clock LINCOLN AVIATOR 2023 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2023, Model line: AVIATOR, Model: LINCOLN AVIATOR 2023Pages: 681, PDF Size: 9.33 MB

Page 90 of 681

E316247E316247316247316247

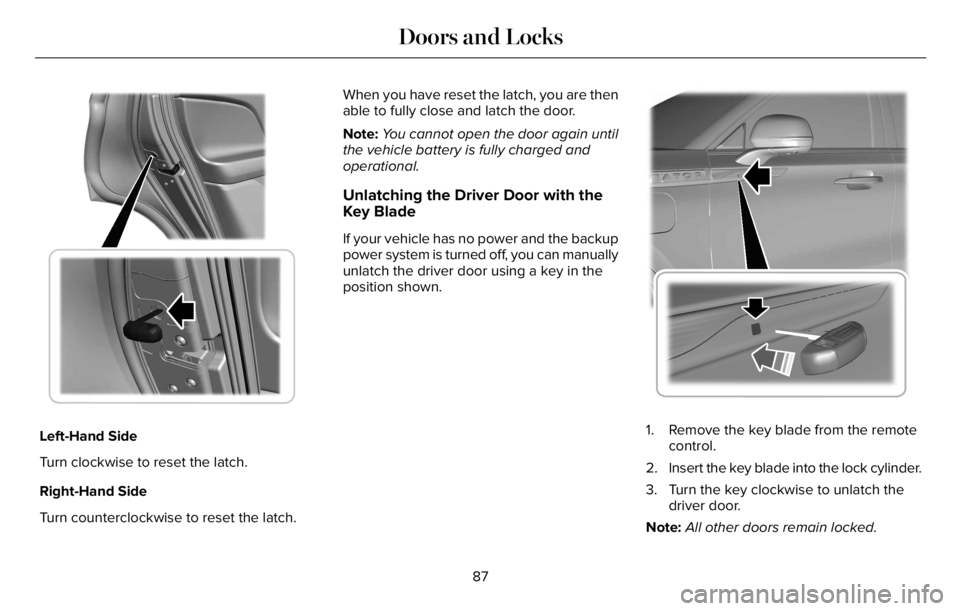

Left-Hand Side

Turn clockwise to reset the latch.

Right-Hand Side

Turn counterclockwise to reset the latch.When you have reset the latch, you are then

able to fully close and latch the door.

Note:You cannot open the door again until

the vehicle battery is fully charged and

operational.

Unlatching the Driver Door with the

Key Blade

If your vehicle has no power and the backup

power system is turned off, you can manually

unlatch the driver door using a key in the

position shown.

E295771

1. Remove the key blade from the remote

control.

2. Insert the key blade into the lock cylinder.

3. Turn the key clockwise to unlatch the

driver door.

Note:All other doors remain locked.

87

Doors and Locks

Page 405 of 681

Do not use supplemental engine oil

additives. They could cause engine damage

that the vehicle warranty may not cover.

1. Clean the area surrounding the engine

oil filler cap before you remove it.

2. Remove the engine oil filler cap.

3. Add engine oil that meets our

specifications. See Capacities and

Specifications (page 465).

4. Reinstall the engine oil filler cap. Turn it

clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note:Soak up any spillage with an

absorbent cloth immediately.

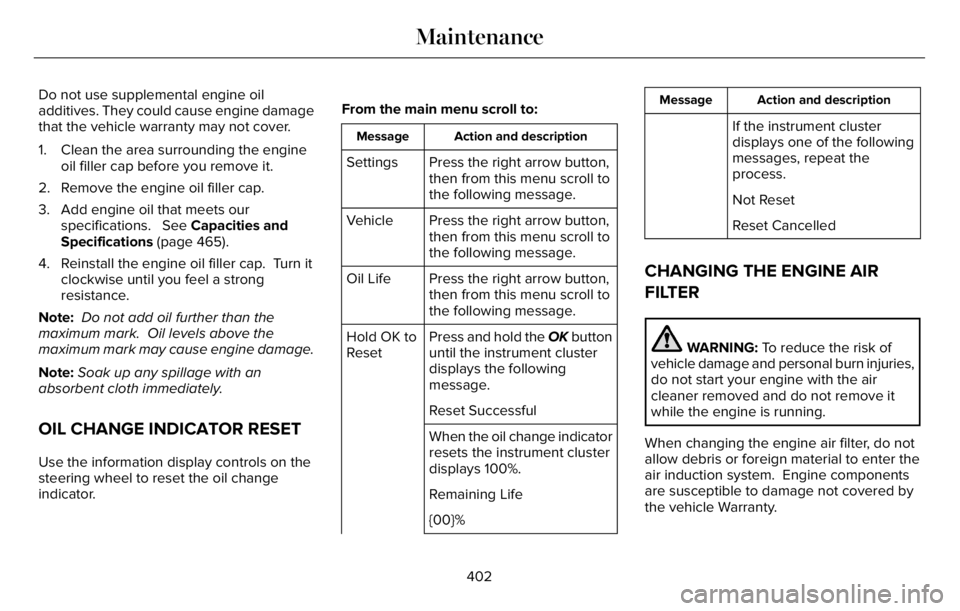

OIL CHANGE INDICATOR RESET

Use the information display controls on the

steering wheel to reset the oil change

indicator.From the main menu scroll to:

Action and description Message

Press the right arrow button,

then from this menu scroll to

the following message. Settings

Press the right arrow button,

then from this menu scroll to

the following message. Vehicle

Press the right arrow button,

then from this menu scroll to

the following message. Oil Life

Press and hold the OK button

until the instrument cluster

displays the following

message. Hold OK to

Reset

Reset Successful

When the oil change indicator

resets the instrument cluster

displays 100%.

Remaining Life

{00}%

Action and description Message

If the instrument cluster

displays one of the following

messages, repeat the

process.

Not Reset

Reset Cancelled

CHANGING THE ENGINE AIR

FILTER

WARNING: To reduce the risk of

vehicle damage and personal burn injuries,

do not start your engine with the air

cleaner removed and do not remove it

while the engine is running.

When changing the engine air filter, do not

allow debris or foreign material to enter the

air induction system. Engine components

are susceptible to damage not covered by

the vehicle Warranty.

402

Maintenance

Page 408 of 681

Note:Automotive fluids are not

interchangeable.

It is very important to use prediluted coolant

approved to the correct specification in order

to avoid plugging the small passageways in

the engine cooling system. See Capacities

and Specifications (page 460). Do not mix

different colors or types of coolant in your

vehicle. Mixing of engine coolants or using

an incorrect coolant may harm the engine or

cooling system components and may not be

covered by the vehicle Warranty.

Note:If prediluted coolant is not available,

use the approved concentrated coolant

diluting it to 50/50 with distilled water. See

Capacities and Specifications (page 460).

Using water that has not been deionised

may contribute to deposit formation,

corrosion and plugging of the small cooling

system passageways.

Note: Coolants marketed for all makes and

models may not be approved to our

specifications and may cause damage to

the cooling system. Resulting component

damage may not be covered by the vehicle

Warranty.If the coolant level is at or below the

minimum mark, add prediluted coolant

immediately.

To top up the coolant level do the following:

1. Unscrew the cap slowly. Any pressure

escapes as you unscrew the cap.

2. Add prediluted coolant approved to the

correct specification. See Capacities and

Specifications (page 460).

3. Add enough prediluted coolant to reach

the correct level.

4. Replace the coolant reservoir cap. Turn

the cap clockwise until it contacts the

hard stop.

5. Check the coolant level in the coolant

reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the correct level.

If you have to add more than 1.1 qt (1 L) of

engine coolant per month, have your vehicle

checked as soon as possible. Operating an

engine with a low level of coolant can result

in engine overheating and possible engine

damage.In case of emergency, you can add a large

amount of water without engine coolant in

order to reach a vehicle service location. In

this instance, qualified personnel:

1. Must drain the cooling system.

2. Chemically clean the coolant system.

3. Refill with engine coolant as soon as

possible.

Water alone, without engine coolant, can

cause engine damage from corrosion,

overheating or freezing.

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze.

Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or additives to

the coolant. These can be harmful and

compromise the corrosion protection of the

coolant.

405

Maintenance

Page 415 of 681

After battery replacement, or in some cases

after charging the battery with an external

charger, the battery management system

requires eight hours of vehicle sleep time to

relearn the battery state of charge. During

this time, your vehicle must remain fully

locked with the ignition switched off.

Note:Prior to relearning the battery state of

charge, the battery management system

may temporarily disable some electrical

systems.

Electrical Accessory Installation

To make sure the battery management

system works correctly, do not connect an

electrical device ground connection directly

to the battery negative post. This can cause

inaccurate measurements of the battery

condition and potential incorrect system

operation.

Note:If you add electrical accessories or

components to the vehicle, it may adversely

affect battery performance and durability.

This may also affect the performance of

other electrical systems in the vehicle.Remove and Reinstall the Battery

Install a battery approved for use by our

specifications. See Capacities and

Specifications (page 460).

To disconnect or remove the battery, do the

following:

1. Apply the parking brake and switch the

ignition off.

2. Switch all electrical equipment off, for

example lights and radio.

3. Wait a minimum of two minutes before

disconnecting the battery.

Note:The engine management system has

a power hold function and remains powered

for a period of time after you switch the

ignition off. This is to allow the system to

store diagnostic and adaptive tables.

Disconnecting the battery without waiting

can cause damage not covered by the

vehicle warranty.

4. Disconnect the negative battery cable

terminal.

5. Disconnect the positive battery cable

terminal.6. Remove the battery securing clamp.

7. Remove the battery.

8. To install, reverse the removal procedure.

Note:Before reconnecting the battery, make

sure the ignition remains switched off.

Note:Make sure to fully tighten the battery

cables.

If you disconnect or replace the vehicle

battery, you must reset the following

features:

• Window bounce-back. See Power

Windows (page 121).

• Clock Settings.

• Pre-set radio stations.

Battery Disposal

E107998

Make sure that you dispose of old

batteries in an environmentally

friendly way. Seek advice from

your local authority about recycling old

batteries.

412

Maintenance

Page 419 of 681

6. Remove the battery securing clamp.

7. Remove the battery.

8. To install, reverse the removal procedure.

Note:Before reconnecting the battery, make

sure the ignition remains switched off.

Note:Make sure to fully tighten the battery

cables.

If you disconnect or replace the vehicle

battery, you must reset the following

features:

• Window bounce-back. See Power

Windows (page 121).

• Clock Settings.

• Pre-set radio stations.

Battery Disposal

E107998

Make sure that you dispose of old

batteries in an environmentally

friendly way. Seek advice from

your local authority about recycling old

batteries.

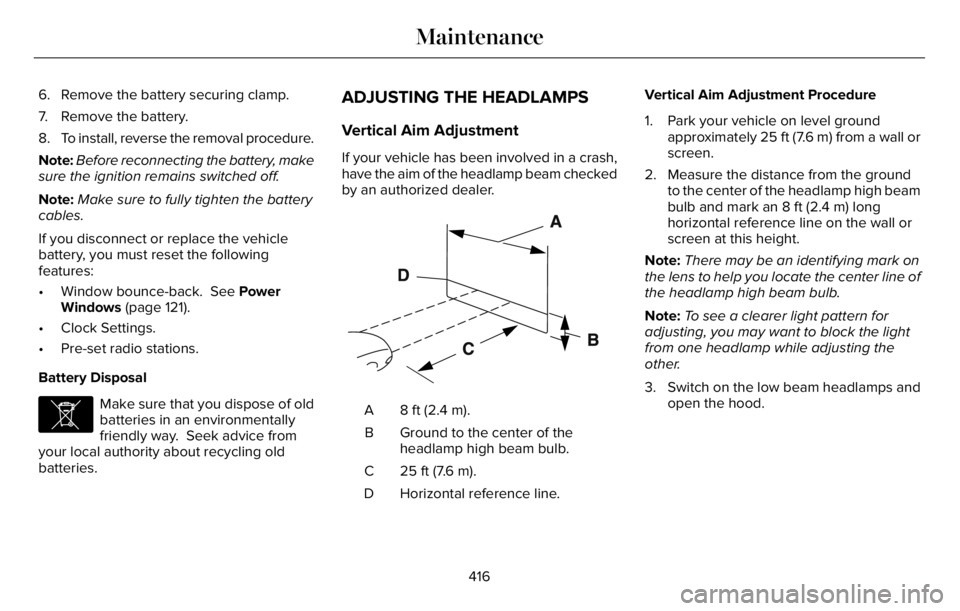

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

If your vehicle has been involved in a crash,

have the aim of the headlamp beam checked

by an authorized dealer.

E142592

8 ft (2.4 m). A

Ground to the center of the

headlamp high beam bulb. B

25 ft (7.6 m). C

Horizontal reference line. DVertical Aim Adjustment Procedure

1. Park your vehicle on level ground

approximately 25 ft (7.6 m) from a wall or

screen.

2. Measure the distance from the ground

to the center of the headlamp high beam

bulb and mark an 8 ft (2.4 m) long

horizontal reference line on the wall or

screen at this height.

Note:There may be an identifying mark on

the lens to help you locate the center line of

the headlamp high beam bulb.

Note:To see a clearer light pattern for

adjusting, you may want to block the light

from one headlamp while adjusting the

other.

3. Switch on the low beam headlamps and

open the hood.

416

Maintenance

Page 420 of 681

E142465

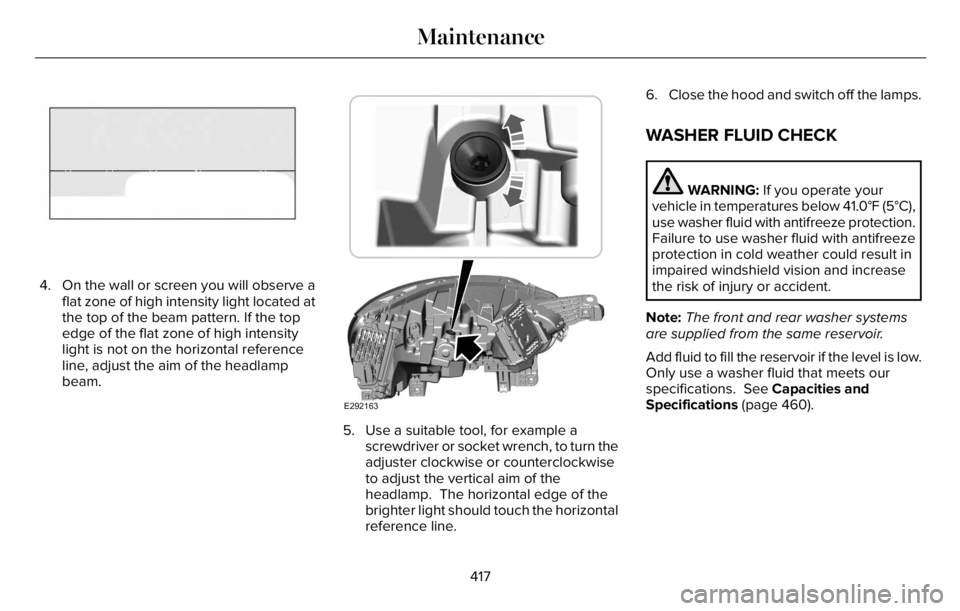

4. On the wall or screen you will observe a

flat zone of high intensity light located at

the top of the beam pattern. If the top

edge of the flat zone of high intensity

light is not on the horizontal reference

line, adjust the aim of the headlamp

beam.

E292163

5. Use a suitable tool, for example a

screwdriver or socket wrench, to turn the

adjuster clockwise or counterclockwise

to adjust the vertical aim of the

headlamp. The horizontal edge of the

brighter light should touch the horizontal

reference line.6. Close the hood and switch off the lamps.

WASHER FLUID CHECK

WARNING: If you operate your

vehicle in temperatures below 41.0°F (5°C),

use washer fluid with antifreeze protection.

Failure to use washer fluid with antifreeze

protection in cold weather could result in

impaired windshield vision and increase

the risk of injury or accident.

Note:The front and rear washer systems

are supplied from the same reservoir.

Add fluid to fill the reservoir if the level is low.

Only use a washer fluid that meets our

specifications. See Capacities and

Specifications (page 460).

417

Maintenance

Page 457 of 681

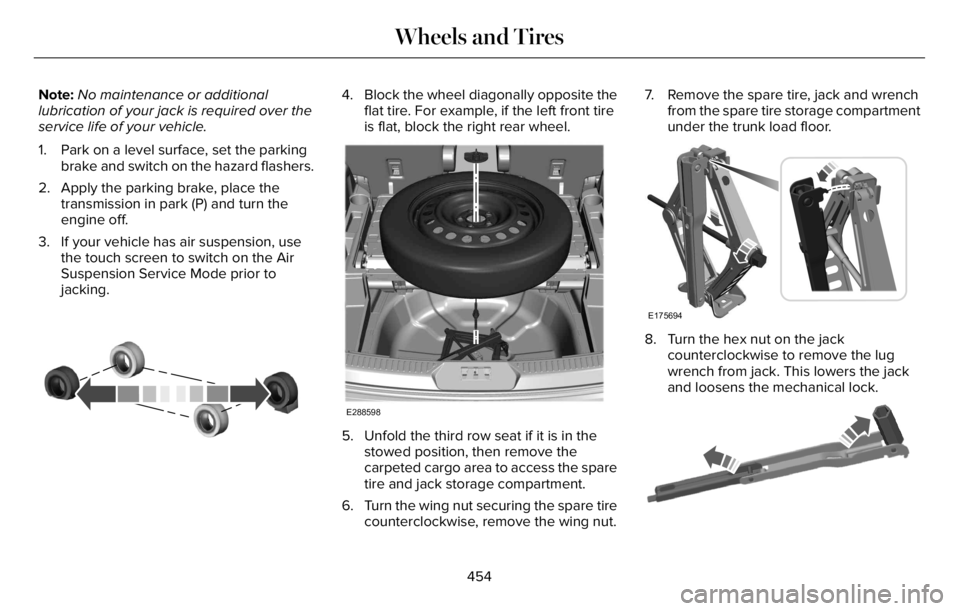

Note:No maintenance or additional

lubrication of your jack is required over the

service life of your vehicle.

1. Park on a level surface, set the parking

brake and switch on the hazard flashers.

2. Apply the parking brake, place the

transmission in park (P) and turn the

engine off.

3. If your vehicle has air suspension, use

the touch screen to switch on the Air

Suspension Service Mode prior to

jacking.

E142551

4. Block the wheel diagonally opposite the

flat tire. For example, if the left front tire

is flat, block the right rear wheel.

E288598

5. Unfold the third row seat if it is in the

stowed position, then remove the

carpeted cargo area to access the spare

tire and jack storage compartment.

6. Turn the wing nut securing the spare tire

counterclockwise, remove the wing nut.7. Remove the spare tire, jack and wrench

from the spare tire storage compartment

under the trunk load floor.

E175694

8. Turn the hex nut on the jack

counterclockwise to remove the lug

wrench from jack. This lowers the jack

and loosens the mechanical lock.

E181744E181744

454

Wheels and Tires

Page 458 of 681

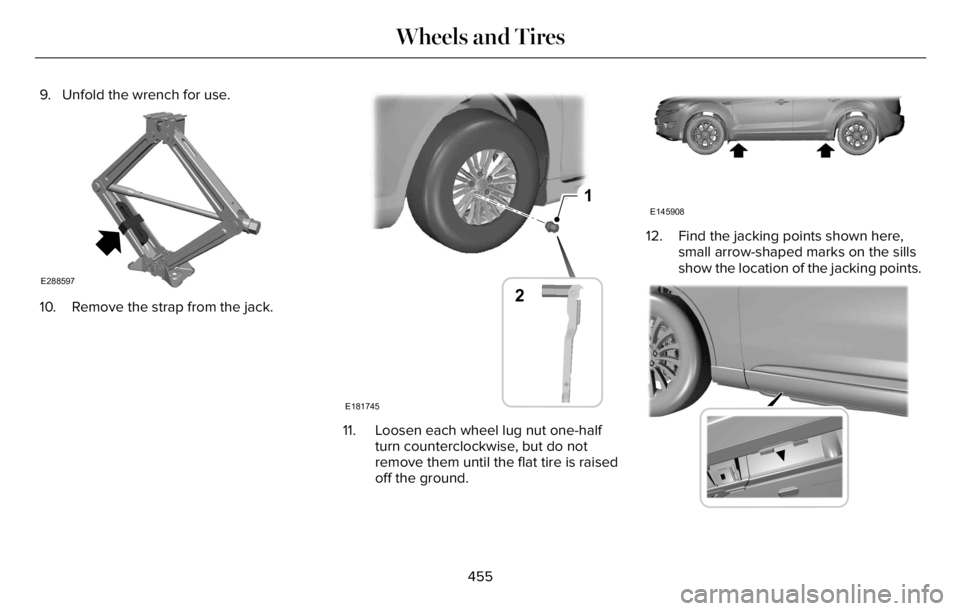

9. Unfold the wrench for use.

E288597

10. Remove the strap from the jack.

1

E181745

2

11. Loosen each wheel lug nut one-half

turn counterclockwise, but do not

remove them until the flat tire is raised

off the ground.

E145908

12. Find the jacking points shown here,

small arrow-shaped marks on the sills

show the location of the jacking points.

E307860E307860

455

Wheels and Tires

Page 459 of 681

13. If your vehicle is equipped with running

boards the jacking points will be

marked on the front and rear of the

running board.

E310613E310613E310E310E310E31011100613613613613

14. Place the jack at the jacking point next

to the tire which you are changing. Turn

the lug wrench handle clockwise until

the flat tire is completely off the ground.

E201156

15. Remove the lug nuts with the lug

wrench.

16. Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward.

17. Install the lug nuts snug against the

hub. Do not fully tighten the lug nuts

until the vehicle is lowered.

18. Turn the wrench handle

counterclockwise to lower the vehicle

completely.

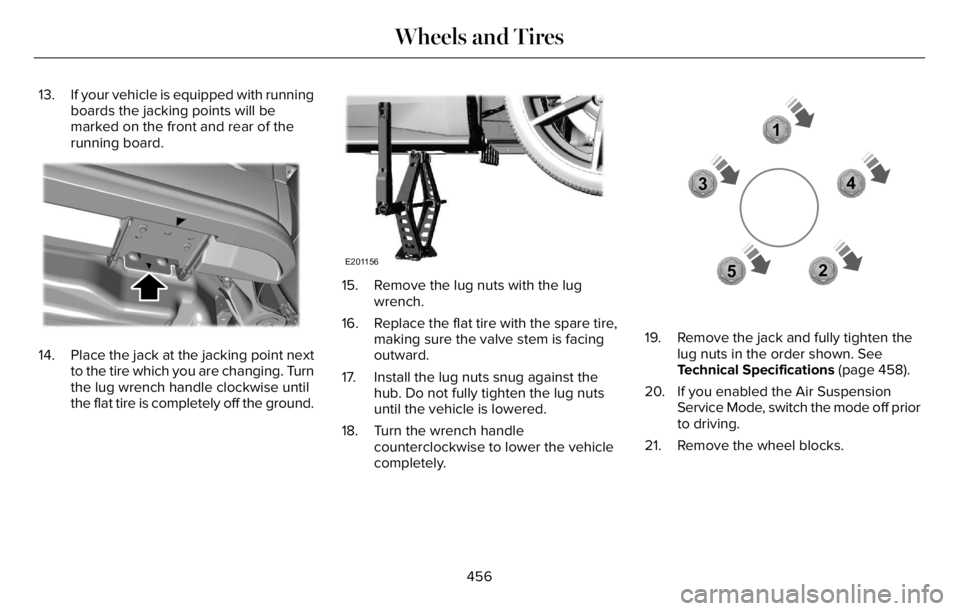

1

2 34

5

E306781E306781

19. Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page 458).

20. If you enabled the Air Suspension

Service Mode, switch the mode off prior

to driving.

21. Remove the wheel blocks.

456

Wheels and Tires

Page 460 of 681

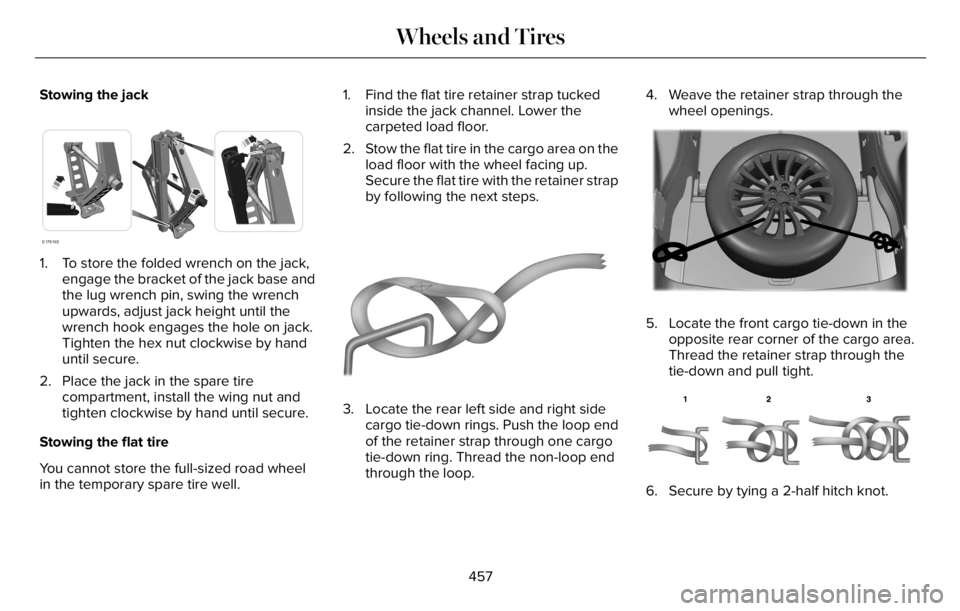

Stowing the jack

E176165

1. To store the folded wrench on the jack,

engage the bracket of the jack base and

the lug wrench pin, swing the wrench

upwards, adjust jack height until the

wrench hook engages the hole on jack.

Tighten the hex nut clockwise by hand

until secure.

2. Place the jack in the spare tire

compartment, install the wing nut and

tighten clockwise by hand until secure.

Stowing the flat tire

You cannot store the full-sized road wheel

in the temporary spare tire well.1. Find the flat tire retainer strap tucked

inside the jack channel. Lower the

carpeted load floor.

2. Stow the flat tire in the cargo area on the

load floor with the wheel facing up.

Secure the flat tire with the retainer strap

by following the next steps.

E142906

3. Locate the rear left side and right side

cargo tie-down rings. Push the loop end

of the retainer strap through one cargo

tie-down ring. Thread the non-loop end

through the loop.4. Weave the retainer strap through the

wheel openings.

E294325EE294E294EE294222929994432533325333222255555E294E294E2E294E294E2E294E294E294E294E294E2944E294E2944E294EE294EE29499994E9994994E2942423253253253253253253232532532532532532525325325323253253232525325355332533555

5. Locate the front cargo tie-down in the

opposite rear corner of the cargo area.

Thread the retainer strap through the

tie-down and pull tight.

E143746

6. Secure by tying a 2-half hitch knot.

457

Wheels and Tires