lock LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1635 of 4087

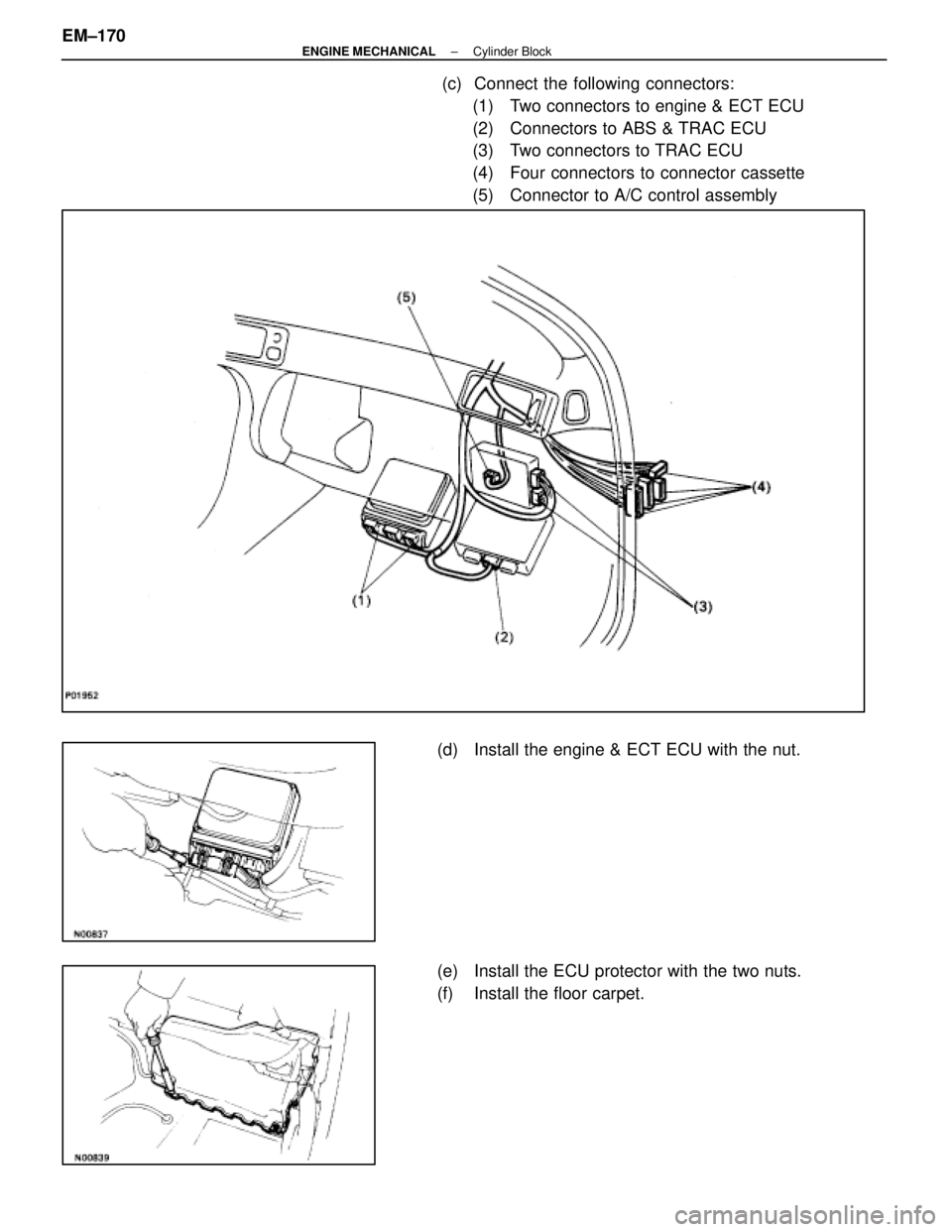

(c) Connect the following connectors:(1) Two connectors to engine & ECT ECU

(2) Connectors to ABS & TRAC ECU

(3) Two connectors to TRAC ECU

(4) Four connectors to connector cassette

(5) Connector to A/C control assembly

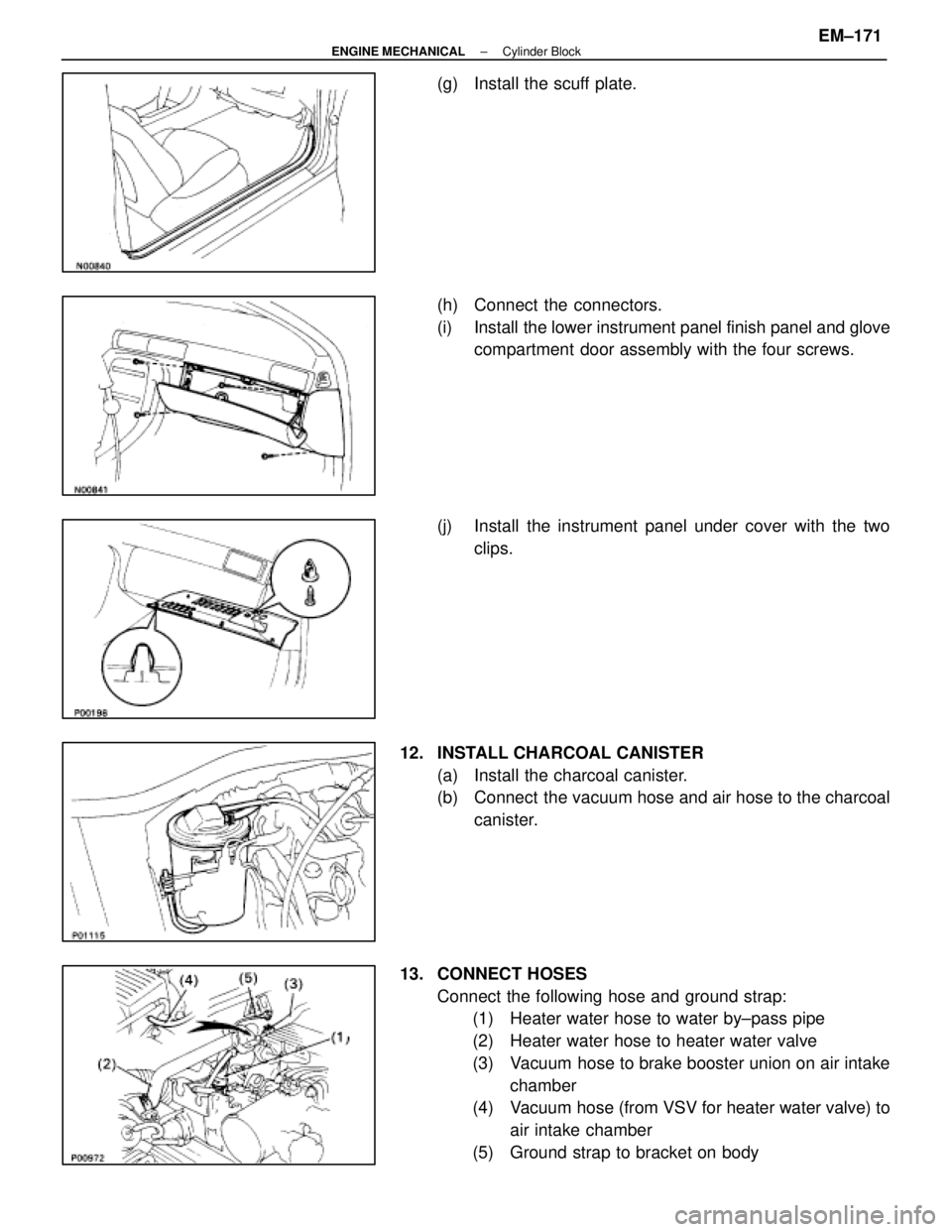

(d) Install the engine & ECT ECU with the nut.

(e) Install the ECU protector with the two nuts.

(f) Install the floor carpet.

EM±170

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1636 of 4087

(g) Install the scuff plate.

(h) Connect the connectors.

(i) Install the lower instrument panel finish panel and glovecompartment door assembly with the four screws.

(j) Install the instrument panel under cover with the two clips.

12. INSTALL CHARCOAL CANISTER (a) Install the charcoal canister.

(b) Connect the vacuum hose and air hose to the charcoalcanister.

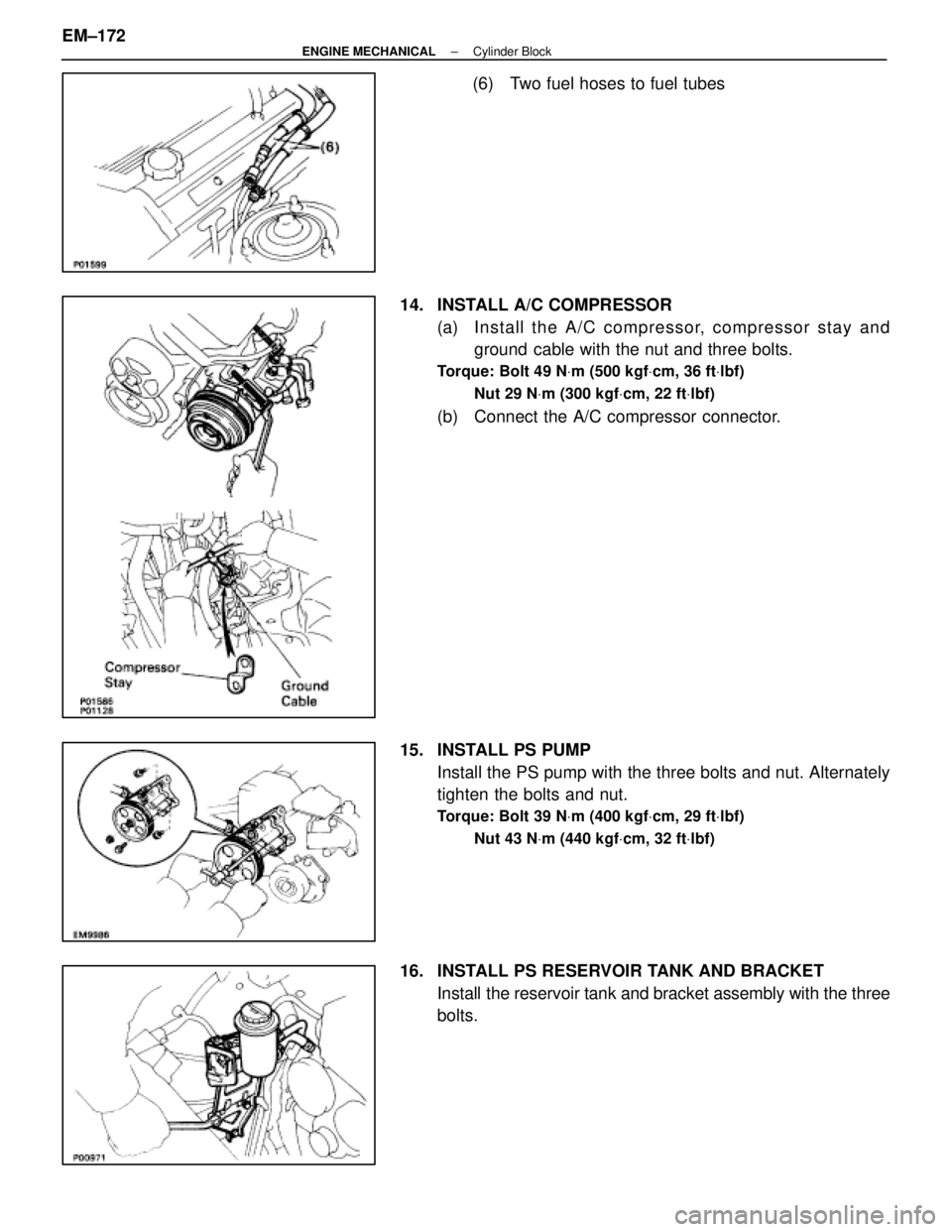

13. CONNECT HOSES Connect the following hose and ground strap:(1) Heater water hose to water by±pass pipe

(2) Heater water hose to heater water valve

(3) Vacuum hose to brake booster union on air intake

chamber

(4) Vacuum hose (from VSV for heater water valve) to

air intake chamber

(5) Ground strap to bracket on body

±

ENGINE MECHANICAL Cylinder BlockEM±171

WhereEverybodyKnowsYourName

Page 1637 of 4087

(6) Two fuel hoses to fuel tubes

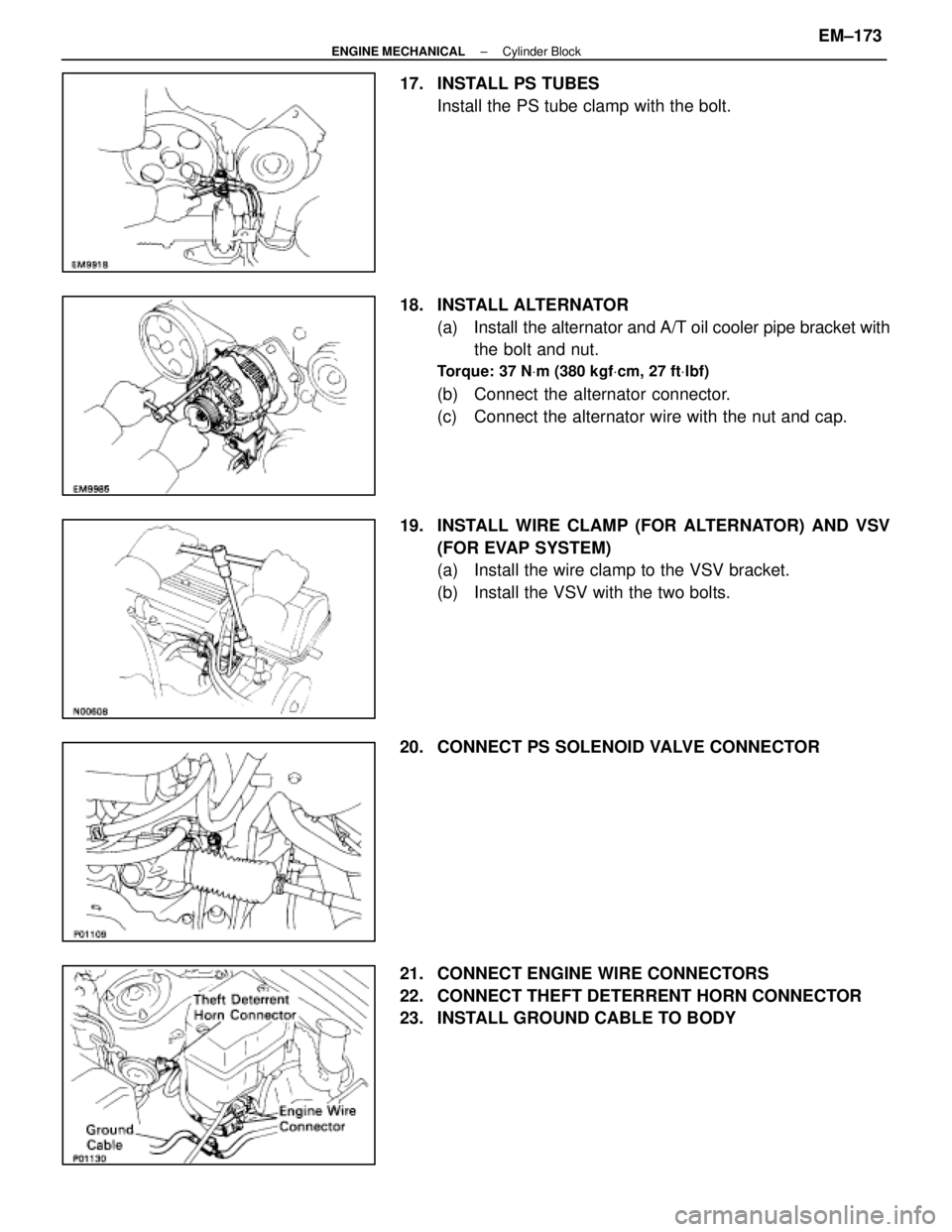

14. INSTALL A/C COMPRESSOR (a) In sta ll th e A/C co mp re sso r, co mp re sso r sta y an dground cable with the nut and three bolts.

Torque: Bolt 49 N Vm (500 kgf Vcm, 36 ft Vlbf)

Nut 29 N Vm (300 kgf Vcm, 22 ft Vlbf)

(b) Connect the A/C compressor connector.

15. INSTALL PS PUMP Install the PS pump with the three bolts and nut. Alternately

tighten the bolts and nut.

Torque: Bolt 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

Nut 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

16. INSTALL PS RESERVOIR TANK AND BRACKET

Install the reservoir tank and bracket assembly with the three

bolts.

EM±172

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1638 of 4087

17. INSTALL PS TUBESInstall the PS tube clamp with the bolt.

18. INSTALL ALTERNATOR (a) Install the alternator and A/T oil cooler pipe bracket withthe bolt and nut.

Torque: 37 N Vm (380 kgf Vcm, 27 ft Vlbf)

(b) Connect the alternator connector.

(c) Connect the alternator wire with the nut and cap.

19. INSTALL WIRE CLAMP (FOR ALTERNATOR) AND VSV (FOR EVAP SYSTEM)

(a) Install the wire clamp to the VSV bracket.

(b) Install the VSV with the two bolts.

20. CONNECT PS SOLENOID VALVE CONNECTOR

21. CONNECT ENGINE WIRE CONNECTORS

22. CONNECT THEFT DETERRENT HORN CONNECTOR

23. INSTALL GROUND CABLE TO BODY

±

ENGINE MECHANICAL Cylinder BlockEM±173

WhereEverybodyKnowsYourName

Page 1639 of 4087

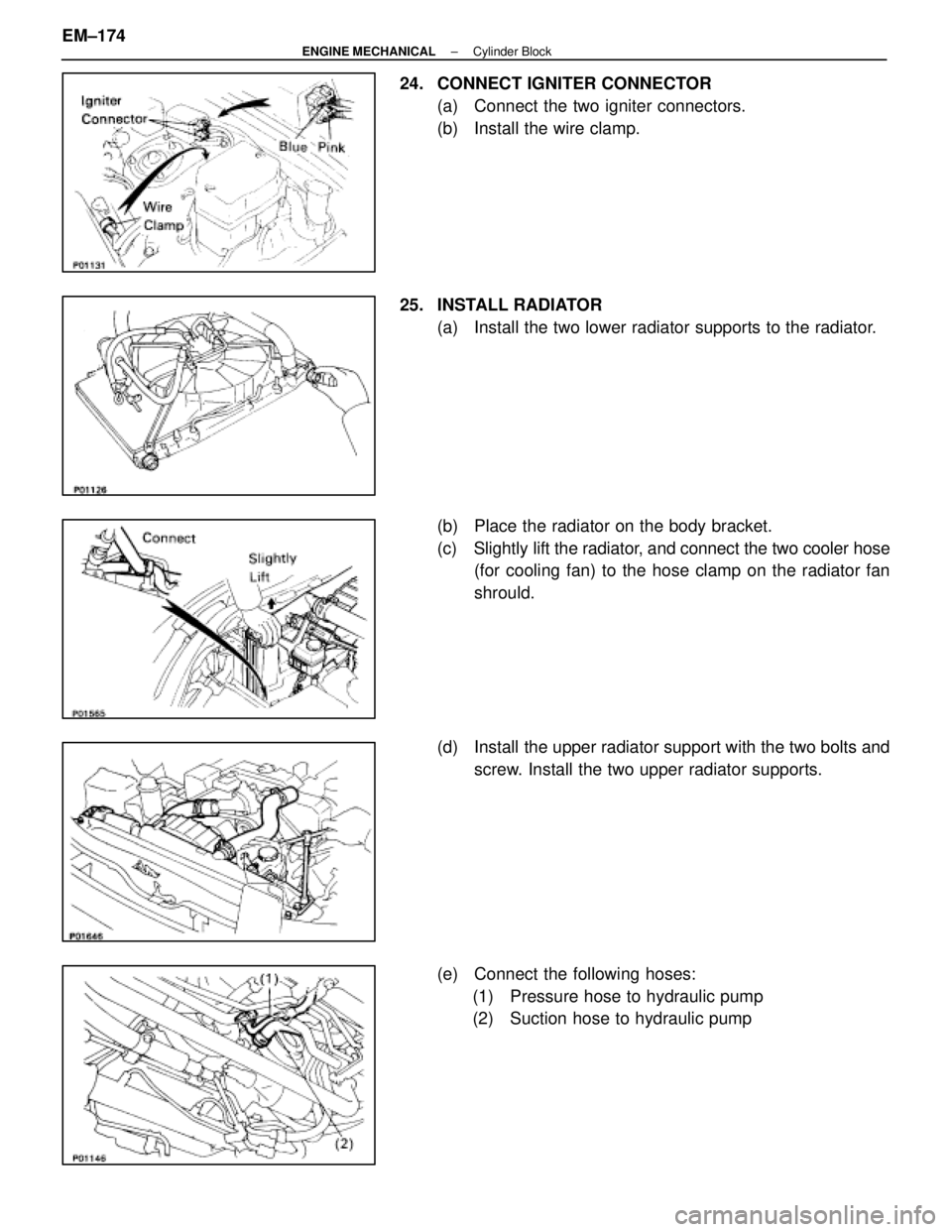

24. CONNECT IGNITER CONNECTOR(a) Connect the two igniter connectors.

(b) Install the wire clamp.

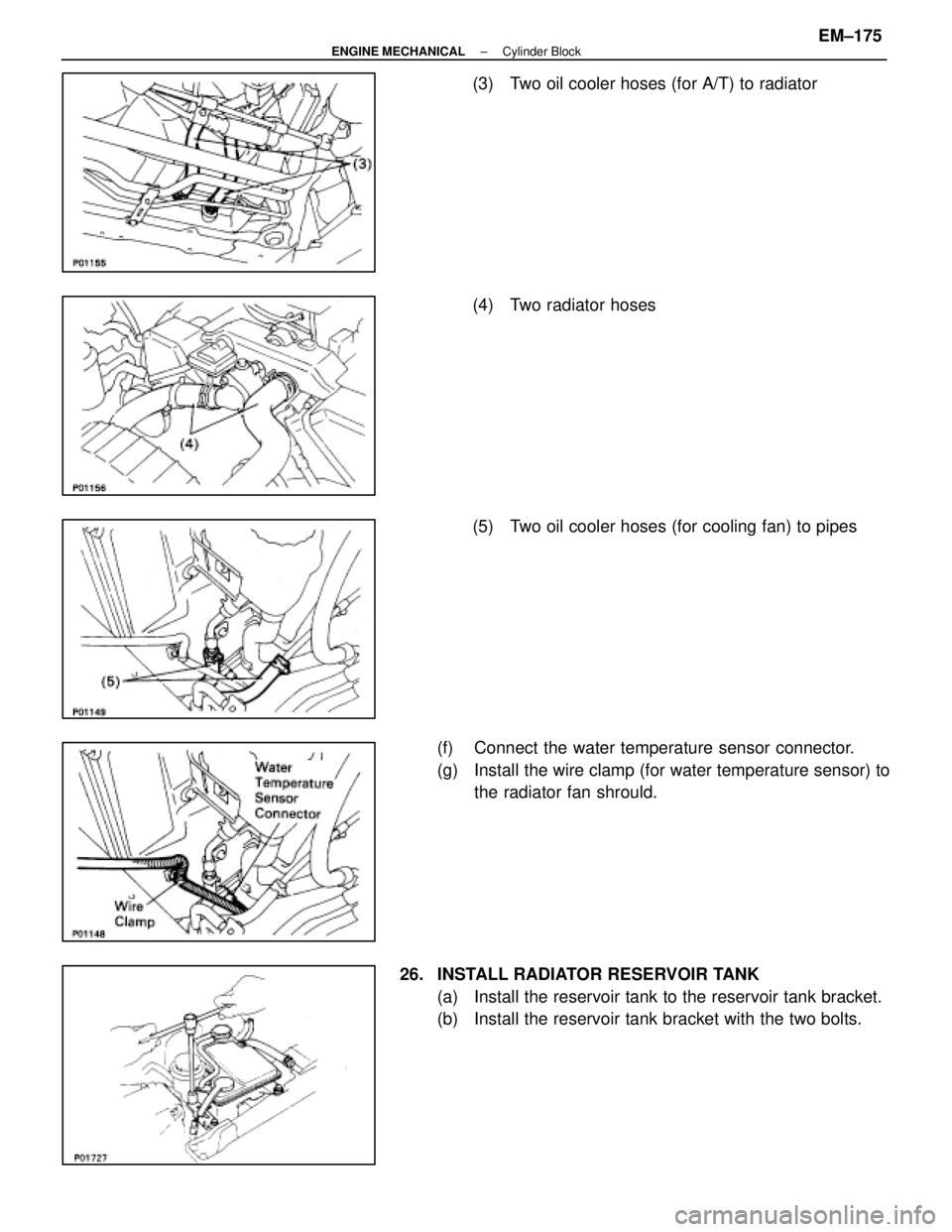

25. INSTALL RADIATOR (a) Install the two lower radiator supports to the radiator.

(b) Place the radiator on the body bracket.

(c) Slightly lift the radiator, and connect the two cooler hose(for cooling fan) to the hose clamp on the radiator fan

shrould.

(d) Install the upper radiator support with the two bolts and screw. Install the two upper radiator supports.

(e) Connect the following hoses: (1) Pressure hose to hydraulic pump

(2) Suction hose to hydraulic pump

EM±174

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1640 of 4087

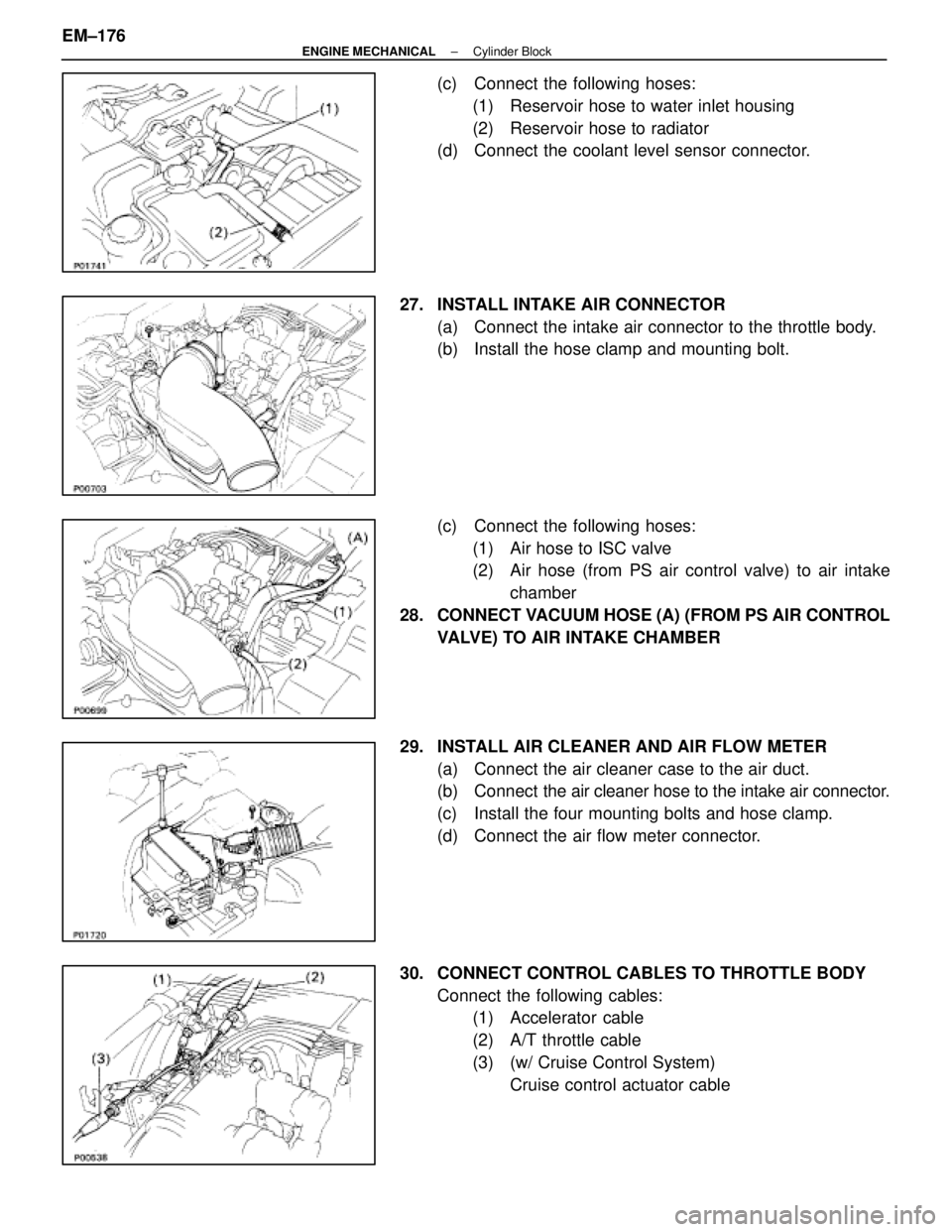

(3) Two oil cooler hoses (for A/T) to radiator

(4) Two radiator hoses

(5) Two oil cooler hoses (for cooling fan) to pipes

(f) Connect the water temperature sensor connector.

(g) Install the wire clamp (for water temperature sensor) to the radiator fan shrould.

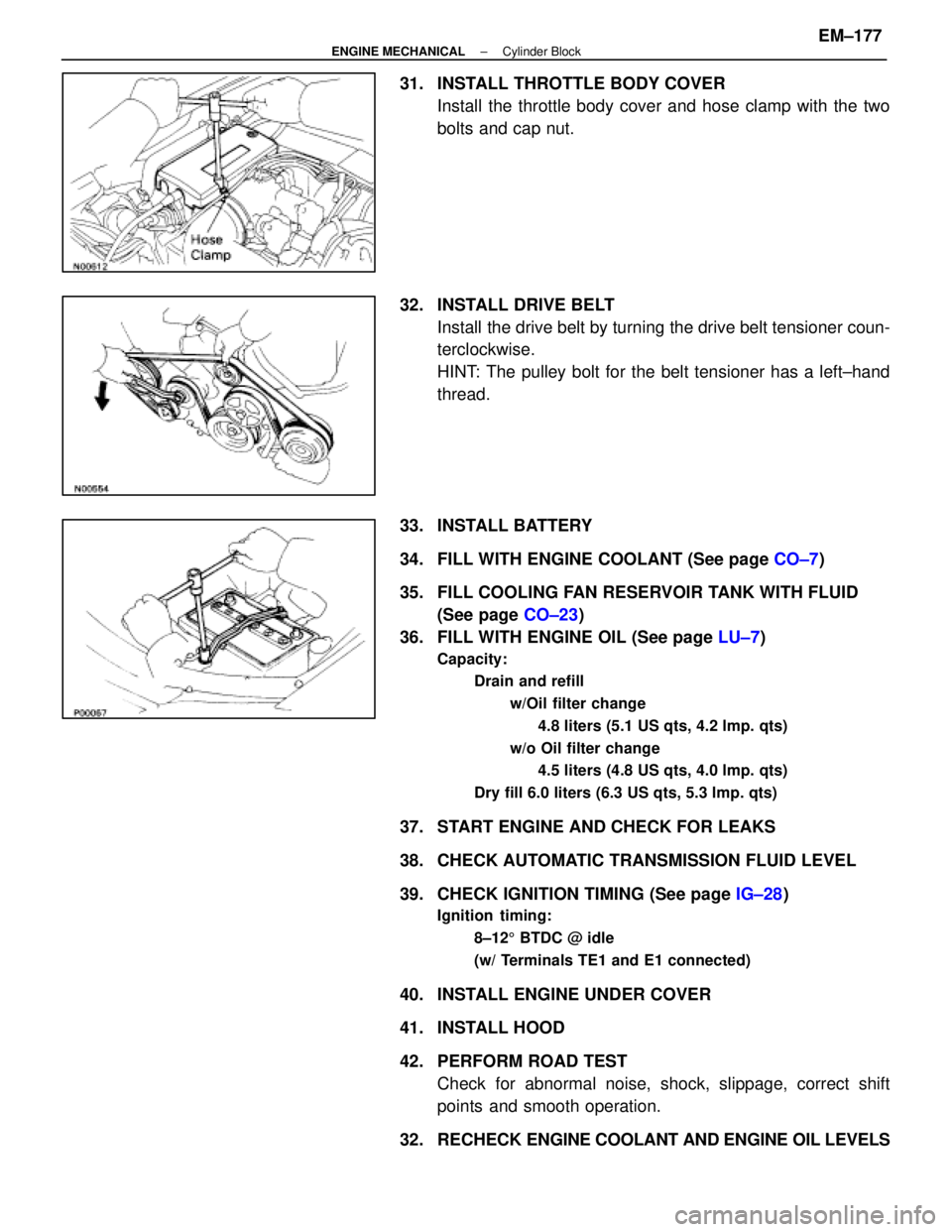

26. INSTALL RADIATOR RESERVOIR TANK (a) Install the reservoir tank to the reservoir tank bracket.

(b) Install the reservoir tank bracket with the two bolts.

±

ENGINE MECHANICAL Cylinder BlockEM±175

WhereEverybodyKnowsYourName

Page 1641 of 4087

(c) Connect the following hoses:(1) Reservoir hose to water inlet housing

(2) Reservoir hose to radiator

(d) Connect the coolant level sensor connector.

27. INSTALL INTAKE AIR CONNECTOR (a) Connect the intake air connector to the throttle body.

(b) Install the hose clamp and mounting bolt.

(c) Connect the following hoses:(1) Air hose to ISC valve

(2) Air hose (from PS air control valve) to air intake chamber

28. CONNECT VACUUM HOSE (A) (FROM PS AIR CONTROL VALVE) TO AIR INTAKE CHAMBER

29. INSTALL AIR CLEANER AND AIR FLOW METER (a) Connect the air cleaner case to the air duct.

(b) Connect the air cleaner hose to the intake air connector.

(c) Install the four mounting bolts and hose clamp.

(d) Connect the air flow meter connector.

30. CONNECT CONTROL CABLES TO THROTTLE BODY Connect the following cables:(1) Accelerator cable

(2) A/T throttle cable

(3) (w/ Cruise Control System)

Cruise control actuator cable

EM±176

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1642 of 4087

31. INSTALL THROTTLE BODY COVERInstall the throttle body cover and hose clamp with the two

bolts and cap nut.

32. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

33. INSTALL BATTERY

34. FILL WITH ENGINE COOLANT (See page CO±7)

35. FILL COOLING FAN RESERVOIR TANK WITH FLUID (See page CO±23)

36. FILL WITH ENGINE OIL (See page LU±7)

Capacity:

Drain and refill

w/Oil filter change4.8 liters (5.1 US qts, 4.2 lmp. qts)

w/o Oil filter change 4.5 liters (4.8 US qts, 4.0 lmp. qts)

Dry fill 6.0 liters (6.3 US qts, 5.3 lmp. qts)

37. START ENGINE AND CHECK FOR LEAKS

38. CHECK AUTOMATIC TRANSMISSION FLUID LEVEL

39. CHECK IGNITION TIMING (See page IG±28)

Ignition timing:

8±125 BTDC @ idle

(w/ Terminals TE1 and E1 connected)

40. INSTALL ENGINE UNDER COVER

41. INSTALL HOOD

42. PERFORM ROAD TEST Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

32. RECHECK ENGINE COOLANT AND ENGINE OIL LEVELS

±

ENGINE MECHANICAL Cylinder BlockEM±177

WhereEverybodyKnowsYourName

Page 1647 of 4087

The 1 UZ±FE engine has 8±cylinders in a V±arrangement at a bank an\

gle of 905. From the front of the RH

bank cylinders are numbered 2±4±6±8, and from the front of the LH b\

ank cylinders are numbered 1 ±3±5±7.

The crankshaft is supported by 5 bearings specified by the inside of the cr\

ankcase. These bearings are made

of a copper and lead alloy. The crankshaft is integrated with 8 weights which are cast along with it\

for balancing. Oil holes are built

into the center of the crankshaft for supplying oil to the connecting ro\

ds, pistons and other components. The ignition order is 1±8±4±3±6±5±7±2. The cylinder\

head is made of aluminum alloy, with a cross flow

type intake and exhaust layout and with pent±roof type combustion chambers. The spark plugs are loca\

ted in

the center of the combustion chambers.

At the front and rear of the intake manifold, a water passage has been p\

rovided which connects the RH

and LH cylinder heads. Exhaust and intake valves are equipped with irregular pitch springs made\

of special valve spring carbon

steel which are capable of following no matter what the engine speed.

The RH and LH intake camshafts are driven by a single timing belt, and a ge\

ar on the intake camshaft en-

gages with a gear on the exhaust camshaft to drive it. The camshaft jour\

nal is supported at 5 (intake) or 4 (ex-

haust) places between the valve lifters of each cylinder and on the front end of the cylinder \

head. Lubrication

of the cam journal gear is accomplished by oil being supplied through the \

oiler port in the center of the camshaft. Adjustment of the valve clearance is done by means of an outer shim type\

system, in which valve adjusting

shims are located above the valve lifters. This permits replacement of the sh\

ims without removal of the cam-

shafts. Pistons are made of high temperature±resistant aluminum alloy, and a depression is built into the piston

head to prevent interference with valves.

Piston pins are the full±floating type, with the pins fastened to neither the piston boss nor the connecting

rods. Instead, snap rings are fitted on both ends of the pins, preventing the\

pins from falling out. The No.1 compression ring is made of steel and the No.2 compression ring\

is made of cast iron. The oil

ring is m ade of a combination of steel and stainless steel. The outer diameter of\

each piston ring is slightly larger

than the diameter of the piston and the flexibility of the rings allows them\

to hug the cylinder walls when they

are mounted on the piston. Compression rings No.1 and No.2 work to prevent \

the leakage of gas from the cylin-

der and the oil ring works to scrape oil off the cylinder walls to prevent it from entering the combustion chamber. The cylinder block is made of aluminum alloy with a bank angle of 90 5. Cast iron cylinders are installed

inside the cylinder block. It has 8 cylinders which are approximately twice the length of th\

e piston stroke. The

top of each cylinder is closed off by the cylinder heads and the lower end of the cylinders becomes the crank-

case, in which the crankshaft is installed. In addition, the cylinder bl\

ock contains a water jacket, through which

coolant is pumped to cool the cylinders. The No.1 and No.2 oil pans are bolted onto the bottom of the cylinder block\

. The No.1 oil pan is made of

aluminum alloy. The No.2 oil pan is an oil reservoir made of pressed steel sheet. An o\

il level sensor is installed

in the No.1 oil pan (If the oil level drops below a set level, a warnin\

g light lights up.). A oil pan baffle plate keeps

sufficient oil in the bottom of the No.2 oil pan even when the vehicle is tilted. \

This dividing plate also prevents

the oil from making waves when the vehicle is stopped suddenly and the oil \

shifts away from the oil pump suction

pipe. Plastic region tightening bolts are used for the cylinder head, main bearing ca\

p and connecting rod.

EM±4

±

ENGINE MECHANICAL Operation

WhereEverybodyKnowsYourName

Page 1657 of 4087

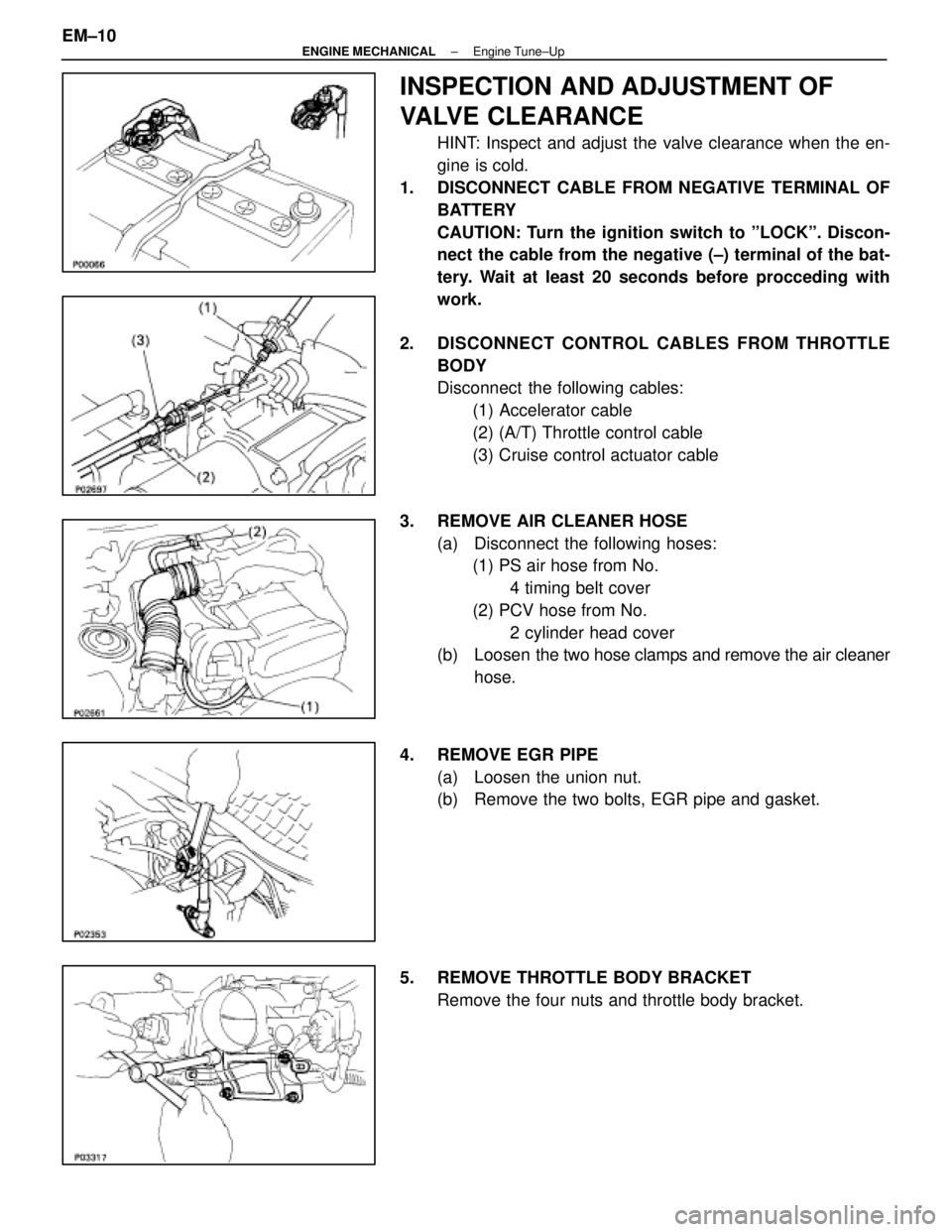

INSPECTION AND ADJUSTMENT OF

VALVE CLEARANCE

HINT: Inspect and adjust the valve clearance when the en-

gine is cold.

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Turn the ignition switch to ºLOCKº. Discon-

nect the cable from the negative (±) terminal of the bat-

tery. Wait at least 20 seconds before procceding with

work.

2. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) (A/T) Throttle control cable

(3) Cruise control actuator cable

3. REMOVE AIR CLEANER HOSE (a) Disconnect the following hoses:(1) PS air hose from No.

4 timing belt cover

(2) PCV hose from No. 2 cylinder head cover

(b) Loosen the two hose clamps and remove the air cleaner

hose.

4. REMOVE EGR PIPE (a) Loosen the union nut.

(b) Remove the two bolts, EGR pipe and gasket.

5. REMOVE THROTTLE BODY BRACKET Remove the four nuts and throttle body bracket.

EM±10

±

ENGINE MECHANICAL Engine Tune±Up

WhereEverybodyKnowsYourName