lock LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1722 of 4087

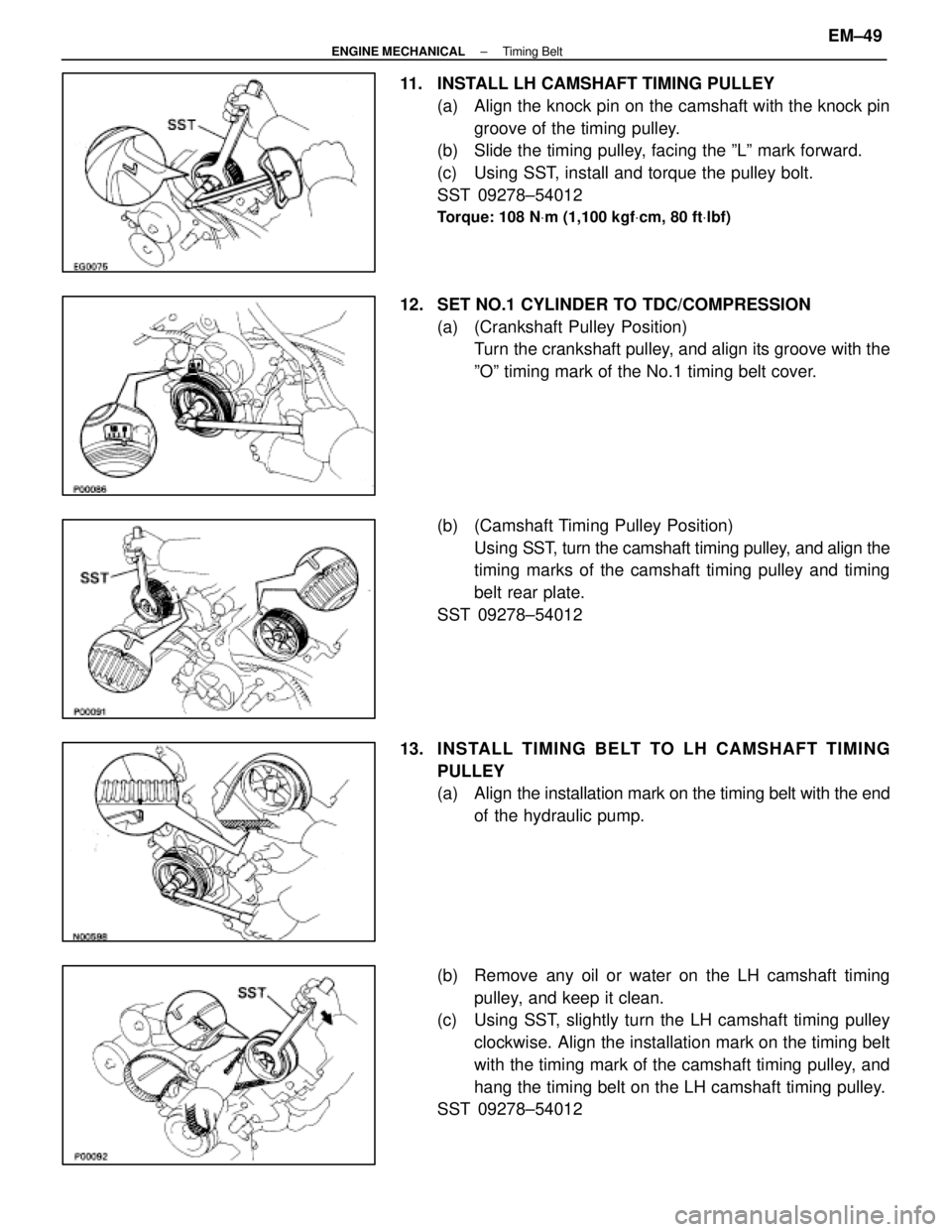

11. INSTALL LH CAMSHAFT TIMING PULLEY(a) Align the knock pin on the camshaft with the knock pingroove of the timing pulley.

(b) Slide the timing pulley, facing the ºLº mark forward.

(c) Using SST, install and torque the pulley bolt.

SST 09278±54012

Torque: 108 N Vm (1,100 kgf Vcm, 80 ft Vlbf)

12. SET NO.1 CYLINDER TO TDC/COMPRESSION

(a) (Crankshaft Pulley Position)Turn the crankshaft pulley, and align its groove with the

ºOº timing mark of the No.1 timing belt cover.

(b) (Camshaft Timing Pulley Position) Using SST, t urn the camshaft timing pulley, and align the

timing marks of the camshaft timing pulley and timing

belt rear plate.

SST 09278±54012

13. INS TALL TIMING BE LT TO LH CAMS HAFT TIMING PULLEY

(a) Align the installation mark on the timing belt with the end

of the hydraulic pump.

(b) Remove any oil or water on the LH camshaft timing pulley, and keep it clean.

(c) Using SST, slightly turn the LH camshaft timing pulley

clockwise. Align the installation mark on the timing belt

with the timing mark of the camshaft timing pulley, and

hang the timing belt on the LH camshaft timing pulley.

SST 09278±54012

±

ENGINE MECHANICAL Timing BeltEM±49

WhereEverybodyKnowsYourName

Page 1723 of 4087

(d) Using SST, align the timing marks of the LH camshaftpulley and timing belt rear plate.

SST 09278±54012

(e) Check that the timing belt has tension between the crankshaft timing pulley and LH camshaft timing pulley.

14. INSTALL TIMING BELT TO RH CAMSHAFT TIMING PULLEY

(a) Remove any oil or water on the RH camshaft timing andwater pump pulley, and keep them clean.

(b) Using SST, slightly turn the RH camshaft timing pulley clockwise. Align the installation mark on the timing belt

with the timing mark of the camshaft timing pulley, and

hang the timing belt on the RH camshaft timing pulley.

SST 09278±54012

(c) Using SST, align the timing marks of the RH camshaft pulley and timing belt rear plate.

SST 09278±54012

(d) Check that the timing belt has tension between the RH

camshaft timing pulley and LH camshaft pulley.

15. SET TIMING BELT TENSIONER (a) Using a press, slowly press in the push rod using981±9,807 N (100±1,000 kgf, 220±2,205 lbf) of

pressure.

(b) Align the holes of the push rod and housing, pass a 1.27

mm hexagon wrench through the holes to keep the

setting position of the push rod.

(c) Release the press.

(d) Install the dust boot to the tensioner.

EM±50

±

ENGINE MECHANICAL Timing Belt

WhereEverybodyKnowsYourName

Page 1724 of 4087

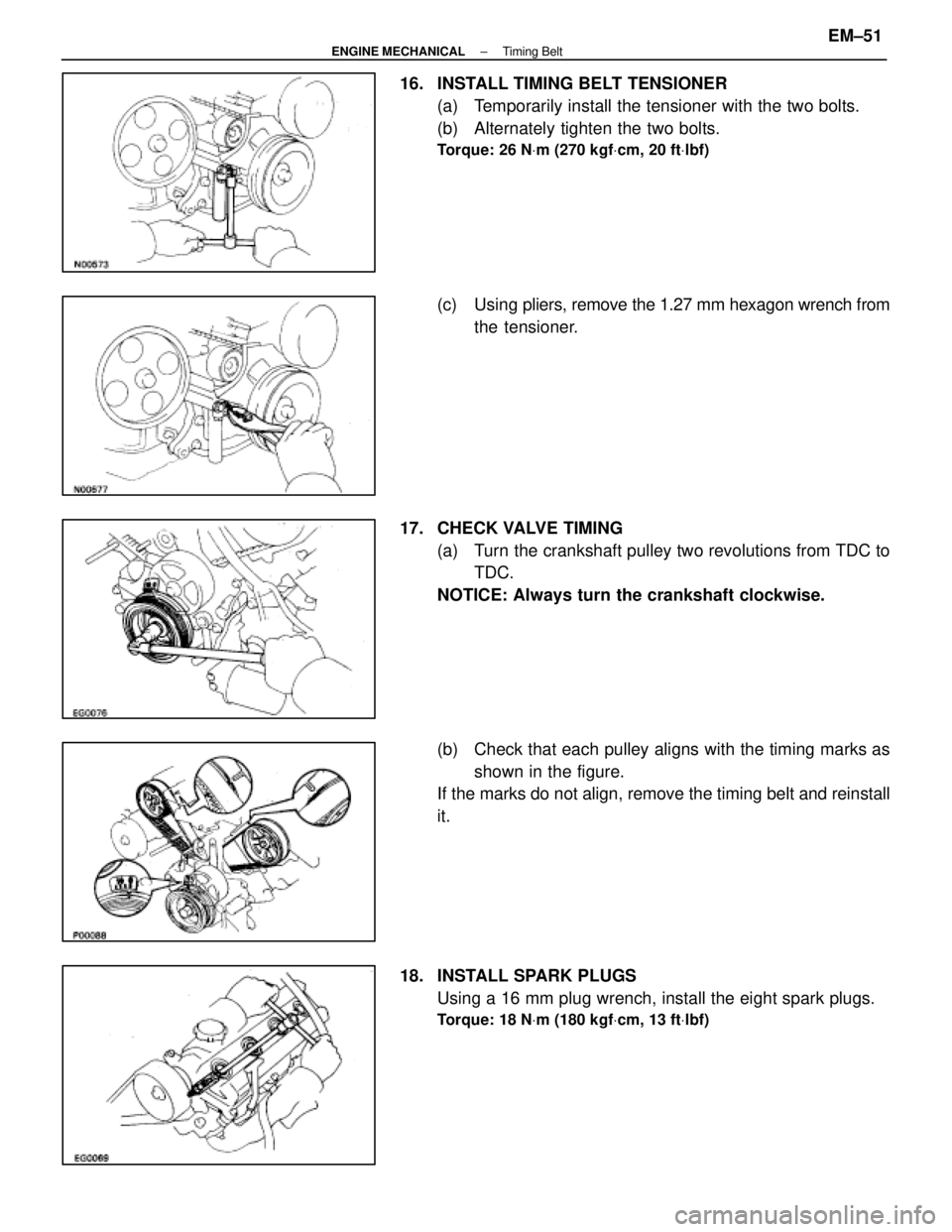

16. INSTALL TIMING BELT TENSIONER(a) Temporarily install the tensioner with the two bolts.

(b) Alternately tighten the two bolts.

Torque: 26 N Vm (270 kgf Vcm, 20 ft Vlbf)

(c) Using pliers, remove the 1.27 mm hexagon wrench from

the tensioner.

17. CHECK VALVE TIMING (a) Turn the crankshaft pulley two revolutions from TDC toTDC.

NOTICE: Always turn the crankshaft clockwise.

(b) Check that each pulley aligns with the timing marks as shown in the figure.

If the marks do not align, remove the timing belt and reinstall

it.

18. INSTALL SPARK PLUGS Using a 16 mm plug wrench, install the eight spark plugs.

Torque: 18 N Vm (180 kgf Vcm, 13 ft Vlbf)

±

ENGINE MECHANICAL Timing BeltEM±51

WhereEverybodyKnowsYourName

Page 1730 of 4087

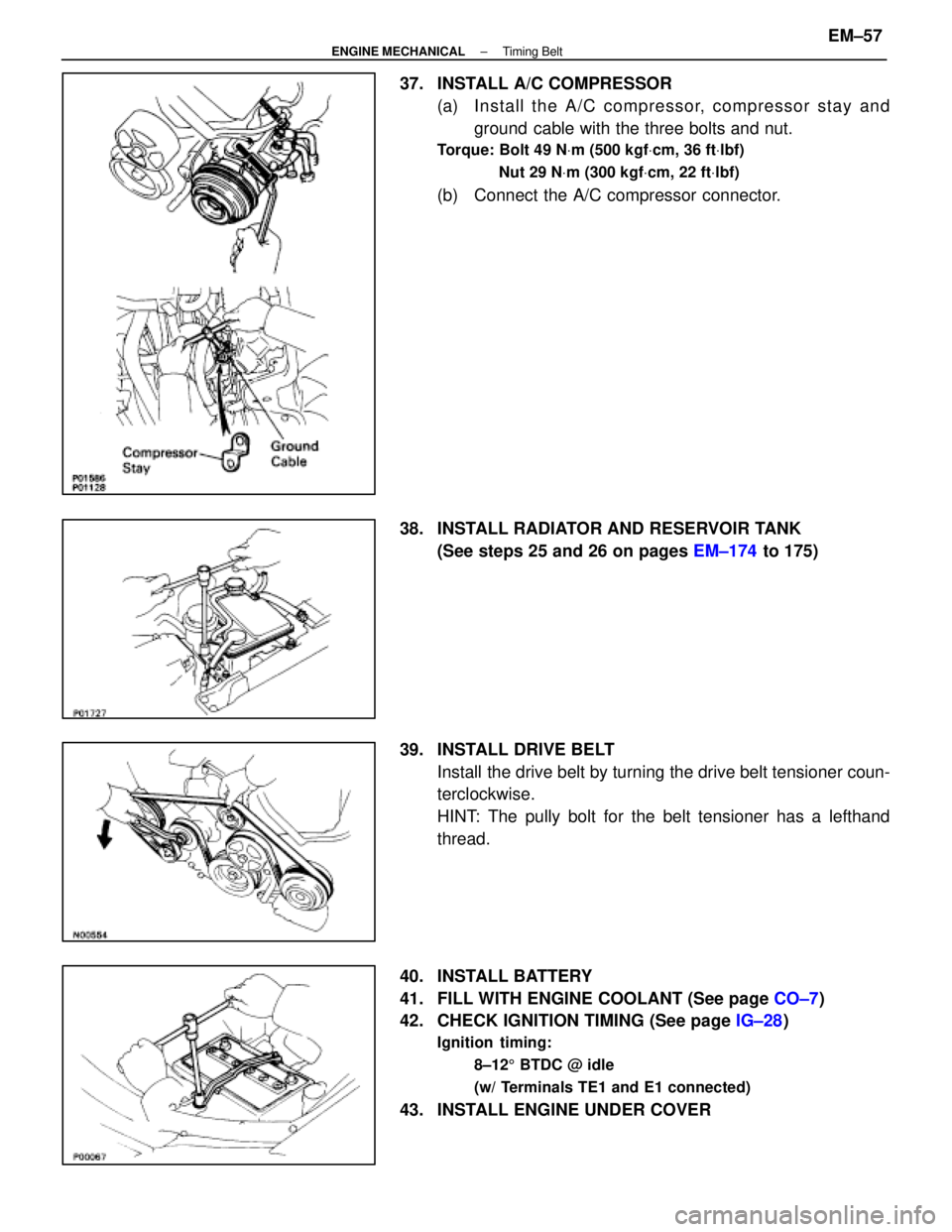

37. INSTALL A/C COMPRESSOR(a) In sta ll th e A/C co mp re sso r, co mp re sso r sta y an dground cable with the three bolts and nut.

Torque: Bolt 49 N Vm (500 kgf Vcm, 36 ft Vlbf)

Nut 29 N Vm (300 kgf Vcm, 22 ft Vlbf)

(b) Connect the A/C compressor connector.

38. INSTALL RADIATOR AND RESERVOIR TANK (See steps 25 and 26 on pages EM±174 to 175)

39. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pully bolt for the belt tensioner has a lefthand

thread.

40. INSTALL BATTERY

41. FILL WITH ENGINE COOLANT (See page CO±7)

42. CHECK IGNITION TIMING (See page IG±28)

Ignition timing:

8±125 BTDC @ idle

(w/ Terminals TE1 and E1 connected)

43. INSTALL ENGINE UNDER COVER

±

ENGINE MECHANICAL Timing BeltEM±57

WhereEverybodyKnowsYourName

Page 1737 of 4087

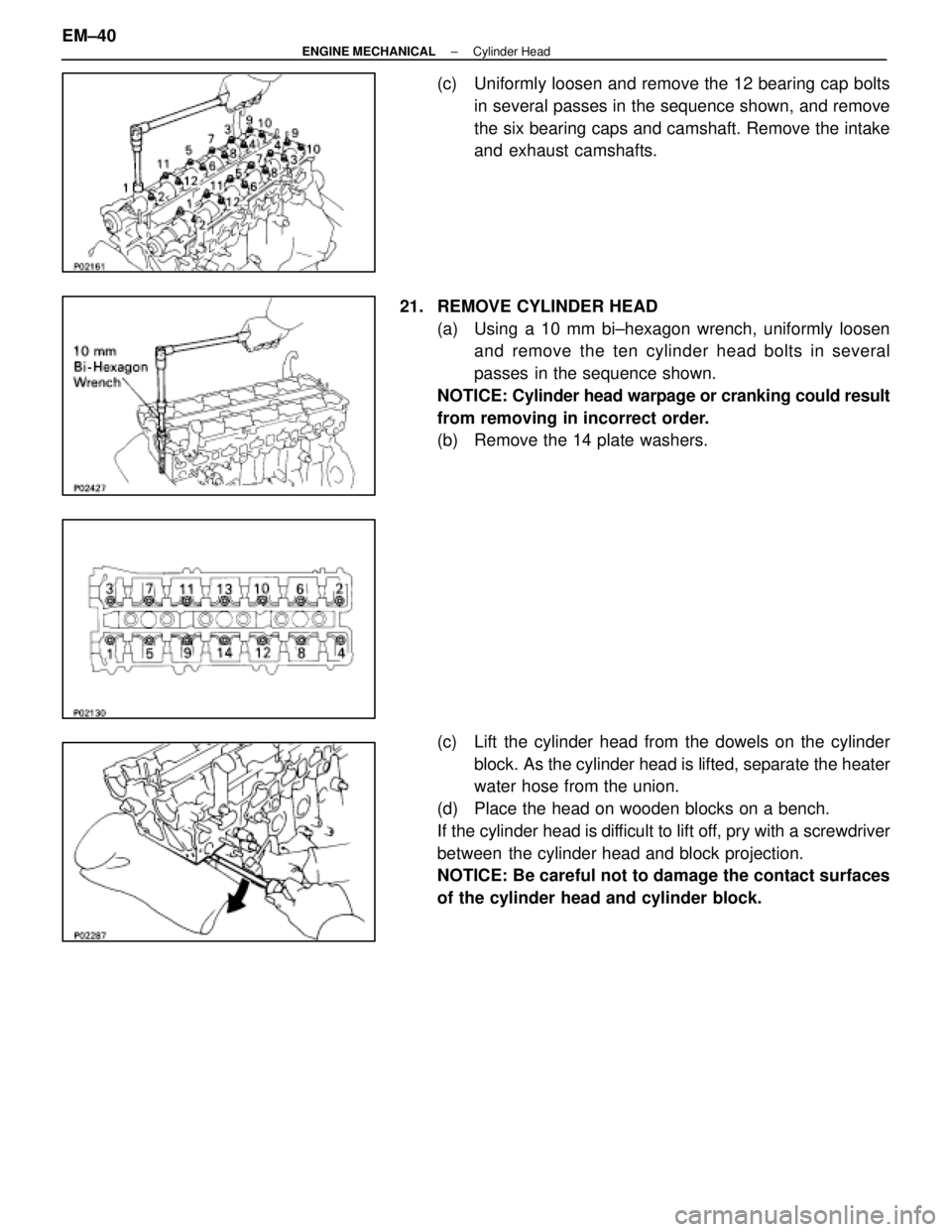

(c) Uniformly loosen and remove the 12 bearing cap boltsin several passes in the sequence shown, and remove

the six bearing caps and camshaft. Remove the intake

and exhaust camshafts.

21. REMOVE CYLINDER HEAD (a) Using a 10 mm bi±hexagon wrench, uniformly loosenand remove the ten cylinder head bolts in several

passes in the sequence shown.

NOTICE: Cylinder head warpage or cranking could result

from removing in incorrect order.

(b) Remove the 14 plate washers.

(c) Lift the cylinder head from the dowels on the cylinder block. As the cylinder head is lifted, separate the heater

water hose from the union.

(d) Place the head on wooden blocks on a bench.

If the cylinder head is difficult to lift off, pry with a screwdriver

between the cylinder head and block projection.

NOTICE: Be careful not to damage the contact surfaces

of the cylinder head and cylinder block.

EM±40

±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName

Page 1739 of 4087

3. REMOVE ENGINE HANGERS

4. REMOVE ENGINE COOLANT TEMPERATURE SENSORAND SENDER GAUGE

5. REMOVE THROTTLE CABLE BRACKET AND GROUND STRAP

6. REMOVE EGR COOLER

INSPECTION, CLEANING AND REPAIR

OF CYLINDER HEAD COMPONENTS

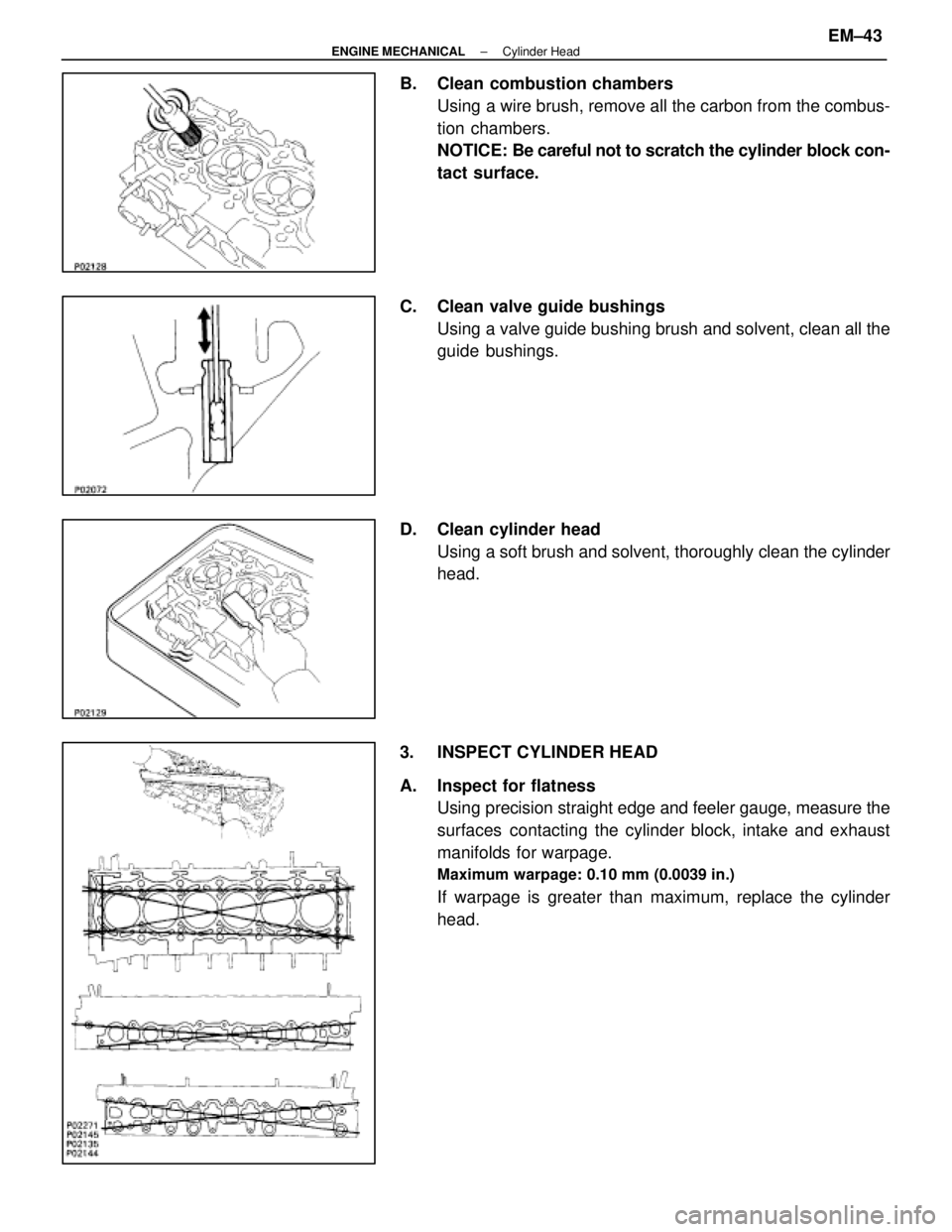

1. CLEAN TOP SURFACES OF PISTONS AND CYLINDER BLOCK

(a) Turn the crankshaft, and bring each piston to top deadcenter (TDC). Using a gasket scraper, remove all the

carbon from the piston top surface.

(b) Using a gasket scraper, remove all the gasket material from the top surface of the cylinder block.

(c) Using compressed air, blow carbon and oil from the bolt

holes.

CAUTION: Protect your eyes when using high±com-

pressed air.

2. CLEAN CYLINDER HEAD

A. Remove gasket material Using a gasket scraper, remove all the gasket material from

the cylinder block surface.

NOTICE: Be careful not to scratch the cylinder block con-

tact surface.

EM±42

±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName

Page 1740 of 4087

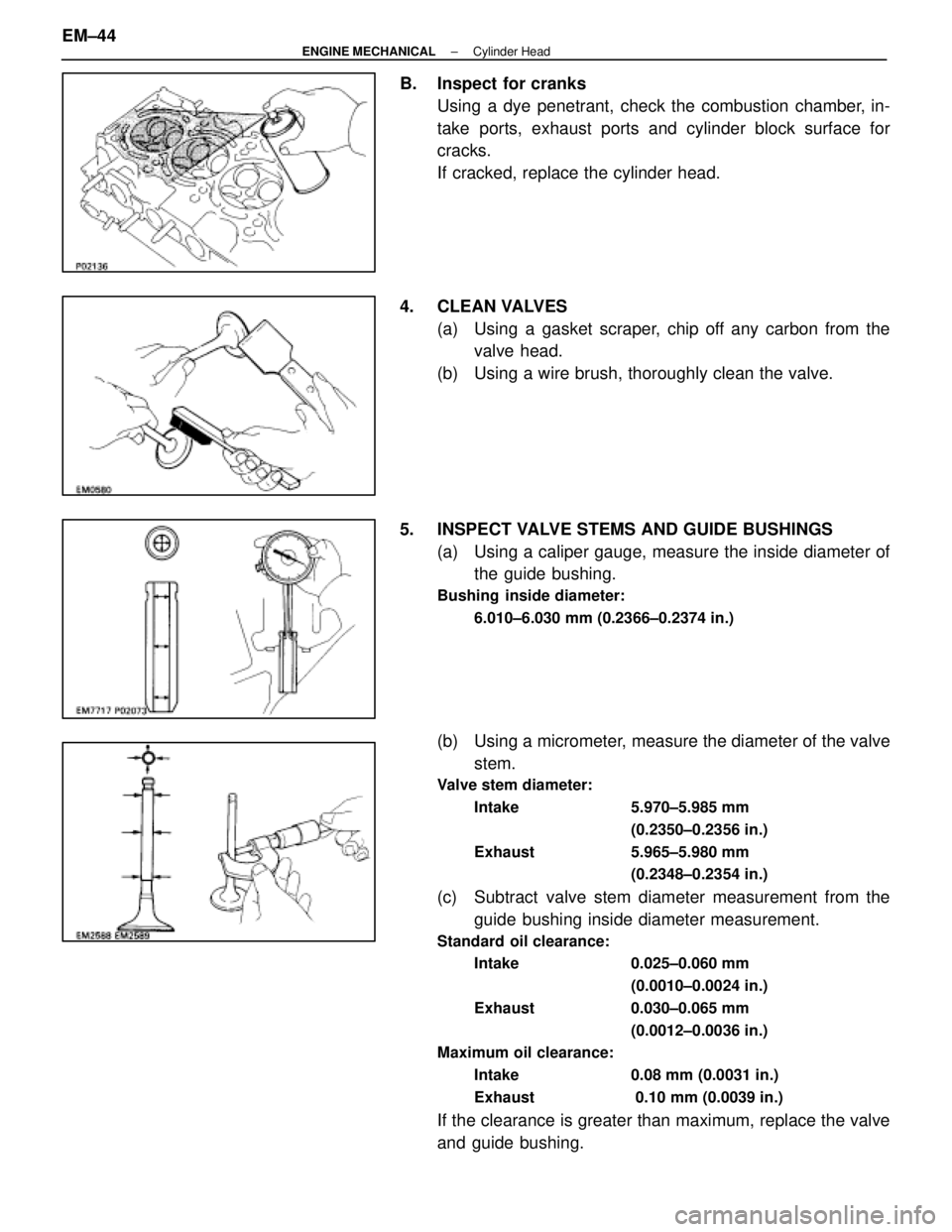

B. Clean combustion chambersUsing a wire brush, remove all the carbon from the combus-

tion chambers.

NOTICE: Be careful not to scratch the cylinder block con-

tact surface.

C. Clean valve guide bushings Using a valve guide bushing brush and solvent, clean all the

guide bushings.

D. Clean cylinder head Using a soft brush and solvent, thoroughly clean the cylinder

head.

3. INSPECT CYLINDER HEAD

A. Inspect for flatness Using precision straight edge and feeler gauge, measure the

surfaces contacting the cylinder block, intake and exhaust

manifolds for warpage.

Maximum warpage: 0.10 mm (0.0039 in.)

If warpage is greater than maximum, replace the cylinder

head.

±

ENGINE MECHANICAL Cylinder HeadEM±43

WhereEverybodyKnowsYourName

Page 1741 of 4087

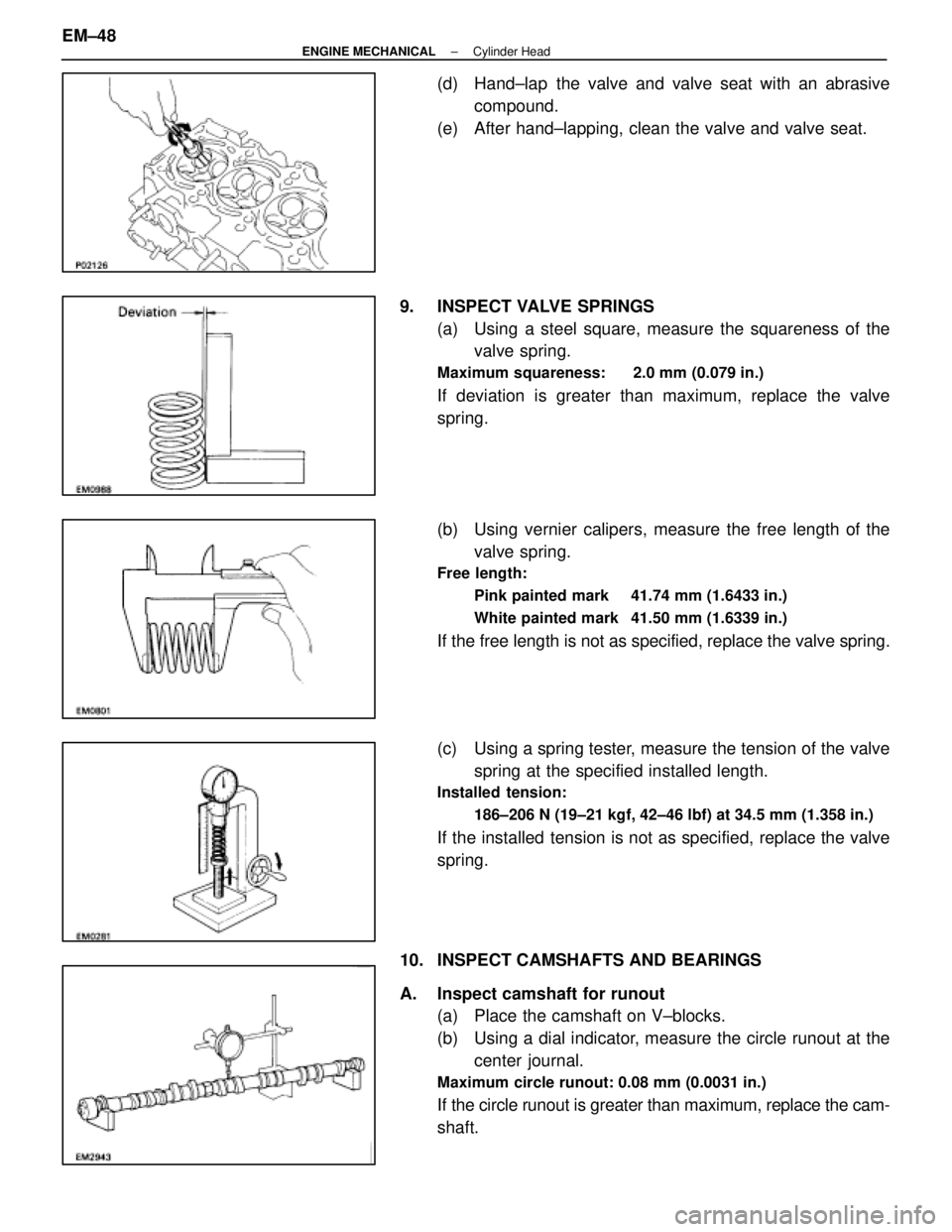

B. Inspect for cranksUsing a dye penetrant, check the combustion chamber, in-

take ports, exhaust ports and cylinder block surface for

cracks.

If cracked, replace the cylinder head.

4. CLEAN VALVES (a) Using a gasket scraper, chip off any carbon from thevalve head.

(b) Using a wire brush, thoroughly clean the valve.

5. INSPECT VALVE STEMS AND GUIDE BUSHINGS (a) Using a caliper gauge, measure the inside diameter ofthe guide bushing.

Bushing inside diameter:

6.010±6.030 mm (0.2366±0.2374 in.)

(b) Using a micrometer, measure the diameter of the valvestem.

Valve stem diameter:

Intake 5.970±5.985 mm (0.2350±0.2356 in.)

Exhaust 5.965±5.980 mm (0.2348±0.2354 in.)

(c) Subtract valve stem diameter measurement from theguide bushing inside diameter measurement.

Standard oil clearance:

Intake 0.025±0.060 mm

(0.0010±0.0024 in.)

Exhaust 0.030±0.065 mm (0.0012±0.0036 in.)

Maximum oil clearance:

Intake 0.08 mm (0.0031 in.)

Exhaust 0.10 mm (0.0039 in.)

If the clearance is greater than maximum, replace the valve

and guide bushing.

EM±44

±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName

Page 1745 of 4087

(d) Hand±lap the valve and valve seat with an abrasivecompound.

(e) After hand±lapping, clean the valve and valve seat.

9. INSPECT VALVE SPRINGS (a) Using a steel square, measure the squareness of thevalve spring.

Maximum squareness: 2.0 mm (0.079 in.)

If deviation is greater than maximum, replace the valve

spring.

(b) Using vernier calipers, measure the free length of the

valve spring.

Free length:

Pink painted mark 41.74 mm (1.6433 in.)

White painted mark 41.50 mm (1.6339 in.)

If the free length is not as specified, replace the valve spring.

(c) Using a spring tester, measure the tension of the valvespring at the specified installed length.

Installed tension:

186±206 N (19±21 kgf, 42±46 lbf) at 34.5 mm (1.358 in.)

If the installed tension is not as specified, replace the valve

spring.

10. INSPECT CAMSHAFTS AND BEARINGS

A. Inspect camshaft for runout (a) Place the camshaft on V±blocks.

(b) Using a dial indicator, measure the circle runout at the

center journal.

Maximum circle runout: 0.08 mm (0.0031 in.)

If the circle runout is greater than maximum, replace the cam-

shaft.

EM±48

±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName

Page 1749 of 4087

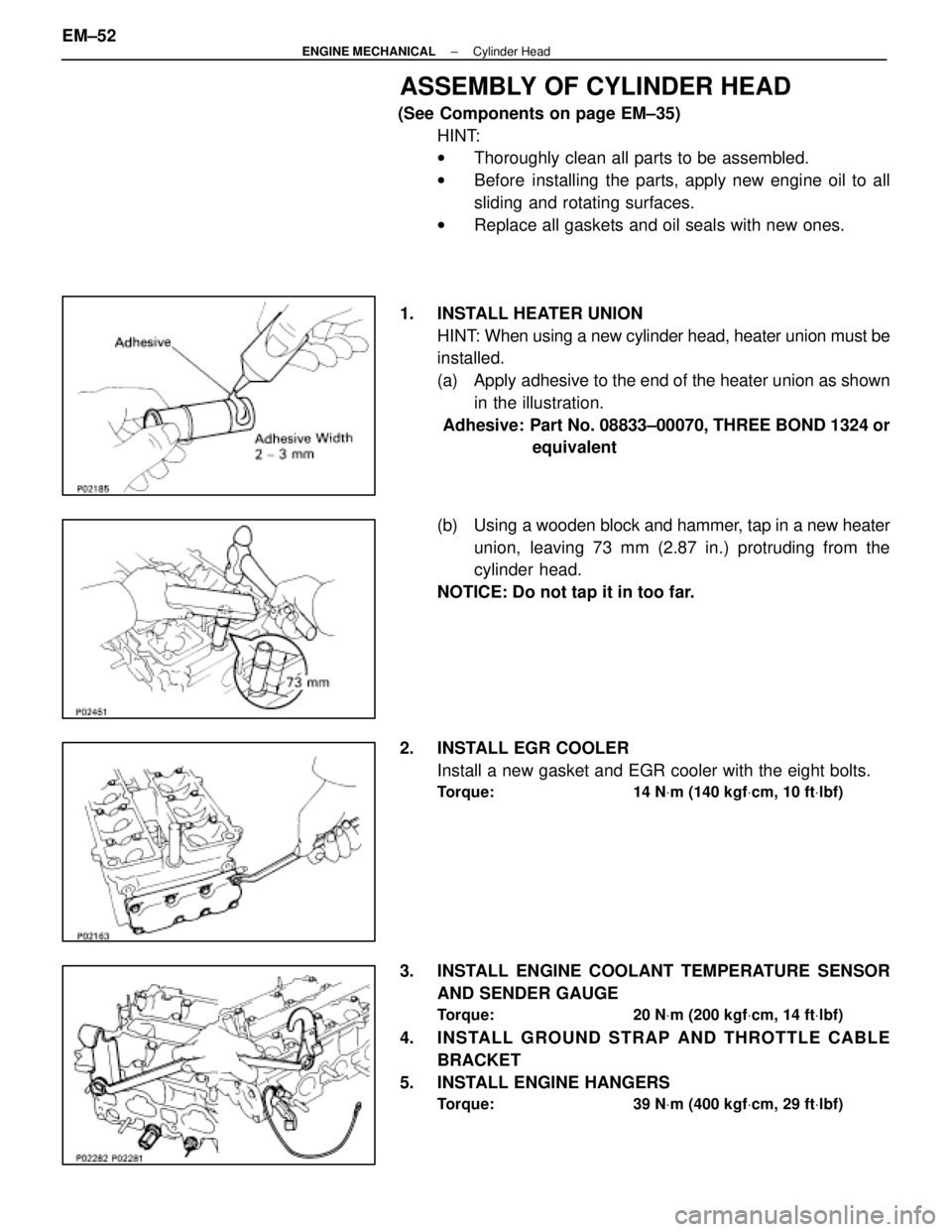

ASSEMBLY OF CYLINDER HEAD

(See Components on page EM±35)HINT:

wThoroughly clean all parts to be assembled.

w Before installing the parts, apply new engine oil to all

sliding and rotating surfaces.

w Replace all gaskets and oil seals with new ones.

1. INSTALL HEATER UNION HINT: When using a new cylinder head, heater union must be

installed.

(a) Apply adhesive to the end of the heater union as shownin the illustration.

Adhesive: Part No. 08833±00070, THREE BOND 1324 or equivalent

(b) Using a wooden block and hammer, tap in a new heater

union, leaving 73 mm (2.87 in.) protruding from the

cylinder head.

NOTICE: Do not tap it in too far.

2. INSTALL EGR COOLER Install a new gasket and EGR cooler with the eight bolts.

Torque: 14 N Vm (140 kgf Vcm, 10 ft Vlbf)

3. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

AND SENDER GAUGE

Torque: 20 N Vm (200 kgf Vcm, 14 ft Vlbf)

4. INSTALL GROUND STRAP AND THROTTLE CABLE

BRACKET

5. INSTALL ENGINE HANGERS

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

EM±52±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName