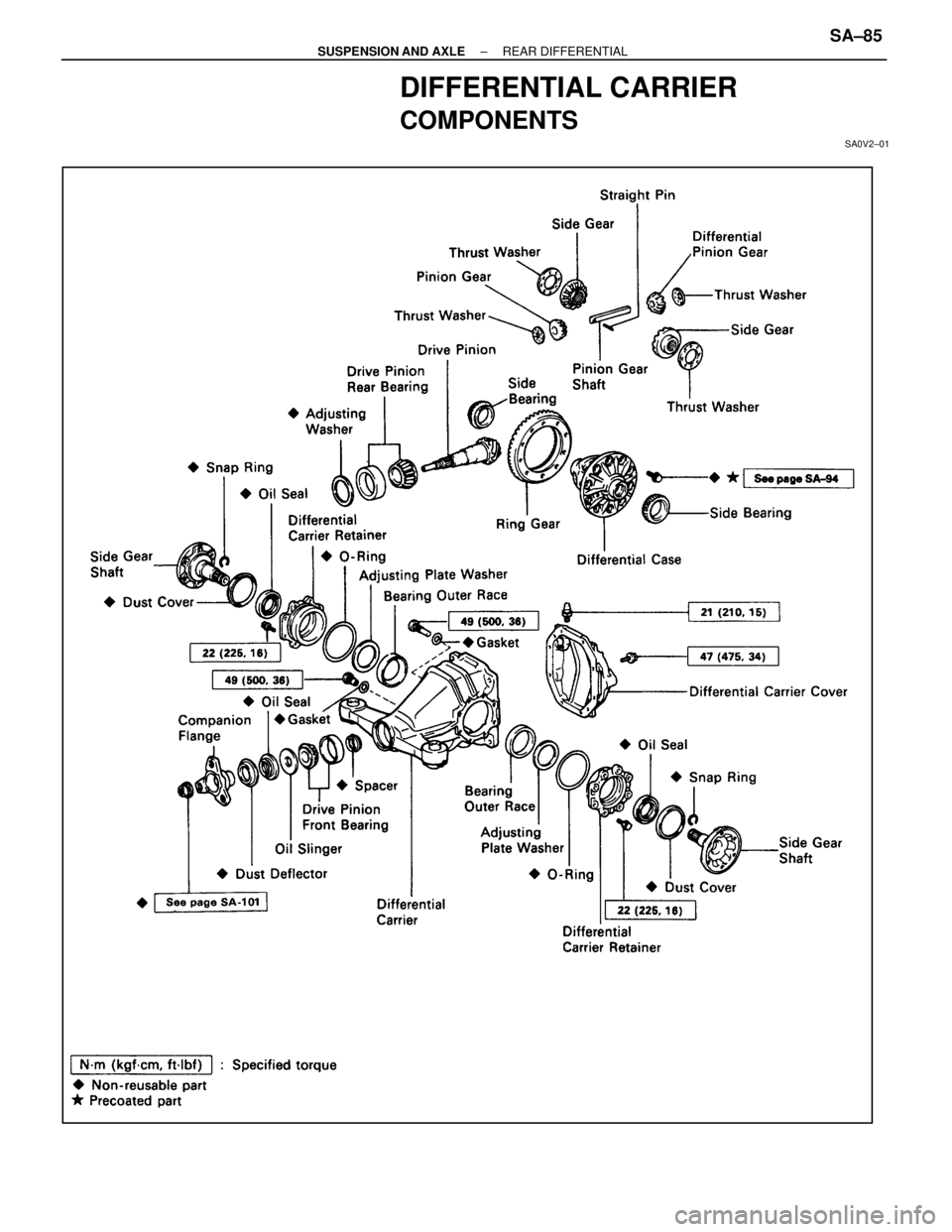

DIFFERENTIAL CARRIER

COMPONENTS

SA0V2±01

±

SUSPENSION AND AXLE REAR DIFFERENTIALSA±85

WhereEverybodyKnowsYourName

Page 3219 of 4087

DIFFERENTIAL CARRIER INSPECTION

SA0V3±05

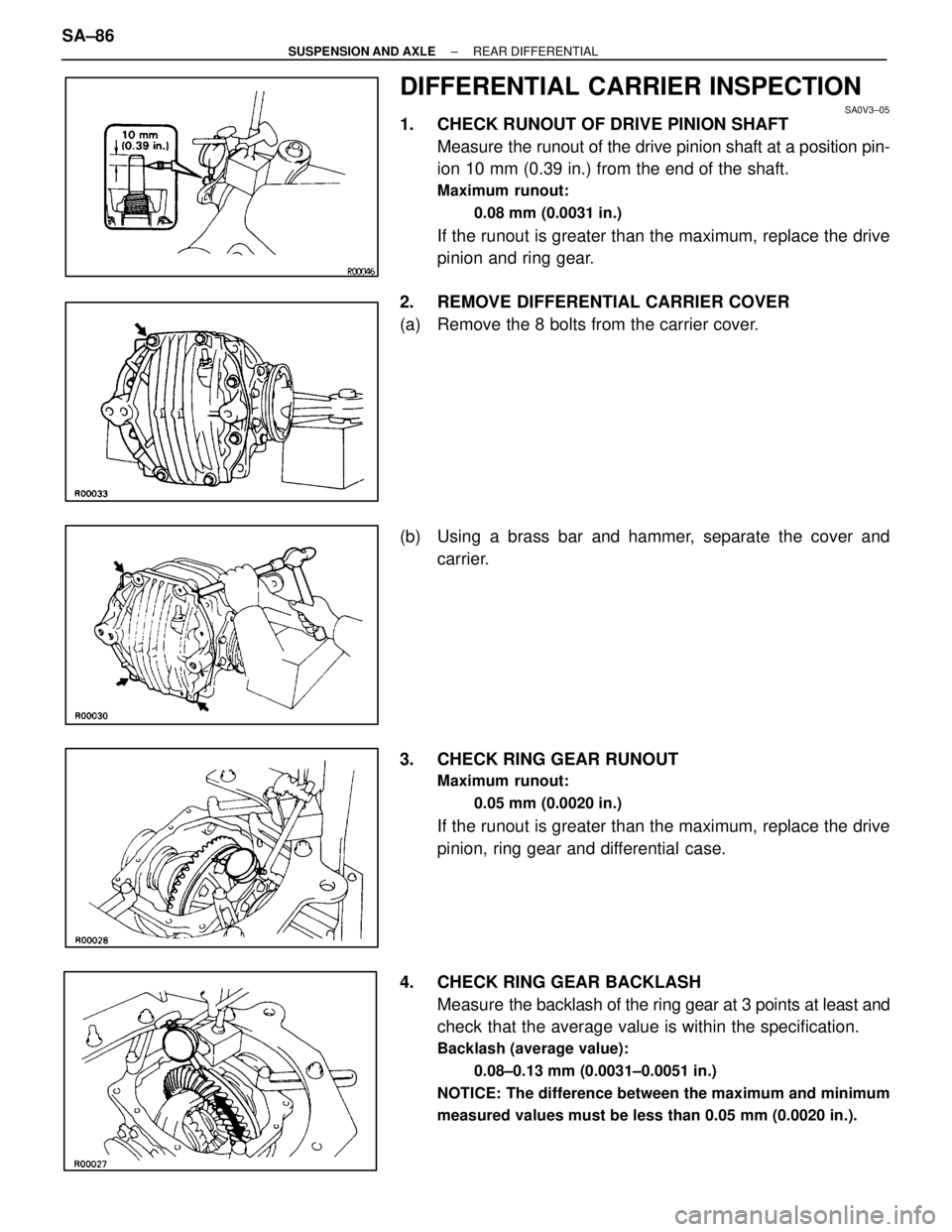

1. CHECK RUNOUT OF DRIVE PINION SHAFTMeasure the runout of the drive pinion shaft at a position pin-

ion 10 mm (0.39 in.) from the end of the shaft.

Maximum runout:

0.08 mm (0.0031 in.)

If the runout is greater than the maximum, replace the drive

pinion and ring gear.

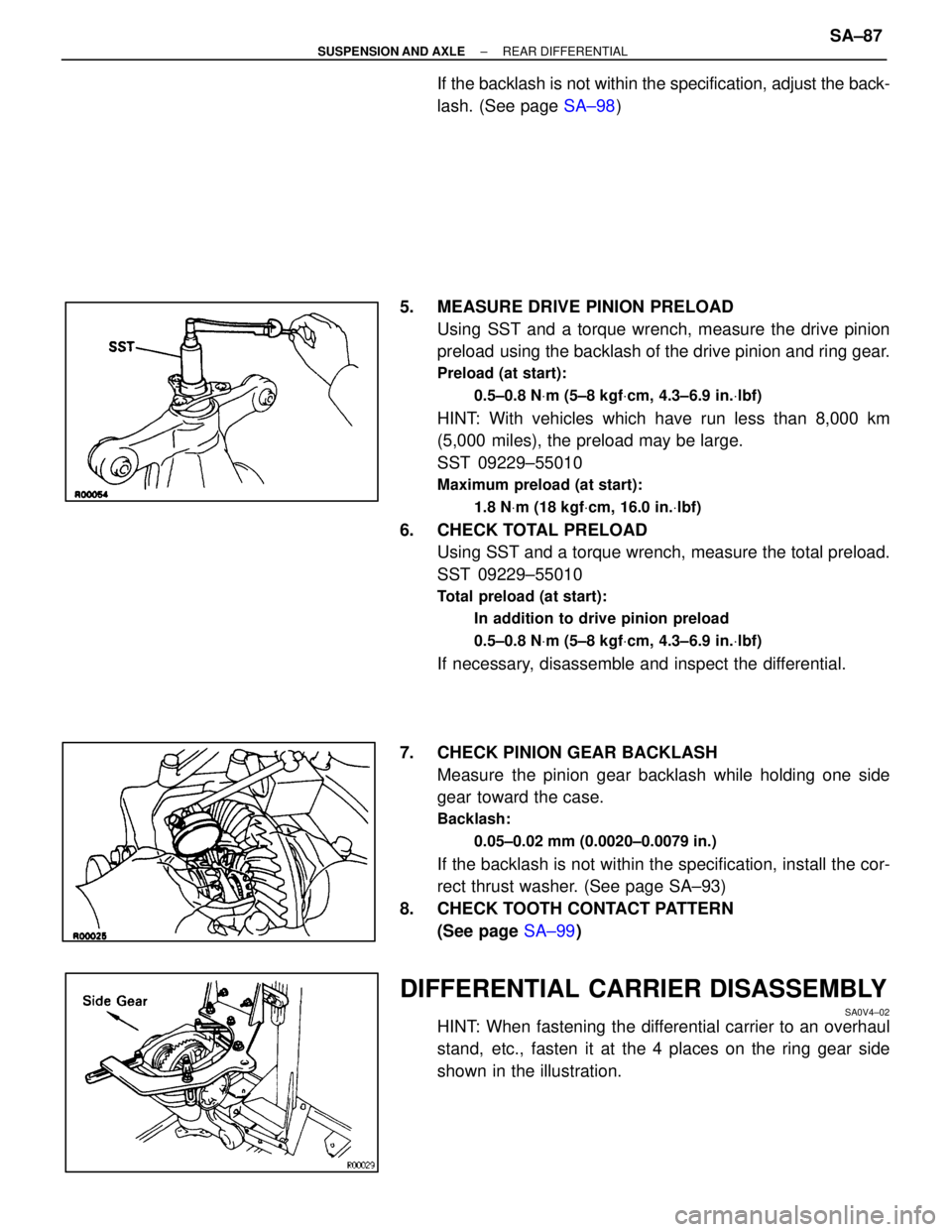

2. REMOVE DIFFERENTIAL CARRIER COVER

(a) Remove the 8 bolts from the carrier cover.

(b) Using a brass bar and hammer, separate the cover and carrier.

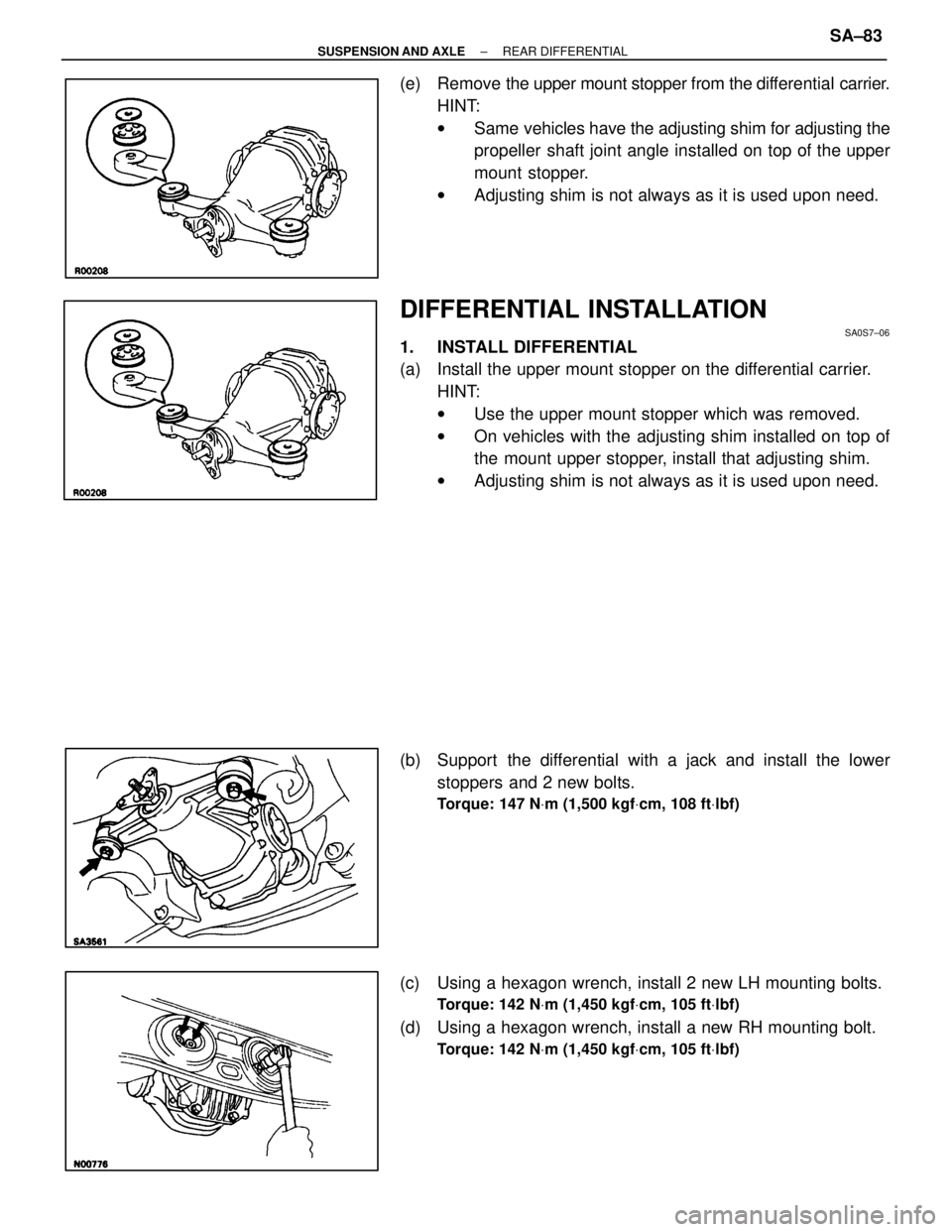

3. CHECK RING GEAR RUNOUT

Maximum runout: 0.05 mm (0.0020 in.)

If the runout is greater than the maximum, replace the drive

pinion, ring gear and differential case.

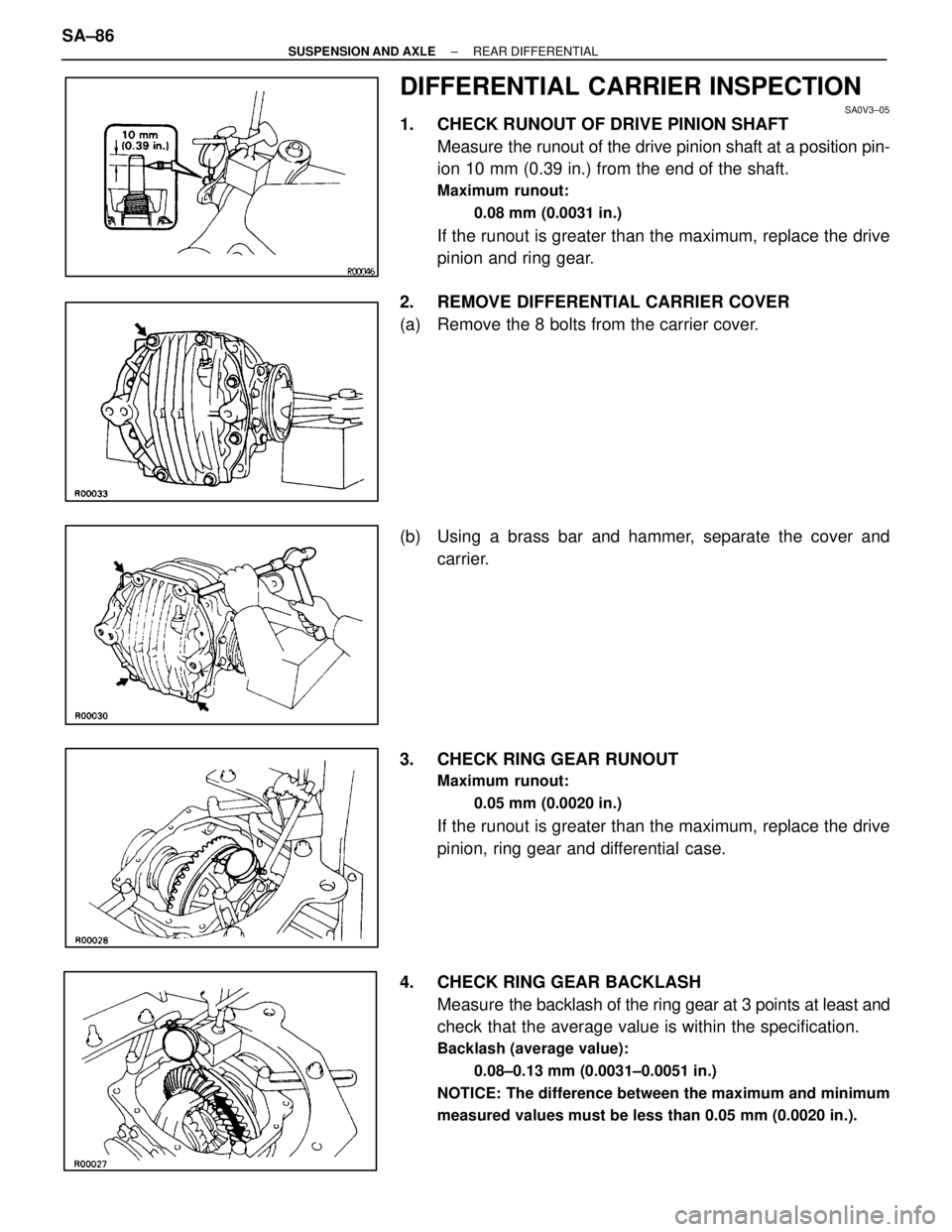

4. CHECK RING GEAR BACKLASH Measure the backlash of the ring gear at 3 points at least and

check that the average value is within the specification.

Backlash (average value):

0.08±0.13 mm (0.0031±0.0051 in.)

NOTICE: The difference between the maximum and minimum

measured values must be less than 0.05 mm (0.0020 in.).

SA±86±

SUSPENSION AND AXLE REAR DIFFERENTIAL

WhereEverybodyKnowsYourName

Page 3220 of 4087

If the backlash is not within the specification, adjust the back-

lash. (See page SA±98)

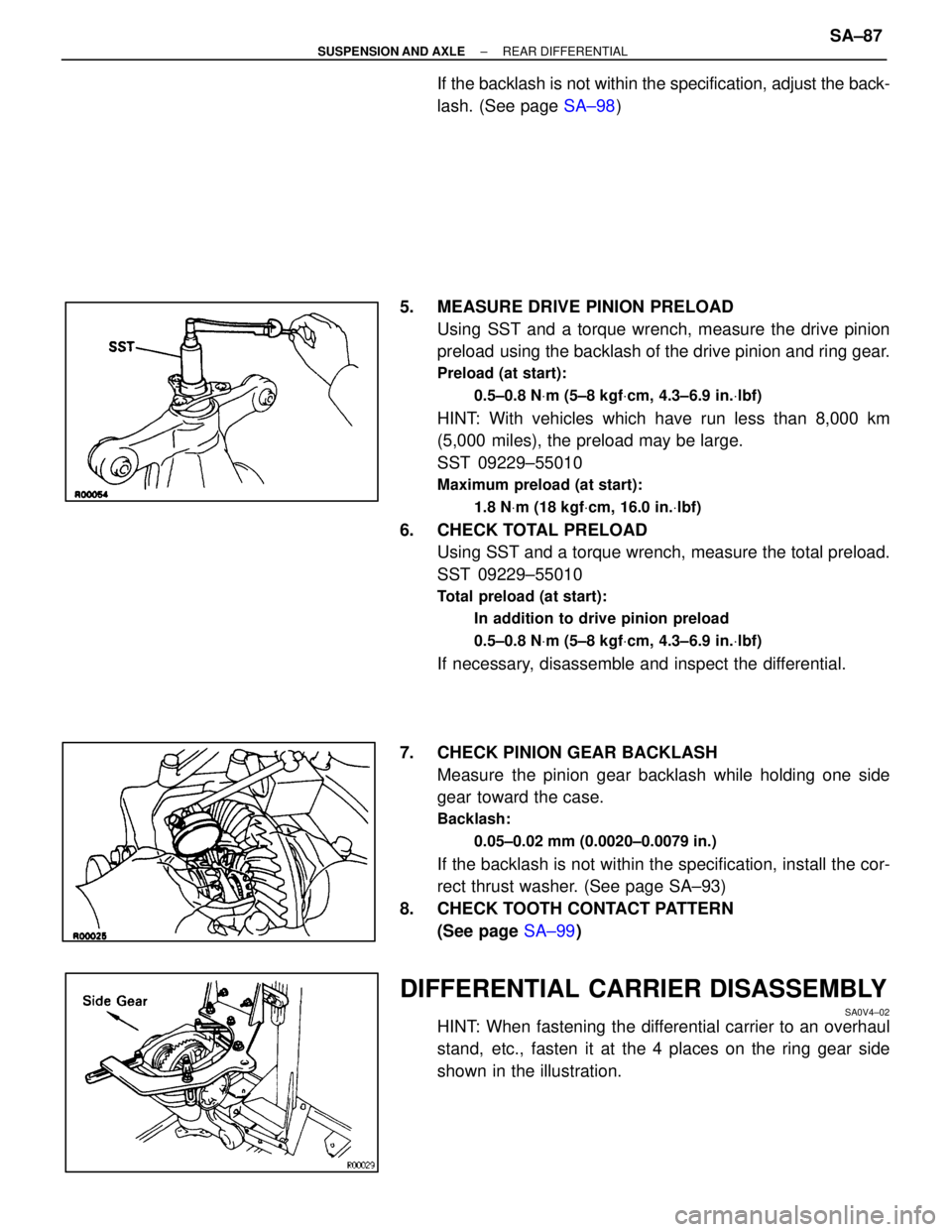

5. MEASURE DRIVE PINION PRELOAD Using SST and a torque wrench, measure the drive pinion

preload using the backlash of the drive pinion and ring gear.

Preload (at start):

0.5±0.8 N Vm (5±8 kgf Vcm, 4.3±6.9 in. Vlbf)

HINT: With vehicles which have run less than 8,000 km

(5,000 miles), the preload may be large.

SST 09229±55010

Maximum preload (at start):

1.8 N Vm (18 kgf Vcm, 16.0 in. Vlbf)

6. CHECK TOTAL PRELOAD

Using SST and a torque wrench, measure the total preload.

SST 09229±55010

Total preload (at start):

In addition to drive pinion preload

0.5±0.8 N Vm (5±8 kgf Vcm, 4.3±6.9 in. Vlbf)

If necessary, disassemble and inspect the differential.

7. CHECK PINION GEAR BACKLASH Measure the pinion gear backlash while holding one side

gear toward the case.

Backlash:

0.05±0.02 mm (0.0020±0.0079 in.)

If the backlash is not within the specification, install the cor-

rect thrust washer. (See page SA±93)

8. CHECK TOOTH CONTACT PATTERN (See page SA±99)

DIFFERENTIAL CARRIER DISASSEMBLY

SA0V4±02

HINT: When fastening the differential carrier to an overhaul

stand, etc., fasten it at the 4 places on the ring gear side

shown in the illustration.

±

SUSPENSION AND AXLE REAR DIFFERENTIALSA±87

WhereEverybodyKnowsYourName

Trending: height adjustment, checking oil, index, steering wheel adjustment, start stop button, transmission oil, door lock