engine LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2286 of 4087

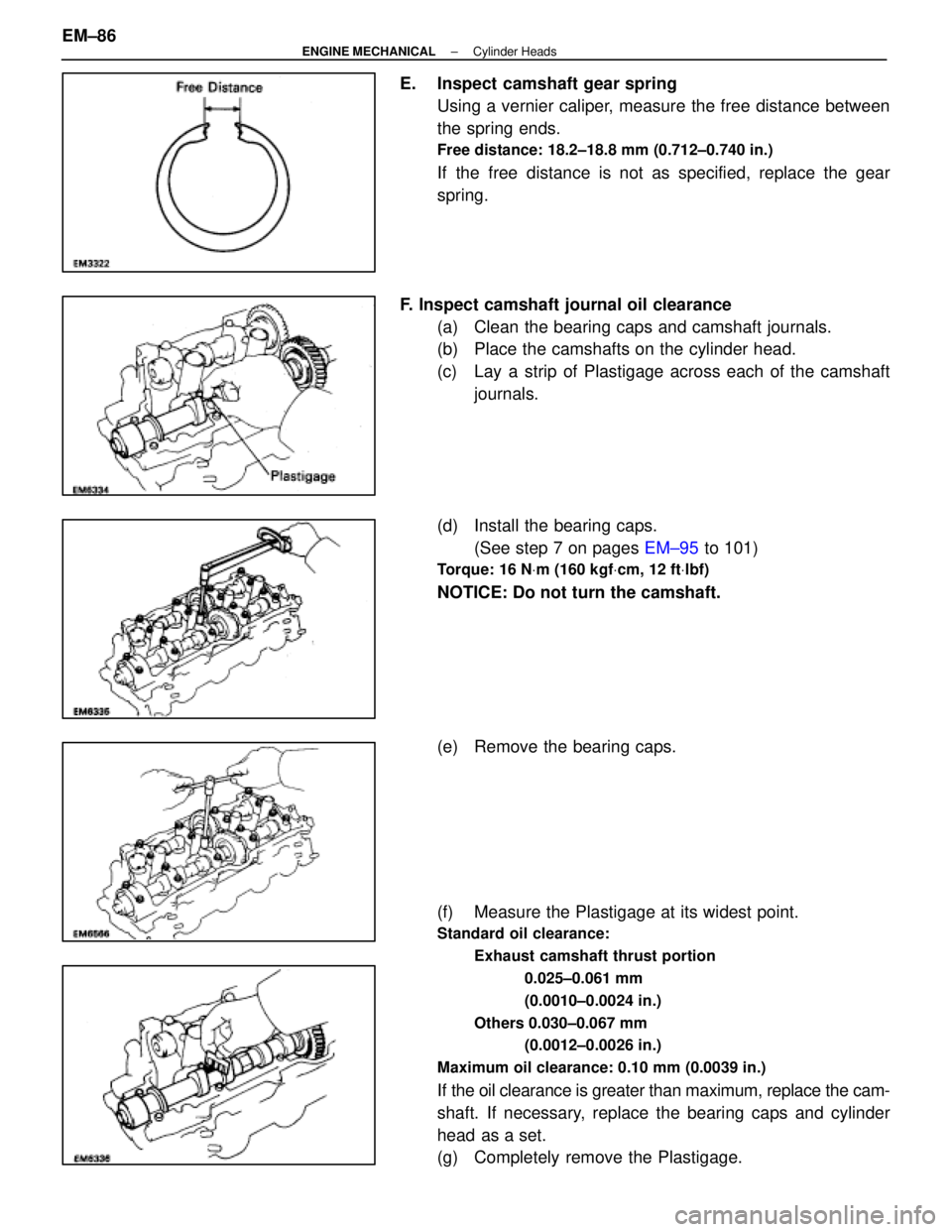

E. Inspect camshaft gear springUsing a vernier caliper, measure the free distance between

the spring ends.

Free distance: 18.2±18.8 mm (0.712±0.740 in.)

If the free distance is not as specified, replace the gear

spring.

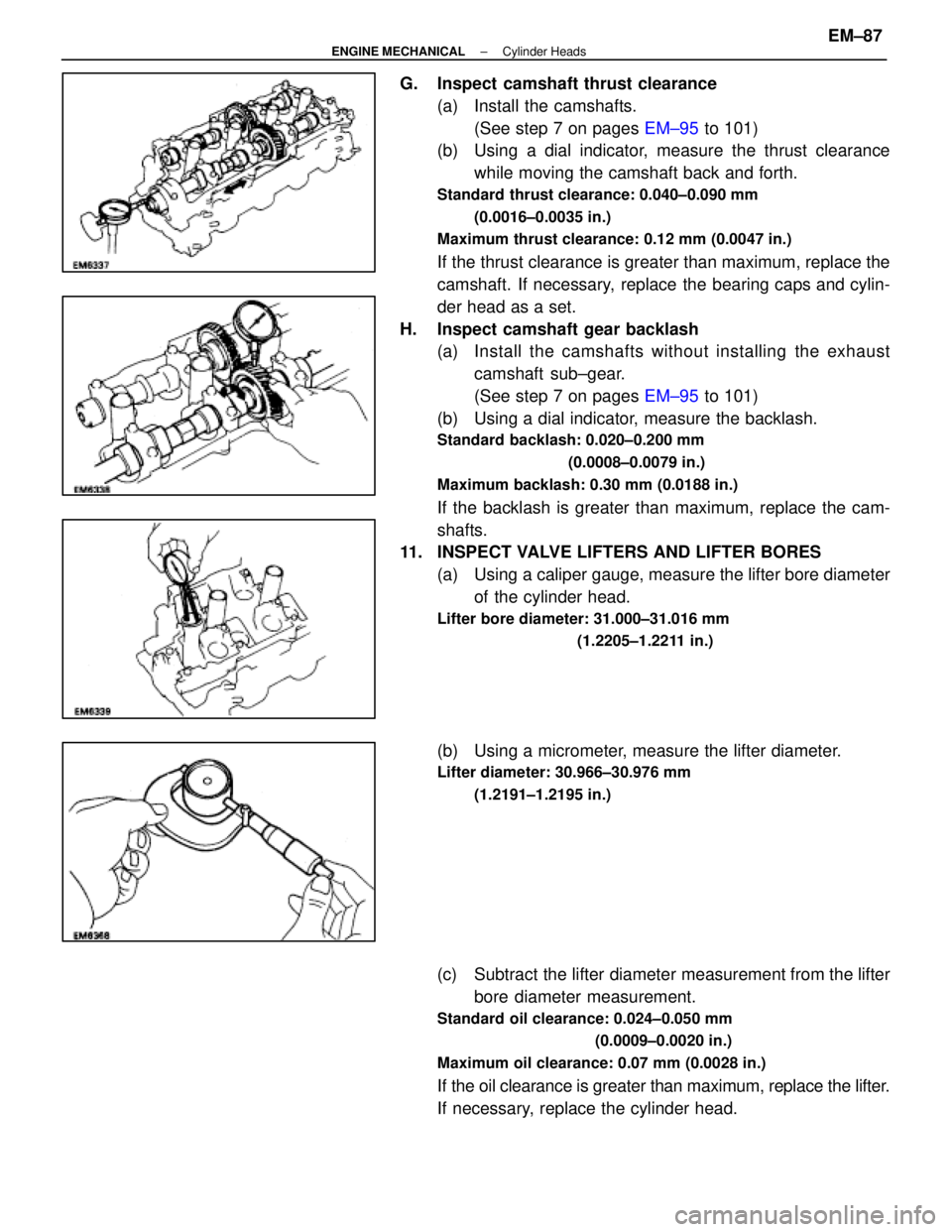

F. Inspect camshaft journal oil clearance (a) Clean the bearing caps and camshaft journals.

(b) Place the camshafts on the cylinder head.

(c) Lay a strip of Plastigage across each of the camshaftjournals.

(d) Install the bearing caps. (See step 7 on pages EM±95 to 101)

Torque: 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

NOTICE: Do not turn the camshaft.

(e) Remove the bearing caps.

(f) Measure the Plastigage at its widest point.

Standard oil clearance:

Exhaust camshaft thrust portion 0.025±0.061 mm

(0.0010±0.0024 in.)

Others 0.030±0.067 mm (0.0012±0.0026 in.)

Maximum oil clearance: 0.10 mm (0.0039 in.)

If the oil clearance is greater than maximum, replace the cam-

shaft. If necessary, replace the bearing caps and cylinder

head as a set.

(g) Completely remove the Plastigage.

EM±86

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 2287 of 4087

G. Inspect camshaft thrust clearance(a) Install the camshafts.(See step 7 on pages EM±95 to 101)

(b) Using a dial indicator, measure the thrust clearance

while moving the camshaft back and forth.

Standard thrust clearance: 0.040±0.090 mm

(0.0016±0.0035 in.)

Maximum thrust clearance: 0.12 mm (0.0047 in.)

If the thrust clearance is greater than maximum, replace the

camshaft. If necessary, replace the bearing caps and cylin-

der head as a set.

H. Inspect camshaft gear backlash (a) Install the camshafts wit hout installing the ex haust

camshaft sub±gear.

(See step 7 on pages EM±95 to 101)

(b) Using a dial indicator, measure the backlash.

Standard backlash: 0.020±0.200 mm

(0.0008±0.0079 in.)

Maximum backlash: 0.30 mm (0.0188 in.)

If the backlash is greater than maximum, replace the cam-

shafts.

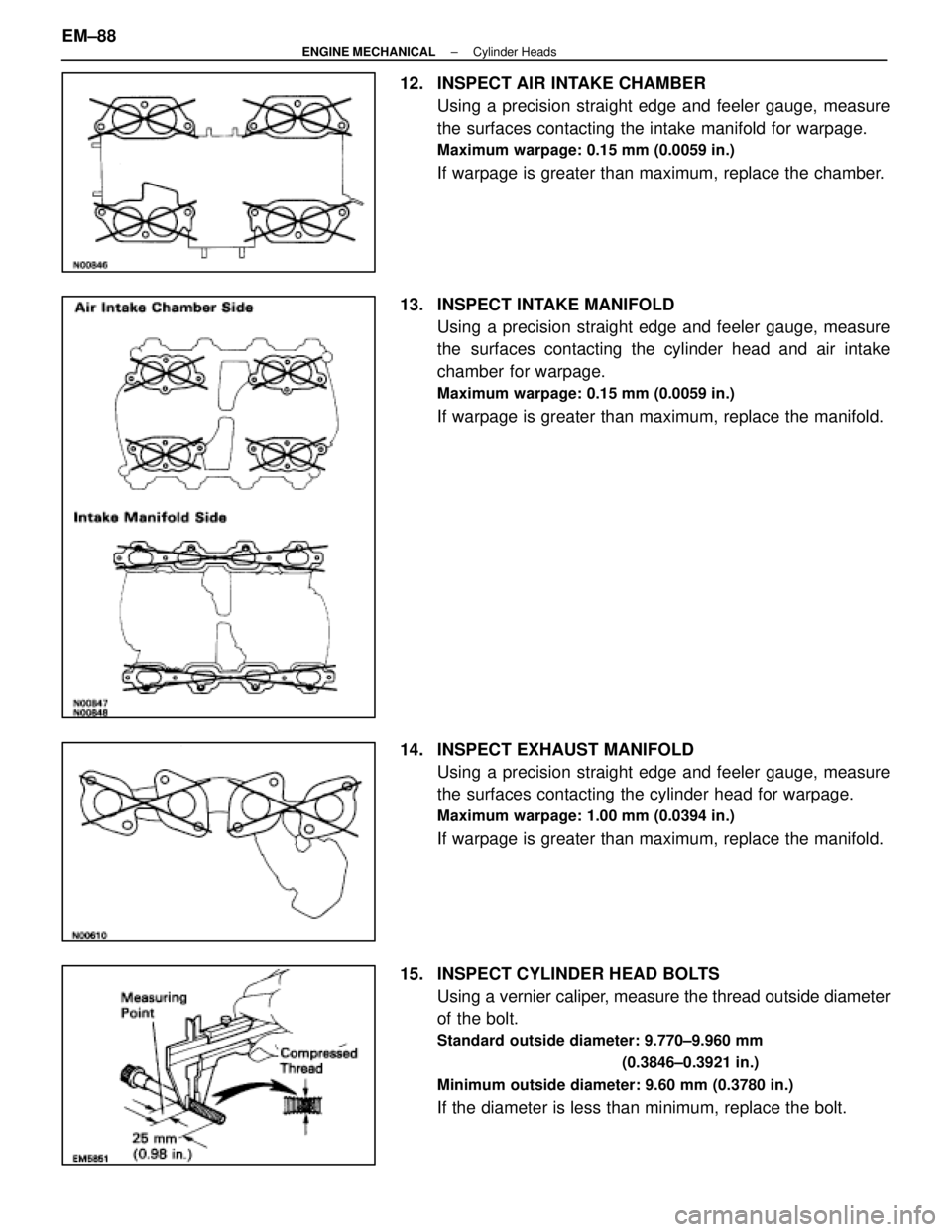

11. INSPECT VALVE LIFTERS AND LIFTER BORES

(a) Using a caliper gauge, measure the lifter bore diameterof the cylinder head.

Lifter bore diameter: 31.000±31.016 mm

(1.2205±1.2211 in.)

(b) Using a micrometer, measure the lifter diameter.

Lifter diameter: 30.966±30.976 mm

(1.2191±1.2195 in.)

(c) Subtract the lifter diameter measurement from the lifterbore diameter measurement.

Standard oil clearance: 0.024±0.050 mm

(0.0009±0.0020 in.)

Maximum oil clearance: 0.07 mm (0.0028 in.)

If the oil clearance is greater than maximum, replace the lifter.

If necessary, replace the cylinder head.

±

ENGINE MECHANICAL Cylinder HeadsEM±87

WhereEverybodyKnowsYourName

Page 2288 of 4087

12. INSPECT AIR INTAKE CHAMBERUsing a precision straight edge and feeler gauge, measure

the surfaces contacting the intake manifold for warpage.

Maximum warpage: 0.15 mm (0.0059 in.)

If warpage is greater than maximum, replace the chamber.

13. INSPECT INTAKE MANIFOLD Using a precision straight edge and feeler gauge, measure

the surfaces contacting the cylinder head and air intake

chamber for warpage.

Maximum warpage: 0.15 mm (0.0059 in.)

If warpage is greater than maximum, replace the manifold.

14. INSPECT EXHAUST MANIFOLD Using a precision straight edge and feeler gauge, measure

the surfaces contacting the cylinder head for warpage.

Maximum warpage: 1.00 mm (0.0394 in.)

If warpage is greater than maximum, replace the manifold.

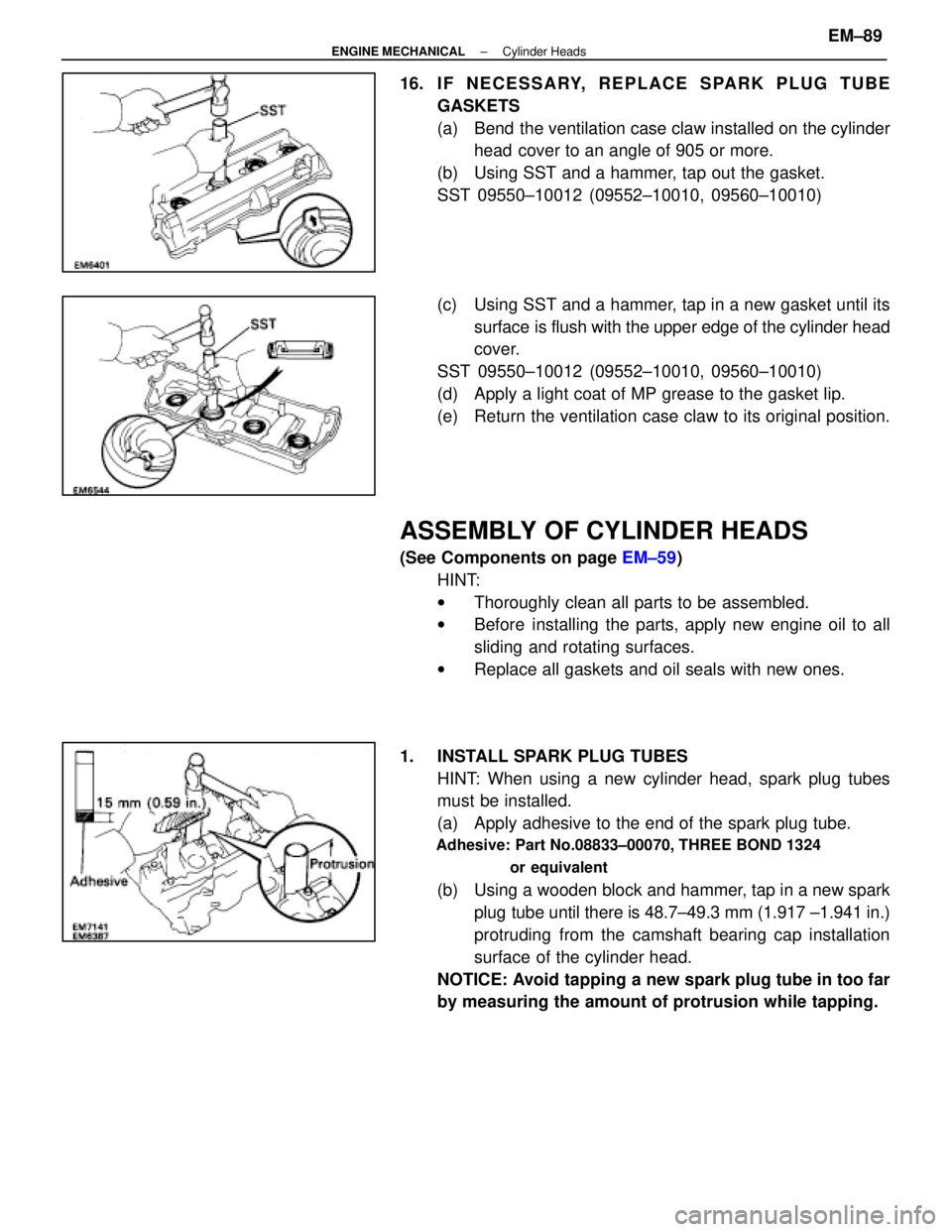

15. INSPECT CYLINDER HEAD BOLTS Using a vernier caliper, measure the thread outside diameter

of the bolt.

Standard outside diameter: 9.770±9.960 mm

(0.3846±0.3921 in.)

Minimum outside diameter: 9.60 mm (0.3780 in.)

If the diameter is less than minimum, replace the bolt.

EM±88

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 2289 of 4087

16. IF NECESSARY, REPLACE SPARK PLUG TUBEGASKETS

(a) Bend the ventilation case claw installed on the cylinderhead cover to an angle of 905 or more.

(b) Using SST and a hammer, tap out the gasket.

SST 09550±10012 (09552±10010, 09560±10010)

(c) Using SST and a hammer, tap in a new gasket until its surface is flush with the upper edge of the cylinder head

cover.

SST 09550±10012 (09552±10010, 09560±10010)

(d) Apply a light coat of MP grease to the gasket lip.

(e) Return the ventilation case claw to its original position.

ASSEMBLY OF CYLINDER HEADS

(See Components on page EM±59)

HINT:

w Thoroughly clean all parts to be assembled.

w Before installing the parts, apply new engine oil to all

sliding and rotating surfaces.

w Replace all gaskets and oil seals with new ones.

1. INSTALL SPARK PLUG TUBES HINT: When using a new cylinder head, spark plug tubes

must be installed.

(a) Apply adhesive to the end of the spark plug tube.

Adhesive: Part No.08833±00070, THREE BOND 1324

or equivalent

(b) Using a wooden block and hammer, tap in a new sparkplug tube until there is 48.7±49.3 mm (1.917 ±1.941 in.)

protruding from the camshaft bearing cap installation

surface of the cylinder head.

NOTICE: Avoid tapping a new spark plug tube in too far

by measuring the amount of protrusion while tapping.

±

ENGINE MECHANICAL Cylinder HeadsEM±89

WhereEverybodyKnowsYourName

Page 2290 of 4087

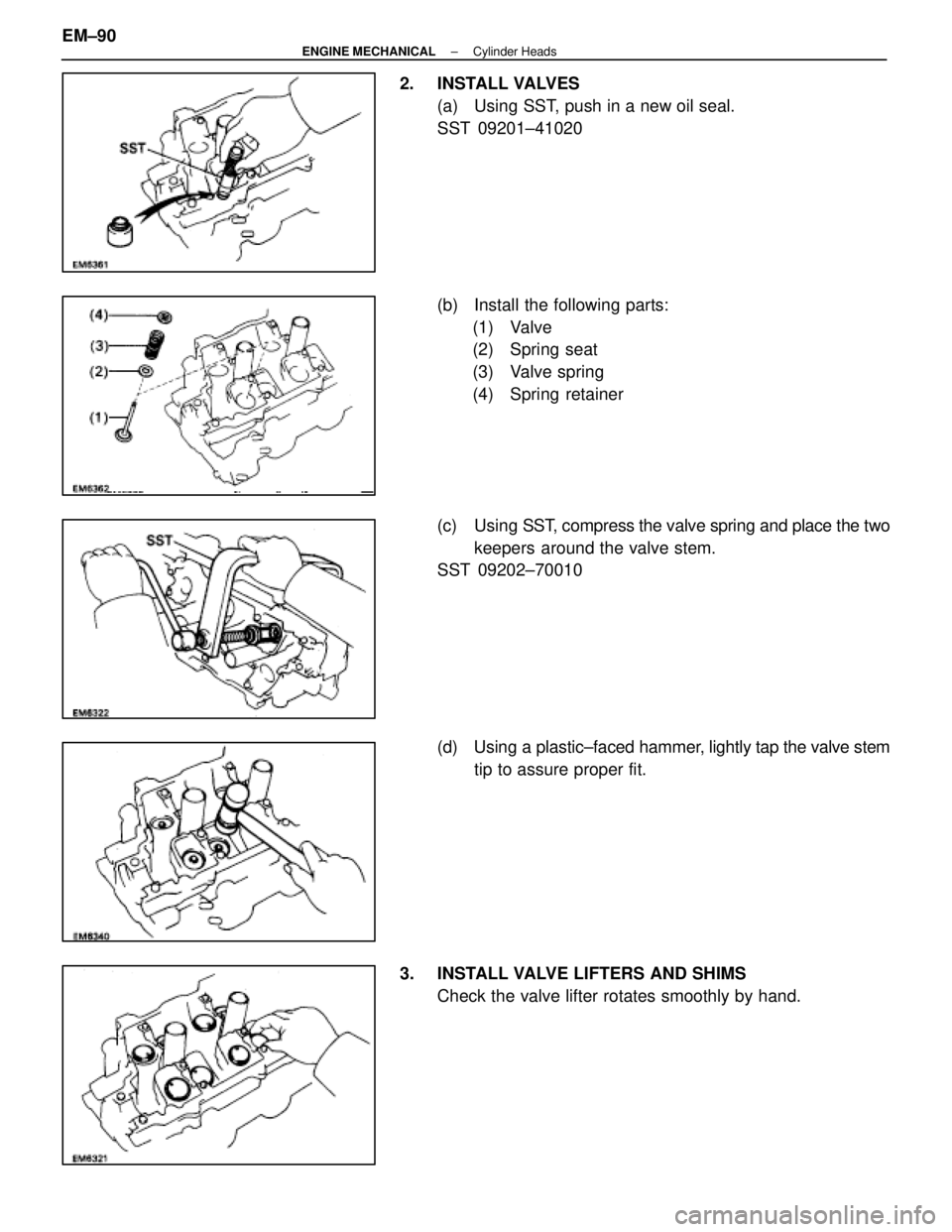

2. INSTALL VALVES(a) Using SST, push in a new oil seal.

SST 09201±41020

(b) Install the following parts:(1) Valve

(2) Spring seat

(3) Valve spring

(4) Spring retainer

(c) Using SST, compress the valve spring and place the two

keepers around the valve stem.

SST 09202±70010

(d) Using a plastic±faced hammer, lightly tap the valve stem

tip to assure proper fit.

3. INSTALL VALVE LIFTERS AND SHIMS Check the valve lifter rotates smoothly by hand.

EM±90

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 2291 of 4087

INSTALLATION OF CYLINDER HEADS

(See Components on pages EM±58 and 59)

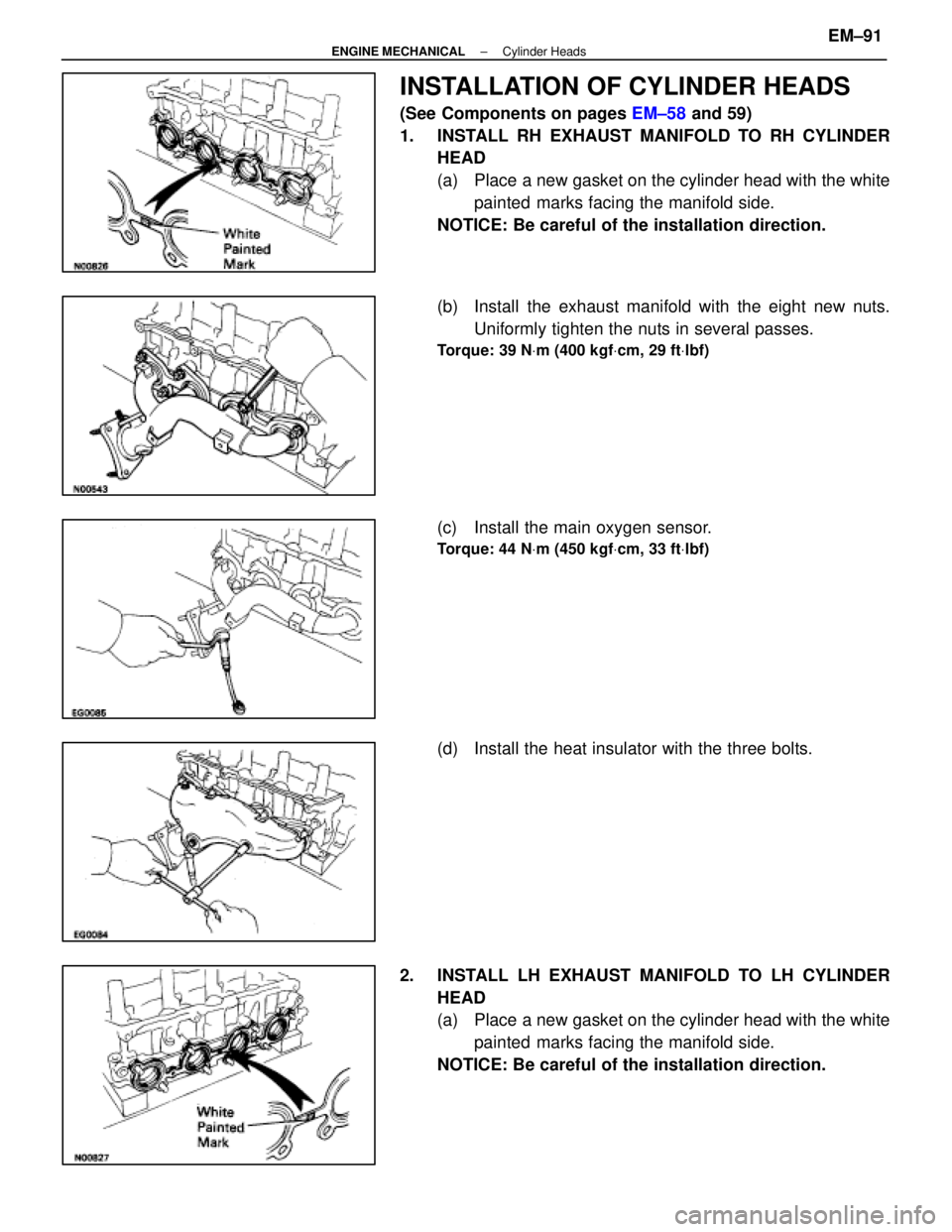

1. INSTALL RH EXHAUST MANIFOLD TO RH CYLINDER HEAD

(a) Place a new gasket on the cylinder head with the white

painted marks facing the manifold side.

NOTICE: Be careful of the installation direction.

(b) Install the exhaust manifold with the eight new nuts. Uniformly tighten the nuts in several passes.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(c) Install the main oxygen sensor.

Torque: 44 N Vm (450 kgf Vcm, 33 ft Vlbf)

(d) Install the heat insulator with the three bolts.

2. INSTALL LH EXHAUST MANIFOLD TO LH CYLINDER HEAD

(a) Place a new gasket on the cylinder head with the whitepainted marks facing the manifold side.

NOTICE: Be careful of the installation direction.

±

ENGINE MECHANICAL Cylinder HeadsEM±91

WhereEverybodyKnowsYourName

Page 2292 of 4087

(b) Install the exhaust manifold with the eight new nuts.Uniformly tighten the nuts in several passes.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(c) Install the main oxygen sensor.

Torque: 44 N Vm (450 kgf Vcm, 33 ft Vlbf)

(d) Install the heat insulator with the three bolts.

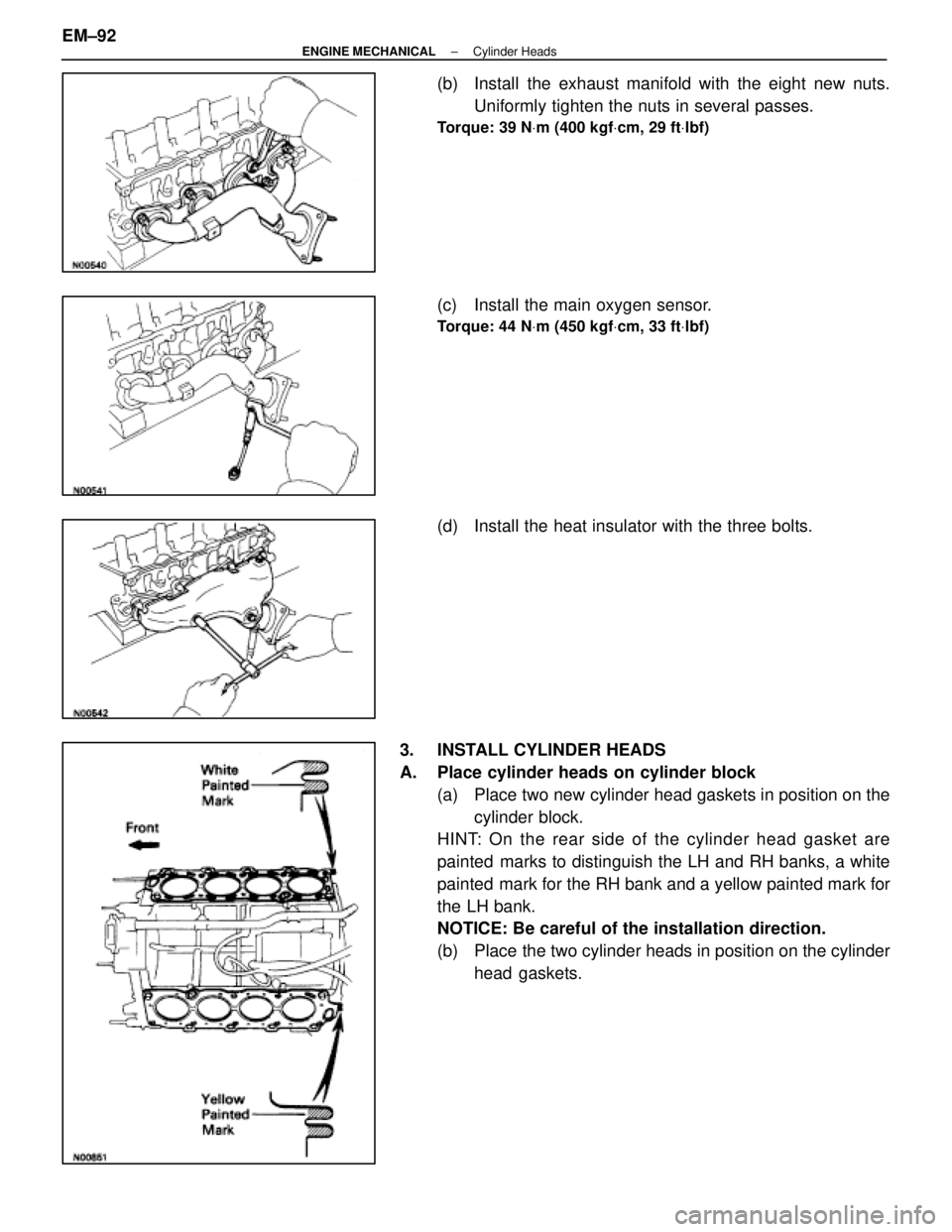

3. INSTALL CYLINDER HEADS

A. Place cylinder heads on cylinder block (a) Place two new cylinder head gaskets in position on thecylinder block.

HINT: On the rear side of the cylinder head gasket are

painted marks to distinguish the LH and RH banks, a white

painted mark for the RH bank and a yellow painted mark for

the LH bank.

NOTICE: Be careful of the installation direction.

(b) Place the two cylinder heads in position on the cylinder

head gaskets.

EM±92

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 2293 of 4087

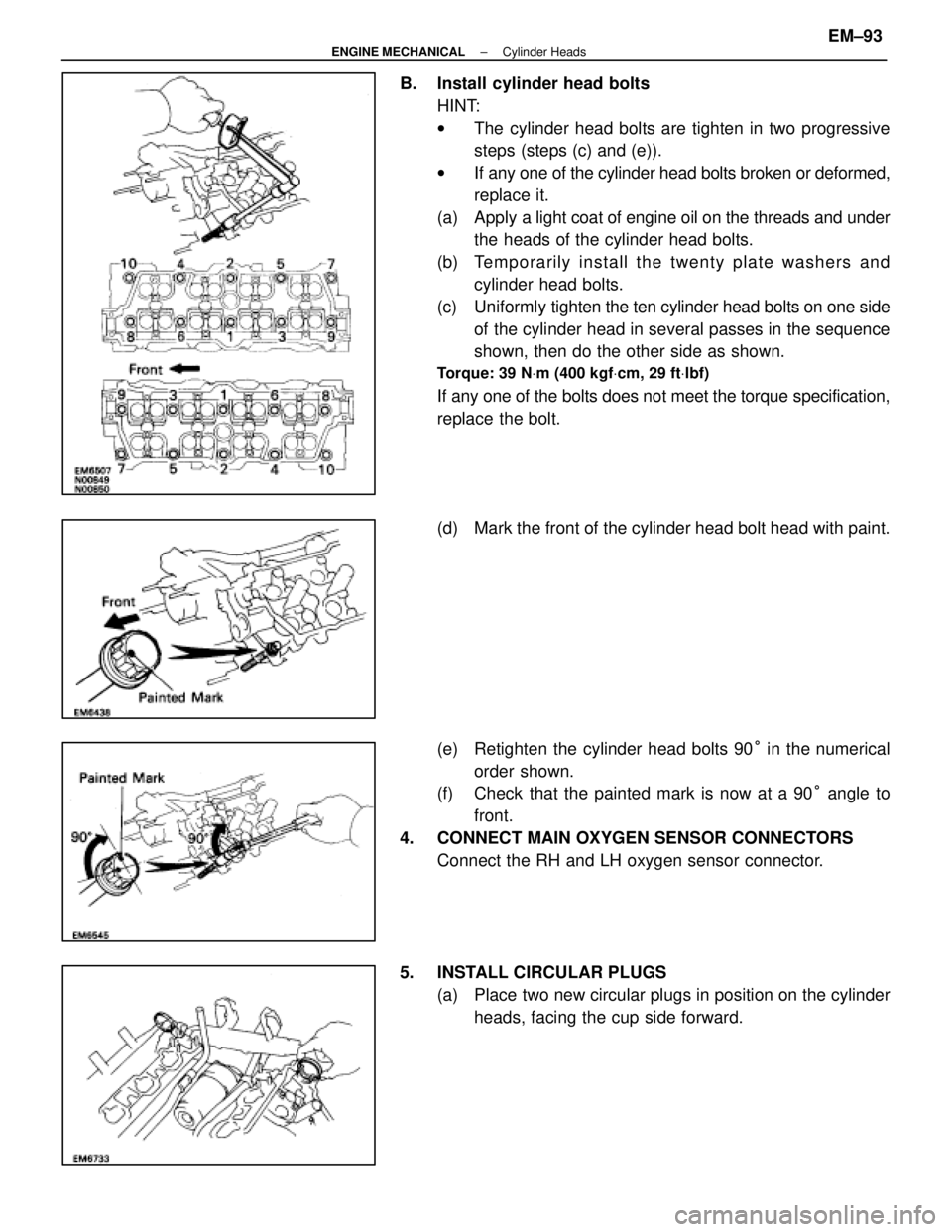

B. Install cylinder head boltsHINT:

wThe cylinder head bolts are tighten in two progressive

steps (steps (c) and (e)).

w If any one of the cylinder head bolts broken or deformed,

replace it.

(a) Apply a light coat of engine oil on the threads and under

the heads of the cylinder head bolts.

(b) Te mp o ra rily in sta ll th e twe n ty pla te wa sh e rs an d cylinder head bolts.

(c) Uniformly tighten the ten cylinder head bolts on one side

of the cylinder head in several passes in the sequence

shown, then do the other side as shown.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

If any one of the bolts does not meet the torque specification,

replace the bolt.

(d) Mark the front of the cylinder head bolt head with paint.

(e) Retighten the cylinder head bolts 90 ° in the numerical

order shown.

(f) Check that the painted mark is now at a 90 ° angle to

front.

4. CONNECT MAIN OXYGEN SENSOR CONNECTORS Connect the RH and LH oxygen sensor connector.

5. INSTALL CIRCULAR PLUGS (a) Place two new circular plugs in position on the cylinderheads, facing the cup side forward.

±

ENGINE MECHANICAL Cylinder HeadsEM±93

WhereEverybodyKnowsYourName

Page 2294 of 4087

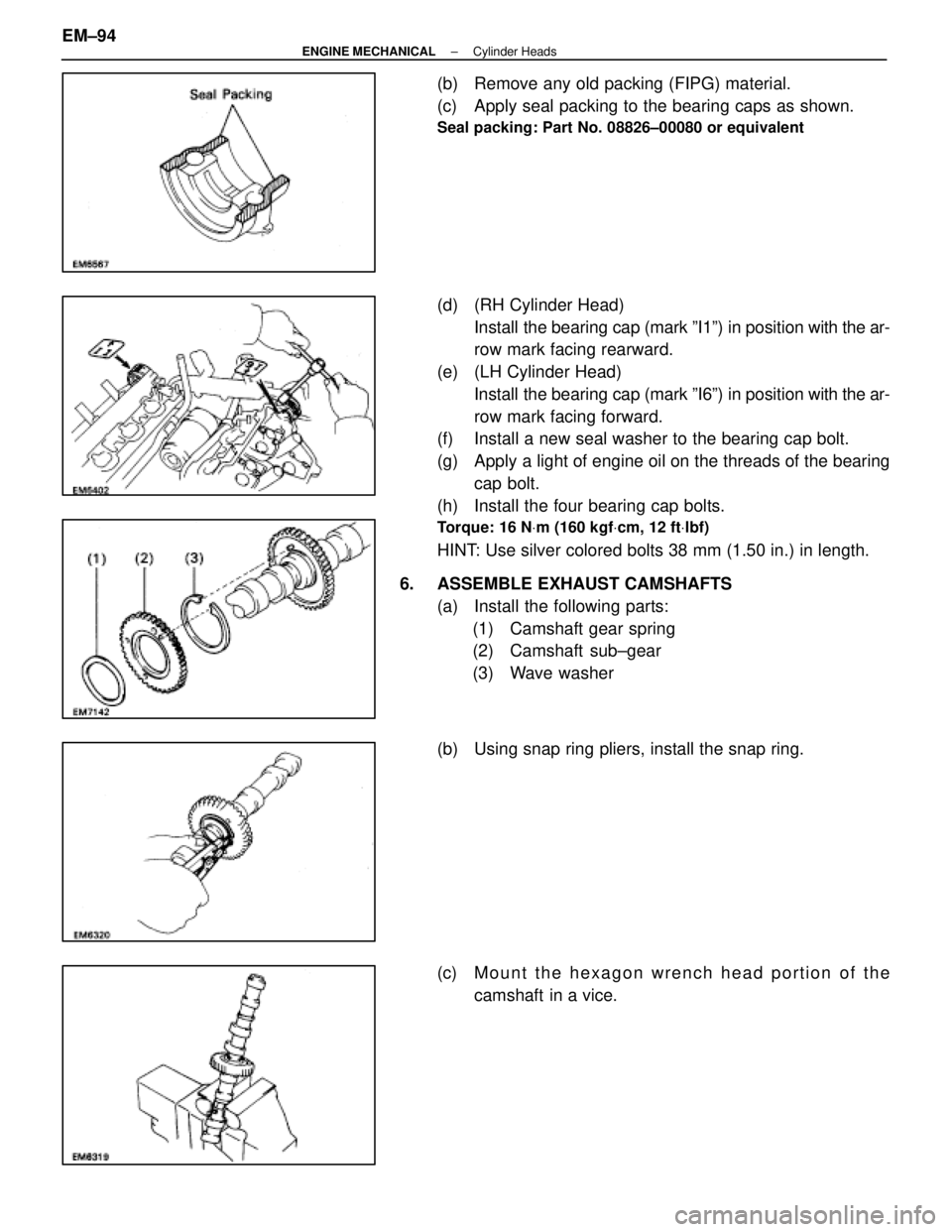

(b) Remove any old packing (FIPG) material.

(c) Apply seal packing to the bearing caps as shown.

Seal packing: Part No. 08826±00080 or equivalent

(d) (RH Cylinder Head)Install the bearing cap (mark ºI1º) in position with the ar-

row mark facing rearward.

(e) (LH Cylinder Head) Install the bearing cap (mark ºI6º) in position with the ar-

row mark facing forward.

(f) Install a new seal washer to the bearing cap bolt.

(g) Apply a light of engine oil on the threads of the bearing

cap bolt.

(h) Install the four bearing cap bolts.

Torque: 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

HINT: Use silver colored bolts 38 mm (1.50 in.) in length.

6. ASSEMBLE EXHAUST CAMSHAFTS (a) Install the following parts:(1) Camshaft gear spring

(2) Camshaft sub±gear

(3) Wave washer

(b) Using snap ring pliers, install the snap ring.

(c) M ount the hexagon wrench head portion of the

camshaft in a vice.

EM±94

±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 2295 of 4087

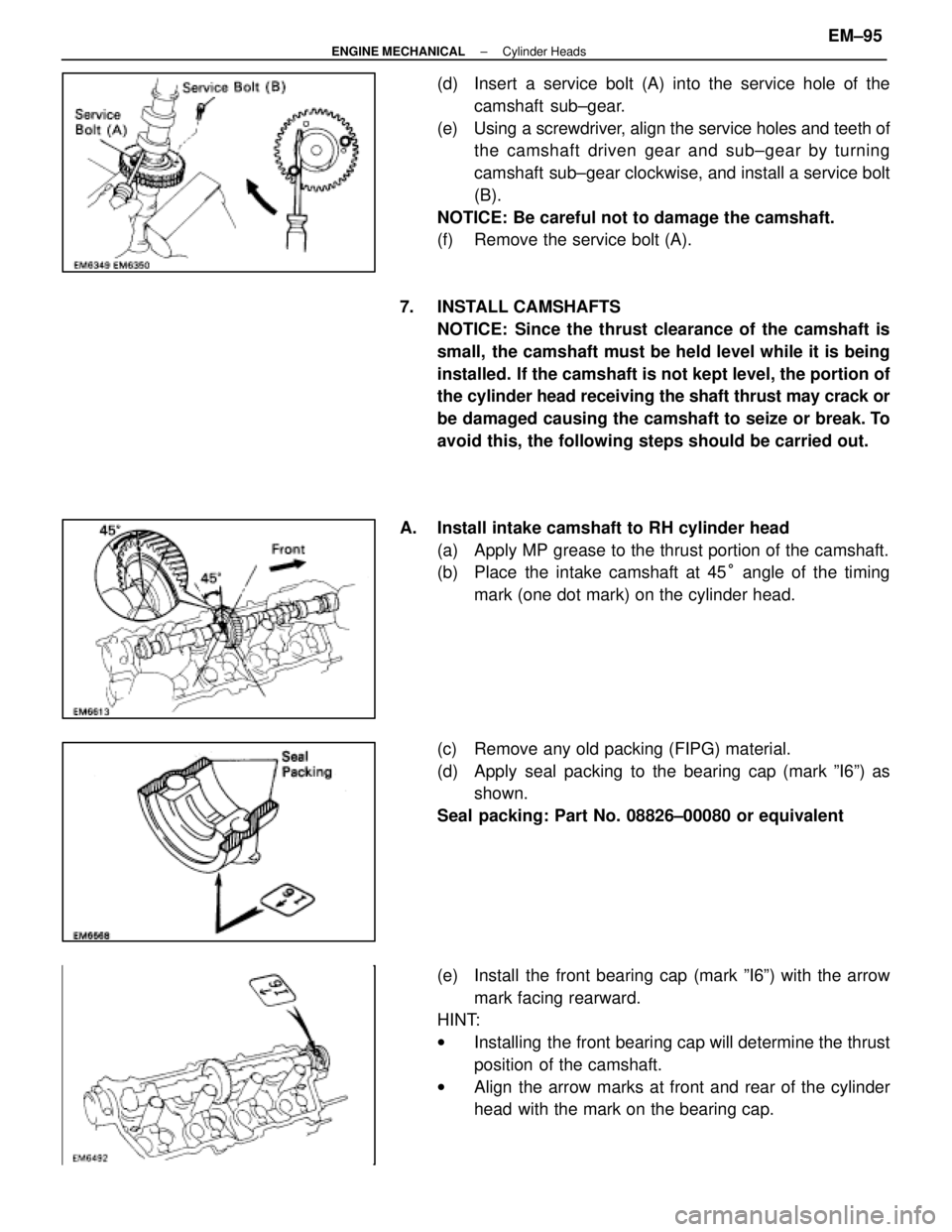

(d) Insert a service bolt (A) into the service hole of thecamshaft sub±gear.

(e) Using a screwdriver, align the service holes and teeth of the camshaft driven gear and sub±gear by turning

camshaft sub±gear clockwise, and install a service bolt

(B).

NOTICE: Be careful not to damage the camshaft.

(f) Remove the service bolt (A).

7. INSTALL CAMSHAFTS NOTICE: Since the thrust clearance of the camshaft is

small, the camshaft must be held level while it is being

installed. If the camshaft is not kept level, the portion of

the cylinder head receiving the shaft thrust may crack or

be damaged causing the camshaft to seize or break. To

avoid this, the following steps should be carried out.

A. Install intake camshaft to RH cylinder head (a) Apply MP grease to the thrust portion of the camshaft.

(b) Place the intake camshaft at 45 ° angle of the timing

mark (one dot mark) on the cylinder head.

(c) Remove any old packing (FIPG) material.

(d) Apply seal packing to the bearing cap (mark ºI6º) as shown.

Seal packing: Part No. 08826±00080 or equivalent

(e) Install the front bearing cap (mark ºI6º) with the arrow mark facing rearward.

HINT:

w Installing the front bearing cap will determine the thrust

position of the camshaft.

w Align the arrow marks at front and rear of the cylinder

head with the mark on the bearing cap.

±

ENGINE MECHANICAL Cylinder HeadsEM±95

WhereEverybodyKnowsYourName