LINCOLN CONTINENTAL 1997 Owners Manual

Manufacturer: LINCOLN, Model Year: 1997, Model line: CONTINENTAL, Model: LINCOLN CONTINENTAL 1997Pages: 321, PDF Size: 2.37 MB

Page 261 of 321

260Do not make any unauthorized changes to your

vehicle or engine. Changes that cause more

unburned fuel to reach the exhaust system can

increase the temperature of the engine or exhaust

system.

By law, anyone who manufactures, repairs, services,

sells, leases, trades vehicles, or supervises a fleet of

vehicles is not permitted to intentionally remove an

emission control device or prevent it from working.

In some of the United States and in Canada,

vehicle owners may be liable if their emission

control device is removed or is prevented from

working.

Do not drive your vehicle if it does not operate

properly. See your dealer if the engine runs on for

more than five seconds after you shut it off or if it

misfires, surges, stalls, or backfires.Information about your vehicle's emission control

system is on the Vehicle Emission Control

Information decal located on or near the engine.

This decal identifies engine displacement and gives

some tune-up specifications.

How to Prepare Your Vehicle for

Inspection/Maintenance (I/M) TestingIn some localities it may become a legal

requirement to pass an Inspection/Maintenance

(I/M) test of the On-Board Diagnostic (OBD) II

system. If the vehicle's powertrain system or its

battery has just been serviced, the OBD II system is

reset to a not ready for I/M testing condition. To

prepare for I/M testing, the law specifies that

additional mixed city and highway driving is

required to complete the check of the OBD II

system.

File:11fnmcc.ex

Update:Fri Sep 6 08:51:16 1996

Page 262 of 321

261

The driving modes required to reach the ready

condition consist of a minimum of 30 minutes of

city and highway driving as described below:q

At least twenty minutes driving in stop and go,

city type traffic with at least four idle periods.

q

At least ten minutes of driving on an

expressway or highway.

Before completing the above driving modes, the

engine must be warmed up and at operating

temperature. Once started, the vehicle must not be

turned off during these driving modes.

Lights and Bulb ReplacementIt is a good idea to check the operation of the

following lights frequently:q

headlamps

q

high-mount brakelamp

q

tail lamps

q

brakelamps

q

hazard flasher

q

turn signals

q

side markers

q

license plate lamps

The alignment of your headlamps should be

checked if:

q

oncoming motorists frequently signal you to turn

off your vehicle's high beams when you do not

have the high beams on

q

the headlamps do not seem to give you enough

light to see clearly at night

q

the headlamp beams are pointed substantially

away from a position slightly down and to the

right

File:11fnmcc.ex

Update:Fri Sep 6 08:51:16 1996

Page 263 of 321

262

HeadlampBulb

WARNING

Handl ea haloge nheadlam pbulb

Removin gth e headlam pbulb

Page 264 of 321

263

3. At the back of the headlamp, pull back and up

slightly on the two right angle brackets to

release the headlamp assembly from the

vehicle.

4. Carefully pull the headlamp assembly away

from the vehicle to expose the back of the bulb

and wiring connector.

5. Remove the electrical connector from the bulb

by grasping the wire with a quick pull

rearward.

6. Remove the retaining ring by turning it 1/8 of

a turn to free it from the socket. Then slide the

ring off the plastic base of the bad bulb.Keep

the ring.You must use it again to hold the

new bulb in place.

7. Carefully remove the bulb assembly from its

socket by gently pulling it rearward without

turning.

Installing the headlamp bulb1. With the flat side of the bulb's plastic base

facing upward, insert the glass end of the bulb

into the socket. You may need to turn the bulb

left or right to line up the grooves in the plastic

base with the tabs in the socket. When the

grooves are aligned, push the bulb into the

socket until the plastic base contacts the rear of

the socket.

2. Slip the bulb retaining ring over the plastic base

until it contacts the rear of the socket. Lock

the ring into the socket by rotating it clockwise

until you feel a ªstop.º

3. Push the electrical connector into the rear of

the plastic base until it snaps, locking it into

position.

4. Carefully position the headlamp assembly onto

the vehicle making sure the alignment pins are

inserted into the proper holes.

File:11fnmcc.ex

Update:Fri Sep 6 08:51:16 1996

Page 265 of 321

2645. Hold the headlamp assembly snugly against the

vehicle and push down on the right angle

brackets to lock the lamp into position.

6. Install the plastic sight shield.

7. Turn the headlamps on and make sure that

they work properly. If the headlamp was

correctly aligned before you changed the bulb,

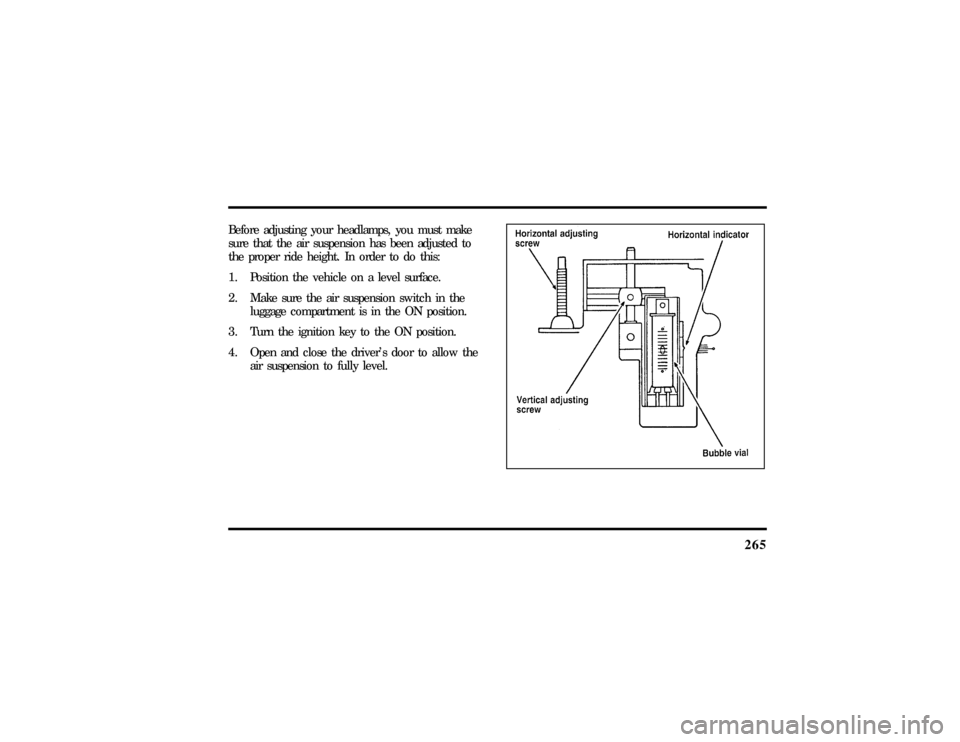

you should not need to align it again.Aiming HeadlampsYour vehicle is equipped with a Vehicle Headlamp

Aim Device (VHAD) on each headlamp body. Each

headlamp may be properly aimed in the horizontal

direction (left/right) and the vertical position

(up/down).NOTE:A non-zero bubble reading does not

necessarily indicate out-of-aim headlamps. If your

vehicle is not positioned on a level surface, the

slope will be included in the level indicator.

Therefore, vertical headlamp adjustment should be

performed only when beam direction appears to be

incorrect or a level surface can be verified.

Tools required: One 4mm socket and ratchet.

The Horizontal aim must be adjusted first.

NOTE:The following procedure assumes that the

vehicle's front structure is in factory alignment

condition. If the vehicle has been in an accident

requiring the front end of the vehicle to be

repaired, the horizontal indicator should be

recalibrated by the servicing facility.

File:11fnmcc.ex

Update:Fri Sep 6 08:51:16 1996

Page 266 of 321

265

Before adjusting your headlamps, you must make

sure that the air suspension has been adjusted to

the proper ride height. In order to do this:

1. Position the vehicle on a level surface.

2. Make sure the air suspension switch in the

luggage compartment is in the ON position.

3. Turn the ignition key to the ON position.

4. Open and close the driver's door to allow the

air suspension to fully level.

File:11fnmcc.ex

Update:Fri Sep 6 08:51:16 1996

Page 267 of 321

266Horizontal aim adjustment1. Open the hood and lift the front end cover

from its velcro attachments. Locate the

horizontal level indicator and adjustment screw.

2. Use a 4mm socket and ratchet to turn the

horizontal adjusting screw until the horizontal

indicator is in line with the ª0º reference.

Vertical aim adjustmentNOTE:The numbers shown on the vial indicate

beam direction in degrees up or down.

1. Locate the vertical level indicator and

adjustment screw.

2. Use a 4mm socket and ratchet to turn the

vertical adjustment screw until the bubble in

the horizontal level indicator is centered in the

vial.

3. Replace the front end cover and close the

hood.

File:11fnmcc.ex

Update:Fri Sep 6 08:51:16 1996

Page 268 of 321

267

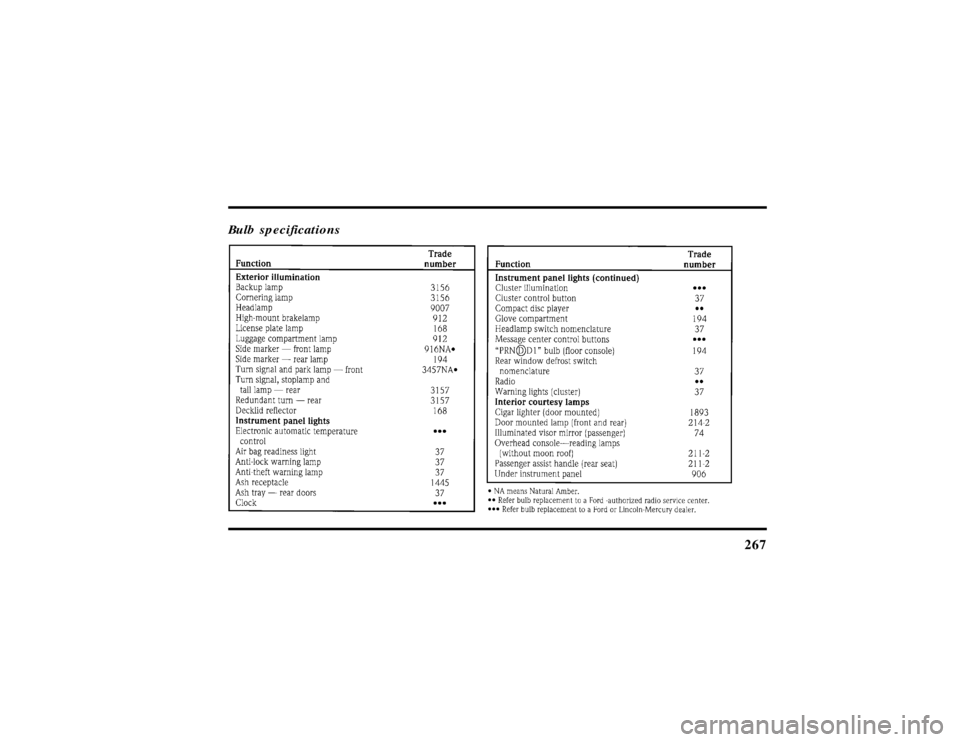

Bulb specifications

File:11fnmcc.ex

Update:Fri Sep 6 08:51:16 1996

Page 269 of 321

268Cleaning Your VehicleWashing and Polishing Your VehicleWash the outside of your vehicle, including the

underside, with a mild detergent.

DO NOT:q

Wash your vehicle with hot water

q

Wash your vehicle while it sits in direct

sunlight

q

Wash your vehicle while the body is hot

Pollen, bird droppings and tree sap can damage the

paint, especially in hot weather. Wash your vehicle

as often as necessary to keep it clean.

Take similar precautions if your vehicle is exposed

to chemical industrial fallout.Paint damage resulting from fallout is not related to

a defect inpaint materials or workmanship and

therefore is not covered by warranty. Ford,

however, believes that continual improvement in

customer satisfaction is a high priority. For this

reason, Ford has authorized its dealers to repair, at

no charge to the owner, the surfaces of new

vehicles damaged by environmental fallout within

12 months or 12,000 miles (20,000 km) of

purchase, whichever comes first. Customers may be

required to bring their vehicle in for inspection by a

Ford representative.

Polish your vehicle to remove harmful deposits and

protect the finish.

Cleaning Chrome and Aluminum PartsWash chrome and aluminum parts with a mild

detergent. Do not use steel wool, abrasive cleaners,

fuel, or strong detergents.

File:11fnmcc.ex

Update:Fri Sep 6 08:51:16 1996

Page 270 of 321

269

Cleaning Plastic PartsSome of your vehicle's exterior trim parts are

plastic. Clean with a tar and road oil remover if

necessary. Use a vinyl cleaner for routine cleaning.

Do not clean plastic parts with thinners, solvents or

petroleum-based cleaners.

If you have your vehicle rustproofed, remove

oversprayed rustproofing with a tar and road oil

remover. If rustproofing is not removed from plastic

and rubber parts, it can cause deterioration.Cleaning the Safety BeltsClean the safety belts with any mild soap solution

that is recommended for cleaning upholstery or

carpets. Do not bleach or dye the belt webbing

because this may weaken it.

Cleaning the Instrument Panel LensClean the instrument panel lens and woodtone trim

with a soft cloth and a glass cleaner. Do not use

paper towel or any abrasive cleaner to clean either

the lens or the woodtone trim as these may cause

scratches.Cleaning the Exterior LampsDo not use dry paper towel, chemical solvents or

abrasive cleaners to clean the lamps, as these may

cause scratches or crack the lamps.Cleaning the Interior LampsYour interior dome lamps and map lamps are plastic

and should be cleaned with a mild detergent

diluted in water. Rinse them with clear water.

File:11fnmcc.ex

Update:Fri Sep 6 08:51:16 1996