lock LINCOLN AVIATOR 2020 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2020, Model line: AVIATOR, Model: LINCOLN AVIATOR 2020Pages: 609, PDF Size: 5.4 MB

Page 369 of 609

Note:

Coolants marketed for all makes and

models may not be approved to our

specifications and may cause damage to

the cooling system. Resulting component

damage may not be covered by the vehicle

Warranty.

If the coolant level is at or below the

minimum mark, add prediluted coolant

immediately.

To top up the coolant level do the following:

1. Unscrew the cap slowly. Any pressure escapes as you unscrew the cap.

2. Add prediluted coolant approved to the correct specification. See Capacities and

Specifications (page 421).

3. Add enough prediluted coolant to reach

the correct level.

4. Replace the coolant reservoir cap. Turn the cap clockwise until it contacts the

hard stop.

5. Check the coolant level in the coolant reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the correct level. If you have to add more than

1.1 qt (1 L) of

engine coolant per month, have your vehicle

checked as soon as possible. Operating an

engine with a low level of coolant can result

in engine overheating and possible engine

damage.

In case of emergency, you can add a large

amount of water without engine coolant in

order to reach a vehicle service location. In

this instance, qualified personnel:

1. Must drain the cooling system.

2. Chemically clean the coolant system.

3. Refill with engine coolant as soon as possible.

Water alone, without engine coolant, can

cause engine damage from corrosion,

overheating or freezing.

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze. Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or additives to

the coolant. These can be harmful and

compromise the corrosion protection of the

coolant.

Recycled Coolant

We do not recommend the use of recycled

coolant as an approved recycling process is

not yet available.

Note:

Dispose of used coolant in the

appropriate manner.

Follow your community's regulations and

standards for recycling and disposing of

automotive fluids.

366

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- Maintenance

Page 375 of 609

For longer, trouble-free operation, keep the

top of the battery clean and dry and the

battery cables tightly fastened to the battery

terminals. If any corrosion is present on the

battery or terminals, remove the cables from

the terminals and clean with a wire brush.

You can neutralize the acid with a solution

of baking soda and water.

We recommend that you disconnect the

negative battery cable terminal from the

battery if you plan to store your vehicle for

an extended period.

Note:

If you only disconnect the negative

battery cable terminal, make sure it is

isolated or placed away from the battery

terminal to avoid unintended connection or

arcing.

If you replace the battery make sure it

matches the electrical requirements of your

vehicle. If you disconnect or replace the battery and

your vehicle has an automatic transmission,

it must relearn its adaptive strategy. Because

of this, the transmission may shift firmly when

first driven. This is normal operation while

the transmission fully updates its operation

to optimum shift feel.

Battery Management System (If Equipped)

The battery management system monitors

battery conditions and takes actions to

extend battery life. If excessive battery drain

is detected, the system temporarily disables

some electrical systems to protect the

battery.

Systems included are:

• Heated rear window.

• Heated seats.

• Climate control.

• Heated steering wheel.

• Audio unit.

• Navigation system. A message may appear in the information

displays to alert you that battery protection

actions are active. These messages are only

for notification that an action is taking place,

and not intended to indicate an electrical

problem or that the battery requires

replacement.

After battery replacement, or in some cases

after charging the battery with an external

charger, the battery management system

requires eight hours of vehicle sleep time to

relearn the battery state of charge. During

this time your vehicle must remain fully

locked with the ignition switched off.

Note:

Prior to relearning the battery state of

charge, the battery management system

may temporarily disable some electrical

systems.

372

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- Maintenance

Page 376 of 609

Electrical Accessory Installation

To make sure the battery management

system works correctly, do not connect an

electrical device ground connection directly

to the battery negative post. This can cause

inaccurate measurements of the battery

condition and potential incorrect system

operation.

Note:

If you add electrical accessories or

components to the vehicle, it may adversely

affect battery performance and durability.

This may also affect the performance of

other electrical systems in the vehicle.

Remove and Reinstall the Battery

To disconnect or remove the battery, do the

following:

1. Apply the parking brake and switch the ignition off.

2. Switch all electrical equipment off, for example lights and radio.

3. Wait a minimum of two minutes before disconnecting the battery. Note:

The engine management system has

a power hold function and remains powered

for a period of time after you switch the

ignition off. This is to allow diagnostic and

adaptive tables to be stored. Disconnecting

the battery without waiting can cause

damage not covered by the vehicle

Warranty.

4. Disconnect the negative battery cable terminal.

5. Disconnect the positive battery cable terminal.

6. Remove the battery securing clamp.

7. Remove the battery.

8. To install, reverse the removal procedure.

Note: Before reconnecting the battery, make

sure the ignition remains switched off.

Note: Make sure the battery cable terminals

are fully tightened. If you disconnect or replace the vehicle

battery, you must reset the following

features:

•

Window bounce-back. See Power

Windows (page 116).

• Clock Settings.

• Pre-set radio stations.

Battery Disposal Make sure that you dispose of old

batteries in an environmentally

friendly way. Seek advice from

your local authority about recycling old

batteries.

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

If your vehicle has been involved in a crash,

have the aim of the headlamp beam checked

by an authorized dealer.

373

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- MaintenanceE107998

Page 377 of 609

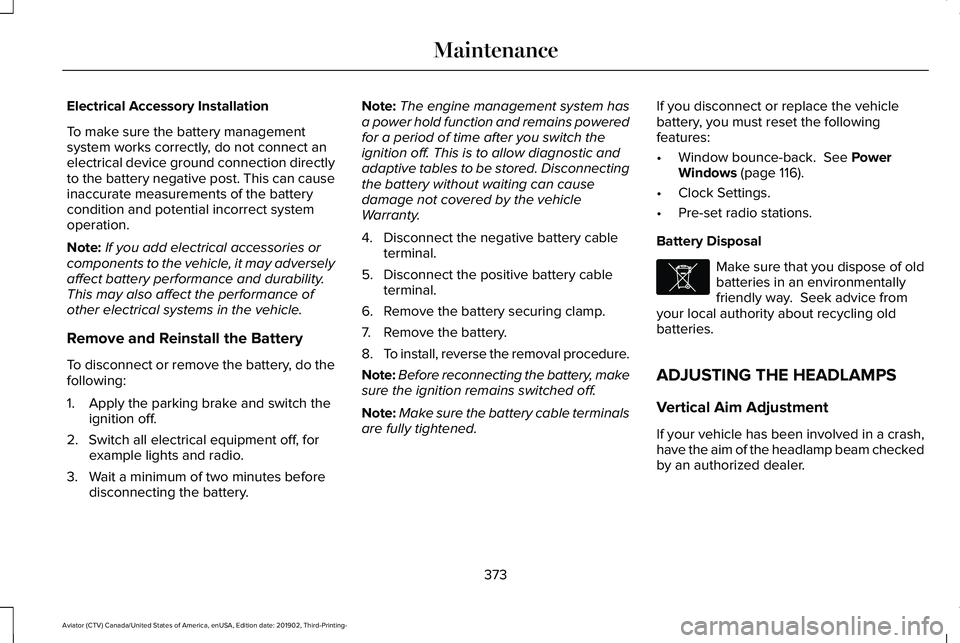

8 ft (2.4 m).

A

Ground to the center of the

headlamp high beam bulb.

B

25 ft (7.6 m).

C

Horizontal reference line.

D

Vertical Aim Adjustment Procedure

1. Park your vehicle on level ground approximately 25 ft (7.6 m) from a wall or

screen. 2. Measure the distance from the ground

to the center of the headlamp high beam

bulb and mark an

8 ft (2.4 m) long

horizontal reference line on the wall or

screen at this height.

Note: There may be an identifying mark on

the lens to help you locate the center line of

the headlamp high beam bulb.

Note: To see a clearer light pattern for

adjusting, you may want to block the light

from one headlamp while adjusting the

other.

3. Switch on the low beam headlamps and

open the hood. 4.

On the wall or screen you will observe a

flat zone of high intensity light located at

the top of the beam pattern. If the top

edge of the flat zone of high intensity

light is not on the horizontal reference

line, adjust the aim of the headlamp

beam. 374

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- MaintenanceE142592 E142465 E292163

Page 378 of 609

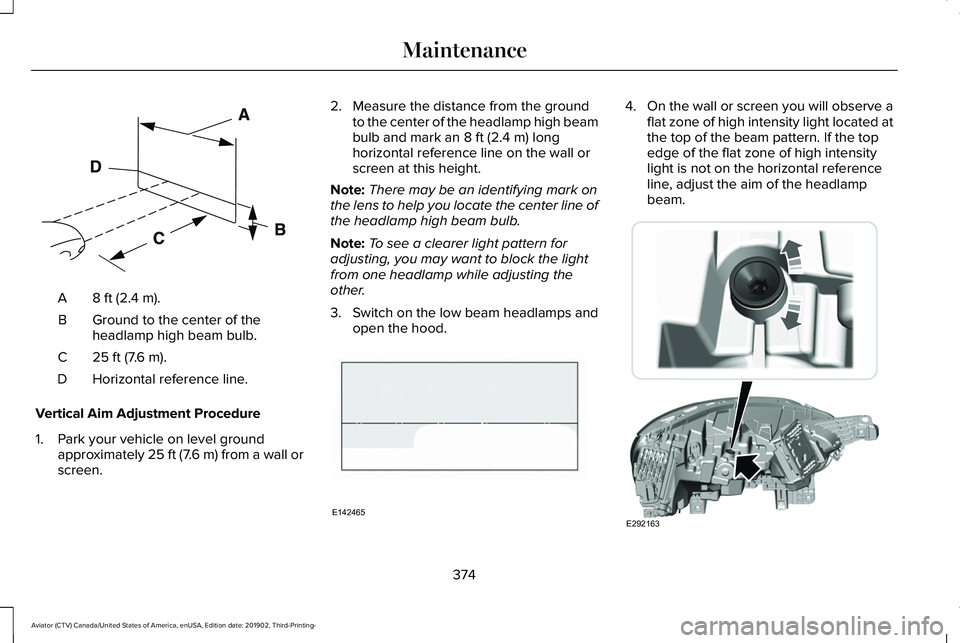

5. Use a suitable tool, for example a

screwdriver or socket wrench, to turn the

adjuster clockwise or counterclockwise

to adjust the vertical aim of the

headlamp. The horizontal edge of the

brighter light should touch the horizontal

reference line.

6. Close the hood and switch off the lamps.

WASHER FLUID CHECK WARNING: If you operate your

vehicle in temperatures below 41.0°F (5°C),

use washer fluid with antifreeze protection.

Failure to use washer fluid with antifreeze

protection in cold weather could result in

impaired windshield vision and increase

the risk of injury or accident.

Note: The front and rear washer systems

are supplied from the same reservoir.

Add fluid to fill the reservoir if the level is low.

Only use a washer fluid that meets our

specifications.

See Capacities and

Specifications (page 421). State or local regulations on volatile organic

compounds may restrict the use of methanol,

a common windshield washer antifreeze

additive. Washer fluids containing

non-methanol antifreeze agents should be

used only if they provide cold weather

protection without damaging the vehicle

’s

paint finish, wiper blades or washer system.

FUEL FILTER

Your vehicle is equipped with a lifetime fuel

filter that is integrated with the fuel tank.

Regular maintenance or replacement is not

needed.

CHECKING THE WIPER BLADES Run the tip of your fingers over the edge of

the blade to check for roughness.

Clean the wiper blades with washer fluid or

water applied with a soft sponge or cloth.

CHANGING THE FRONT WIPER

BLADES - VEHICLES WITHOUT:

HEATED WIPER BLADES

You can improve poor wiper quality by

cleaning the wiper blades and the

windshield.

Replace the wiper blades at least annually

for optimum performance.

375

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- MaintenanceE142463

Page 379 of 609

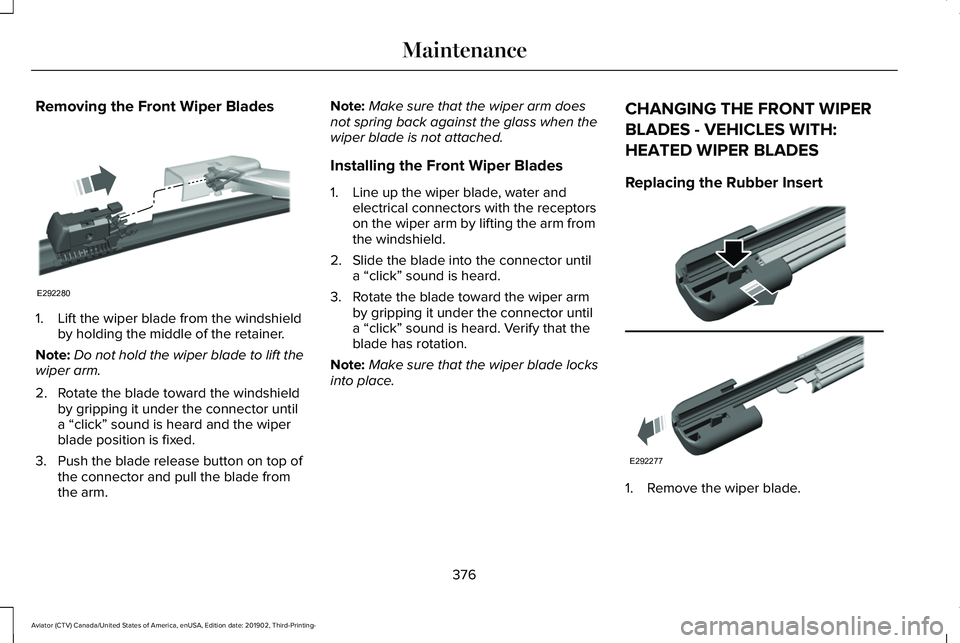

Removing the Front Wiper Blades

1. Lift the wiper blade from the windshield

by holding the middle of the retainer.

Note: Do not hold the wiper blade to lift the

wiper arm.

2. Rotate the blade toward the windshield by gripping it under the connector until

a “click” sound is heard and the wiper

blade position is fixed.

3. Push the blade release button on top of the connector and pull the blade from

the arm. Note:

Make sure that the wiper arm does

not spring back against the glass when the

wiper blade is not attached.

Installing the Front Wiper Blades

1. Line up the wiper blade, water and electrical connectors with the receptors

on the wiper arm by lifting the arm from

the windshield.

2. Slide the blade into the connector until a “click” sound is heard.

3. Rotate the blade toward the wiper arm by gripping it under the connector until

a “click” sound is heard. Verify that the

blade has rotation.

Note: Make sure that the wiper blade locks

into place. CHANGING THE FRONT WIPER

BLADES - VEHICLES WITH:

HEATED WIPER BLADES

Replacing the Rubber Insert

1. Remove the wiper blade.

376

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- MaintenanceE292280 E292277

Page 380 of 609

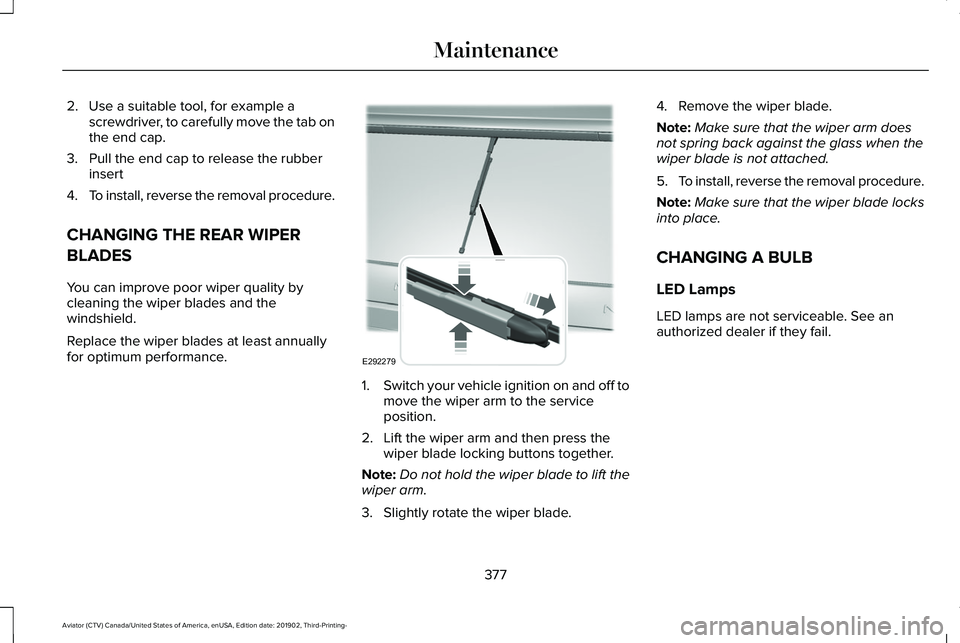

2. Use a suitable tool, for example a

screwdriver, to carefully move the tab on

the end cap.

3. Pull the end cap to release the rubber insert

4. To install, reverse the removal procedure.

CHANGING THE REAR WIPER

BLADES

You can improve poor wiper quality by

cleaning the wiper blades and the

windshield.

Replace the wiper blades at least annually

for optimum performance. 1.

Switch your vehicle ignition on and off to

move the wiper arm to the service

position.

2. Lift the wiper arm and then press the wiper blade locking buttons together.

Note: Do not hold the wiper blade to lift the

wiper arm.

3. Slightly rotate the wiper blade. 4. Remove the wiper blade.

Note:

Make sure that the wiper arm does

not spring back against the glass when the

wiper blade is not attached.

5. To install, reverse the removal procedure.

Note: Make sure that the wiper blade locks

into place.

CHANGING A BULB

LED Lamps

LED lamps are not serviceable. See an

authorized dealer if they fail.

377

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- MaintenanceE292279

Page 384 of 609

•

Do not allow wax to come in contact with

any non-body (low-gloss black) colored

trim. The wax will discolor or stain the

parts over time.

•Roof racks.

• Bumpers.

• Grained door handles.

• Side moldings.

• Mirror housings.

• Windshield cowl area.

• Do not apply wax to glass areas.

• After waxing, your car's paint should feel

smooth, and be free of streaks and

smudges.

CLEANING THE ENGINE

Engines are more efficient when they are

clean because grease and dirt buildup keep

the engine warmer than normal. When washing:

•

Take care when using a power washer

to clean the engine. The high-pressure

fluid could penetrate the sealed parts

and cause damage.

• Do not spray a hot engine with cold water

to avoid cracking the engine block or

other engine components.

• Spray Motorcraft Engine Shampoo and

Degreaser on all parts that require

cleaning and pressure rinse clean. In

Canada, use Motorcraft Engine Shampoo.

Note: If your vehicle has an engine cover

remove the cover before application of

Motorcraft Engine Shampoo and Degreaser.

Immediately rinse away any over spray.

• Never wash or rinse the engine while it

is hot or running; water in the running

engine may cause internal damage.

• Never wash or rinse any ignition coil,

spark plug wire or spark plug well, or the

area in and around these locations.

• Cover the battery, power distribution box,

and air filter assembly to prevent water

damage when cleaning the engine. CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmental

fallout can result in windshield and wiper

blade contamination. Dirty windshield and

wipers will result in poor windshield wiper

operation. Keep the windshield and wiper

blades clean to maintain windshield wiper

performance.

To clean the windshield and wiper blades:

•

Clean the windshield with a non-abrasive

glass cleaner. When cleaning the interior

of the windshield, avoid getting any glass

cleaner on the instrument panel or door

panels. Wipe any glass cleaner off these

surfaces immediately.

• For windshields contaminated with tree

sap, chemicals, wax or bugs, clean the

entire windshield using steel wool (no

greater than 0000 grade) in a circular

motion and rinse with water.

• Clean the wiper blades with isopropyl

rubbing alcohol or windshield washer

concentrate.

381

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- Vehicle Care

Page 414 of 609

4.

Turn the hazard flashers on then off three

times. You must accomplish this within

10 seconds. If you successfully enter the

reset mode, the horn sounds once, the

system indicator flashes and a message

shows in the information display. If this

does not occur, please try again starting

at step 2. If after repeated attempts to

enter the reset mode, the horn does not

sound, the system indicator does not

flash and no message shows in the

information display, seek service from

your authorized dealer.

5. Train the tire pressure monitoring system

sensors in the tires using the following

system reset sequence starting with the

left front tire in the following clockwise

order: Left front - driver side front tire,

Right front - passenger side front tire,

Right rear - passenger side rear tire, Left

rear - driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds. Note:

The single horn tone confirms that the

sensor identification code has been learned

by the module for this position. If a double

horn is heard, the reset procedure was

unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease the

air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver side

rear tire, the system indicator stops

flashing, and a message shows in the

information display.

10. Turn the ignition off. If two short horn beeps are heard, the reset procedure

was unsuccessful and you must repeat

it. If after repeating the procedure and

two short beeps are heard when the

ignition is turned to off, seek assistance

from your authorized dealer. 11. Set all four tires to the recommended

air pressure as indicated on the Safety

Compliance Certification Label, affixed

to either the door hinge pillar,

door-latch post, or the door edge that

meets the door-latch post, next to the

driver seating position or Tire Label

located on the B-Pillar or the edge of

the driver door.

CHANGING A ROAD WHEEL WARNING: If the tire pressure

monitor sensor becomes damaged it may

not function.

Note: You should only use tire sealants in

roadside emergencies as they may cause

damage to the tire pressure monitoring

system sensor.

411

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- Wheels and Tires

Page 416 of 609

•

Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability.

3. Full-size dissimilar spare without label

on wheel.

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed

70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time.

• Use commercial car washing equipment.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly.

The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability. •

Wet weather driving capability.

• All-wheel driving capability.

When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

• Towing a trailer.

• Driving vehicles equipped with a camper

body.

• Driving vehicles with a load on the cargo

rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly and

seek service as soon as possible.

Tire Change Procedure WARNING:

The jack supplied with

this vehicle is only intended for changing

wheels. Do not use the vehicle jack other

than when you are changing a wheel in an

emergency. WARNING:

Check that the vehicle

jack is not damaged or deformed and the

thread is lubricated and clean. WARNING:

When one of the front

wheels is off the ground, the transmission

alone will not prevent the vehicle from

moving or slipping off the jack, even if the

transmission is in park (P). WARNING:

To help prevent your

vehicle from moving when changing a

wheel, shift the transmission into park (P),

set the parking brake and use an

appropriate block or wheel chock to

secure the wheel diagonally opposite to

the wheel being changed. For example,

when changing the front left wheel, place

an appropriate block or wheel chock on

the right rear wheel.

413

Aviator (CTV) Canada/United States of America, enUSA, Edition date: 201902, Third-Printing- Wheels and Tires