wheel LINCOLN AVIATOR 2004 Owner's Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2004, Model line: AVIATOR, Model: LINCOLN AVIATOR 2004Pages: 336, PDF Size: 3.69 MB

Page 223 of 336

Exceeding the Safety Certification Label axle weight rating limits

could result in substandard vehicle handling, performance,

engine, transmission and/or structural damage, serious damage to the

vehicle, loss of control and personal injury.

GCW (Gross Combined Weight)± is the weight of the loaded vehicle

(GVW) plus the weight of the fully loaded trailer.

GCWR (Gross Combined Weight Rating)± is the maximum allowable

weight of the vehicle and the loaded trailer ± including all cargo and

passengers ± that the vehicle can handle without risking damage.

(Important: The towing vehicle's braking system is rated for operation at

GVWR, not at GCWR. Separate functional brakes should be used for safe

control of towed vehicles and for trailers weighing more than 680 kg

[1,500 lbs]).The GCW must never exceed the GCWR.

Maximum Loaded Trailer Weight± is the highest possible weight of a

fully loaded trailer the vehicle can tow. It assumes a vehicle with only

mandatory options, no cargo (internal or external), a tongue load of

10±15% (conventional trailer) or king pin weight of 15±25% (fifth wheel

trailer), and driver only (68 kg [150 lbs]).Consult your dealership (or

the RV and Trailer Towing Guide provided by your dealership) for

more detailed information.

Tongue Load or Fifth Wheel King Pin Weight± refers to the amount

of the weight that a trailer pushes down on a trailer hitch.

Examples:For a 2268 kg (5000 lbs.) conventional trailer, multiply 5000

by 0.10 and 0.15 to obtain a proper tongue load range of 227 to 340 kg

(500 to 750 lbs.). For an 5216 kg (11,500 lbs.) fifth wheel trailer,

multiply by 0.15 and 0.25 to obtain a proper king pin load range of 782

to 1304 kg (1,725 to 2,875 lbs.)

Do not exceed the GVWR or the GAWR specified on the

certification label.

Driving

223

Page 229 of 336

Driving while you tow

When towing a trailer:

²Turn off the speed control. The speed control may shut off

automatically when you are towing on long, steep grades.

²Consult your local motor vehicle speed regulations for towing a trailer.

²To eliminate excessive shifting, use a lower gear. This will also assist

in transmission cooling. (For additional information, refer to the

Driving with a 5±speed automatic transmissionsection in this

chapter.)

²Under extreme conditions with large frontal trailers, high outside

temperatures and highway speeds, the coolant gauge may indicate

higher than normal coolant temperatures. If this occurs, reduce speed

until the coolant temperature returns to the normal range. Refer to

Engine coolant temperature gaugein theInstrument cluster

chapter.

²Anticipate stops and brake gradually.

²Do not exceed the GCWR rating or transmission damage may occur.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your scheduled maintenance guide for

more information.

Trailer towing tips

²Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

²Allow more distance for stopping with a trailer attached.

²If you are driving down a long or steep hill, shift to a lower gear. Do

not apply the brakes continuously, as they may overheat and become

less effective.

²The trailer tongue weight should be 10±15% of the loaded trailer

weight.

²After you have traveled 80 km (50 miles), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

²To aid in engine/transmission cooling and A/C efficiency during hot

weather while stopped in traffic, place the gearshift lever in P (Park).

²Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer's wheels.

Driving

229

Page 230 of 336

Launching or retrieving a boat

Disconnect the wiring to the trailer before backing the trailer

into the water. Reconnect the wiring to the trailer after the

trailer is removed from the water.

When backing down a ramp during boat launching or retrieval:

²do not allow the static water level to rise above the bottom edge of

the rear bumper.

²do not allow waves to break higher than 15 cm (6 inches) above the

bottom edge of the rear bumper.

Exceeding these limits may allow water to enter vehicle components:

²causing internal damage to the components.

²affecting driveability, emissions and reliability.

Replace the rear axle lubricant any time the axle has been submerged in

water. Rear axle lubricant quantities are not to be checked or changed

unless a leak is suspected or repair required.

RECREATIONAL TOWING (ALL WHEELS ON THE GROUND)

Follow these guidelines for your specific powertrain combination to tow

your vehicle with all four wheels on the ground (such as behind a

recreational vehicle).

These guidelines are designed to ensure that your transmission is not

damaged due to insufficient lubrication.

Rear Wheel Drive (RWD) 4x2 vehicles:

This applies to all 4x2 trucks/sport utilities with rear wheel drive capability.

²Place the transmission in N (Neutral).

²Maximum speed is 56 km/h (35 mph).

²Maximum distance is 80 km (50 miles).

If a distance of 80 km (50 miles) or a speed of 56 km/h (35 mph) must

be exceeded, you must disconnect the driveshaft. Ford recommends the

driveshaft be removed/installed only by a qualified technician. See your

local dealer for driveshaft removal/installation.

Improper removal/installation of the driveshaft can cause

transmission fluid loss, damage to the driveshaft and internal

transmission components.

AWD vehicles:

Vehicles equipped with AWD cannot be towed with any wheels on the

ground as vehicle damage may occur.

Driving

230

Page 243 of 336

CHANGING THE TIRES

If you get a flat tire while driving:

²do not brake heavily.

²gradually decrease the vehicle's speed.

²hold the steering wheel firmly.

²slowly move to a safe place on the side of the road.

The use of tire sealants may damage your tires. The use of tire

sealants may also damage your tire pressure monitoring system

(if equipped).

If your vehicle is equipped with a tire pressure monitoring

system, refer toTire Pressure Monitoring System (if

equipped)in theMaintenance and specificationssection for

important information. If the tire pressure monitor sensor becomes

damaged, it will no longer function.

Spare tire information

Your spare tire is not equipped with a tire pressure monitoring system

(TPMS) sensor. The tire pressure monitoring system indicator light will

illuminate when the spare is in use. To restore full functionality of the

monitoring system, all road wheels equipped with tire pressure

monitoring sensors must be mounted on the vehicle.

Have flat tires serviced by a dealer or qualified technician in order to

prevent damage to the TPMS sensor. Replace the spare tire with a road

tire as soon as possible.

If your vehicle is equipped with AWD, a spare tire of a different

diameter than the road tires should not be used. Such a tire

could make the vehicle difficult to control as well as result in damage

to driveline components.

Roadside Emergencies

243

Page 244 of 336

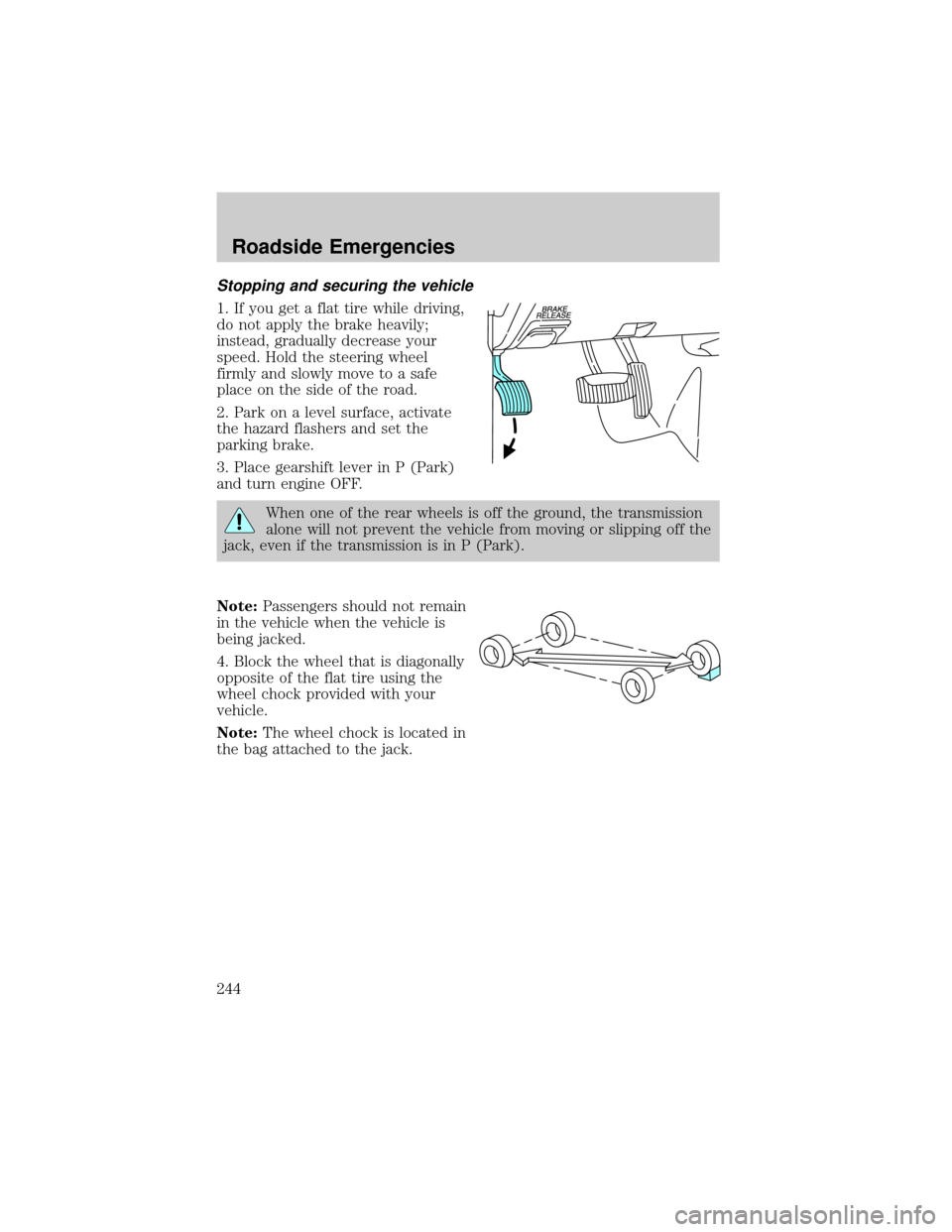

Stopping and securing the vehicle

1. If you get a flat tire while driving,

do not apply the brake heavily;

instead, gradually decrease your

speed. Hold the steering wheel

firmly and slowly move to a safe

place on the side of the road.

2. Park on a level surface, activate

the hazard flashers and set the

parking brake.

3. Place gearshift lever in P (Park)

and turn engine OFF.

When one of the rear wheels is off the ground, the transmission

alone will not prevent the vehicle from moving or slipping off the

jack, even if the transmission is in P (Park).

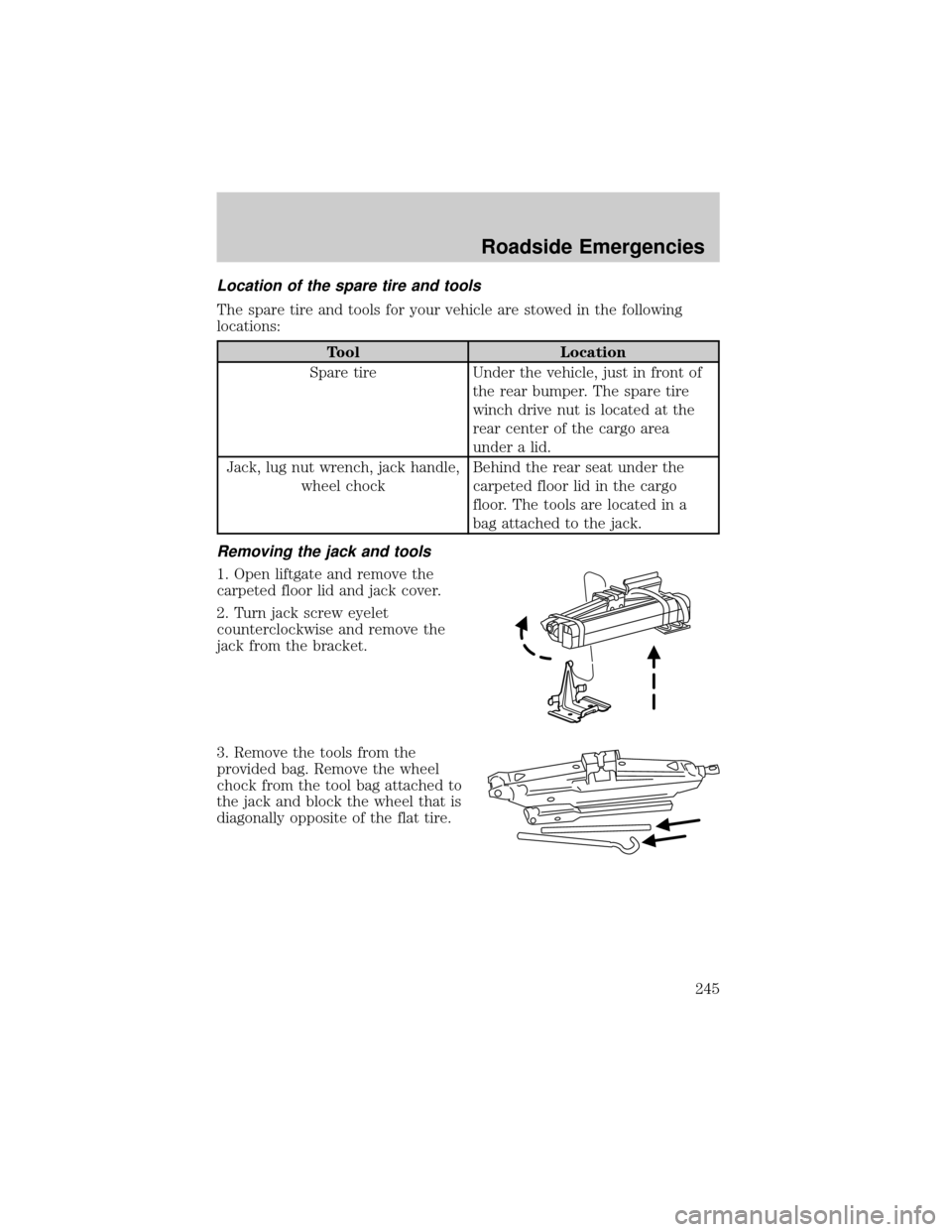

Note:Passengers should not remain

in the vehicle when the vehicle is

being jacked.

4. Block the wheel that is diagonally

opposite of the flat tire using the

wheel chock provided with your

vehicle.

Note:The wheel chock is located in

the bag attached to the jack.

Roadside Emergencies

244

Page 245 of 336

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Tool Location

Spare tire Under the vehicle, just in front of

the rear bumper. The spare tire

winch drive nut is located at the

rear center of the cargo area

under a lid.

Jack, lug nut wrench, jack handle,

wheel chockBehind the rear seat under the

carpeted floor lid in the cargo

floor. The tools are located in a

bag attached to the jack.

Removing the jack and tools

1. Open liftgate and remove the

carpeted floor lid and jack cover.

2. Turn jack screw eyelet

counterclockwise and remove the

jack from the bracket.

3. Remove the tools from the

provided bag. Remove the wheel

chock from the tool bag attached to

the jack and block the wheel that is

diagonally opposite of the flat tire.

Roadside Emergencies

245

Page 247 of 336

3. Turn the wrench

counterclockwise until the tire is

lowered to the ground and the cable

has slack. When turning the wrench,

make sure that it does not scuff the

kick plate.

4. Slide the tire rearward, lift one

side and remove the retainer from

the spare tire.

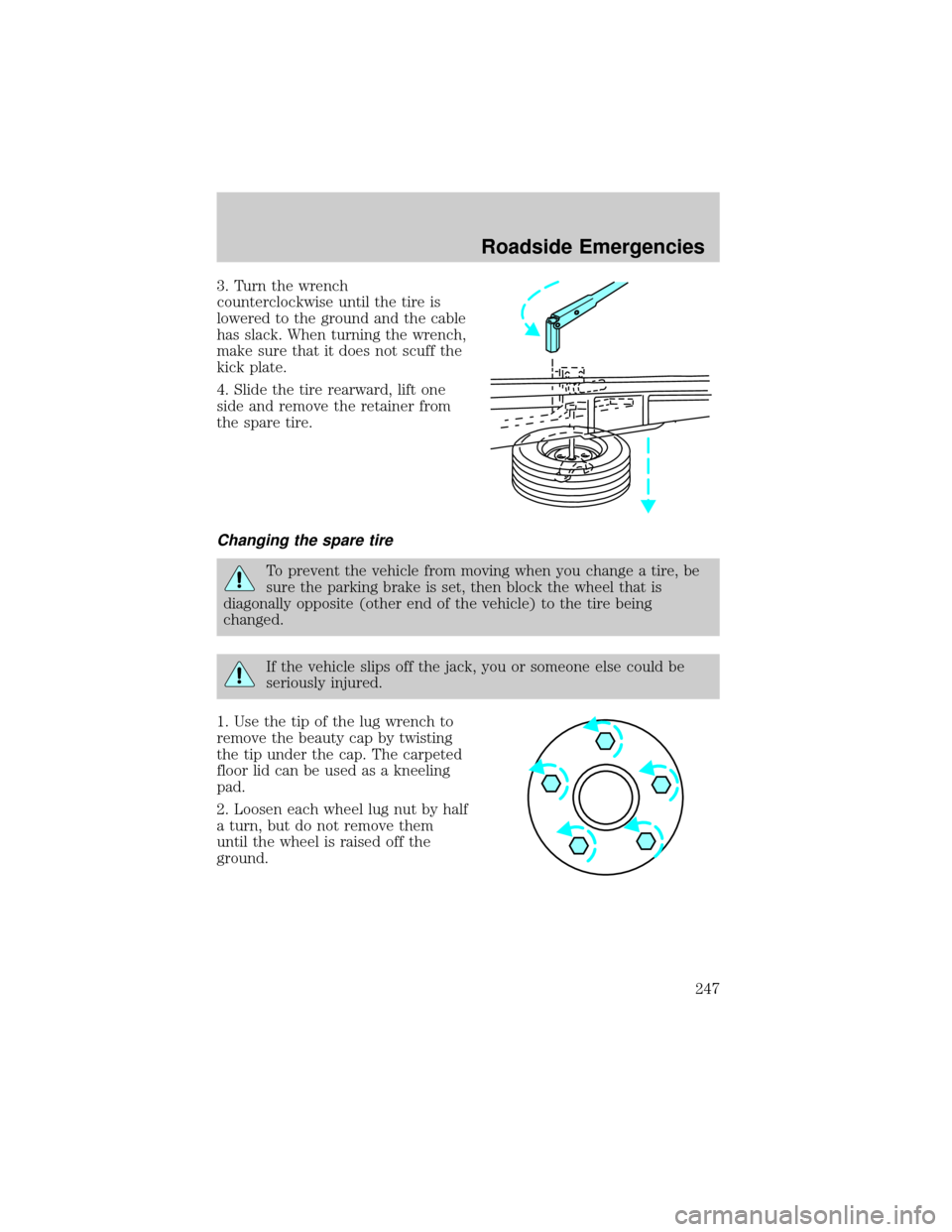

Changing the spare tire

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block the wheel that is

diagonally opposite (other end of the vehicle) to the tire being

changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

1. Use the tip of the lug wrench to

remove the beauty cap by twisting

the tip under the cap. The carpeted

floor lid can be used as a kneeling

pad.

2. Loosen each wheel lug nut by half

a turn, but do not remove them

until the wheel is raised off the

ground.

Roadside Emergencies

247

Page 249 of 336

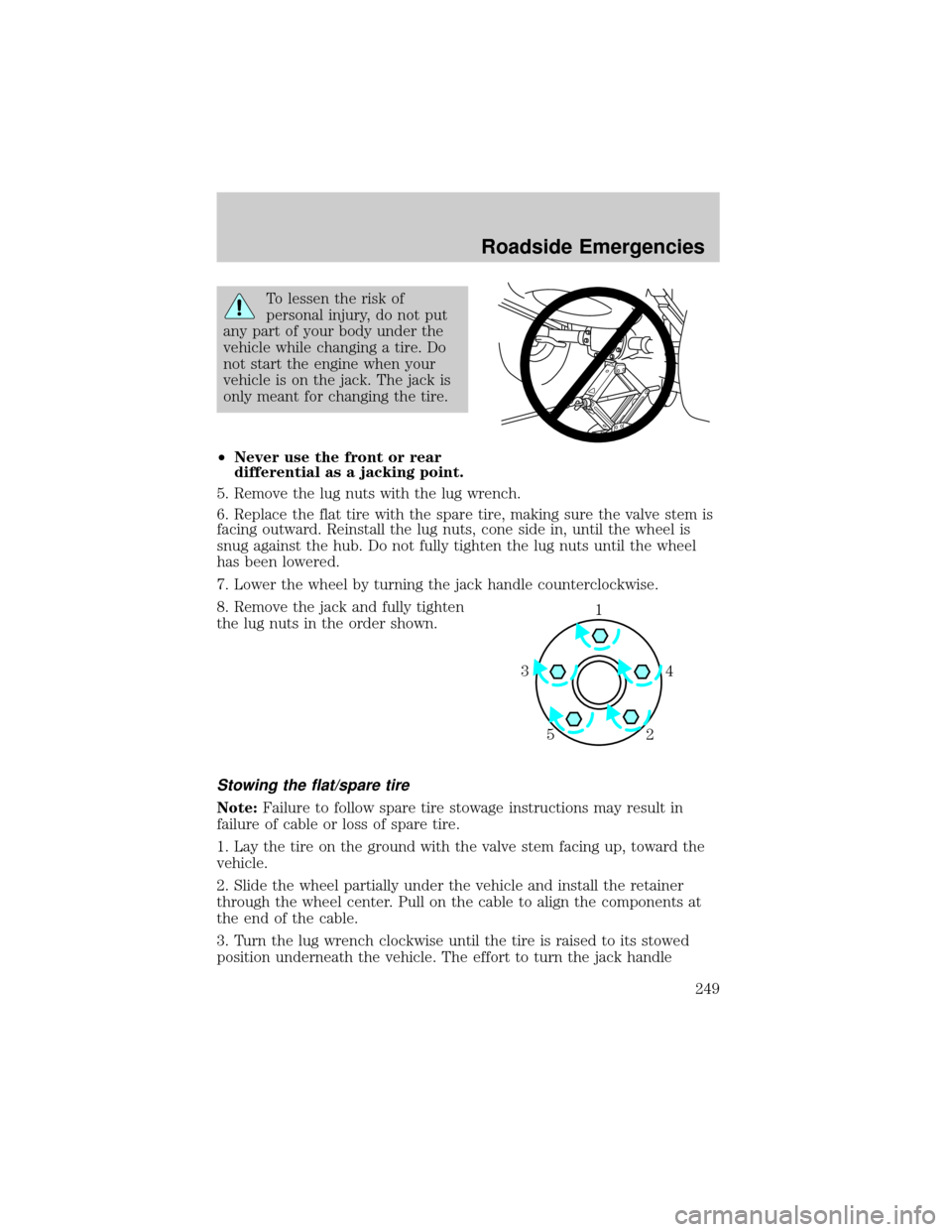

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

²Never use the front or rear

differential as a jacking point.

5. Remove the lug nuts with the lug wrench.

6. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts, cone side in, until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

7. Lower the wheel by turning the jack handle counterclockwise.

8. Remove the jack and fully tighten

the lug nuts in the order shown.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing up, toward the

vehicle.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the lug wrench clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

1

4 3

2 5

Roadside Emergencies

249

Page 250 of 336

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your dealer for

assistance at your earliest convenience.

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. If your vehicle is equipped with a spare tire lock and key, be sure to

install the spare tire lock into the bumper drive tube with the spare tire

lock key and jack handle.

6. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, per scheduled maintenance guide), or at any

time that the spare tire is disturbed through service of other

components.

Re-stowing the jack and tools

1. Unblock the wheels.

2. Replace beauty cap, stow the jack and tools in their respective

locations, making sure they are fully secured so they do not rattle when

you drive.

Wheel lug nut torque specifications

Retighten the lug nuts to the specified torque at 800 km (500 miles)

after any wheel disturbance (rotation, flat tire, wheel removal, etc.).

Bolt size Wheel lug nut torque*

Nm Lb-ft

1¤2x 20 113-153 84-114

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

When a wheel is installed, always remove any corrosion, dirt or

foreign materials present on the mounting surfaces of the wheel

or the surface of the front disc brake hub and rotor that contacts the

wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the

wheel to come off while the vehicle is in motion, resulting in loss of

control.

Roadside Emergencies

250

Page 256 of 336

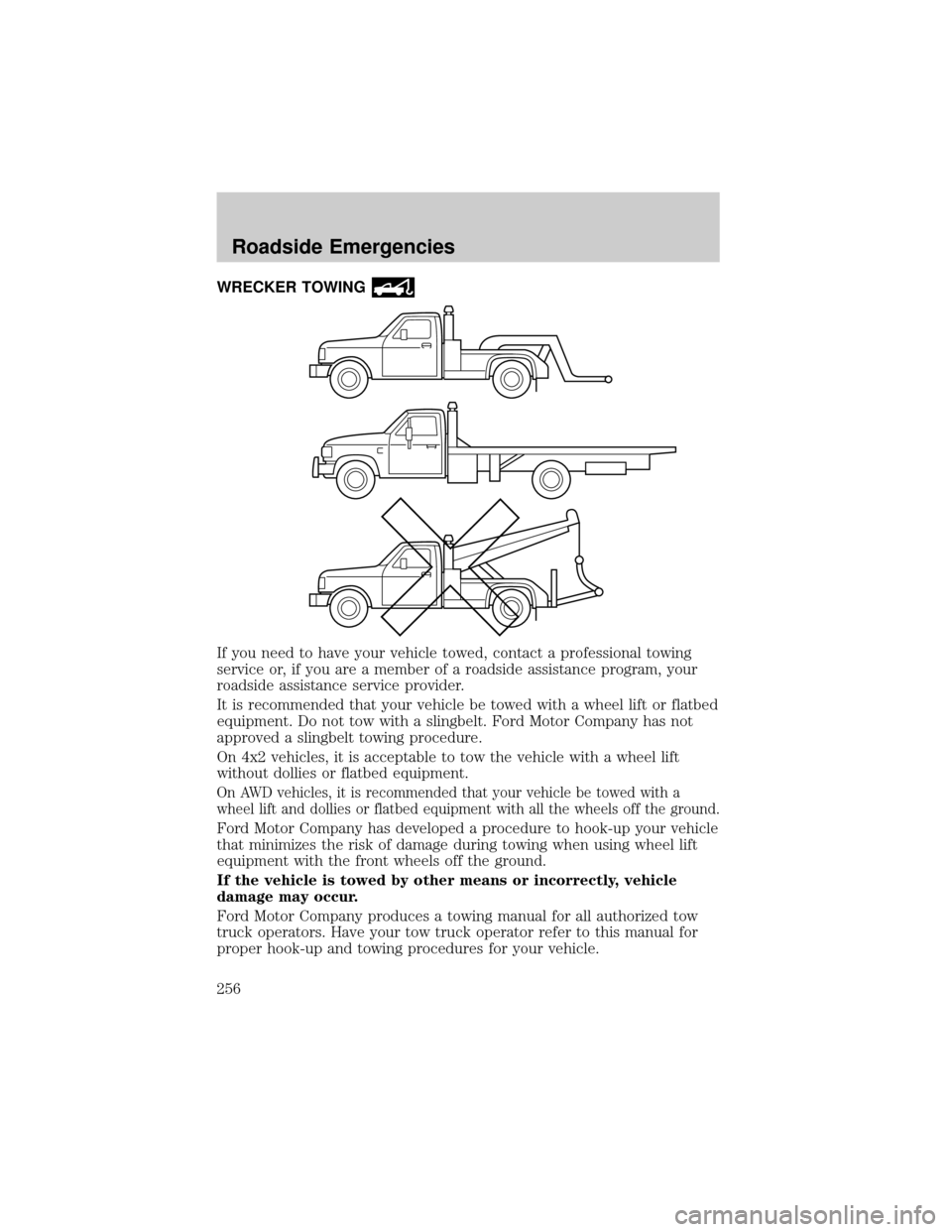

WRECKER TOWING

If you need to have your vehicle towed, contact a professional towing

service or, if you are a member of a roadside assistance program, your

roadside assistance service provider.

It is recommended that your vehicle be towed with a wheel lift or flatbed

equipment. Do not tow with a slingbelt. Ford Motor Company has not

approved a slingbelt towing procedure.

On 4x2 vehicles, it is acceptable to tow the vehicle with a wheel lift

without dollies or flatbed equipment.

On AWD vehicles, it is recommended that your vehicle be towed with a

wheel lift and dollies or flatbed equipment with all the wheels off the ground.

Ford Motor Company has developed a procedure to hook-up your vehicle

that minimizes the risk of damage during towing when using wheel lift

equipment with the front wheels off the ground.

If the vehicle is towed by other means or incorrectly, vehicle

damage may occur.

Ford Motor Company produces a towing manual for all authorized tow

truck operators. Have your tow truck operator refer to this manual for

proper hook-up and towing procedures for your vehicle.

Roadside Emergencies

256