brake LINCOLN CONTINENTAL 2000 User Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2000, Model line: CONTINENTAL, Model: LINCOLN CONTINENTAL 2000Pages: 232, PDF Size: 1.7 MB

Page 97 of 232

The front outboard and rear safety restraints in the vehicle are

combination lap and shoulder belts. The front passenger and rear seat

safety belts have two types of locking modes described below:

Vehicle sensitive mode

The vehicle sensitive mode is the normal retractor mode, allowing free

shoulder belt length adjustment to your movements and locking in

response to vehicle movement. For example, if the driver brakes

suddenly or turns a corner sharply, or the vehicle receives an impact of

approximately 8 km/h (5 mph) or more, the combination safety belts will

lock to help reduce forward movement of the driver and passengers.

Automatic locking mode

In this mode, the shoulder belt is automatically pre-locked. The belt will

still retract to remove any slack in the shoulder belt.

The automatic locking mode is not available on the driver safety belt.

When to use the automatic locking mode

²Anytimea child safety seat is installed in the vehicle. Children 12

years old and under should be properly restrained in the rear seat

whenever possible. Refer toSafety Restraints for ChildrenorSafety

Seats for Childrenlater in this chapter.

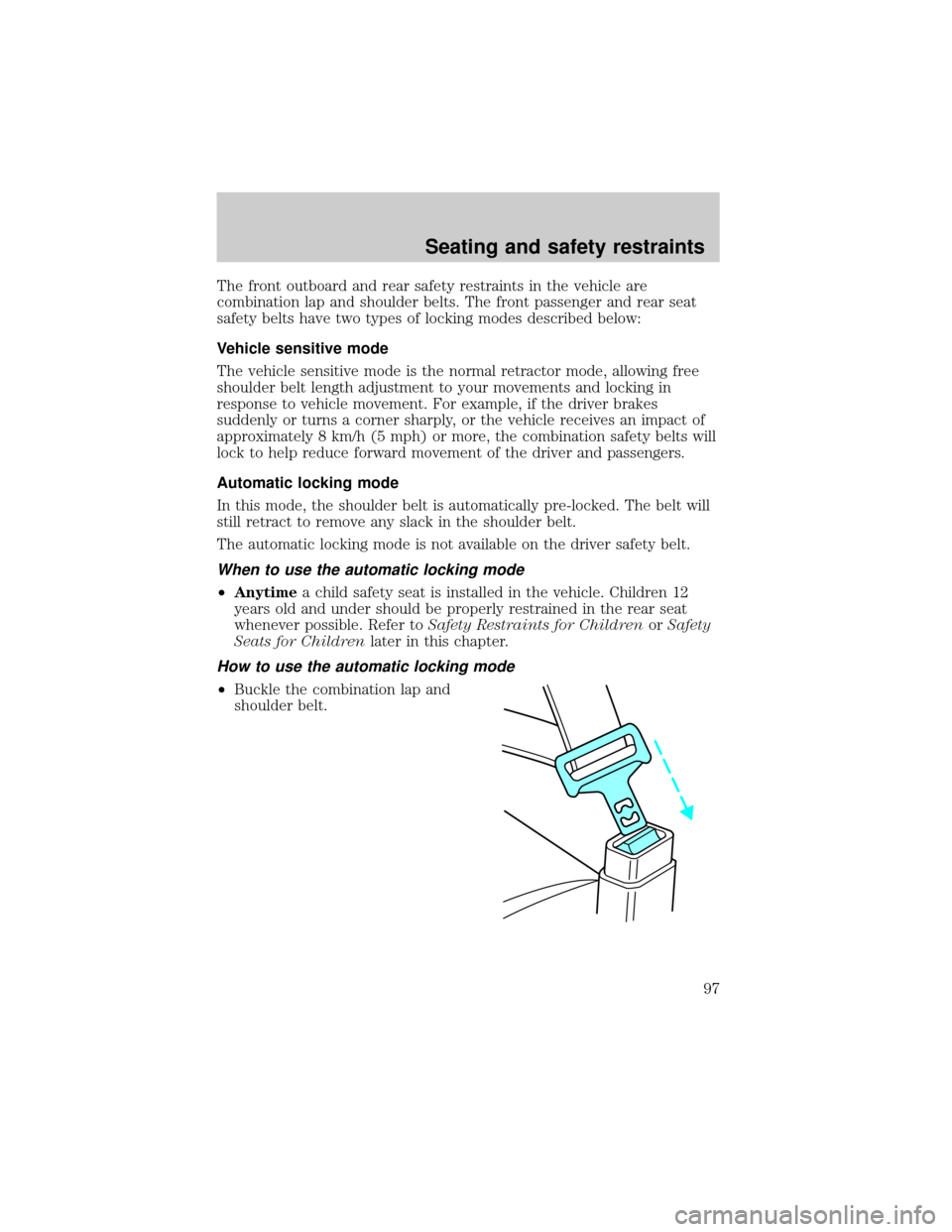

How to use the automatic locking mode

²Buckle the combination lap and

shoulder belt.

Seating and safety restraints

97

Page 102 of 232

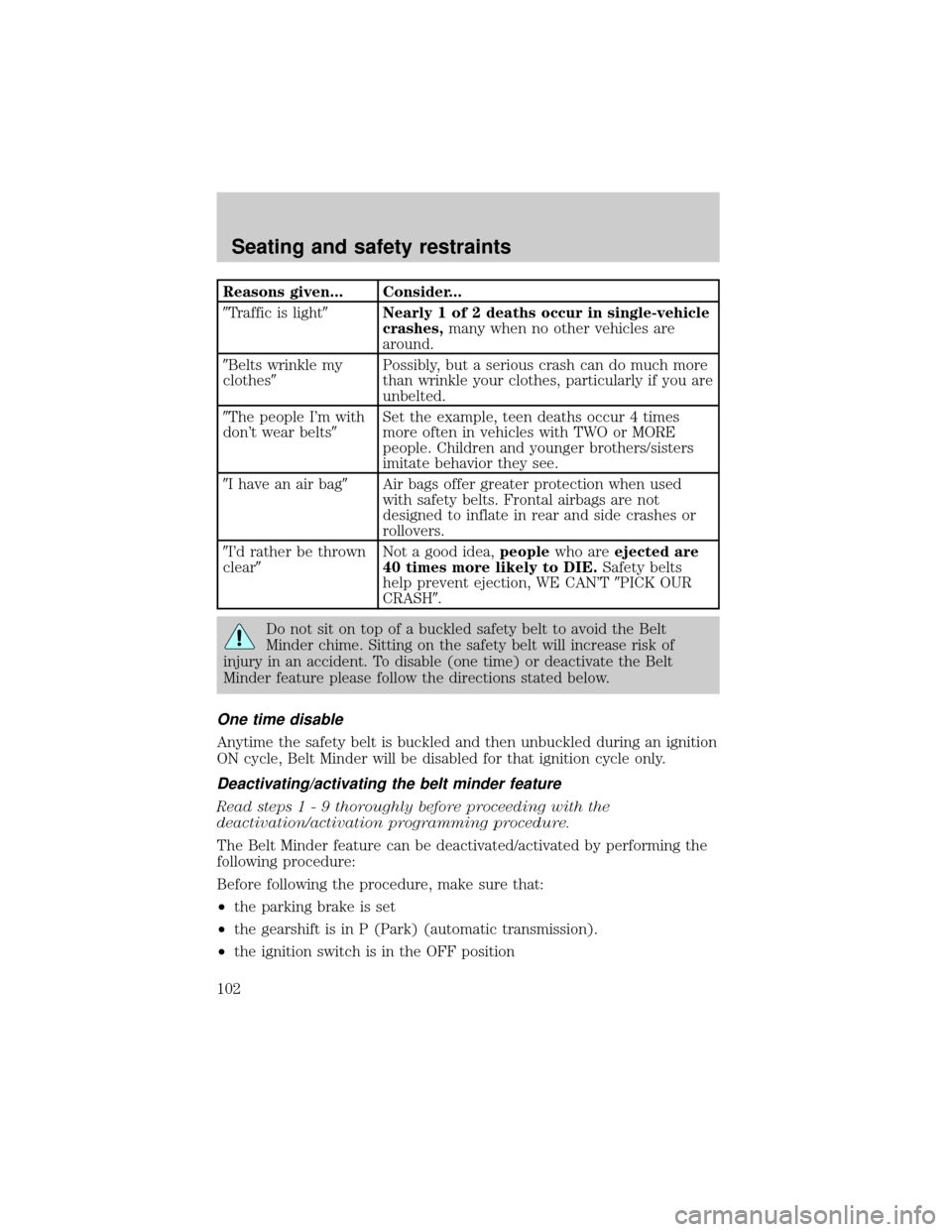

Reasons given... Consider...

9Traffic is light9Nearly 1 of 2 deaths occur in single-vehicle

crashes,many when no other vehicles are

around.

9Belts wrinkle my

clothes9Possibly, but a serious crash can do much more

than wrinkle your clothes, particularly if you are

unbelted.

9The people I'm with

don't wear belts9Set the example, teen deaths occur 4 times

more often in vehicles with TWO or MORE

people. Children and younger brothers/sisters

imitate behavior they see.

9I have an air bag9Air bags offer greater protection when used

with safety belts. Frontal airbags are not

designed to inflate in rear and side crashes or

rollovers.

9I'd rather be thrown

clear9Not a good idea,peoplewho areejected are

40 times more likely to DIE.Safety belts

help prevent ejection, WE CAN'T9PICK OUR

CRASH9.

Do not sit on top of a buckled safety belt to avoid the Belt

Minder chime. Sitting on the safety belt will increase risk of

injury in an accident. To disable (one time) or deactivate the Belt

Minder feature please follow the directions stated below.

One time disable

Anytime the safety belt is buckled and then unbuckled during an ignition

ON cycle, Belt Minder will be disabled for that ignition cycle only.

Deactivating/activating the belt minder feature

Read steps1-9thoroughly before proceeding with the

deactivation/activation programming procedure.

The Belt Minder feature can be deactivated/activated by performing the

following procedure:

Before following the procedure, make sure that:

²the parking brake is set

²the gearshift is in P (Park) (automatic transmission).

²the ignition switch is in the OFF position

Seating and safety restraints

102

Page 104 of 232

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, wears or cuts, replacing if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

assemblies, buckle support assemblies (slide bar-if equipped), shoulder

belt height adjusters (if equipped), shoulder belt guide on seatback (if

equipped), child safety seat tether bracket assemblies (if equipped), and

attaching hardware, should be inspected after a collision. Ford

recommends that all safety belt assemblies used in vehicles involved in a

collision be replaced. However, if the collision was minor and a qualified

technician finds that the belts do not show damage and continue to

operate properly, they do not need to be replaced. Safety belt assemblies

not in use during a collision should also be inspected and replaced if

either damage or improper operation is noted.

Failure to inspect and if necessary replace the safety belt

assembly under the above conditions could result in severe

personal injuries in the event of a collision.

Refer toCleaning and maintaining the safety beltsin the

Maintenance and caresection.

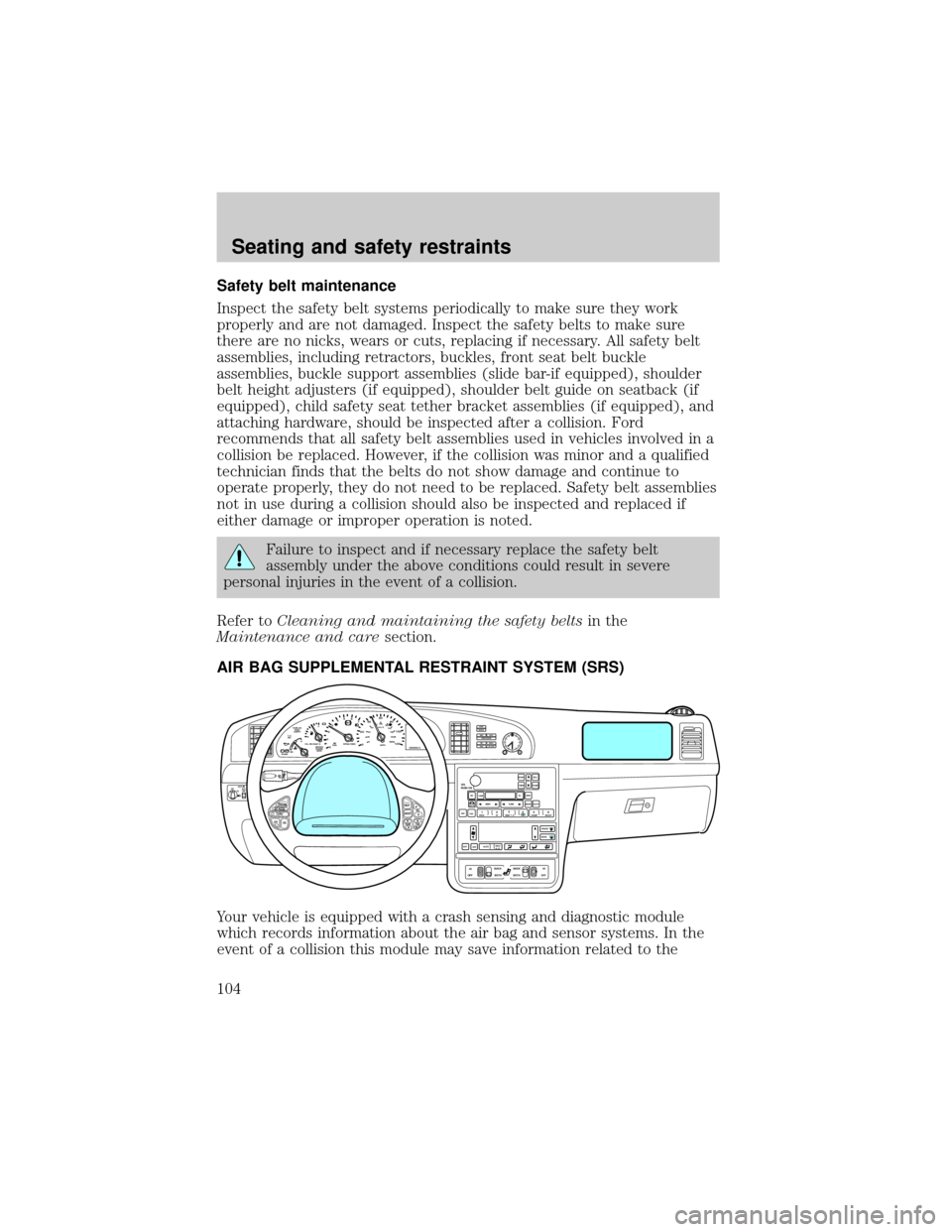

AIR BAG SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Your vehicle is equipped with a crash sensing and diagnostic module

which records information about the air bag and sensor systems. In the

event of a collision this module may save information related to the

RESUME

SET ACCEL

COAST

OFF

ONNEXT

MODEVOL

TEMPFAN

80

MPH km/h

ABS

P!BRAKE

+ –

RPMx1000NORMT/C

OFF

CHEFFILL ON RIGHT

SERVICE

ENGINE

SOON AIR

BAG TURN ON

HEAD

LAMPS0 123456

7

0 2060

80

100

1200 204060100

120

140

160

180

200

40

000000.0

SYSTEM

DRIVER ID

MENU

TRIP

RESETSELECT

DISPLAYDTE ECONVEHICLE HANDLINGNITNOCLATNE

VOL

PUSH ONTAPE

MUTESEEK

TUNE

AM

FM

REW

FFSIDE 1 2

COMP

SHUFF

EXT

OFFMAX

A/CCDEJ

RDS

SCAN AUTO

AUTO

123

4

56

FRONT

REAR

BASS

TREBSELBAL

FADEP0FFLIGHTS

AUTO

LAMPHI

LO

F

S

OFF

HIHI

OFF OFFBACK

BOTH BOTHBACK00

Seating and safety restraints

104

Page 121 of 232

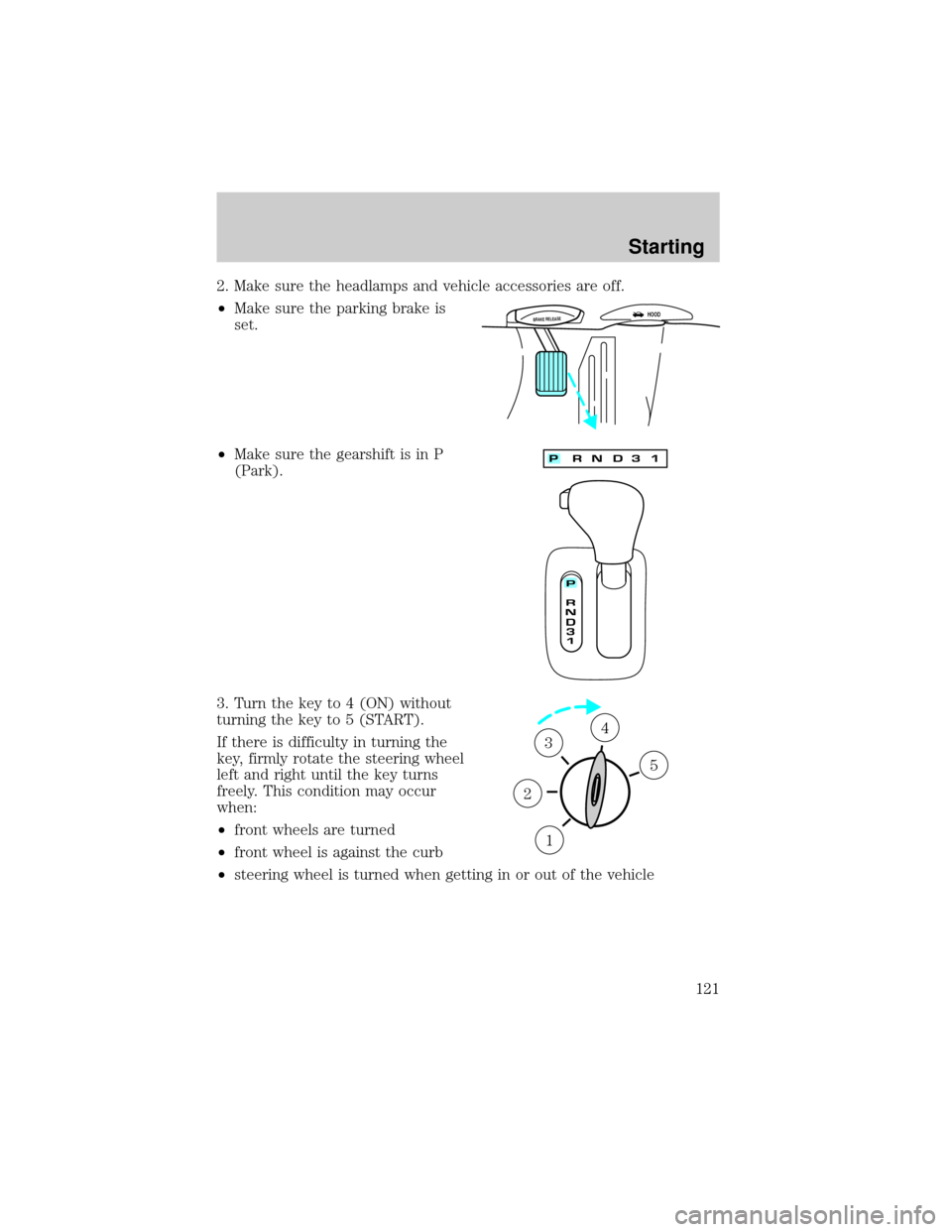

2. Make sure the headlamps and vehicle accessories are off.

²Make sure the parking brake is

set.

²Make sure the gearshift is in P

(Park).

3. Turn the key to 4 (ON) without

turning the key to 5 (START).

If there is difficulty in turning the

key, firmly rotate the steering wheel

left and right until the key turns

freely. This condition may occur

when:

²front wheels are turned

²front wheel is against the curb

²steering wheel is turned when getting in or out of the vehicle

BRAKE RELEASEHOOD

1

2

34

5

Starting

121

Page 122 of 232

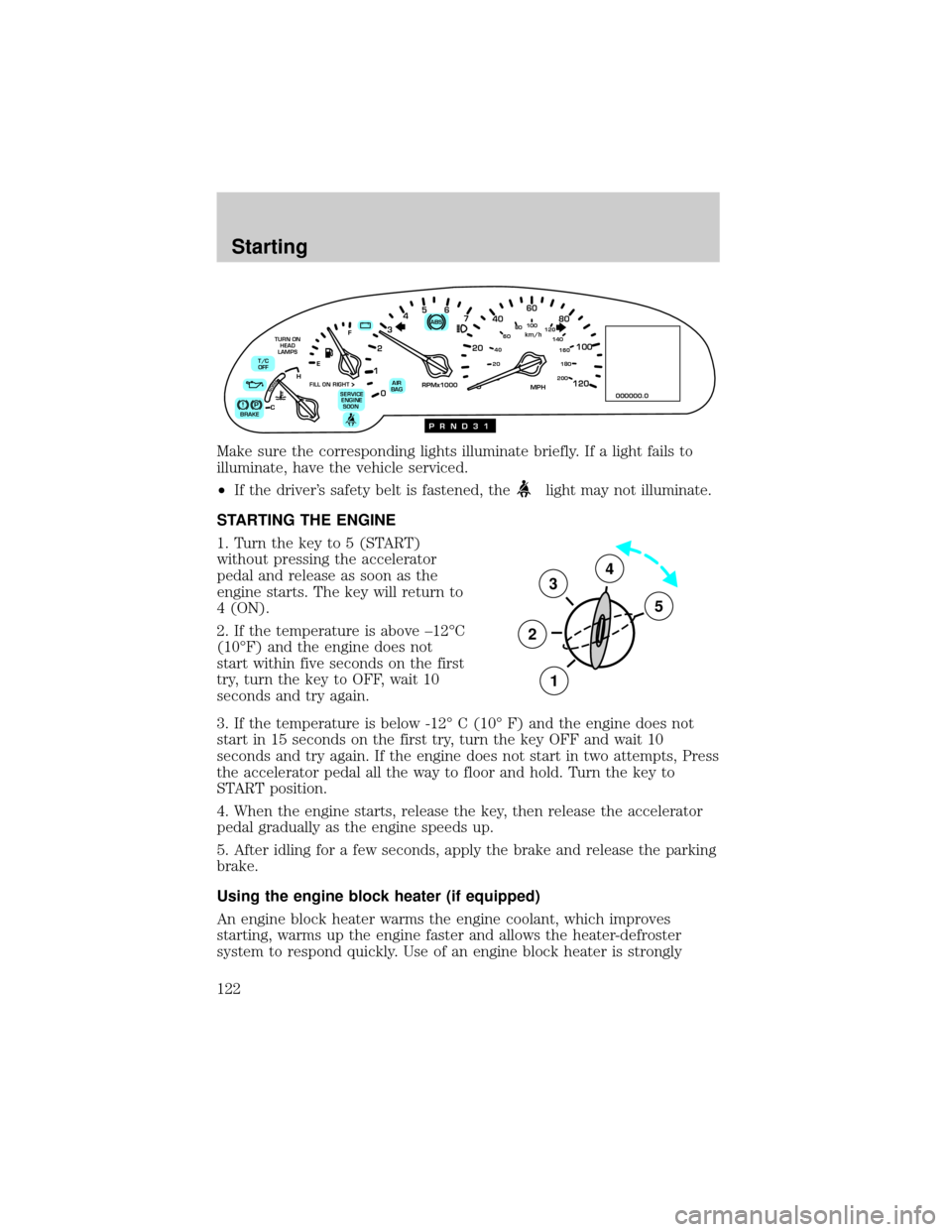

Make sure the corresponding lights illuminate briefly. If a light fails to

illuminate, have the vehicle serviced.

²If the driver's safety belt is fastened, the

light may not illuminate.

STARTING THE ENGINE

1. Turn the key to 5 (START)

without pressing the accelerator

pedal and release as soon as the

engine starts. The key will return to

4 (ON).

2. If the temperature is above ±12ÉC

(10ÉF) and the engine does not

start within five seconds on the first

try, turn the key to OFF, wait 10

seconds and try again.

3. If the temperature is below -12É C (10É F) and the engine does not

start in 15 seconds on the first try, turn the key OFF and wait 10

seconds and try again. If the engine does not start in two attempts, Press

the accelerator pedal all the way to floor and hold. Turn the key to

START position.

4. When the engine starts, release the key, then release the accelerator

pedal gradually as the engine speeds up.

5. After idling for a few seconds, apply the brake and release the parking

brake.

Using the engine block heater (if equipped)

An engine block heater warms the engine coolant, which improves

starting, warms up the engine faster and allows the heater-defroster

system to respond quickly. Use of an engine block heater is strongly

80

MPH km/h

ABS

P!BRAKE

+ –

RPMx1000NORM

T/C

OFF

CHEF

FILL ON RIGHT

SERVICE

ENGINE

SOON AIR

BAG TURN ON

HEAD

LAMPS0 123456

7

0 2060

80

100

120

0 204060100

120

140

160

180

200

40

000000.0

P R N D 3 1

3

2

1

5

4

Starting

122

Page 125 of 232

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

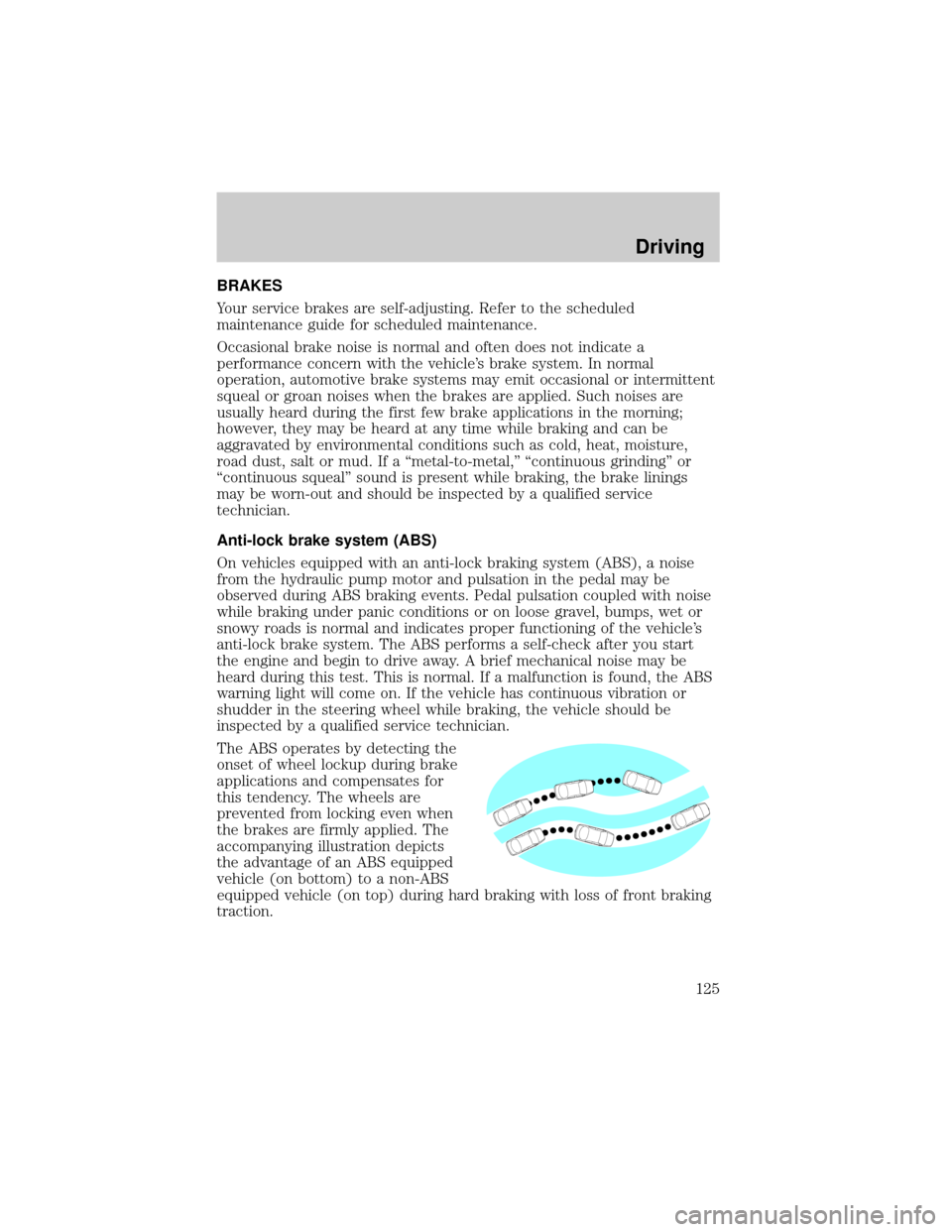

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

125

Page 126 of 232

ABS warning lampABS

TheABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned to the ON position. If the light does not

illuminate momentarily at start up, remains on or continues to flash, the

ABS needs to be serviced.

With the ABS light on, the anti-lock

brake system is disabled and normal

braking is still effective unless the

brake warning light also remains

illuminated with parking brake

released. (If your brake warning lamp illuminates, have your vehicle

serviced immediately.)

Using ABS

²In an emergency or when maximum efficiency from the ABS is

required, apply continuous force on the brake. The ABS will be

activated immediately, thus allowing you to retain full steering control

of your vehicle and, providing there is sufficient space, will enable you

to avoid obstacles and bring the vehicle to a controlled stop.

²The Anti-Lock system does not decrease the time necessary to apply

the brakes or always reduce stopping distance. Always leave enough

room between your vehicle and the vehicle in front of you to stop.

²We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

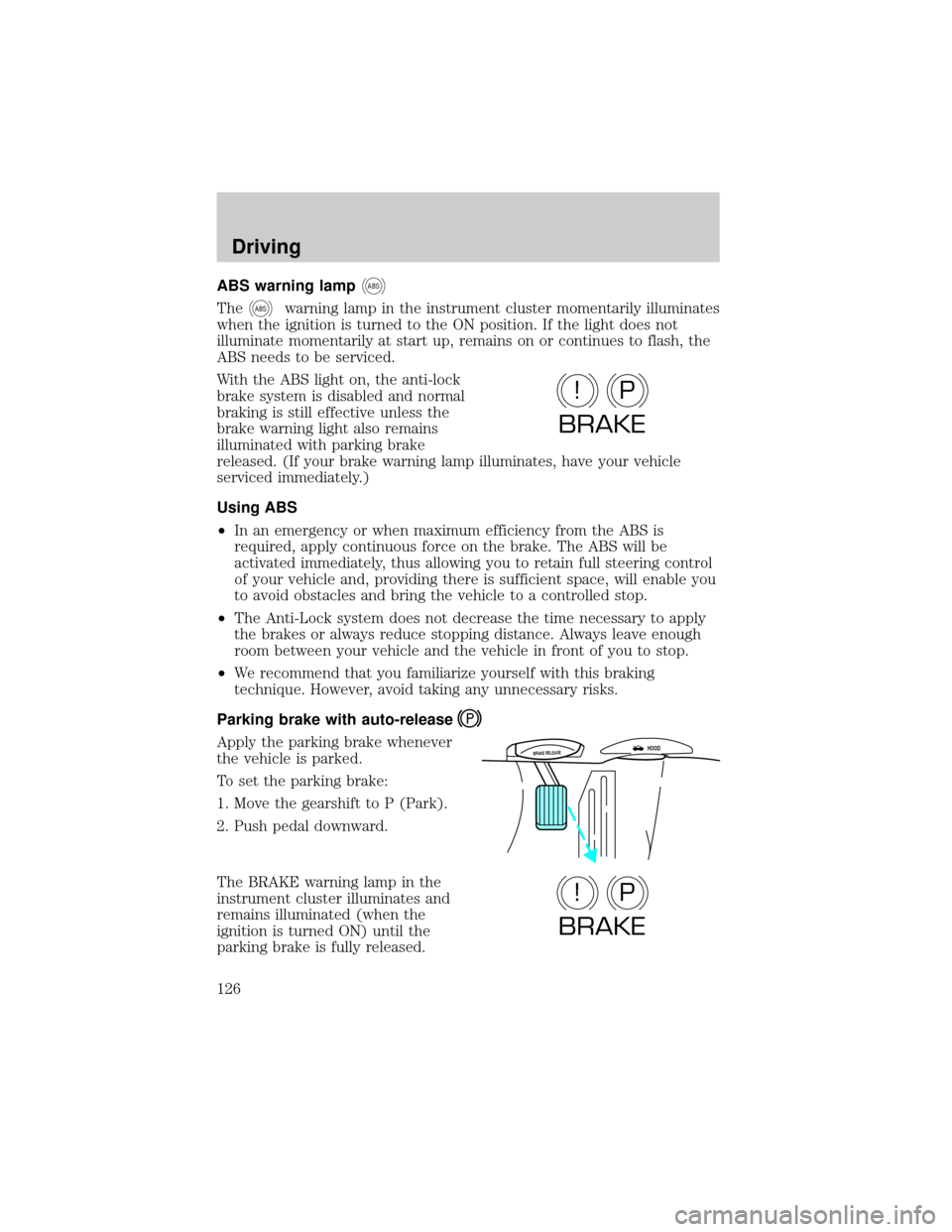

Parking brake with auto-release

Apply the parking brake whenever

the vehicle is parked.

To set the parking brake:

1. Move the gearshift to P (Park).

2. Push pedal downward.

The BRAKE warning lamp in the

instrument cluster illuminates and

remains illuminated (when the

ignition is turned ON) until the

parking brake is fully released.

P!

BRAKE

BRAKE RELEASEHOOD

P!

BRAKE

Driving

126

Page 127 of 232

Always set the parking brake fully and make sure the gearshift is

latched in P (Park). Turn off the ignition whenever you leave

your vehicle.

The parking brake is not recommended to stop a moving vehicle.

However, if the normal brakes fail, the parking brake can be used to stop

your vehicle in an emergency. Since the parking brake applies only the

rear brakes, the vehicle's stopping distance will increase greatly and the

handling of your vehicle will be adversely affected.

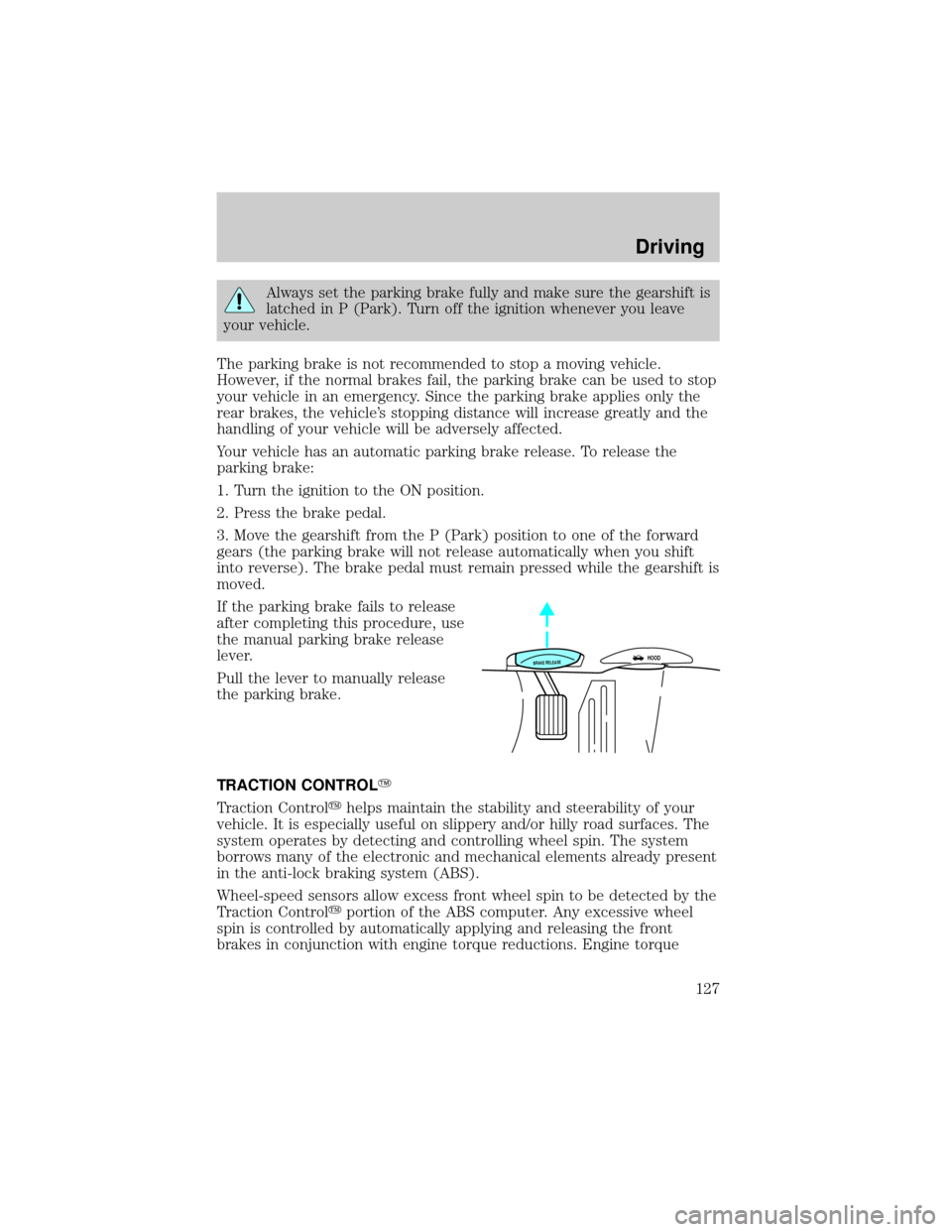

Your vehicle has an automatic parking brake release. To release the

parking brake:

1. Turn the ignition to the ON position.

2. Press the brake pedal.

3. Move the gearshift from the P (Park) position to one of the forward

gears (the parking brake will not release automatically when you shift

into reverse). The brake pedal must remain pressed while the gearshift is

moved.

If the parking brake fails to release

after completing this procedure, use

the manual parking brake release

lever.

Pull the lever to manually release

the parking brake.

TRACTION CONTROLY

Traction Controlyhelps maintain the stability and steerability of your

vehicle. It is especially useful on slippery and/or hilly road surfaces. The

system operates by detecting and controlling wheel spin. The system

borrows many of the electronic and mechanical elements already present

in the anti-lock braking system (ABS).

Wheel-speed sensors allow excess front wheel spin to be detected by the

Traction Controlyportion of the ABS computer. Any excessive wheel

spin is controlled by automatically applying and releasing the front

brakes in conjunction with engine torque reductions. Engine torque

BRAKE RELEASEHOOD

Driving

127

Page 128 of 232

reduction is realized via the fully electronic spark and fuel injection

systems. This process is very sensitive to driving conditions and very fast

acting. The front wheels ªsearchº for optimum traction several times a

second and adjustments are made accordingly.

The Traction Controlysystem will allow your vehicle to make better use

of available traction on slippery surfaces. The system is a driver aid

which makes your vehicle easier to handle primarily on snow and ice

covered roads.

During Traction Controlyoperation, TRACTION CONTROL ACTIVE is

displayed on the message center. You may hear an electric motor type of

sound coming from the engine compartment and the engine will not

ªrev-upº when you push further on the accelerator. This is normal

system behavior.

If you should become stuck in snow or on a very slippery road surface,

try switching the Traction Controlysystem off. This may allow excess

wheel spin to ªdigº the vehicle out or enable a successful ªrockingº

maneuver. Refer toMessage centerin theInstrumentationchapter.

If the Traction Controlysystem is cycled excessively, the brake portion

of the system will shut down to prevent the front brakes from

overheating. A limited Traction Controlyfunction using only engine

torque reduction will still control wheels from over-spinning. When the

front brakes have cooled down, the system will again function normally.

Anti-lock braking is not affected by this condition and will function

normally during the cool down period.

If a system fault is detected, CHECK TRACTION CONTROL is displayed

on the message center and your vehicle should be serviced.

STEERING

Your vehicle is equipped with power steering. Power steering uses energy

from the engine to help steer the vehicle.

To prevent damage to the power steering pump:

²Never hold the steering wheel to the extreme right or the extreme left

for more than a few seconds when the engine is running.

²Do not operate the vehicle with a low power steering pump fluid level.

If the power steering system breaks down (or if the engine is turned

off), you can steer the vehicle manually, but it takes more effort.

Driving

128

Page 130 of 232

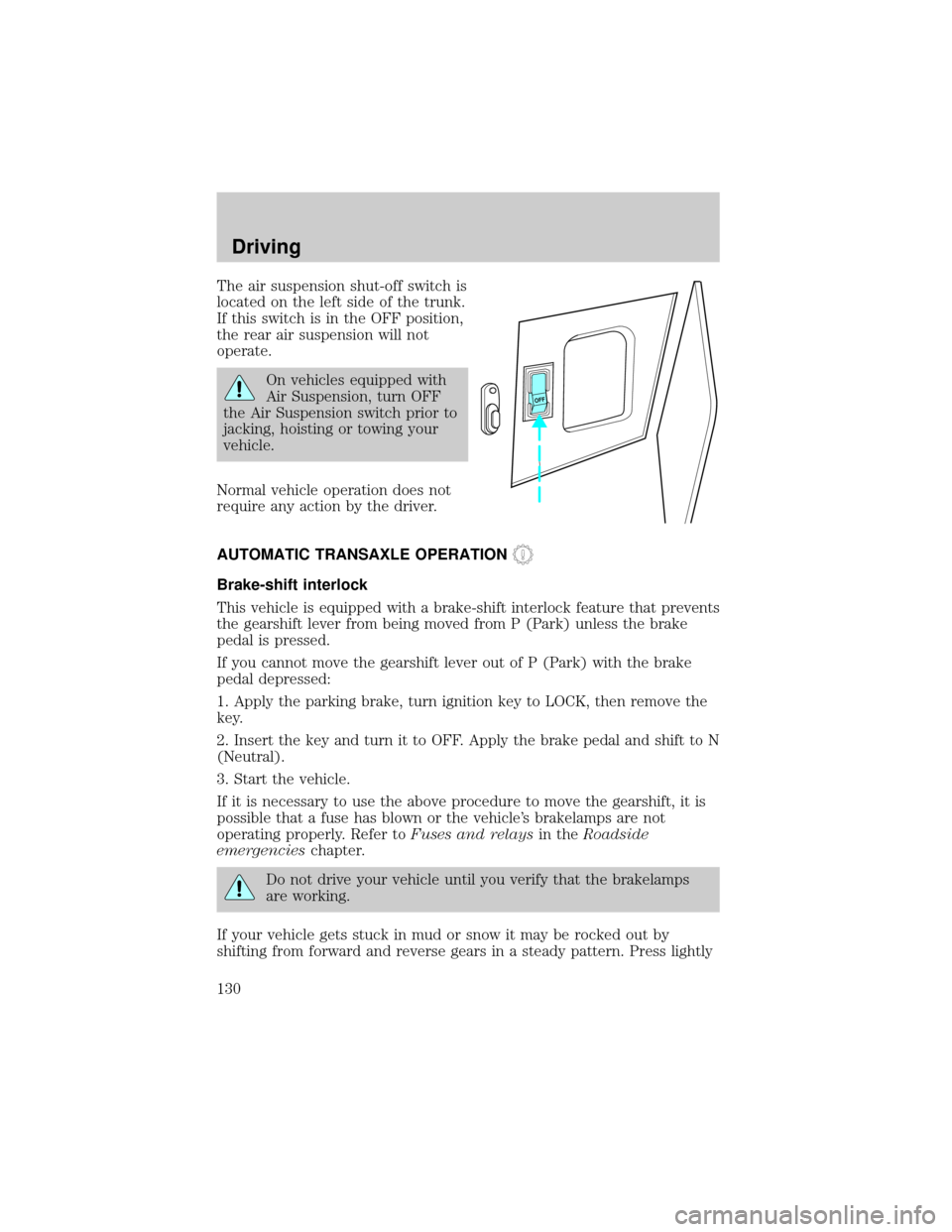

The air suspension shut-off switch is

located on the left side of the trunk.

If this switch is in the OFF position,

the rear air suspension will not

operate.

On vehicles equipped with

Air Suspension, turn OFF

the Air Suspension switch prior to

jacking, hoisting or towing your

vehicle.

Normal vehicle operation does not

require any action by the driver.

AUTOMATIC TRANSAXLE OPERATION

Brake-shift interlock

This vehicle is equipped with a brake-shift interlock feature that prevents

the gearshift lever from being moved from P (Park) unless the brake

pedal is pressed.

If you cannot move the gearshift lever out of P (Park) with the brake

pedal depressed:

1. Apply the parking brake, turn ignition key to LOCK, then remove the

key.

2. Insert the key and turn it to OFF. Apply the brake pedal and shift to N

(Neutral).

3. Start the vehicle.

If it is necessary to use the above procedure to move the gearshift, it is

possible that a fuse has blown or the vehicle's brakelamps are not

operating properly. Refer toFuses and relaysin theRoadside

emergencieschapter.

Do not drive your vehicle until you verify that the brakelamps

are working.

If your vehicle gets stuck in mud or snow it may be rocked out by

shifting from forward and reverse gears in a steady pattern. Press lightly

OFF

Driving

130