engine LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1824 of 4087

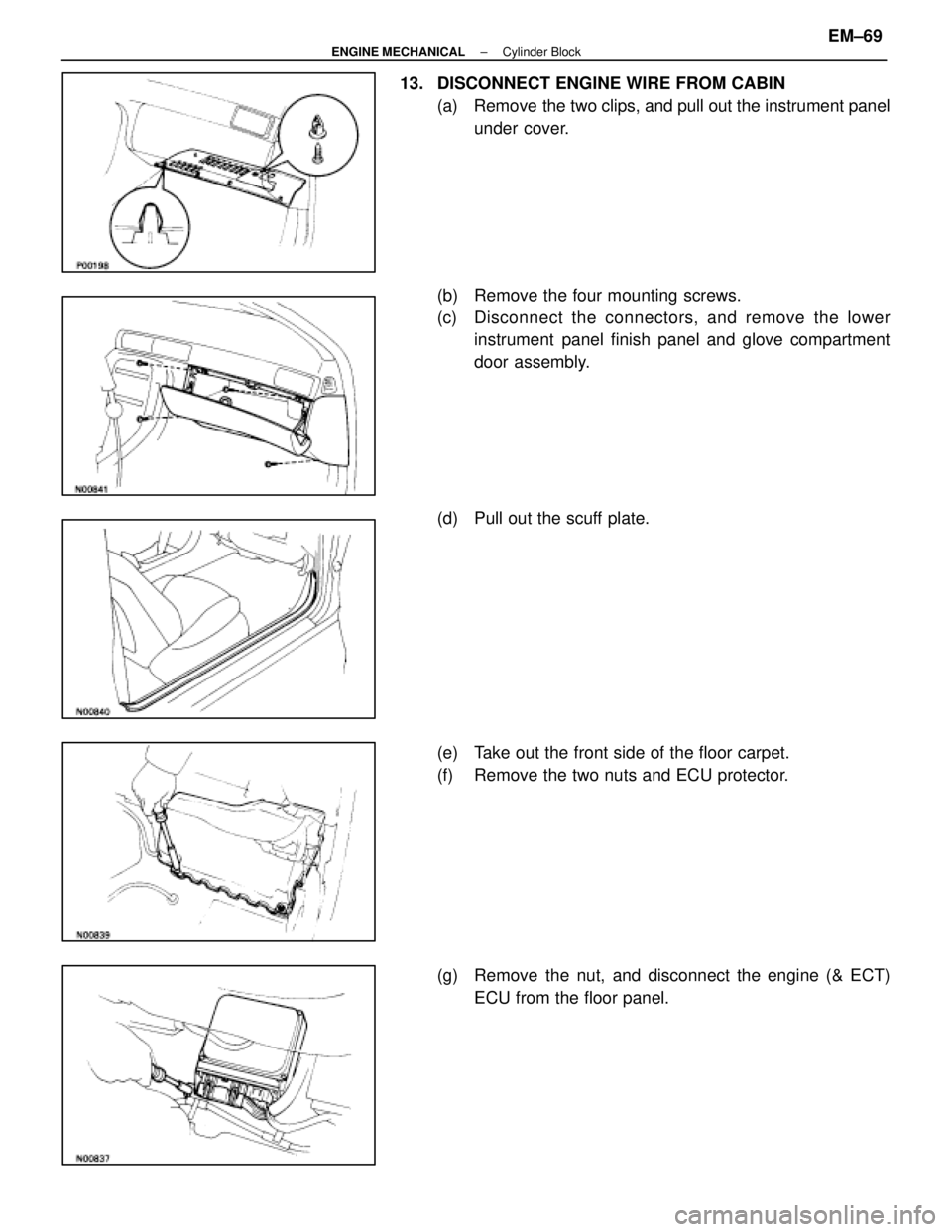

13. DISCONNECT ENGINE WIRE FROM CABIN(a) Remove the two clips, and pull out the instrument panelunder cover.

(b) Remove the four mounting screws.

(c) Disc onnect the connectors, and remove the lower

instrument panel finish panel and glove compartment

door assembly.

(d) Pull out the scuff plate.

(e) Take out the front side of the floor carpet.

(f) Remove the two nuts and ECU protector.

(g) Remove the nut, and disconnect the engine (& ECT) ECU from the floor panel.

±

ENGINE MECHANICAL Cylinder BlockEM±69

WhereEverybodyKnowsYourName

Page 1825 of 4087

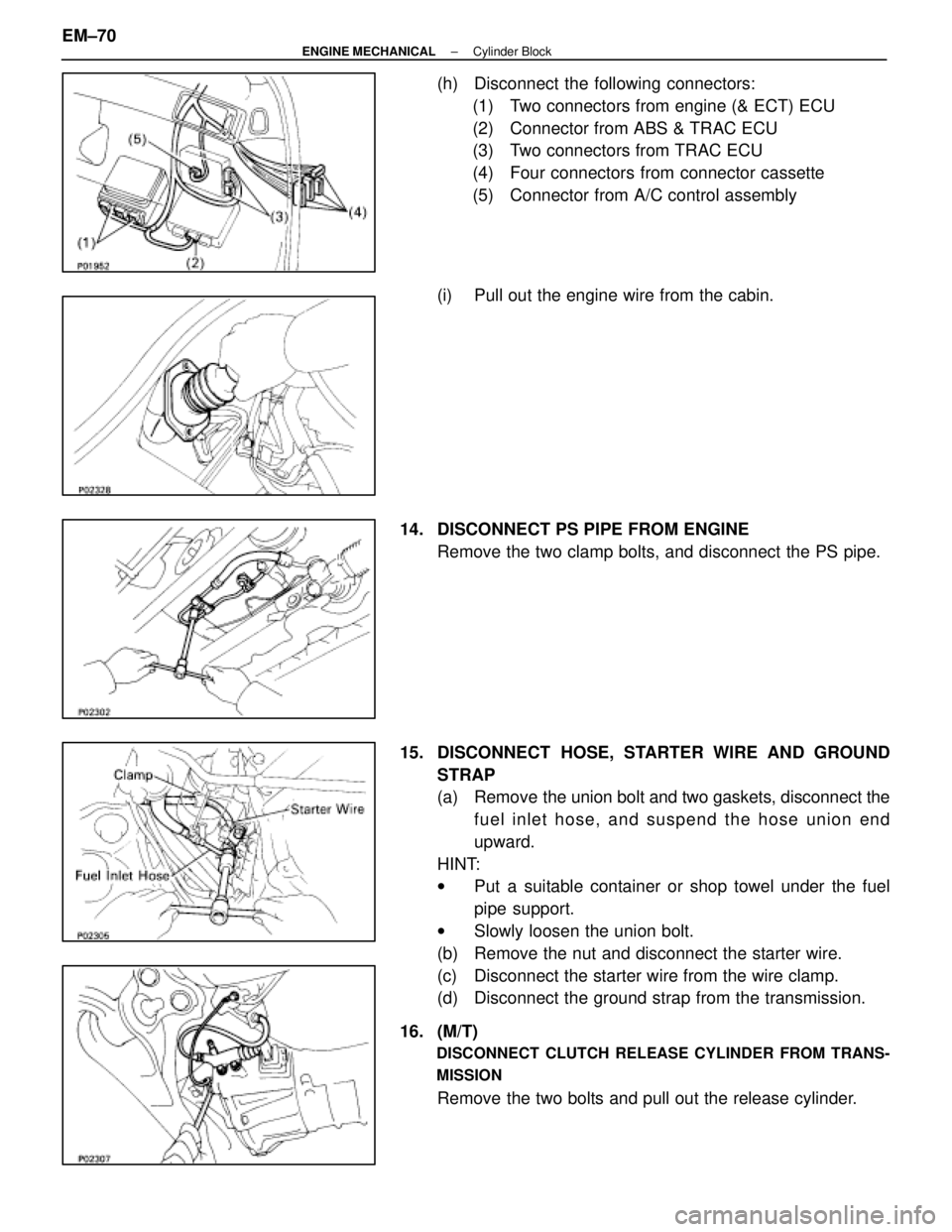

(h) Disconnect the following connectors:(1) Two connectors from engine (& ECT) ECU

(2) Connector from ABS & TRAC ECU

(3) Two connectors from TRAC ECU

(4) Four connectors from connector cassette

(5) Connector from A/C control assembly

(i) Pull out the engine wire from the cabin.

14. DISCONNECT PS PIPE FROM ENGINE Remove the two clamp bolts, and disconnect the PS pipe.

15. DISCONNECT HOSE, STARTER WIRE AND GROUND STRAP

(a) Remove the union bolt and two gaskets, disconnect thefuel inlet hose, and suspend the hose union end

upward.

HINT:

w Put a suitable container or shop towel under the fuel

pipe support.

w Slowly loosen the union bolt.

(b) Remove the nut and disconnect the starter wire.

(c) Disconnect the starter wire from the wire clamp.

(d) Disconnect the ground strap from the transmission.

16. (M/T)

DISCONNECT CLUTCH RELEASE CYLINDER FROM TRANS-

MISSION

Remove the two bolts and pull out the release cylinder.

EM±70

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1826 of 4087

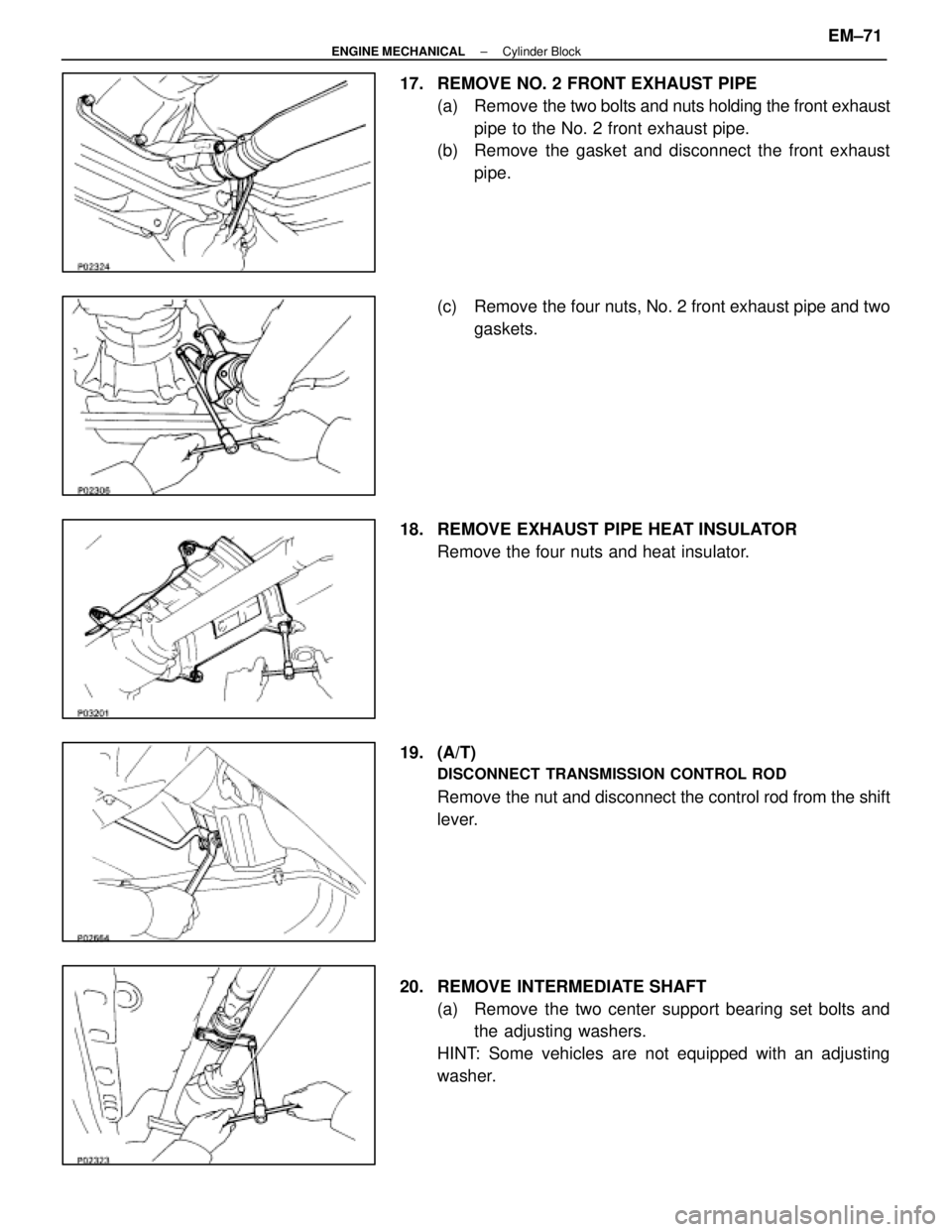

17. REMOVE NO. 2 FRONT EXHAUST PIPE(a) Remove the two bolts and nuts holding the front exhaust

pipe to the No. 2 front exhaust pipe.

(b) Remove the gasket and disconnect the front exhaust

pipe.

(c) Remove the four nuts, No. 2 front exhaust pipe and two gaskets.

18. REMOVE EXHAUST PIPE HEAT INSULATOR Remove the four nuts and heat insulator.

19. (A/T)

DISCONNECT TRANSMISSION CONTROL ROD

Remove the nut and disconnect the control rod from the shift

lever.

20. REMOVE INTERMEDIATE SHAFT (a) Remove the two center support bearing set bolts andthe adjusting washers.

HINT: Some vehicles are not equipped with an adjusting

washer.

±

ENGINE MECHANICAL Cylinder BlockEM±71

WhereEverybodyKnowsYourName

Page 1827 of 4087

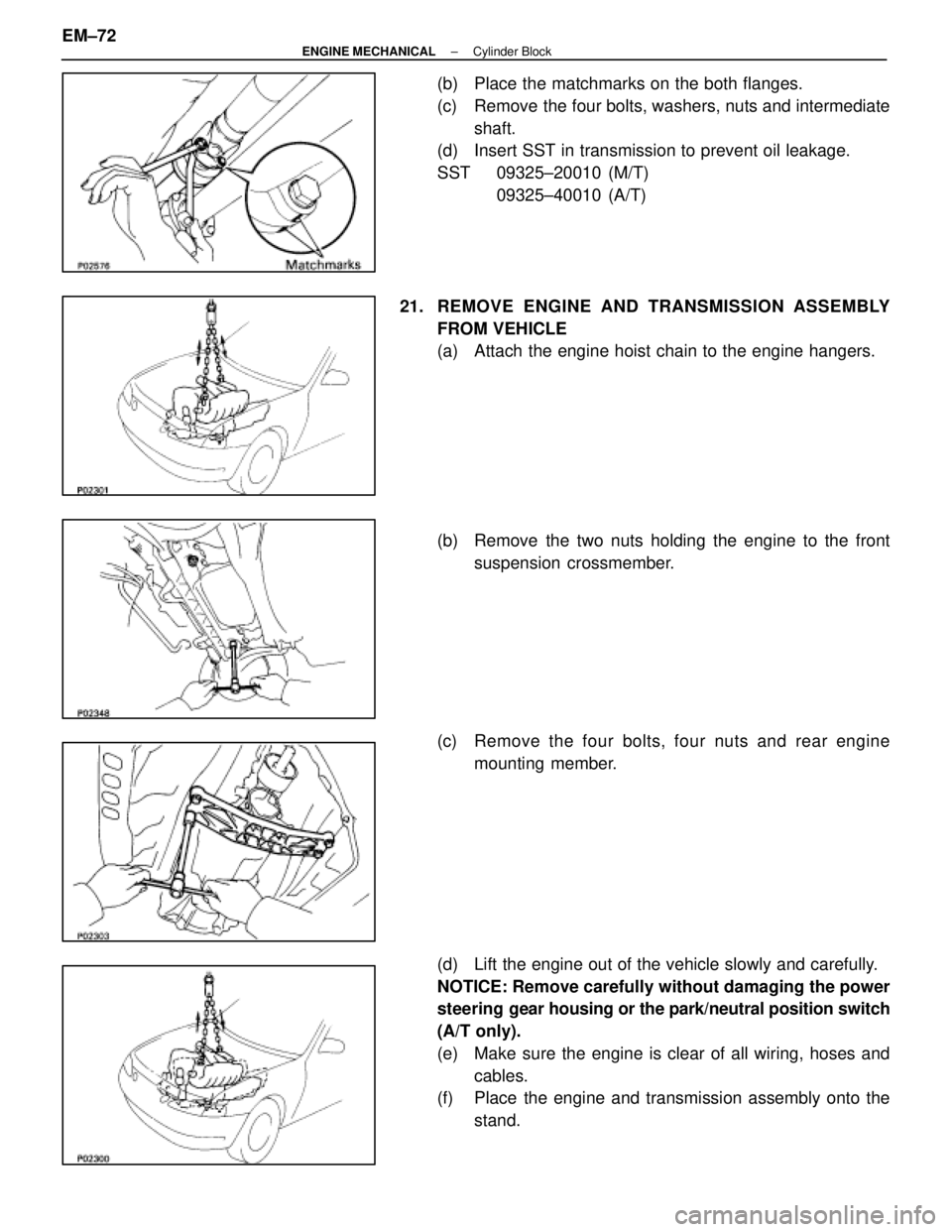

(b) Place the matchmarks on the both flanges.

(c) Remove the four bolts, washers, nuts and intermediateshaft.

(d) Insert SST in transmission to prevent oil leakage.

SST 09325±20010 (M/T)

09325±40010 (A/T)

21. REMOVE ENGINE AND T RANSMISSION ASSEMBLY

FROM VEHICLE

(a) Attach the engine hoist chain to the engine hangers.

(b) Remove the two nuts holding the engine to the front suspension crossmember.

(c) Remove the four bolts, four nuts and rear engine mounting member.

(d) Lift the engine out of the vehicle slowly and carefully.

NOTICE: Remove carefully without damaging the power

steering gear housing or the park/neutral position switch

(A/T only).

(e) Make sure the engine is clear of all wiring, hoses and cables.

(f) Place the engine and transmission assembly onto the

stand.

EM±72

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1828 of 4087

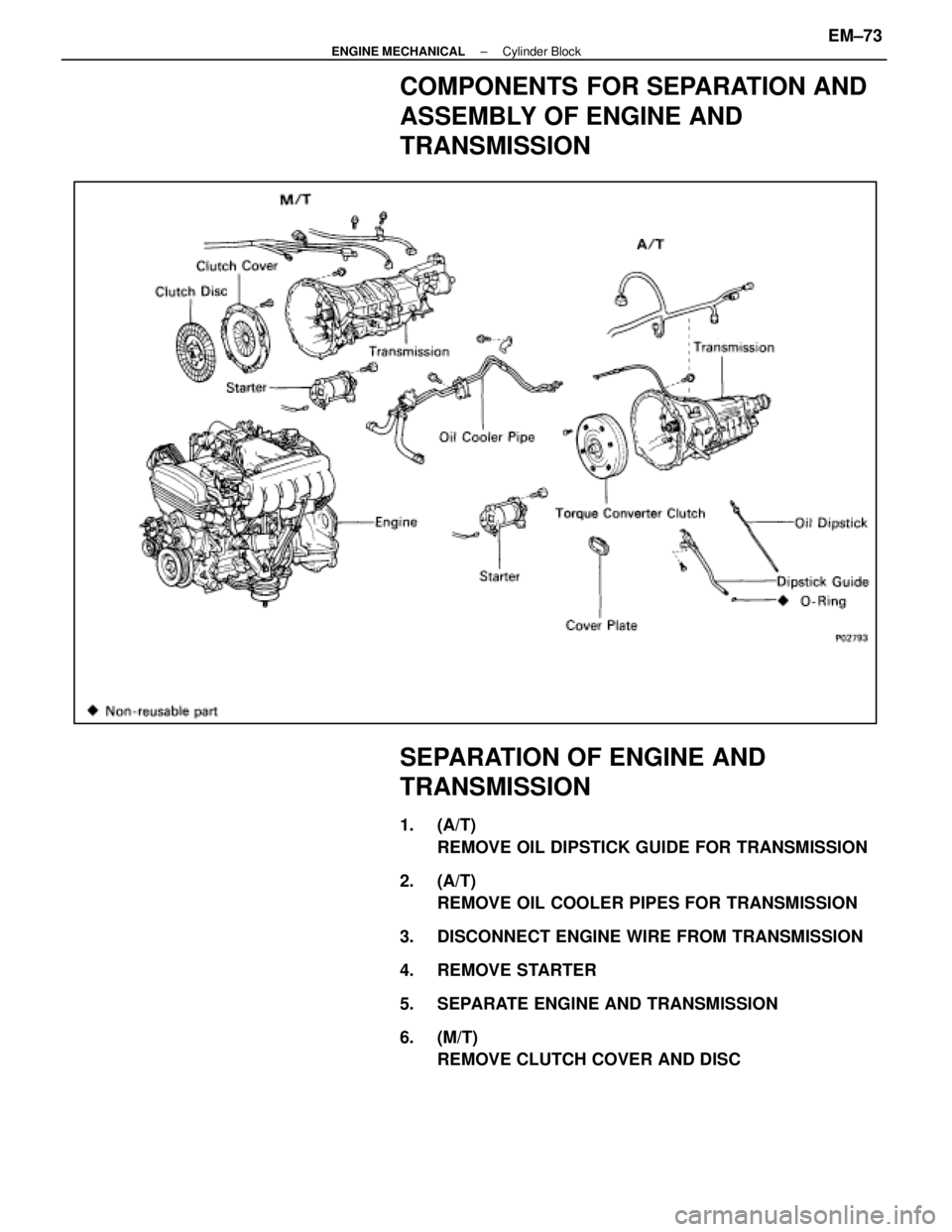

COMPONENTS FOR SEPARATION AND

ASSEMBLY OF ENGINE AND

TRANSMISSION

SEPARATION OF ENGINE AND

TRANSMISSION

1. (A/T)REMOVE OIL DIPSTICK GUIDE FOR TRANSMISSION

2. (A/T) REMOVE OIL COOLER PIPES FOR TRANSMISSION

3. DISCONNECT ENGINE WIRE FROM TRANSMISSION

4. REMOVE STARTER

5. SEPARATE ENGINE AND TRANSMISSION

6. (M/T) REMOVE CLUTCH COVER AND DISC

±

ENGINE MECHANICAL Cylinder BlockEM±73

WhereEverybodyKnowsYourName

Page 1829 of 4087

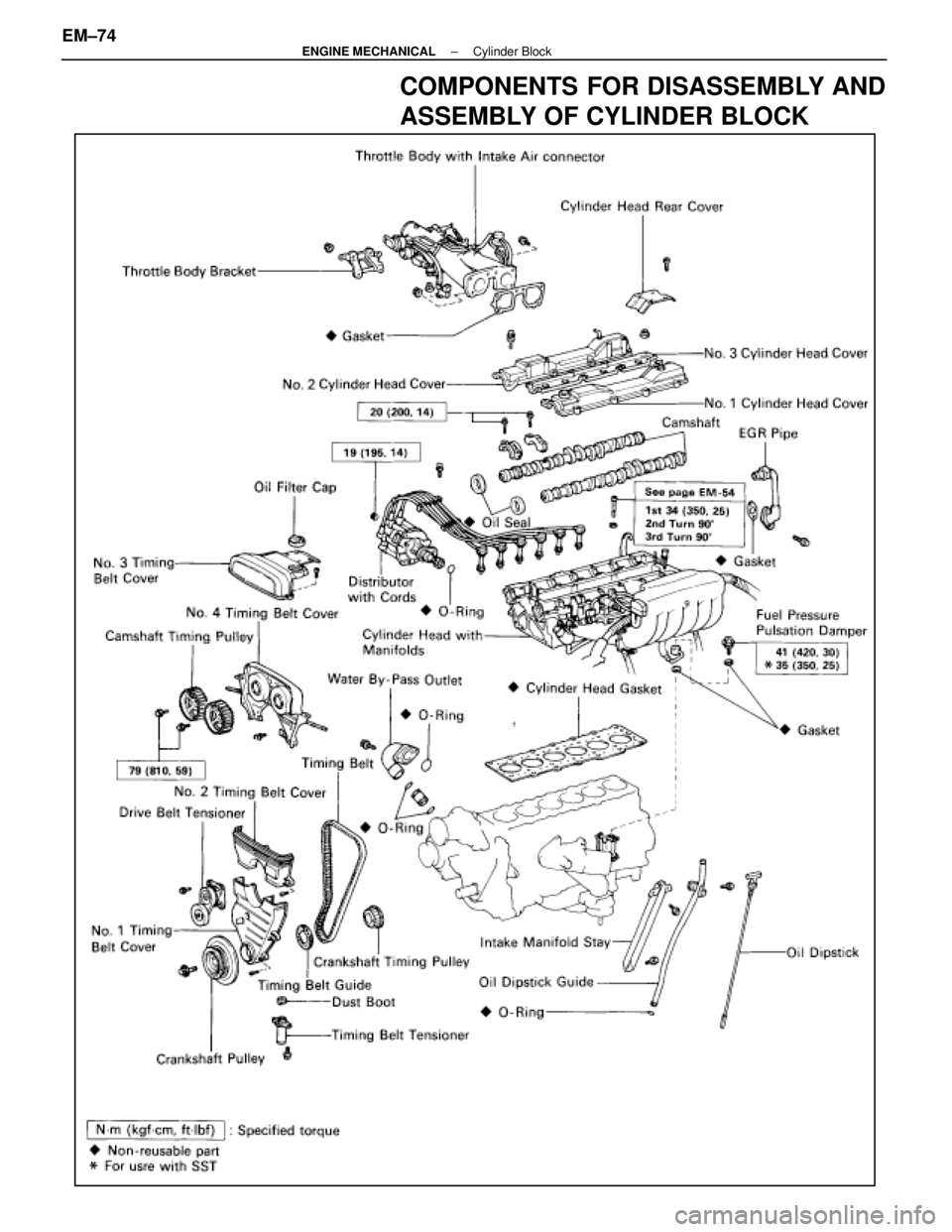

COMPONENTS FOR DISASSEMBLY AND

ASSEMBLY OF CYLINDER BLOCK

EM±74±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1830 of 4087

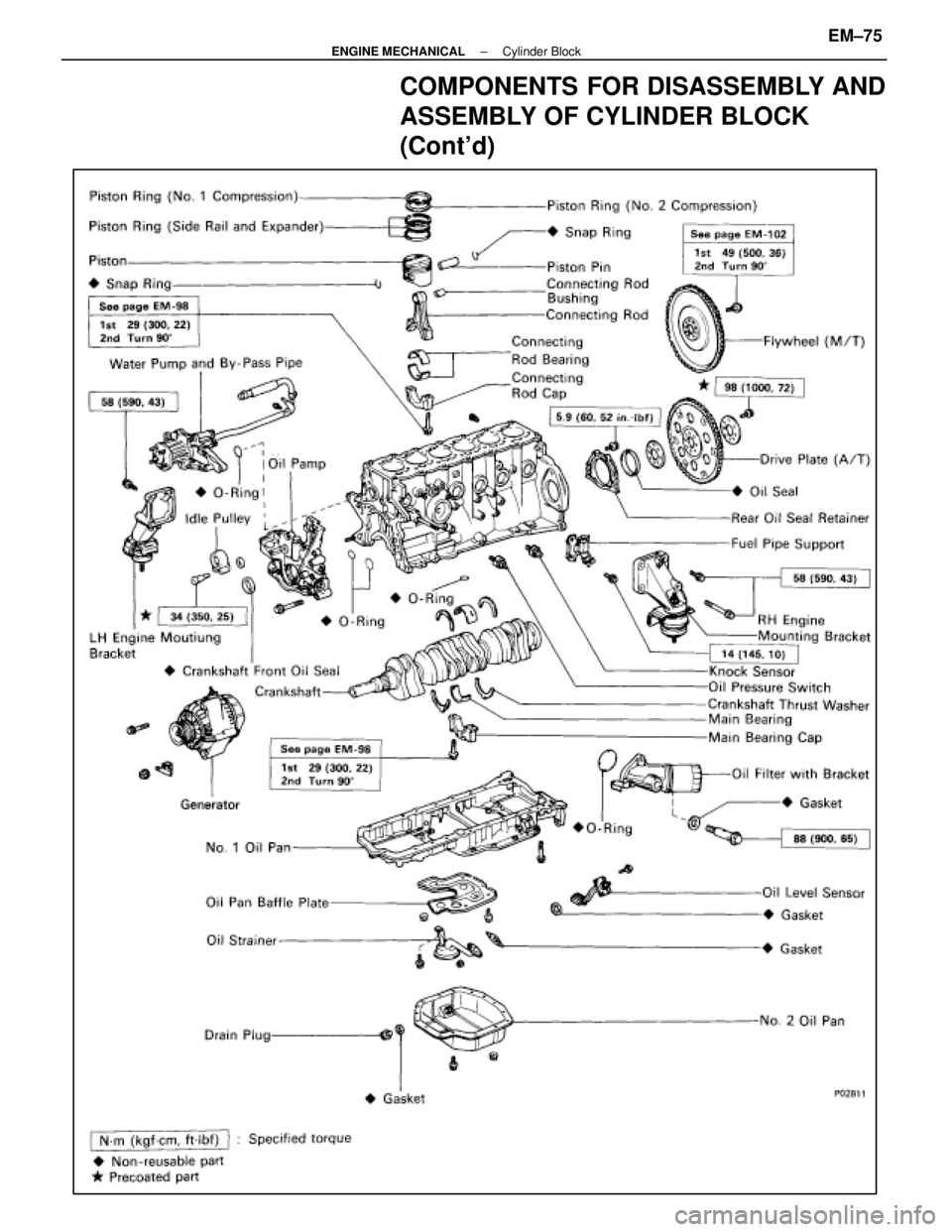

COMPONENTS FOR DISASSEMBLY AND

ASSEMBLY OF CYLINDER BLOCK

(Cont'd)

±

ENGINE MECHANICAL Cylinder BlockEM±75

WhereEverybodyKnowsYourName

Page 1831 of 4087

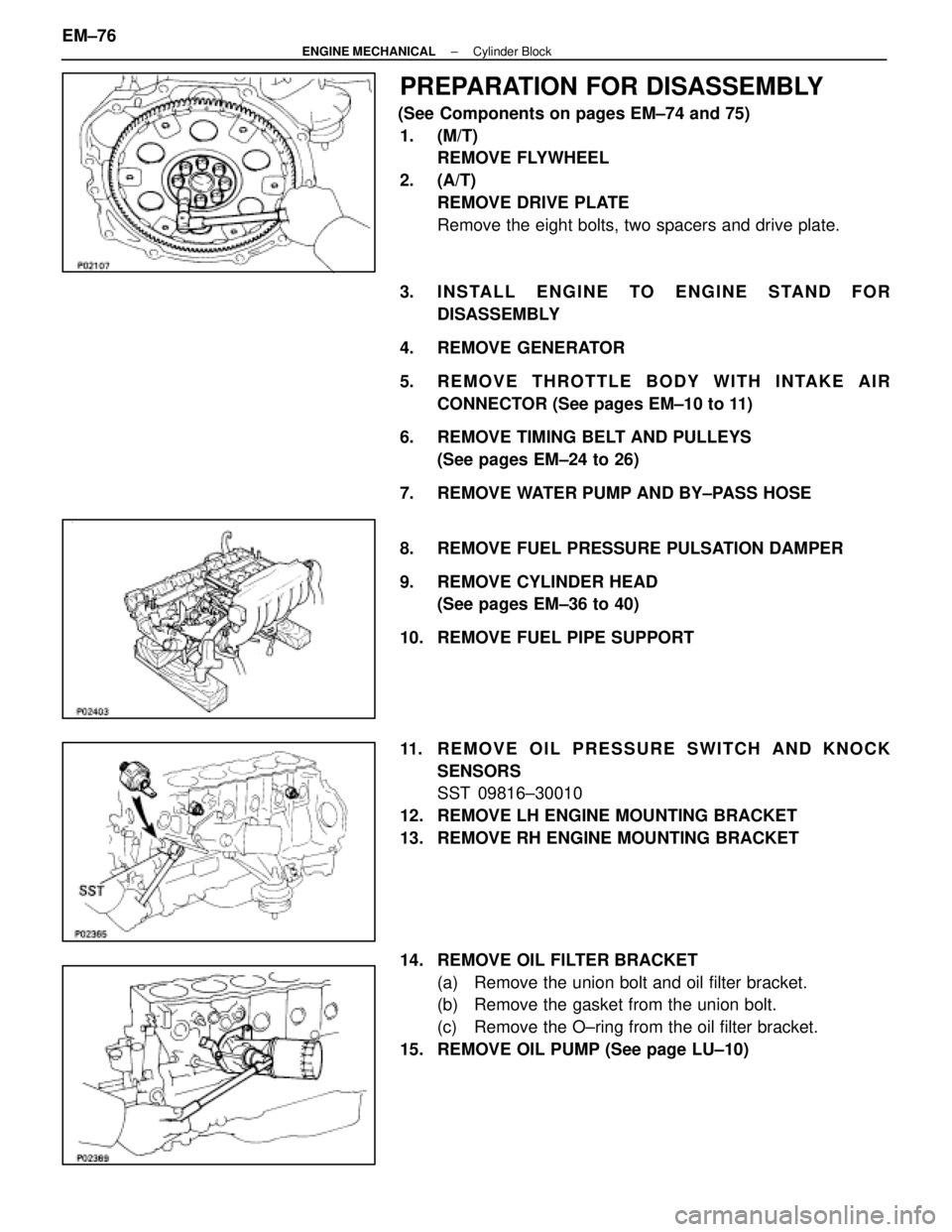

PREPARATION FOR DISASSEMBLY

(See Components on pages EM±74 and 75)1. (M/T) REMOVE FLYWHEEL

2. (A/T) REMOVE DRIVE PLATE

Remove the eight bolts, two spacers and drive plate.

3. INSTALL ENGINE TO ENGINE STAND FOR DISASSEMBLY

4. REMOVE GENERATOR

5. REMOVE THROTTLE BODY WITH INTAKE AIR CONNECTOR (See pages EM±10 to 11)

6. REMOVE TIMING BELT AND PULLEYS (See pages EM±24 to 26)

7. REMOVE WATER PUMP AND BY±PASS HOSE

8. REMOVE FUEL PRESSURE PULSATION DAMPER

9. REMOVE CYLINDER HEAD (See pages EM±36 to 40)

10. REMOVE FUEL PIPE SUPPORT

11. REMOVE OIL PRESSURE SWITCH AND KNOCK SENSORS

SST 09816±30010

12. REMOVE LH ENGINE MOUNTING BRACKET

13. REMOVE RH ENGINE MOUNTING BRACKET

14. REMOVE OIL FILTER BRACKET (a) Remove the union bolt and oil filter bracket.

(b) Remove the gasket from the union bolt.

(c) Remove the O±ring from the oil filter bracket.

15. REMOVE OIL PUMP (See page LU±10)

EM±76

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1832 of 4087

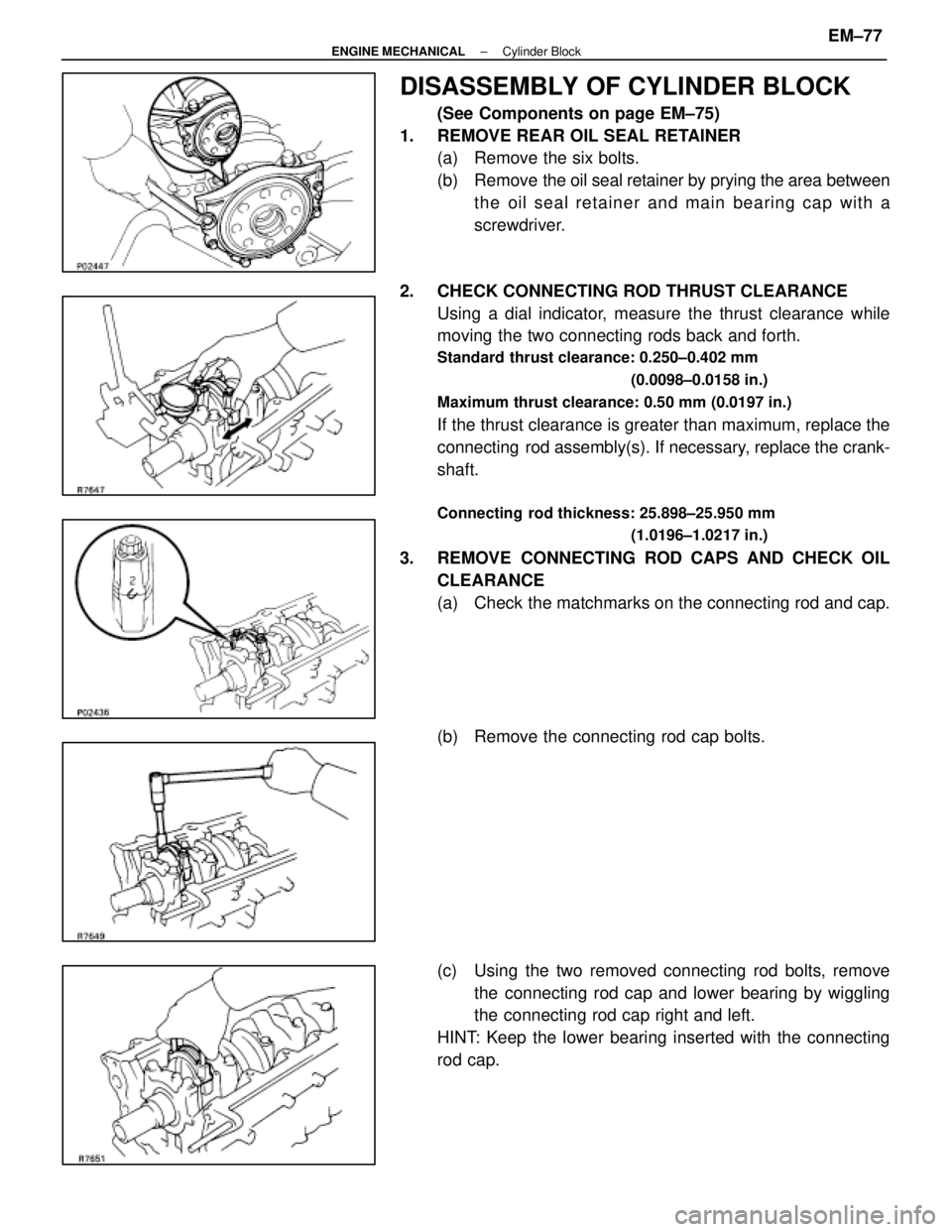

DISASSEMBLY OF CYLINDER BLOCK

(See Components on page EM±75)

1. REMOVE REAR OIL SEAL RETAINER (a) Remove the six bolts.

(b) Remove the oil seal retainer by prying the area between

the oil seal retainer and main bearing cap with a

screwdriver.

2. CHECK CONNECTING ROD THRUST CLEARANCE Using a dial indicator, measure the thrust clearance while

moving the two connecting rods back and forth.

Standard thrust clearance: 0.250±0.402 mm

(0.0098±0.0158 in.)

Maximum thrust clearance: 0.50 mm (0.0197 in.)

If the thrust clearance is greater than maximum, replace the

connecting rod assembly(s). If necessary, replace the crank-

shaft.

Connecting rod thickness: 25.898±25.950 mm (1.0196±1.0217 in.)

3. REMOVE CONNECTING ROD CAPS AND CHECK OILCLEARANCE

(a) Check the matchmarks on the connecting rod and cap.

(b) Remove the connecting rod cap bolts.

(c) Using the two removed connecting rod bolts, removethe connecting rod cap and lower bearing by wiggling

the connecting rod cap right and left.

HINT: Keep the lower bearing inserted with the connecting

rod cap.

±

ENGINE MECHANICAL Cylinder BlockEM±77

WhereEverybodyKnowsYourName

Page 1833 of 4087

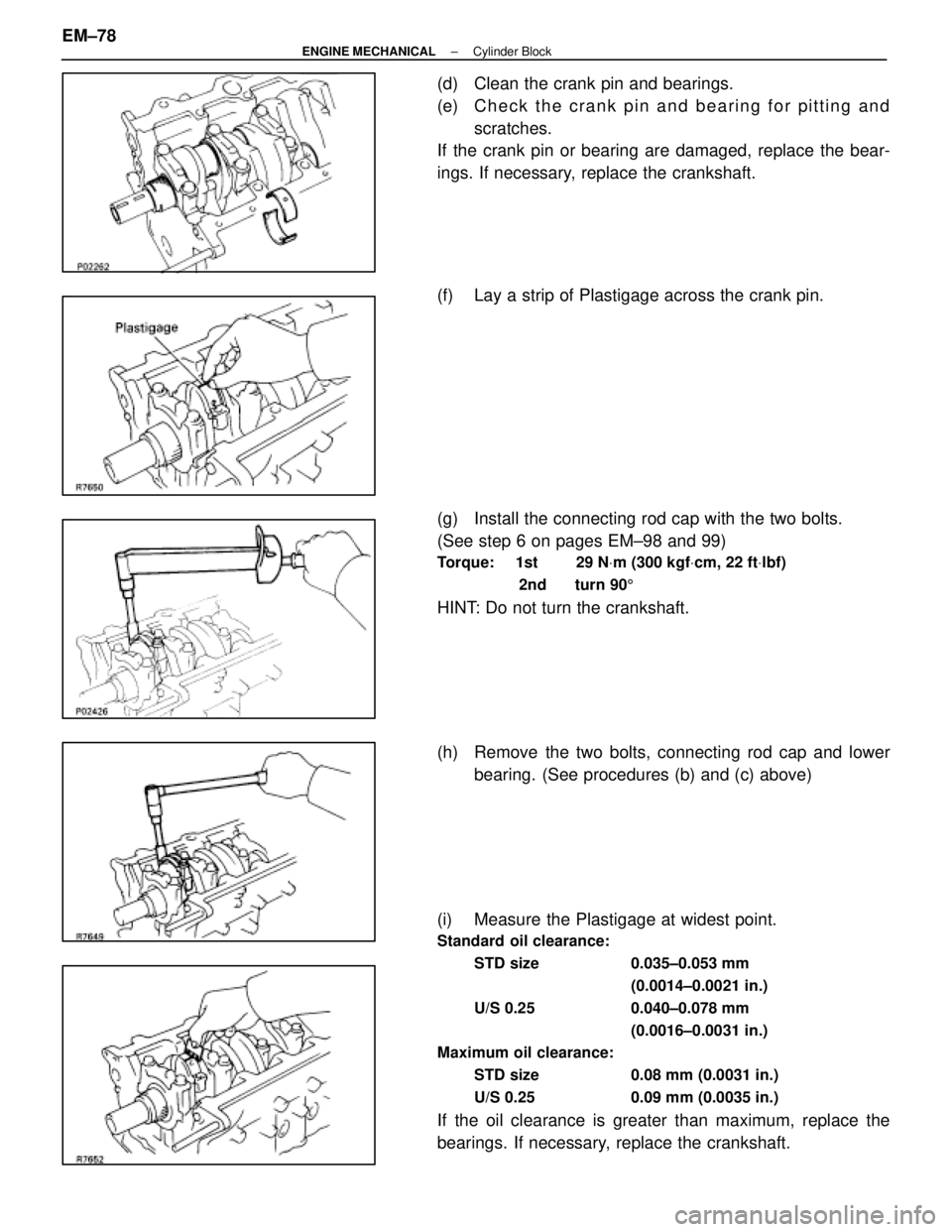

(d) Clean the crank pin and bearings.

(e) C h e c k t h e c r a n k p i n a n d b e a r i n g f o r p i t t i n g a n dscratches.

If the crank pin or bearing are damaged, replace the bear-

ings. If necessary, replace the crankshaft.

(f) Lay a strip of Plastigage across the crank pin.

(g) Install the connecting rod cap with the two bolts.

(See step 6 on pages EM±98 and 99)

Torque: 1st 29 N Vm (300 kgf Vcm, 22 ft Vlbf)

2nd turn 90 5

HINT: Do not turn the crankshaft.

(h) Remove the two bolts, connecting rod cap and lower

bearing. (See procedures (b) and (c) above)

(i) Measure the Plastigage at widest point.

Standard oil clearance: STD size 0.035±0.053 mm (0.0014±0.0021 in.)

U/S 0.25 0.040±0.078 mm (0.0016±0.0031 in.)

Maximum oil clearance:

STD size 0.08 mm (0.0031 in.)

U/S 0.25 0.09 mm (0.0035 in.)

If the oil clearance is greater than maximum, replace the

bearings. If necessary, replace the crankshaft.

EM±78

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName