check engine LINCOLN CONTINENTAL 2001 User Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2001, Model line: CONTINENTAL, Model: LINCOLN CONTINENTAL 2001Pages: 224, PDF Size: 1.82 MB

Page 116 of 224

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

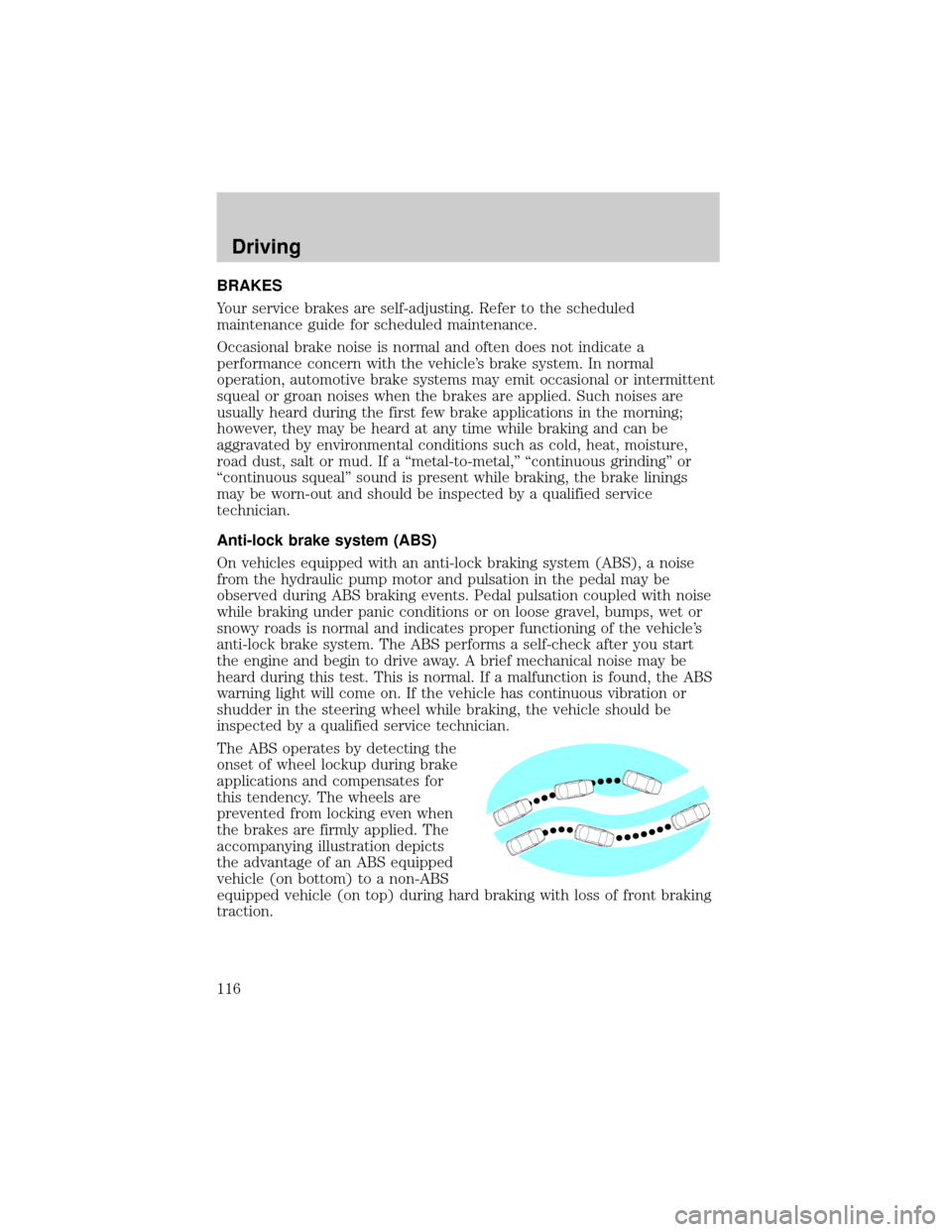

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

116

Page 119 of 224

Wheel-speed sensors allow excess front wheel spin to be detected by the

Traction Controlyportion of the ABS computer. Any excessive wheel

spin is controlled by automatically applying and releasing the front

brakes in conjunction with engine torque reductions. Engine torque

reduction is realized via the fully electronic spark and fuel injection

systems. This process is very sensitive to driving conditions and very fast

acting. The front wheels ªsearchº for optimum traction several times a

second and adjustments are made accordingly.

The Traction Controlysystem will allow your vehicle to make better use

of available traction on slippery surfaces. The system is a driver aid

which makes your vehicle easier to handle primarily on snow and ice

covered roads.

During Traction Controlyoperation, TRACTION CONTROL ACTIVE is

displayed on the message center. You may hear an electric motor type of

sound coming from the engine compartment and the engine will not

ªrev-upº when you push further on the accelerator. This is normal

system behavior.

If you should become stuck in snow or on a very slippery road surface,

try switching the Traction Controlysystem off. This may allow excess

wheel spin to ªdigº the vehicle out or enable a successful ªrockingº

maneuver. Refer toMessage centerin theInstrumentationchapter.

If the Traction Controlysystem is cycled excessively, the brake portion

of the system will shut down to prevent the front brakes from

overheating. A limited Traction Controlyfunction using only engine

torque reduction will still control wheels from over-spinning. When the

front brakes have cooled down, the system will again function normally.

Anti-lock braking is not affected by this condition and will function

normally during the cool down period.

If a system fault is detected, CHECK TRACTION CONTROL is displayed

on the message center and your vehicle should be serviced.

STEERING

Your vehicle is equipped with power steering. Power steering uses energy

from the engine to help steer the vehicle.

To prevent damage to the power steering pump:

²Never hold the steering wheel to the extreme right or the extreme left

for more than a few seconds when the engine is running.

Driving

119

Page 120 of 224

²Do not operate the vehicle with a low power steering pump fluid level

(below the MIN mark on the reservoir).

If the power steering system breaks down (or if the engine is turned

off), you can steer the vehicle manually, but it takes more effort.

If the steering wanders or pulls, the condition could be caused by any of

the following:

²underinflated tire(s) on any wheel(s)

²uneven vehicle loading

²high crown in center of road

²high crosswinds

²wheels out of alignment

²loose or worn suspension components

Speed sensitive steering

The steering in your vehicle is speed sensitive. At high speeds, steering

assist will decrease to improve steering feel. At lower speeds,

maneuverability will be increased.

SeeElectronic Message Centerin theInstrumentationchapter for

personalized adjustment.

If the amount of effort required to steer your vehicle changes at a

constant vehicle speed, have the power steering system checked by your

dealer or a qualified service technician.

AIR SUSPENSION SYSTEM

The air suspension system is designed to improve ride, handling and

general vehicle performance during:

²certain road conditions

²steering maneuvers

²braking

²accelerations

This system keeps the rear of your vehicle at a constant level by

automatically adding air or releasing air from the springs.

If you exceed the load limit, the rear air suspension may not operate and

the system warning CHECK RIDE CONTROL may appear on the message

center.

Driving

120

Page 130 of 224

If you do not install trailer lights correctly, you may cause damage to the

vehicle's lighting system or other vehicle systems.

Driving while you tow

When towing a trailer:

²Ensure that you turn off your speed control. The speed control may

shut off automatically when you are towing on long, steep grades.

²Consult your local motor vehicle speed regulations for towing a trailer.

²Shift out of D (Overdrive) and into 3 (Third) or a lower gear when

towing up or down steep hills. This will eliminate excessive

downshifting and upshifting for optimum fuel economy and transaxle

cooling.

²Anticipate stops and brake gradually.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your scheduled maintenance guide for

more information.

Trailer towing tips

²Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

²Allow more distance for stopping with a trailer attached.

²The trailer tongue weight should be 10% of the loaded trailer weight.

²After you have traveled 80 km (50 miles), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

²When stopped in traffic for long periods of time in hot weather, place

the gearshift in P (Park) and increase idle speed. This aids engine

cooling and air conditioner efficiency.

²Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer's wheels.

Recreational towing

Follow these guidelines for your specific powertrain combination to tow

your vehicle with all four wheels on the ground (such as behind a

recreational vehicle).

Driving

130

Page 150 of 224

SERVICE RECOMMENDATIONS

To help you service your vehicle:

²We highlight do-it-yourself items in the engine compartment for easy

location.

²We provide a scheduled maintenance guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

the necessary parts and service. Check your ªWarranty Guideº to find out

which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

²Do not work on a hot engine.

²When the engine is running, keep loose clothing, jewelry or long hair

away from moving parts.

²Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

²Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must ªrelearnº its idle

conditions before your vehicle will drive properly, as explained in the

Batterysection in this chapter.

Working with the engine off

1. Set the parking brake, and ensure the gearshift is securely latched in

park.

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Maintenance and care

150

Page 153 of 224

ENGINE OIL

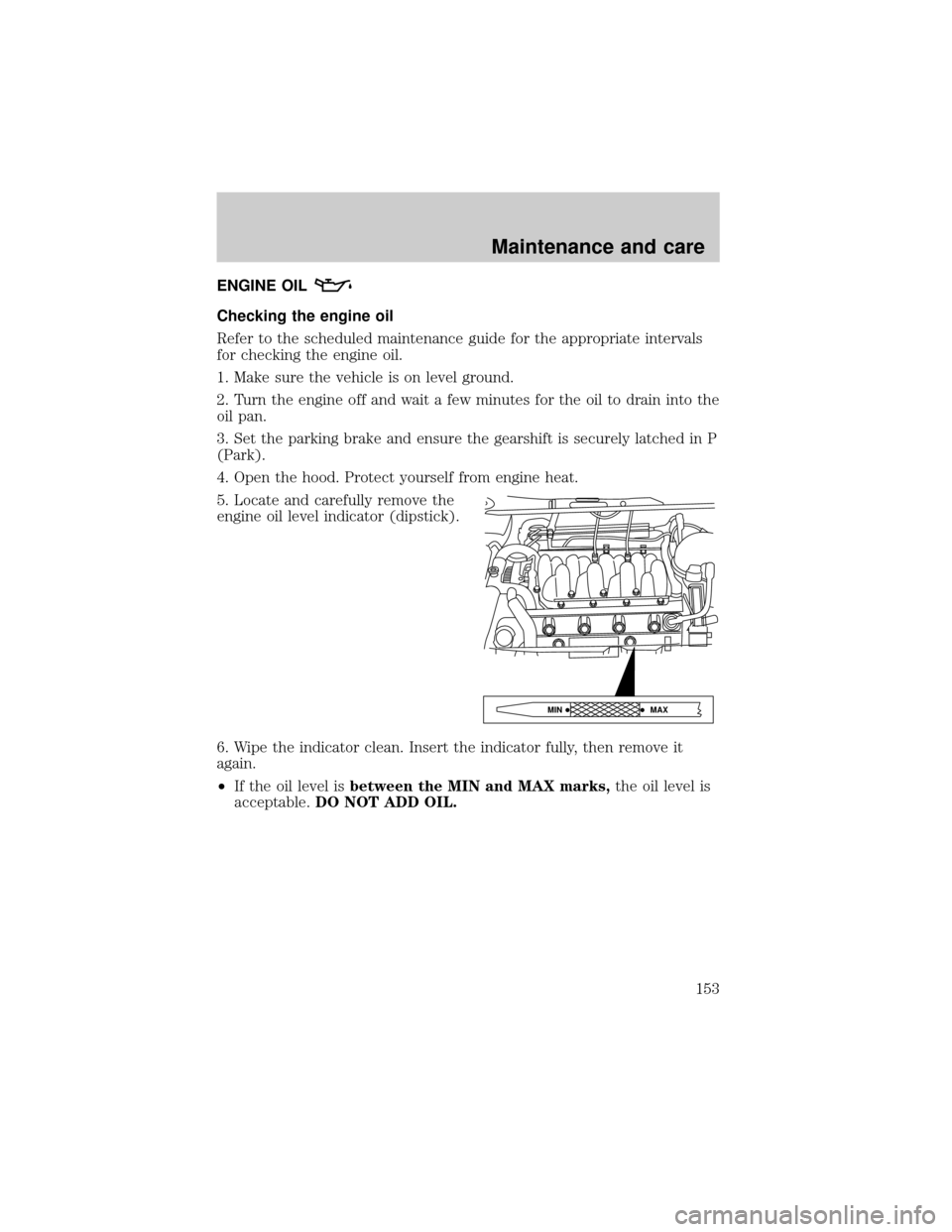

Checking the engine oil

Refer to the scheduled maintenance guide for the appropriate intervals

for checking the engine oil.

1. Make sure the vehicle is on level ground.

2. Turn the engine off and wait a few minutes for the oil to drain into the

oil pan.

3. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

4. Open the hood. Protect yourself from engine heat.

5. Locate and carefully remove the

engine oil level indicator (dipstick).

6. Wipe the indicator clean. Insert the indicator fully, then remove it

again.

²If the oil level isbetween the MIN and MAX marks,the oil level is

acceptable.DO NOT ADD OIL.

MAX MIN

Maintenance and care

153

Page 154 of 224

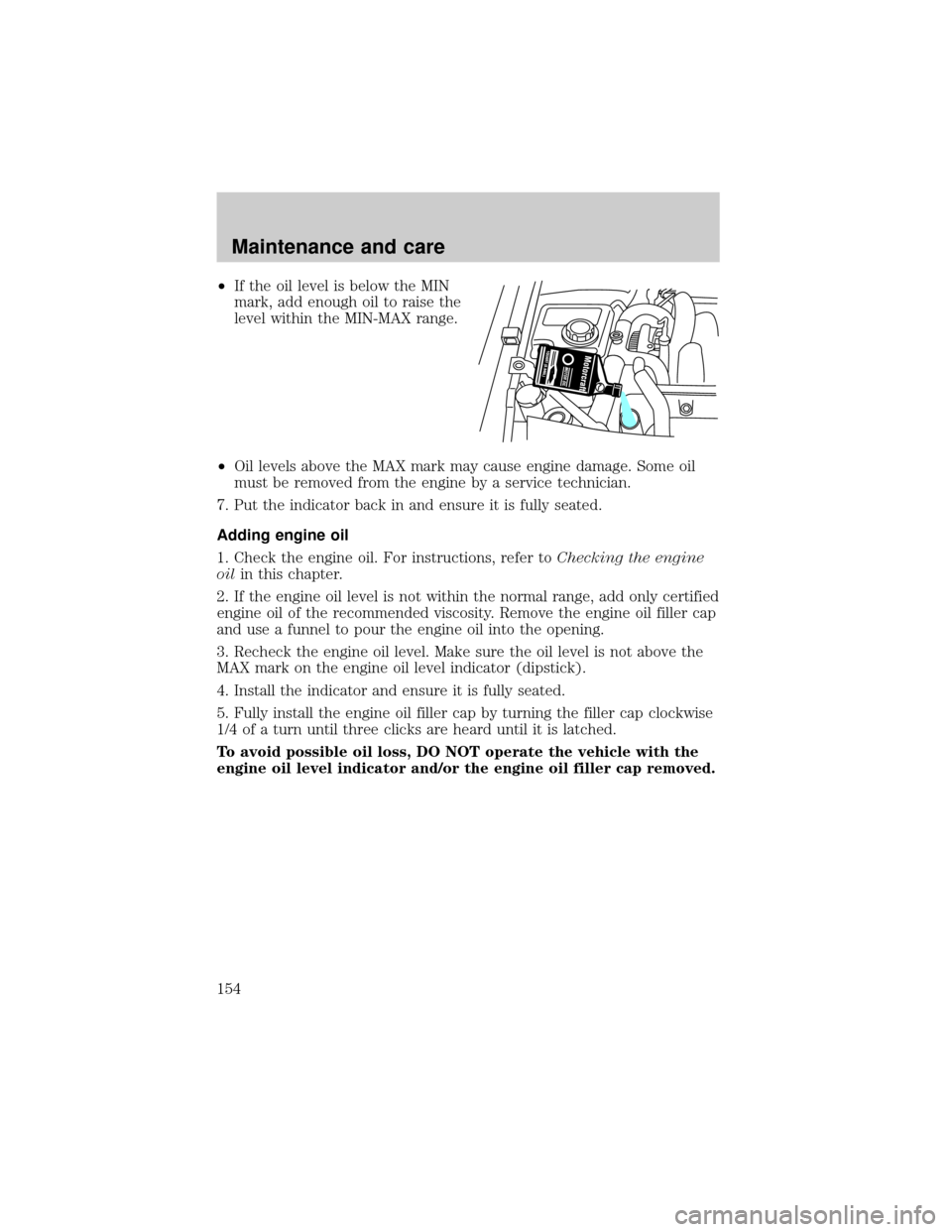

²If the oil level is below the MIN

mark, add enough oil to raise the

level within the MIN-MAX range.

²Oil levels above the MAX mark may cause engine damage. Some oil

must be removed from the engine by a service technician.

7. Put the indicator back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until three clicks are heard until it is latched.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Maintenance and care

154

Page 157 of 224

WINDSHIELD WASHER FLUID

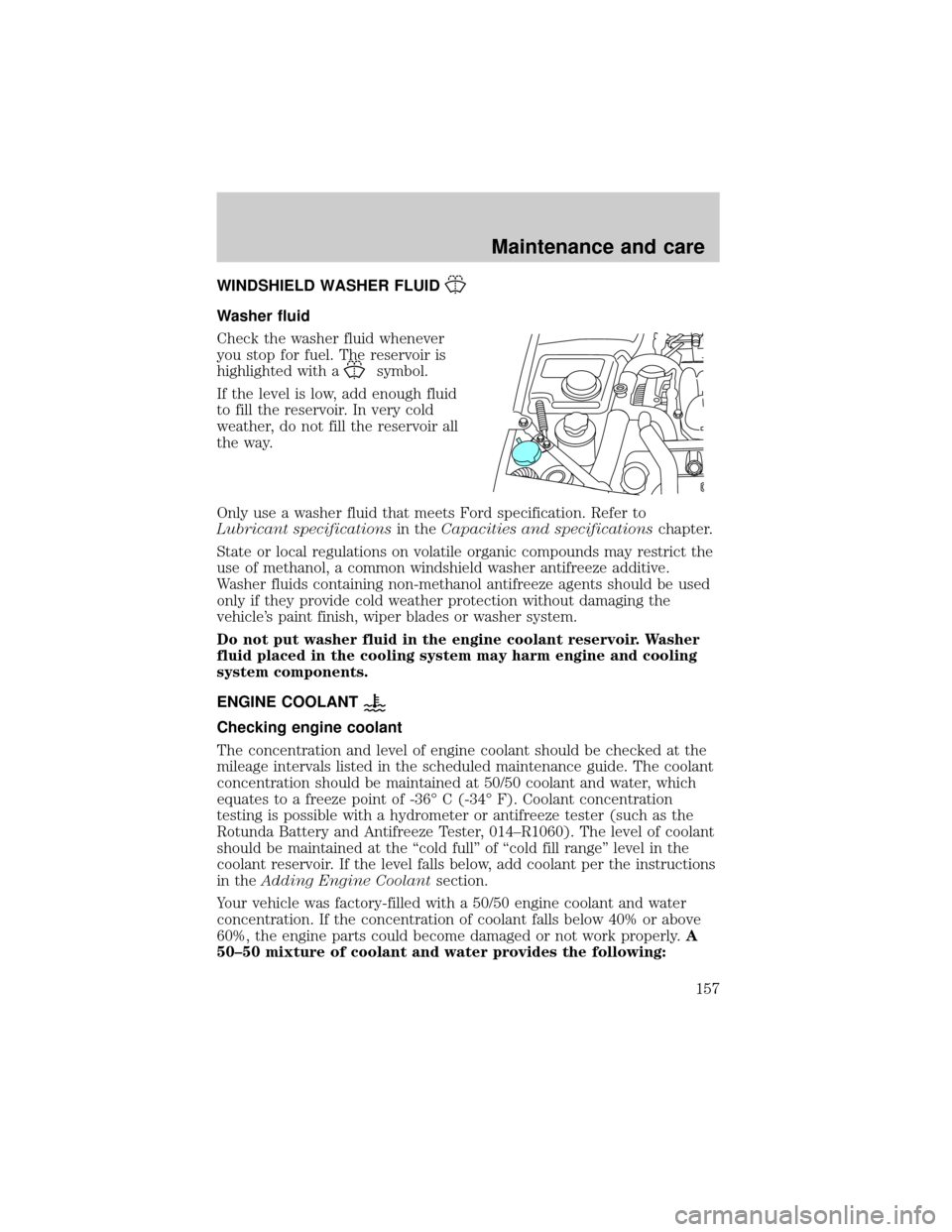

Washer fluid

Check the washer fluid whenever

you stop for fuel. The reservoir is

highlighted with a

symbol.

If the level is low, add enough fluid

to fill the reservoir. In very cold

weather, do not fill the reservoir all

the way.

Only use a washer fluid that meets Ford specification. Refer to

Lubricant specificationsin theCapacities and specificationschapter.

State or local regulations on volatile organic compounds may restrict the

use of methanol, a common windshield washer antifreeze additive.

Washer fluids containing non-methanol antifreeze agents should be used

only if they provide cold weather protection without damaging the

vehicle's paint finish, wiper blades or washer system.

Do not put washer fluid in the engine coolant reservoir. Washer

fluid placed in the cooling system may harm engine and cooling

system components.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

mileage intervals listed in the scheduled maintenance guide. The coolant

concentration should be maintained at 50/50 coolant and water, which

equates to a freeze point of -36É C (-34É F). Coolant concentration

testing is possible with a hydrometer or antifreeze tester (such as the

Rotunda Battery and Antifreeze Tester, 014±R1060). The level of coolant

should be maintained at the ªcold fullº of ªcold fill rangeº level in the

coolant reservoir. If the level falls below, add coolant per the instructions

in theAdding Engine Coolantsection.

Your vehicle was factory-filled with a 50/50 engine coolant and water

concentration. If the concentration of coolant falls below 40% or above

60%, the engine parts could become damaged or not work properly.A

50±50 mixture of coolant and water provides the following:

Maintenance and care

157

Page 158 of 224

²freeze protection down to -36É C (-34É F).

²boiling protection up to 129É C (265É F).

²protection against rust and other forms of corrosion.

²enables calibrated gages to function properly.

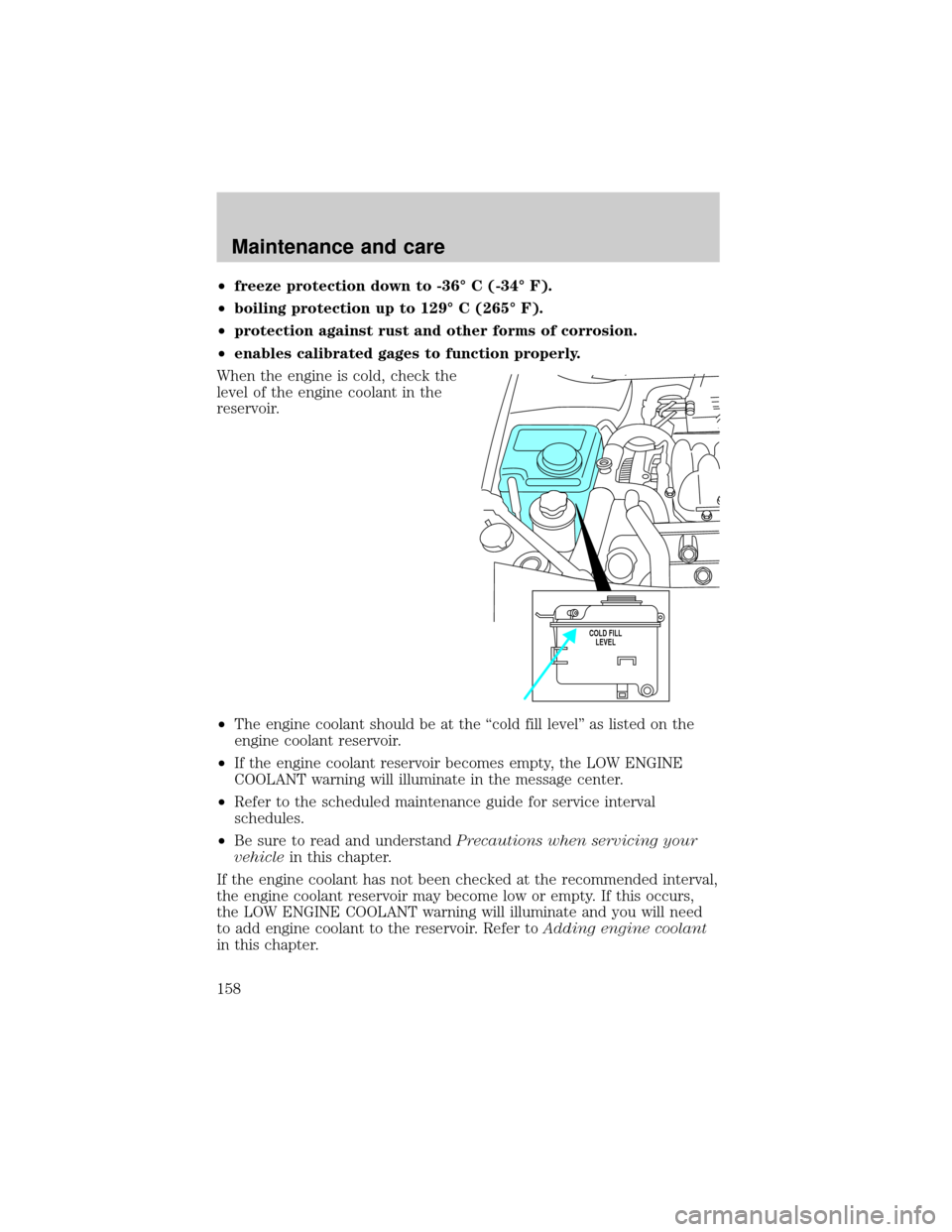

When the engine is cold, check the

level of the engine coolant in the

reservoir.

²The engine coolant should be at the ªcold fill levelº as listed on the

engine coolant reservoir.

²If the engine coolant reservoir becomes empty, the LOW ENGINE

COOLANT warning will illuminate in the message center.

²Refer to the scheduled maintenance guide for service interval

schedules.

²Be sure to read and understandPrecautions when servicing your

vehiclein this chapter.

If the engine coolant has not been checked at the recommended interval,

the engine coolant reservoir may become low or empty. If this occurs,

the LOW ENGINE COOLANT warning will illuminate and you will need

to add engine coolant to the reservoir. Refer toAdding engine coolant

in this chapter.

COLD FILL

LEVEL

Maintenance and care

158

Page 160 of 224

²Engine coolant concentrations above 60% or below 40% will

decrease the freeze protection characteristics of the engine

coolant and may cause engine damage.

Plain water may be added in an emergency, but youmustreplace it with

a 50/50 mixture of engine coolant and distilled water as soon as possible.

Check the coolant level in the reservoir before you drive your vehicle the

next few times (with the engine cool). If necessary, add a50/50

mixtureof engine coolant and distilled water to the engine coolant

reservoir until the coolant level is at the ªcold fill levelº or within the

ªcold fill rangeº as listed on the reservoir (depending upon application).

Have your dealer check the engine cooling system for leaks if you have

to add more than 1.0 liter (1.0 quart) of engine coolant per month.

To avoid scalding hot steam or coolant from being released from

the engine cooling system, never remove the reservoir cap while

the engine is running or hot. Failure to follow this warning may result

in damage to the engine's cooling system and possible severe personal

injury.

If you must remove the coolant cap, follow these steps to avoid personal

injury:

1. Before you remove the cap, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the cap. Slowly

turn cap counterclockwise until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

Recycled engine coolant

Ford Motor Company recommends the use of a recycled engine coolant

produced by Ford-approved processes.

Not all coolant recycling processes produce coolant which meets Ford

specification WSS-M97B51±A1. Use of a recycled engine coolant which

does not meet the Ford G05 specification may harm engine and cooling

system components.

Maintenance and care

160