ECU LEXUS SC400 1991 Service Workshop Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 231 of 4087

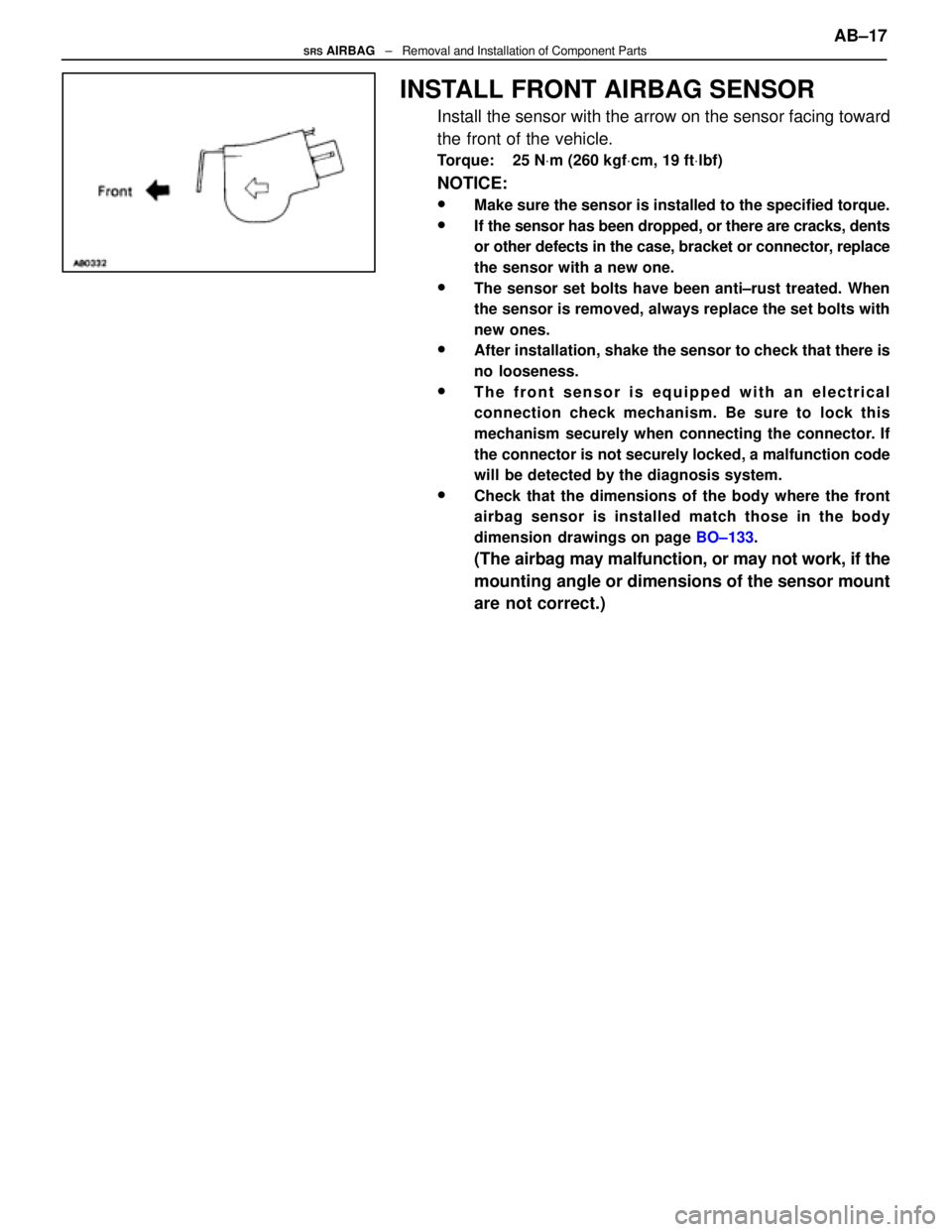

INSTALL FRONT AIRBAG SENSOR

Install the sensor with the arrow on the sensor facing toward

the front of the vehicle.

Torque: 25 NVm (260 kgf Vcm, 19 ft Vlbf)

NOTICE:

wMake sure the sensor is installed to the specified torque.

wIf the sensor has been dropped, or there are cracks, dents

or other defects in the case, bracket or connector, replace

the sensor with a new one.

wThe sensor set bolts have been anti±rust treated. When

the sensor is removed, always replace the set bolts with

new ones.

wAfter installation, shake the sensor to check that there is

no looseness.

wThe front sensor is equipped with an electrical

connection check mechanism. Be sure to lock this

mechanism securely when connecting the connector. If

the connector is not securely locked, a malfunction code

will be detected by the diagnosis system.

wCheck that the dimensions of the body where the front

airbag sensor is installed match those in the body

dimension drawings on page BO±133.

(The airbag may malfunction, or may not work, if the

mounting angle or dimensions of the sensor mount

are not correct.) AB±17

SRS AIRBAG

± Removal and Installation of Component Parts

WhereEverybodyKnowsYourName

Page 233 of 4087

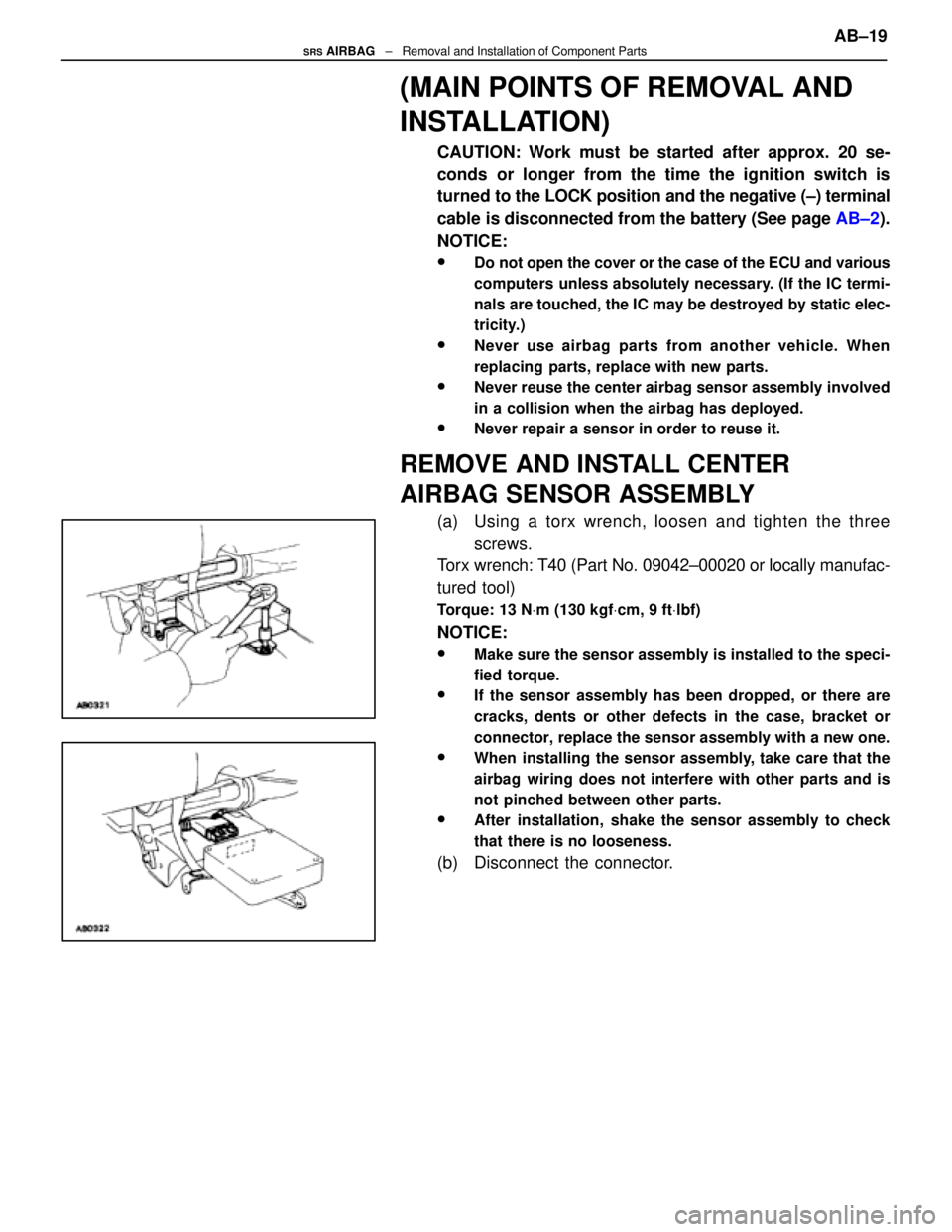

(MAIN POINTS OF REMOVAL AND

INSTALLATION)

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the LOCK position and the negative (±) terminal

cable is disconnected from the battery (See page AB±2).

NOTICE:

wDo not open the cover or the case of the ECU and various

computers unless absolutely necessary. (If the IC termi-

nals are touched, the IC may be destroyed by static elec-

tricity.)

wNever use airbag parts from another vehicle. When

replacing parts, replace with new parts.

wNever reuse the center airbag sensor assembly involved

in a collision when the airbag has deployed.

wNever repair a sensor in order to reuse it.

REMOVE AND INSTALL CENTER

AIRBAG SENSOR ASSEMBLY

(a) Using a torx wrench, loosen and tighten the three screws.

Torx wrench: T40 (Part No. 09042±00020 or locally manufac-

tured tool)

Torque: 13 N Vm (130 kgf Vcm, 9 ft Vlbf)

NOTICE:

wMake sure the sensor assembly is installed to the speci-

fied torque.

wIf the sensor assembly has been dropped, or there are

cracks, dents or other defects in the case, bracket or

connector, replace the sensor assembly with a new one.

wWhen installing the sensor assembly, take care that the

airbag wiring does not interfere with other parts and is

not pinched between other parts.

wAfter installation, shake the sensor assembly to check

that there is no looseness.

(b) Disconnect the connector. AB±19

SRS AIRBAG

± Removal and Installation of Component Parts

WhereEverybodyKnowsYourName

Page 246 of 4087

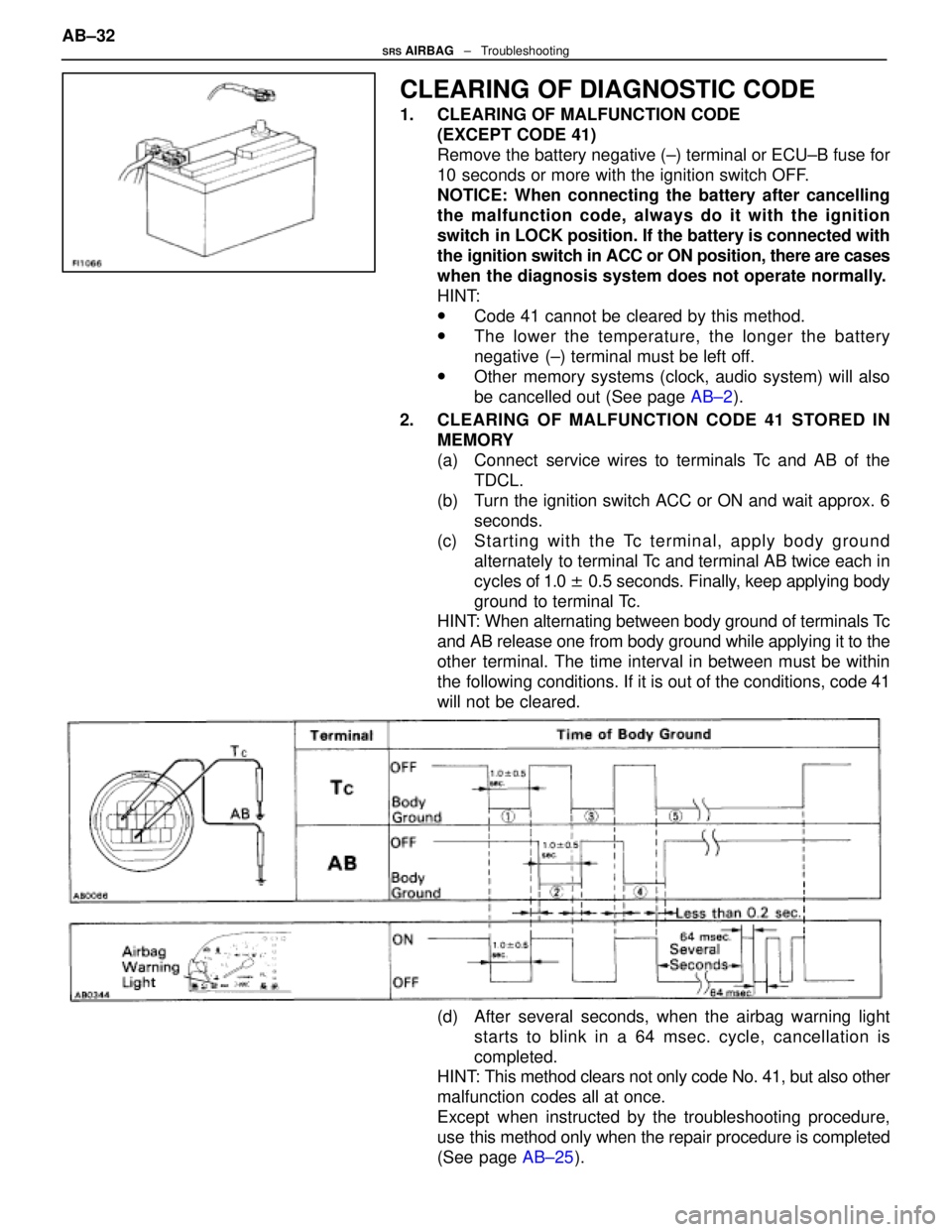

CLEARING OF DIAGNOSTIC CODE

1. CLEARING OF MALFUNCTION CODE(EXCEPT CODE 41)

Remove the battery negative (±) terminal or ECU±B fuse for

10 seconds or more with the ignition switch OFF.

NOTICE: When connecting the battery after cancelling

the malfunction code, always do it with the ignition

switch in LOCK position. If the battery is connected with

the ignition switch in ACC or ON position, there are cases

when the diagnosis system does not operate normally.

HINT:

wCode 41 cannot be cleared by this method.

wThe lower the temperature, the longer the battery

negative (±) terminal must be left off.

wOther memory systems (clock, audio system) will also

be cancelled out (See page AB±2).

2. CLEARING OF MALFUNCTION CODE 41 STORED IN MEMORY

(a) Connect service wires to terminals Tc and AB of theTDCL.

(b) Turn the ignition switch ACC or ON and wait approx. 6 seconds.

(c) S ta rtin g with th e Tc te rmin a l, ap p ly bo d y gr ound

alternately to terminal Tc and terminal AB twice each in

cycles of 1.0 ± 0.5 seconds. Finally, keep applying body

ground to terminal Tc.

HINT: When alternating between body ground of terminals Tc

and AB release one from body ground while applying it to the

other terminal. The time interval in between must be within

the following conditions. If it is out of the conditions, code 41

will not be cleared.

(d) After several seconds, when the airbag warning light

starts to blink in a 64 msec. cycle, cancellation is

completed.

HINT: This method clears not only code No. 41, but also other

malfunction codes all at once.

Except when instructed by the troubleshooting procedure,

use this method only when the repair procedure is completed

(See page AB±25).

AB±32

SRS AIRBAG

± Troubleshooting

WhereEverybodyKnowsYourName

Page 247 of 4087

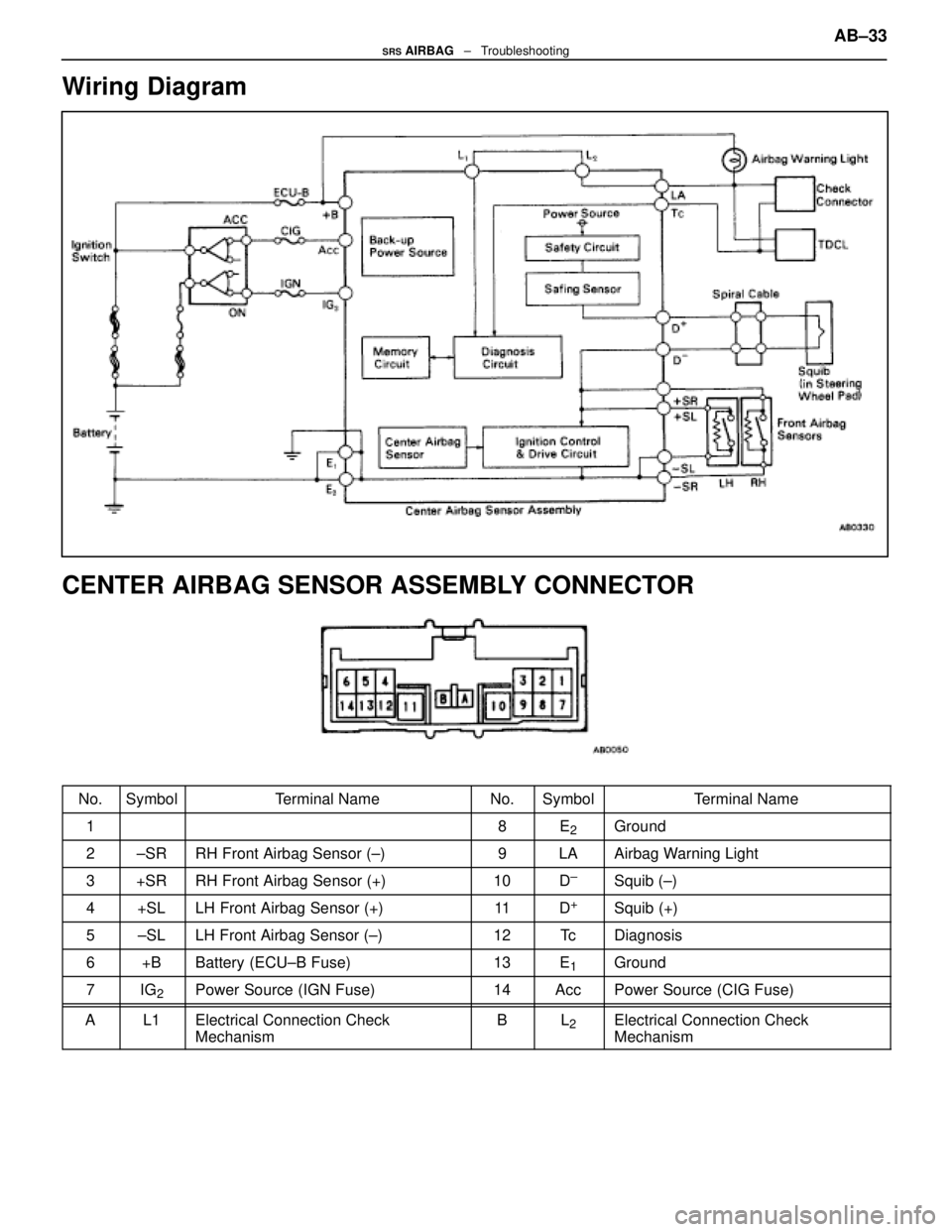

Wiring Diagram

CENTER AIRBAG SENSOR ASSEMBLY CONNECTOR

No.SymbolTerminal NameNo.SymbolTerminal Name

18E2Ground

2±SRRH Front Airbag Sensor (±)9LAAirbag Warning Light

3+SRRH Front Airbag Sensor (+)10D±Squib (±)

4+SLLH Front Airbag Sensor (+)11D+Squib (+)

5±SLLH Front Airbag Sensor (±)12TcDiagnosis

6+BBattery (ECU±B Fuse)13E1Ground

7IG2Power Source (IGN Fuse)14AccPower Source (CIG Fuse)

AL1Electrical Connection Check

MechanismBL2Electrical Connection Check

Mechanism

AB±33SRS AIRBAG ± Troubleshooting

WhereEverybodyKnowsYourName

Page 288 of 4087

AT00S±01

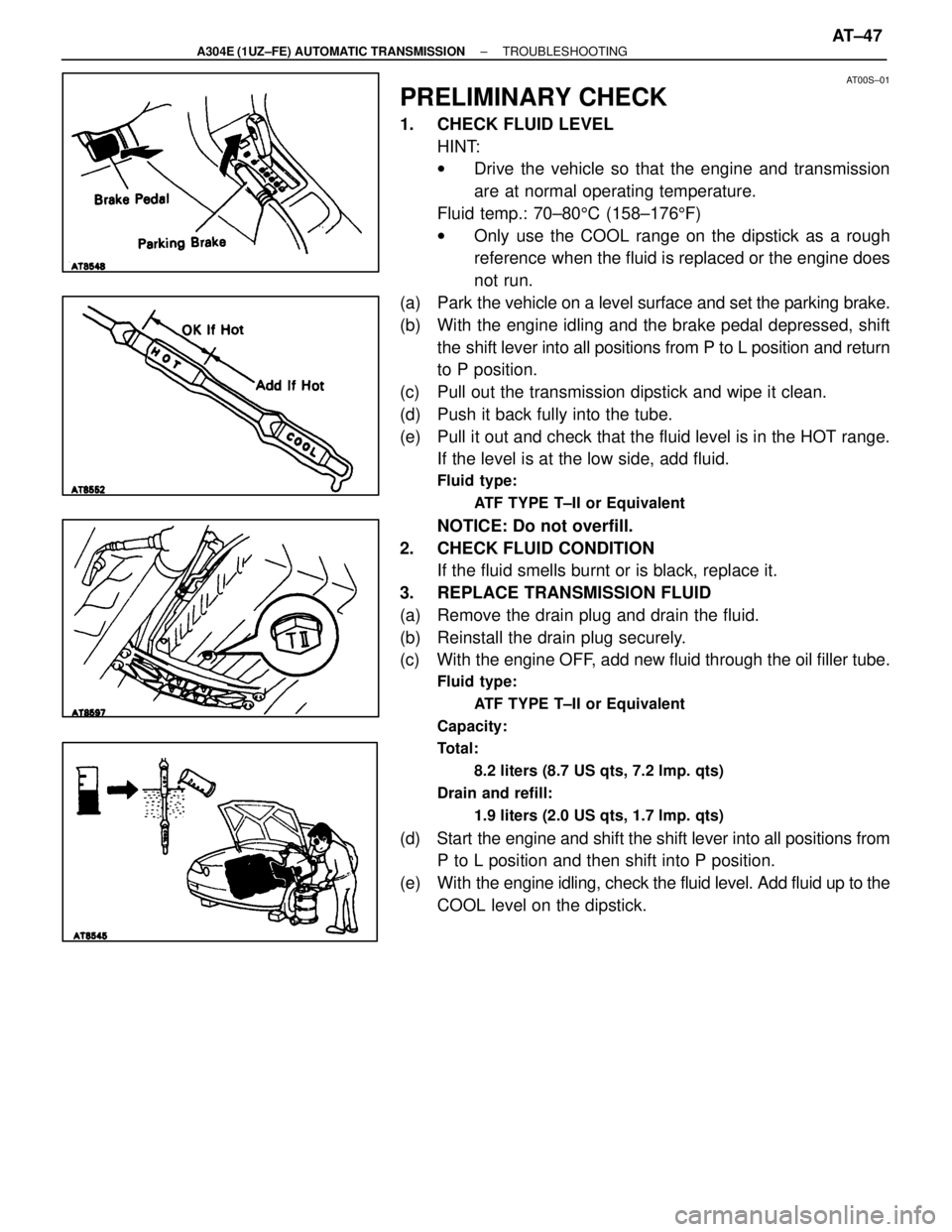

PRELIMINARY CHECK

1. CHECK FLUID LEVELHINT:

wDrive the vehicle so that the engine and transmission

are at normal operating temperature.

Fluid temp.: 70±80 5C (158±176 5F)

w Only use the COOL range on the dipstick as a rough

reference when the fluid is replaced or the engine does

not run.

(a) Park the vehicle on a level surface and set the parking brake.

(b) With the engine idling and the brake pedal depressed, shift the shift lever into all positions from P to L position and return

to P position.

(c) Pull out the transmission dipstick and wipe it clean.

(d) Push it back fully into the tube.

(e) Pull it out and check that the fluid level is in the HOT range. If the level is at the low side, add fluid.

Fluid type:

ATF TYPE T±II or Equivalent

NOTICE: Do not overfill.

2. CHECK FLUID CONDITION If the fluid smells burnt or is black, replace it.

3. REPLACE TRANSMISSION FLUID

(a) Remove the drain plug and drain the fluid.

(b) Reinstall the drain plug securely.

(c) With the engine OFF, add new fluid through the oil filler tube.

Fluid type:

ATF TYPE T±II or Equivalent

Capacity:

Total: 8.2 liters (8.7 US qts, 7.2 lmp. qts)

Drain and refill: 1.9 liters (2.0 US qts, 1.7 lmp. qts)

(d) Start the engine and shift the shift lever into all positions fromP to L position and then shift into P position.

(e) With the engine idling, check the fluid level. Add fluid up to the

COOL level on the dipstick.

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION TROUBLESHOOTINGAT±47

WhereEverybodyKnowsYourName

Page 356 of 4087

AT±66

IN±33

WIRING DIAGRAM

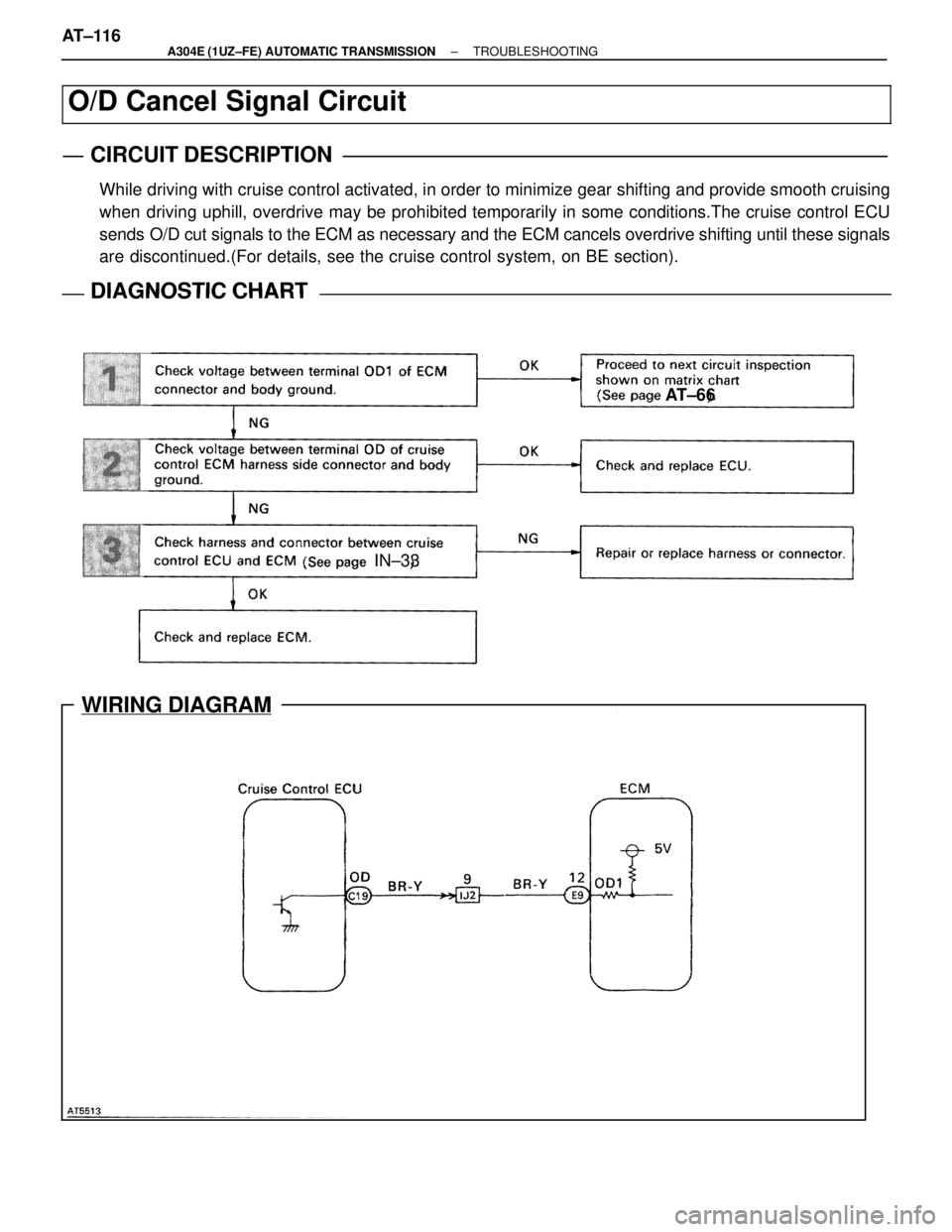

O/D Cancel Signal Circuit

CIRCUIT DESCRIPTION

While driving with cruise control activated, in order to minimize gear shifti\

ng and provide smooth cruising

when driving uphill, overdrive may be prohibited temporarily in some conditions.The cruise control ECU

sends O/D cut signals to the ECM as necessary and the ECM cancels overdrive s\

hifting until these signals

are discontinued.(For details, see the cruise control system, on BE sectio\

n).

DIAGNOSTIC CHARTDIAGNOSTIC CHART

AT±116±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION TROUBLESHOOTING

WhereEverybodyKnowsYourName

Page 357 of 4087

NGOK

NGOK

OKNG

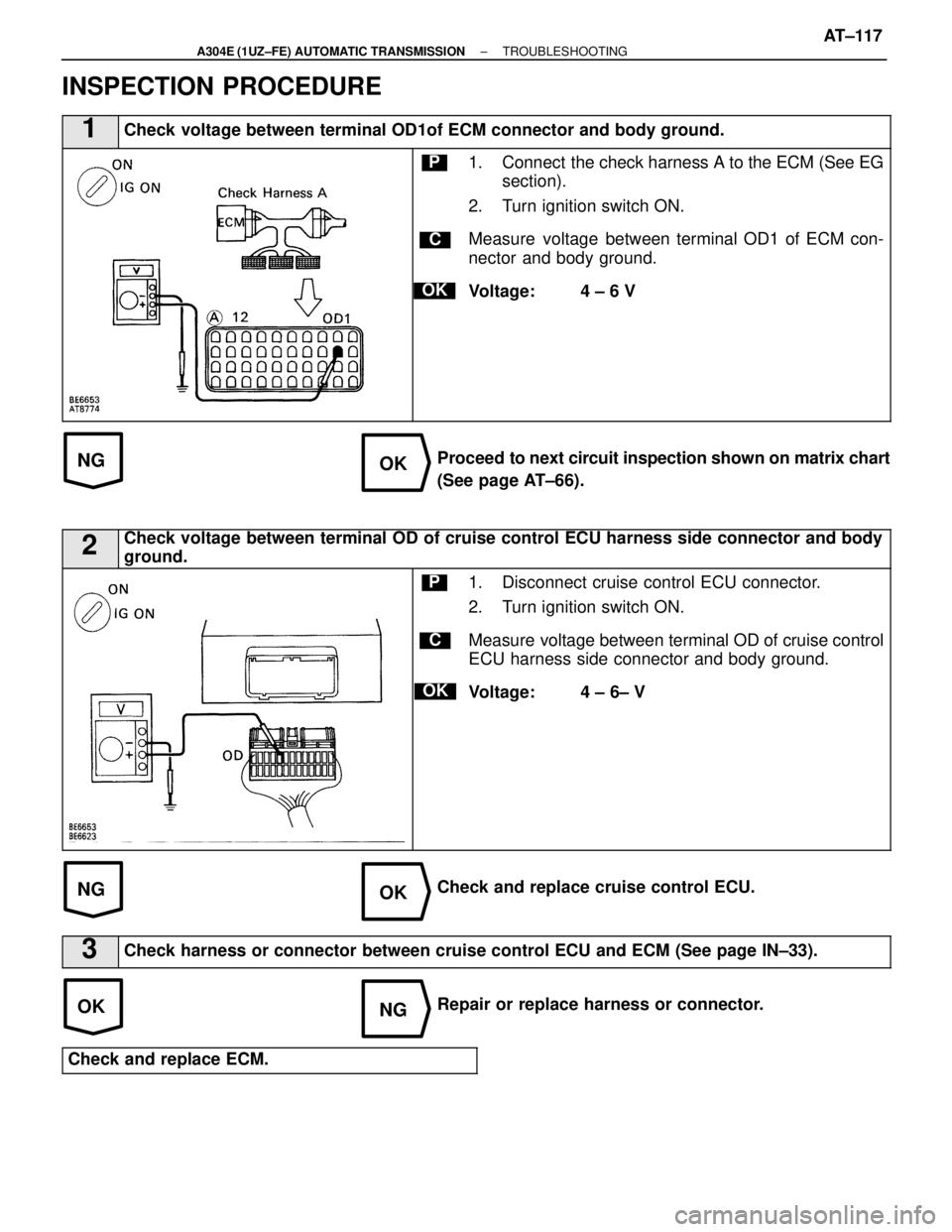

INSPECTION PROCEDURE

1Check voltage between terminal OD1of ECM connector and body ground.

C

OK

P1. Connect the check harness A to the ECM (See EGsection).

2. Turn ignition switch ON.

Measure voltage between terminal OD1 of ECM con-

nector and body ground.

Voltage: 4 ± 6 V

Proceed to next circuit inspection shown on matrix chart

(See page AT±66).

2Check voltage between terminal OD of cruise control ECU harness side con\

nector and body

ground.

C

OK

P1. Disconnect cruise control ECU connector.

2. Turn ignition switch ON.

Measure voltage between terminal OD of cruise control

ECU harness side connector and body ground.

Voltage: 4 ± 6± V

Check and replace cruise control ECU.

3Check harness or connector between cruise control ECU and ECM (See page\

IN±33).

Repair or replace harness or connector.

Check and replace ECM.

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION TROUBLESHOOTINGAT±117

WhereEverybodyKnowsYourName

Page 406 of 4087

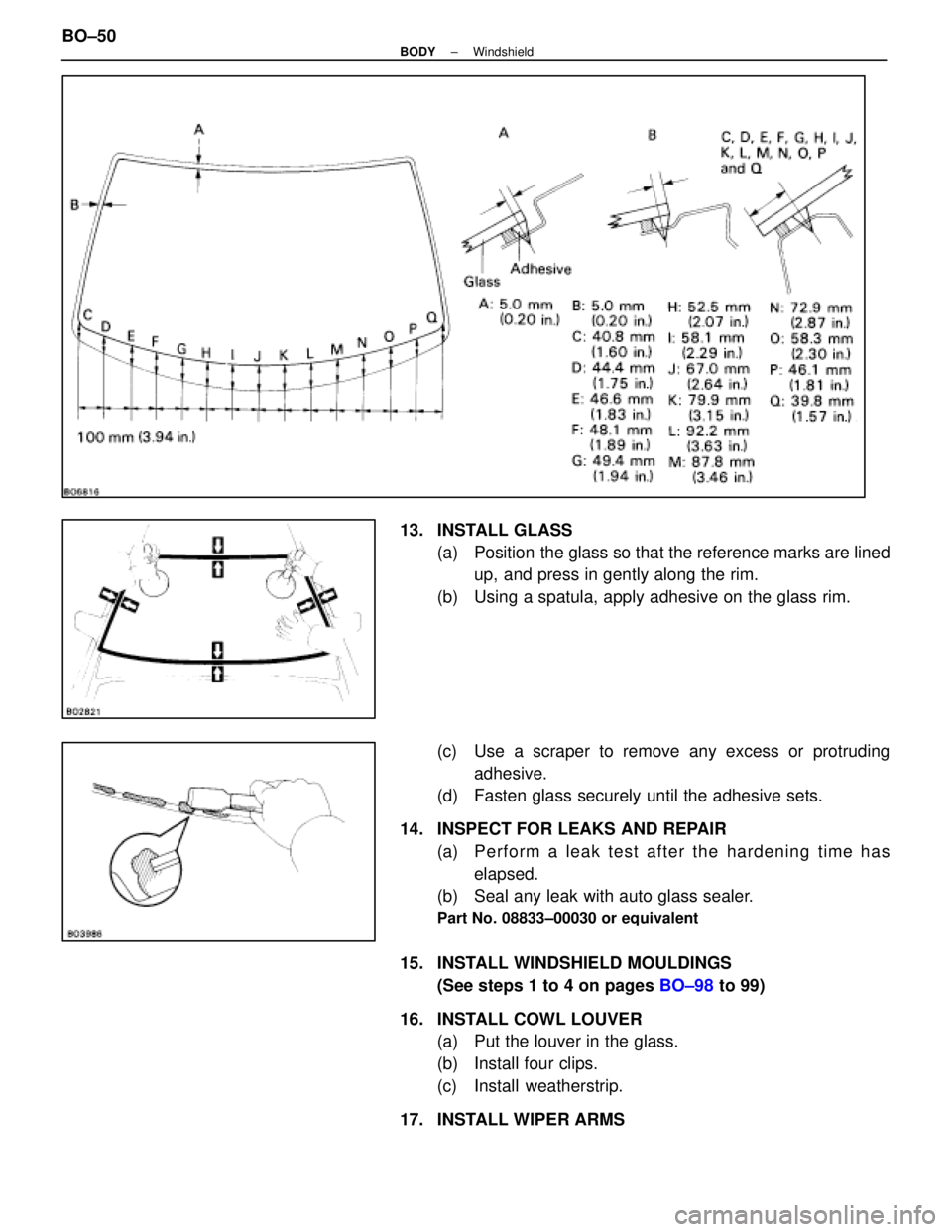

13. INSTALL GLASS(a) Position the glass so that the reference marks are linedup, and press in gently along the rim.

(b) Using a spatula, apply adhesive on the glass rim.

(c) Use a scraper to remove any excess or protruding adhesive.

(d) Fasten glass securely until the adhesive sets.

14. INSPECT FOR LEAKS AND REPAIR (a) P e rfo rm a le a k te st afte r th e ha r dening time has

elapsed.

(b) Seal any leak with auto glass sealer.

Part No. 08833±00030 or equivalent

15. INSTALL WINDSHIELD MOULDINGS

(See steps 1 to 4 on pages BO±98 to 99)

16. INSTALL COWL LOUVER (a) Put the louver in the glass.

(b) Install four clips.

(c) Install weatherstrip.

17. INSTALL WIPER ARMS

BO±50

±

BODY Windshield

WhereEverybodyKnowsYourName

Page 413 of 4087

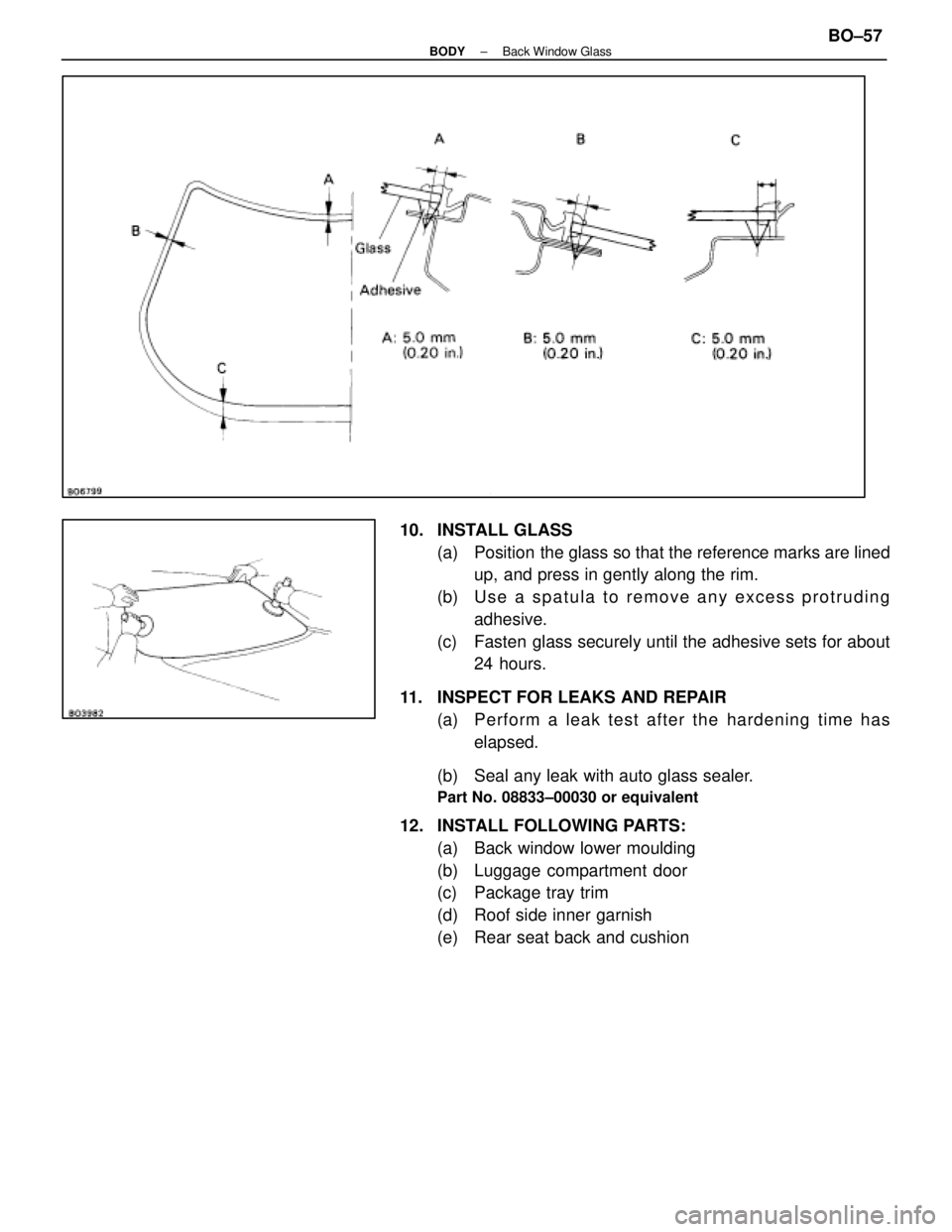

10. INSTALL GLASS(a) Position the glass so that the reference marks are linedup, and press in gently along the rim.

(b) U s e a s p a t u l a t o r e m o v e a n y e x c e s s p r o t r u d i n g adhesive.

(c) Fasten glass securely until the adhesive sets for about 24 hours.

11. INSPECT FOR LEAKS AND REPAIR (a) P e rfo rm a le a k te st afte r th e ha r dening time has

elapsed.

(b) Seal any leak with auto glass sealer.

Part No. 08833±00030 or equivalent

12. INSTALL FOLLOWING PARTS: (a) Back window lower moulding

(b) Luggage compartment door

(c) Package tray trim

(d) Roof side inner garnish

(e) Rear seat back and cushion

±

BODY Back Window GlassBO±57

WhereEverybodyKnowsYourName

Page 482 of 4087

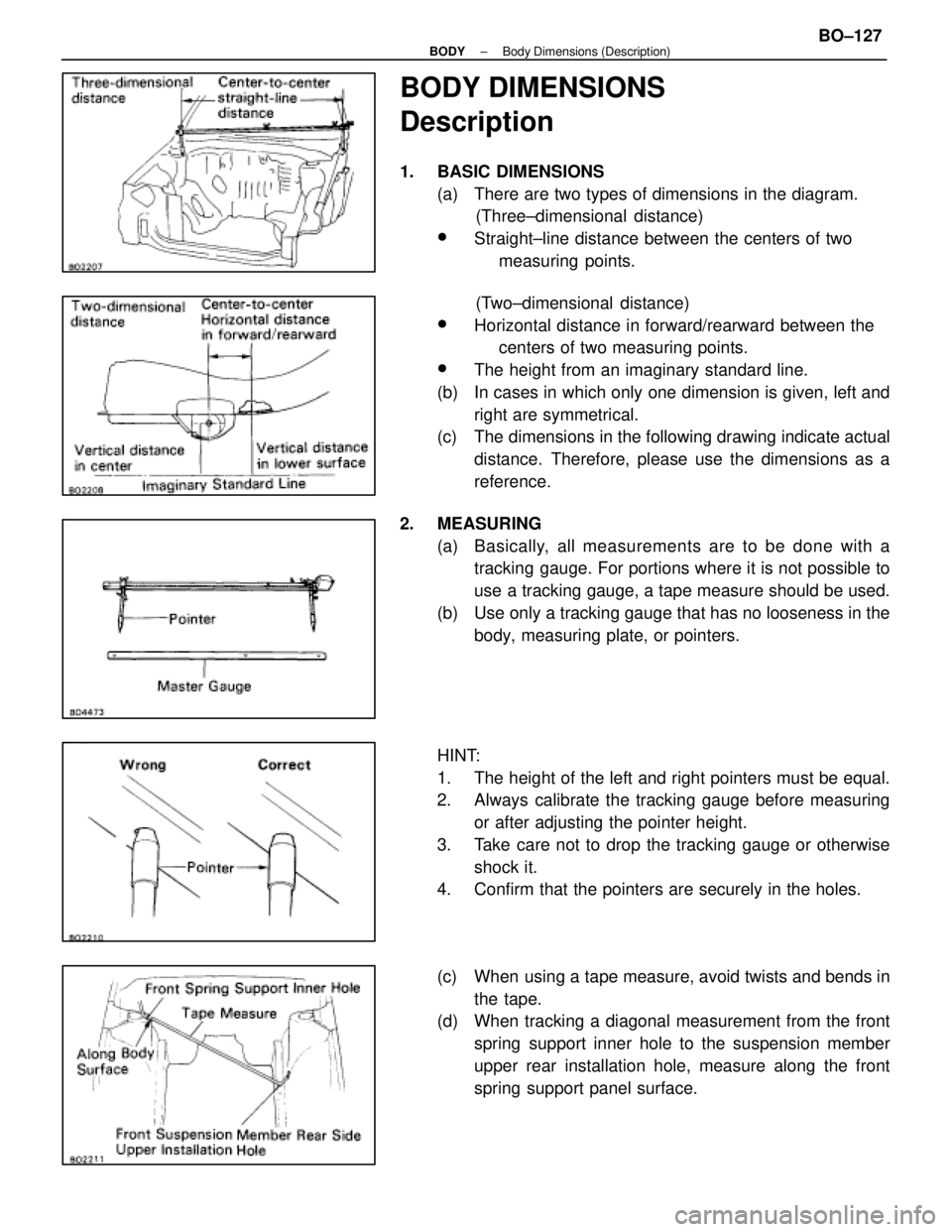

BODY DIMENSIONS

Description

1. BASIC DIMENSIONS(a) There are two types of dimensions in the diagram. (Three±dimensional distance)

wStraight±line distance between the centers of two

measuring points.

(Two±dimensional distance)

wHorizontal distance in forward/rearward between the centers of two measuring points.

wThe height from an imaginary standard line.

(b) In cases in which only one dimension is given, left and right are symmetrical.

(c) The dimensions in the following drawing indicate actual

distance. Therefore, please use the dimensions as a

reference.

2. MEASURING (a) Basically, all measurements are to be done with atracking gauge. For portions where it is not possible to

use a tracking gauge, a tape measure should be used.

(b) Use only a tracking gauge that has no looseness in the body, measuring plate, or pointers.

HINT:

1. The height of the left and right pointers must be equal.

2. Always calibrate the tracking gauge before measuring or after adjusting the pointer height.

3. Take care not to drop the tracking gauge or otherwise shock it.

4. Confirm that the pointers are securely in the holes.

(c) When using a tape measure, avoid twists and bends in

the tape.

(d) When tracking a diagonal measurement from the front

spring support inner hole to the suspension member

upper rear installation hole, measure along the front

spring support panel surface.

±

BODY Body Dimensions (Description)BO±127

WhereEverybodyKnowsYourName