lock LINCOLN CONTINENTAL 2002 Workshop Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2002, Model line: CONTINENTAL, Model: LINCOLN CONTINENTAL 2002Pages: 240, PDF Size: 1.79 MB

Page 160 of 240

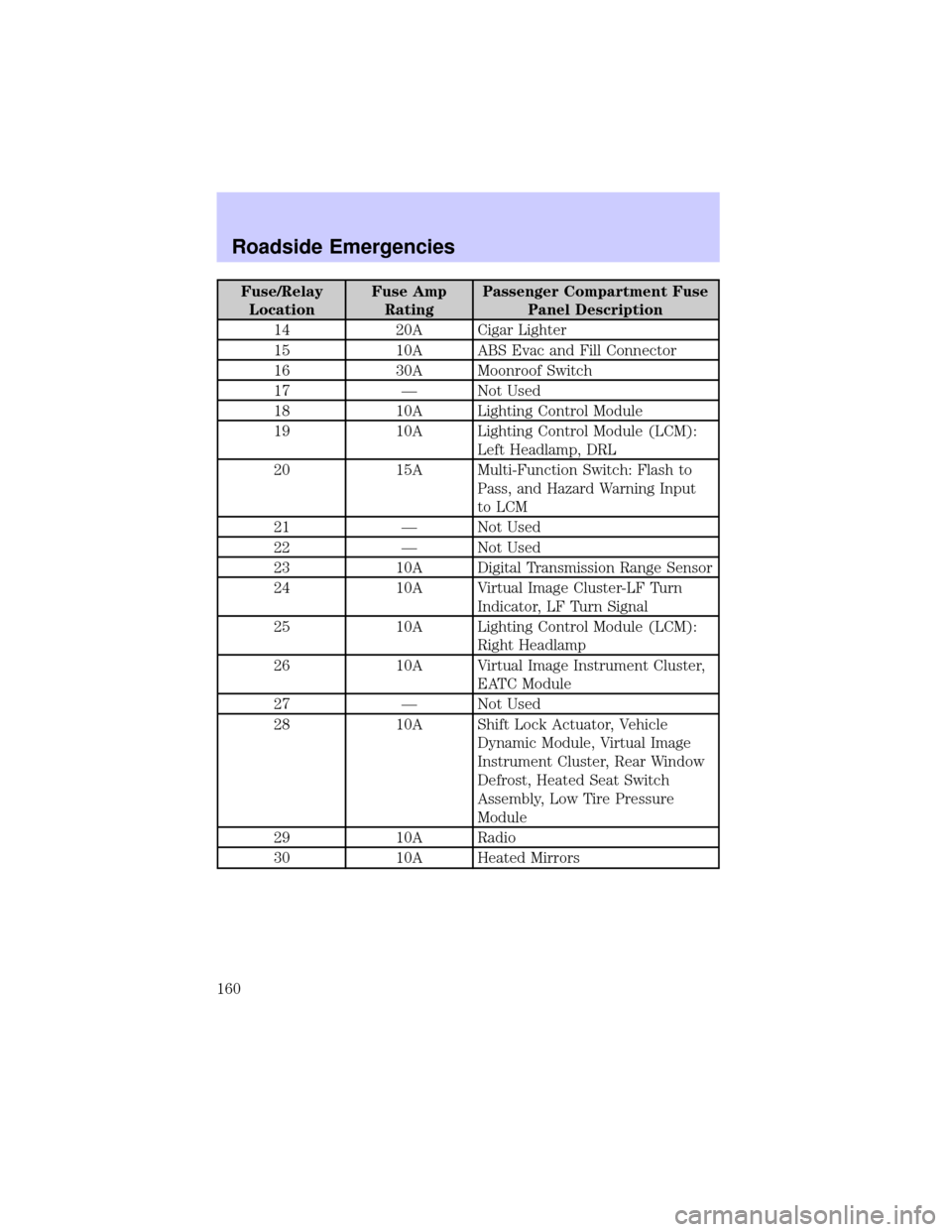

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

14 20A Cigar Lighter

15 10A ABS Evac and Fill Connector

16 30A Moonroof Switch

17 Ð Not Used

18 10A Lighting Control Module

19 10A Lighting Control Module (LCM):

Left Headlamp, DRL

20 15A Multi-Function Switch: Flash to

Pass, and Hazard Warning Input

to LCM

21 Ð Not Used

22 Ð Not Used

23 10A Digital Transmission Range Sensor

24 10A Virtual Image Cluster-LF Turn

Indicator, LF Turn Signal

25 10A Lighting Control Module (LCM):

Right Headlamp

26 10A Virtual Image Instrument Cluster,

EATC Module

27 Ð Not Used

28 10A Shift Lock Actuator, Vehicle

Dynamic Module, Virtual Image

Instrument Cluster, Rear Window

Defrost, Heated Seat Switch

Assembly, Low Tire Pressure

Module

29 10A Radio

30 10A Heated Mirrors

Roadside Emergencies

160

Page 161 of 240

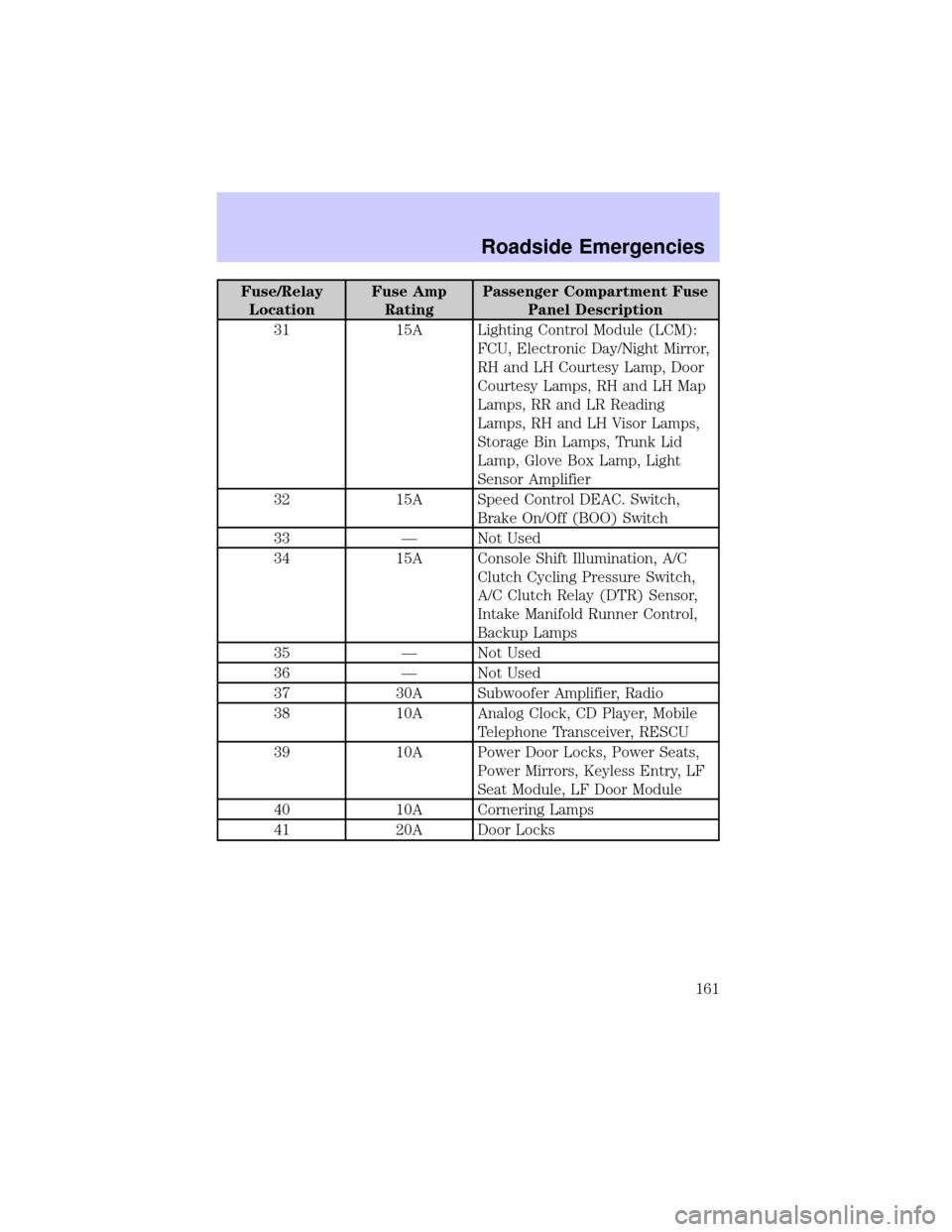

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

31 15A Lighting Control Module (LCM):

FCU, Electronic Day/Night Mirror,

RH and LH Courtesy Lamp, Door

Courtesy Lamps, RH and LH Map

Lamps, RR and LR Reading

Lamps, RH and LH Visor Lamps,

Storage Bin Lamps, Trunk Lid

Lamp, Glove Box Lamp, Light

Sensor Amplifier

32 15A Speed Control DEAC. Switch,

Brake On/Off (BOO) Switch

33 Ð Not Used

34 15A Console Shift Illumination, A/C

Clutch Cycling Pressure Switch,

A/C Clutch Relay (DTR) Sensor,

Intake Manifold Runner Control,

Backup Lamps

35 Ð Not Used

36 Ð Not Used

37 30A Subwoofer Amplifier, Radio

38 10A Analog Clock, CD Player, Mobile

Telephone Transceiver, RESCU

39 10A Power Door Locks, Power Seats,

Power Mirrors, Keyless Entry, LF

Seat Module, LF Door Module

40 10A Cornering Lamps

41 20A Door Locks

Roadside Emergencies

161

Page 163 of 240

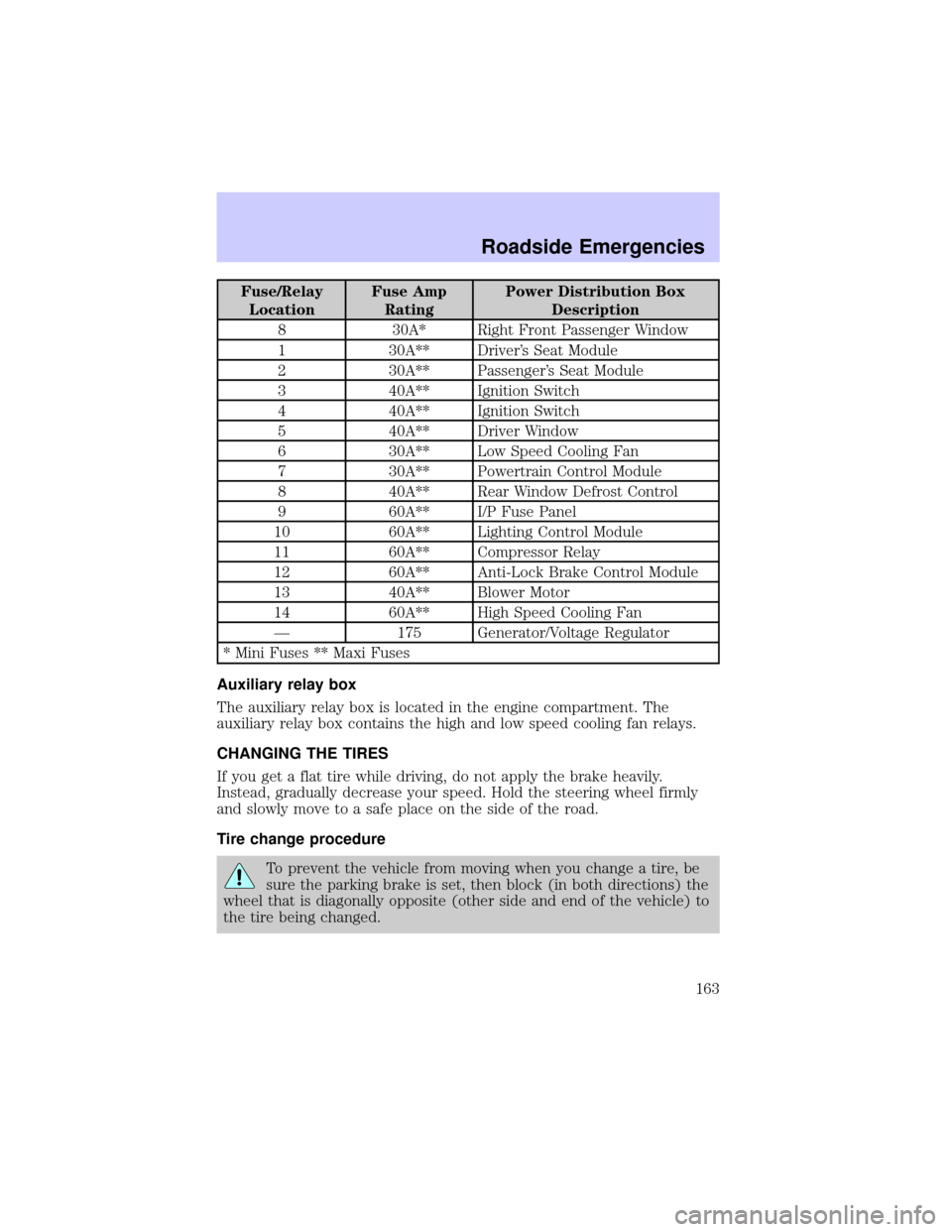

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box

Description

8 30A* Right Front Passenger Window

1 30A** Driver's Seat Module

2 30A** Passenger's Seat Module

3 40A** Ignition Switch

4 40A** Ignition Switch

5 40A** Driver Window

6 30A** Low Speed Cooling Fan

7 30A** Powertrain Control Module

8 40A** Rear Window Defrost Control

9 60A** I/P Fuse Panel

10 60A** Lighting Control Module

11 60A** Compressor Relay

12 60A** Anti-Lock Brake Control Module

13 40A** Blower Motor

14 60A** High Speed Cooling Fan

Ð 175 Generator/Voltage Regulator

* Mini Fuses ** Maxi Fuses

Auxiliary relay box

The auxiliary relay box is located in the engine compartment. The

auxiliary relay box contains the high and low speed cooling fan relays.

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

Tire change procedure

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block (in both directions) the

wheel that is diagonally opposite (other side and end of the vehicle) to

the tire being changed.

Roadside Emergencies

163

Page 164 of 240

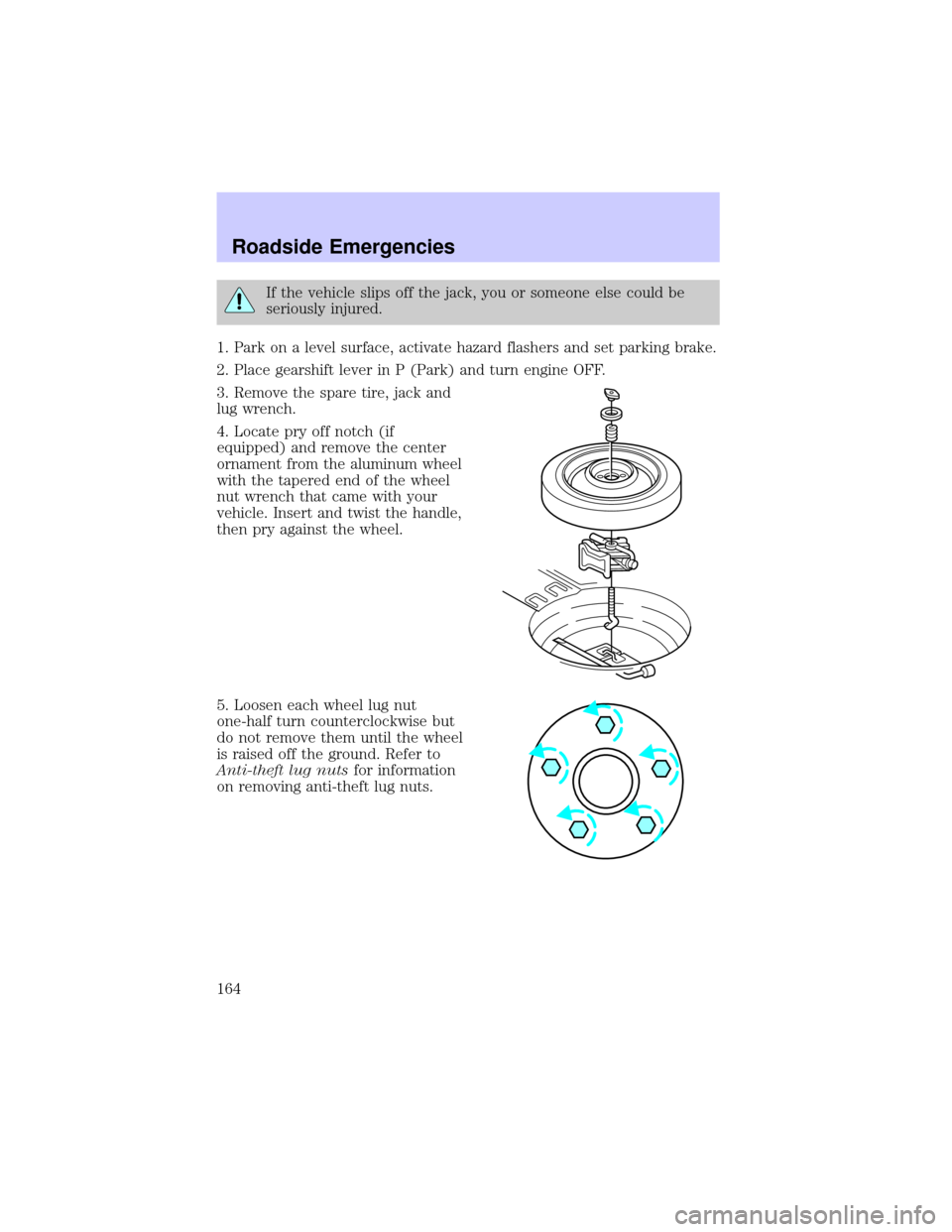

If the vehicle slips off the jack, you or someone else could be

seriously injured.

1. Park on a level surface, activate hazard flashers and set parking brake.

2. Place gearshift lever in P (Park) and turn engine OFF.

3. Remove the spare tire, jack and

lug wrench.

4. Locate pry off notch (if

equipped) and remove the center

ornament from the aluminum wheel

with the tapered end of the wheel

nut wrench that came with your

vehicle. Insert and twist the handle,

then pry against the wheel.

5. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground. Refer to

Anti-theft lug nutsfor information

on removing anti-theft lug nuts.

Roadside Emergencies

164

Page 165 of 240

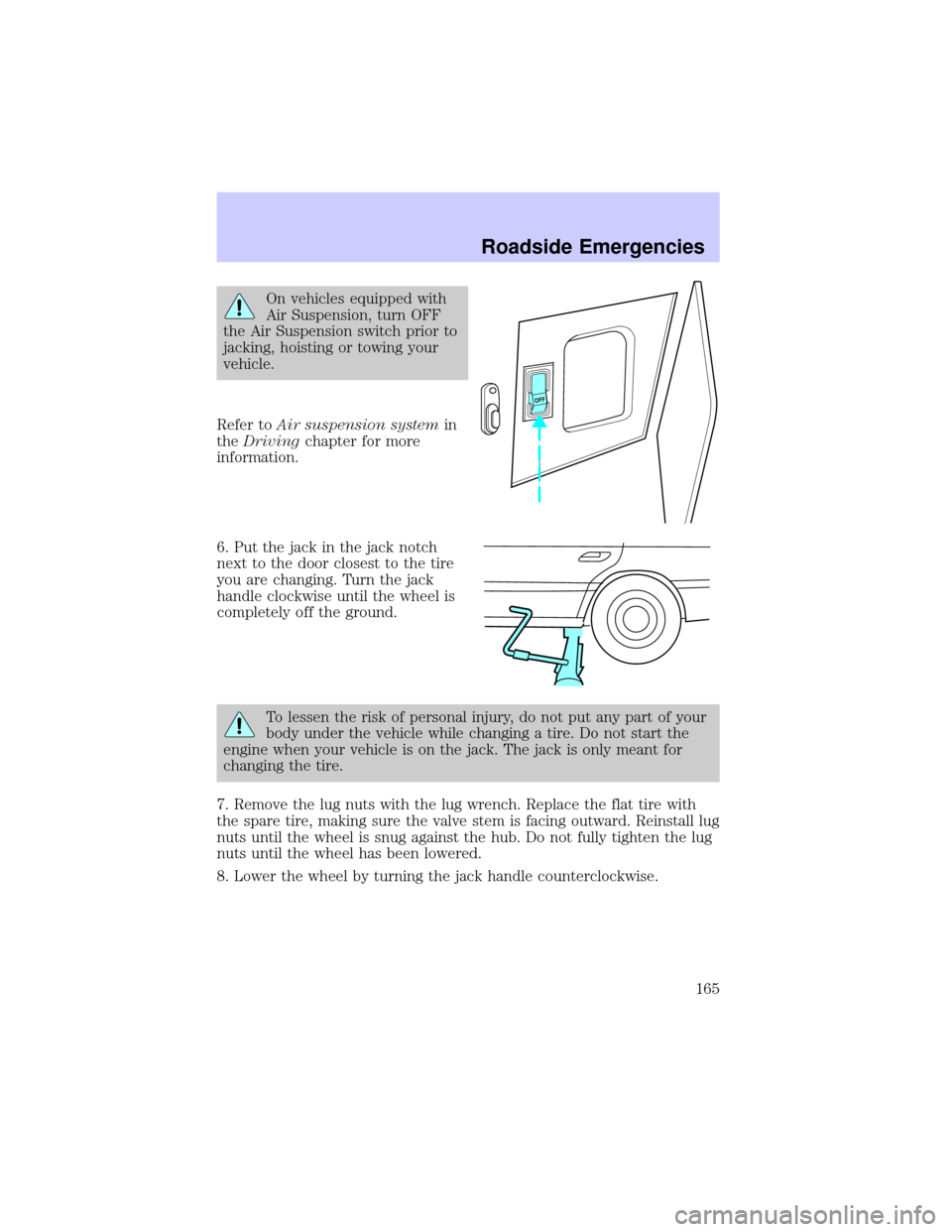

On vehicles equipped with

Air Suspension, turn OFF

the Air Suspension switch prior to

jacking, hoisting or towing your

vehicle.

Refer toAir suspension systemin

theDrivingchapter for more

information.

6. Put the jack in the jack notch

next to the door closest to the tire

you are changing. Turn the jack

handle clockwise until the wheel is

completely off the ground.

To lessen the risk of personal injury, do not put any part of your

body under the vehicle while changing a tire. Do not start the

engine when your vehicle is on the jack. The jack is only meant for

changing the tire.

7. Remove the lug nuts with the lug wrench. Replace the flat tire with

the spare tire, making sure the valve stem is facing outward. Reinstall lug

nuts until the wheel is snug against the hub. Do not fully tighten the lug

nuts until the wheel has been lowered.

8. Lower the wheel by turning the jack handle counterclockwise.

OFF

Roadside Emergencies

165

Page 166 of 240

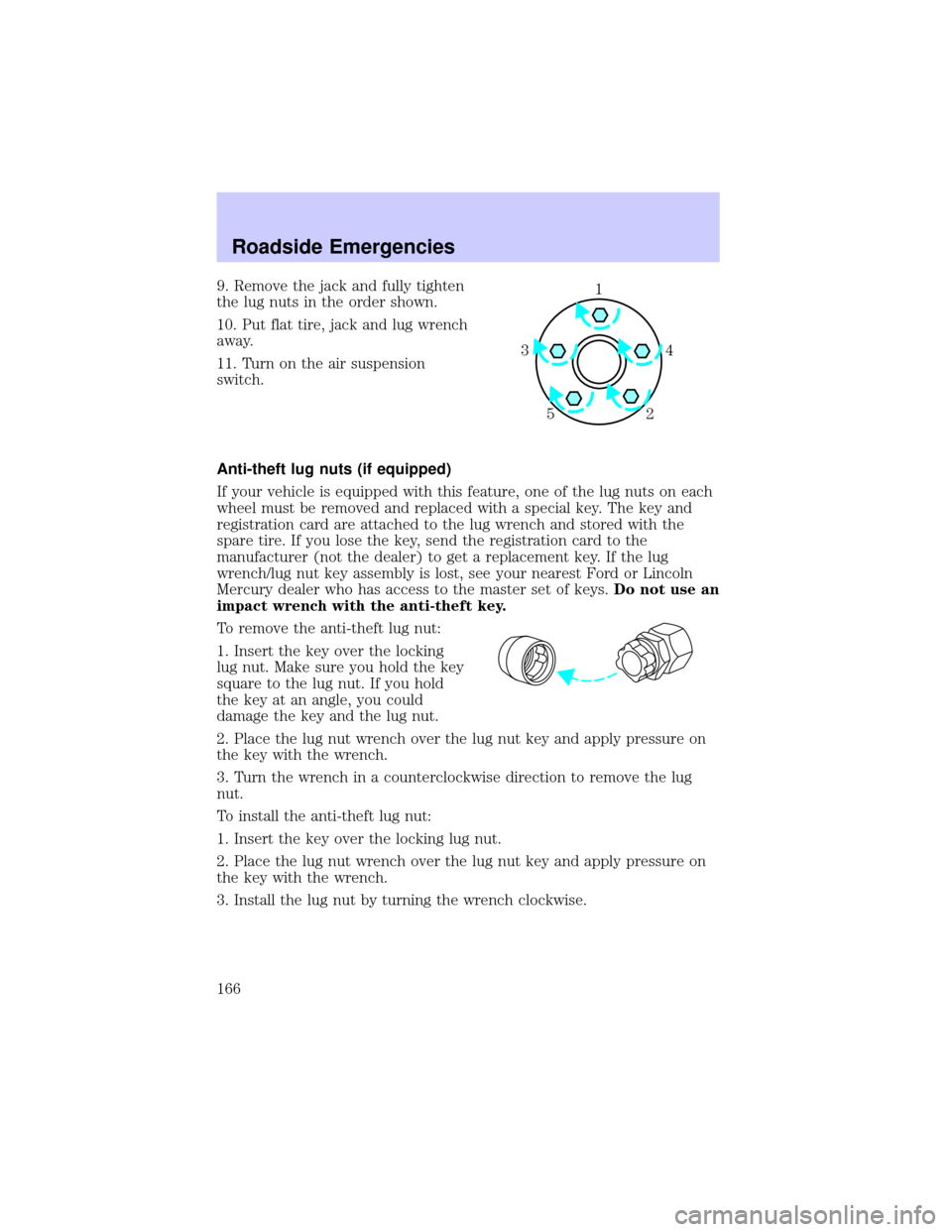

9. Remove the jack and fully tighten

the lug nuts in the order shown.

10. Put flat tire, jack and lug wrench

away.

11. Turn on the air suspension

switch.

Anti-theft lug nuts (if equipped)

If your vehicle is equipped with this feature, one of the lug nuts on each

wheel must be removed and replaced with a special key. The key and

registration card are attached to the lug wrench and stored with the

spare tire. If you lose the key, send the registration card to the

manufacturer (not the dealer) to get a replacement key. If the lug

wrench/lug nut key assembly is lost, see your nearest Ford or Lincoln

Mercury dealer who has access to the master set of keys.Do not use an

impact wrench with the anti-theft key.

To remove the anti-theft lug nut:

1. Insert the key over the locking

lug nut. Make sure you hold the key

square to the lug nut. If you hold

the key at an angle, you could

damage the key and the lug nut.

2. Place the lug nut wrench over the lug nut key and apply pressure on

the key with the wrench.

3. Turn the wrench in a counterclockwise direction to remove the lug

nut.

To install the anti-theft lug nut:

1. Insert the key over the locking lug nut.

2. Place the lug nut wrench over the lug nut key and apply pressure on

the key with the wrench.

3. Install the lug nut by turning the wrench clockwise.1

4 3

2 5

Roadside Emergencies

166

Page 186 of 240

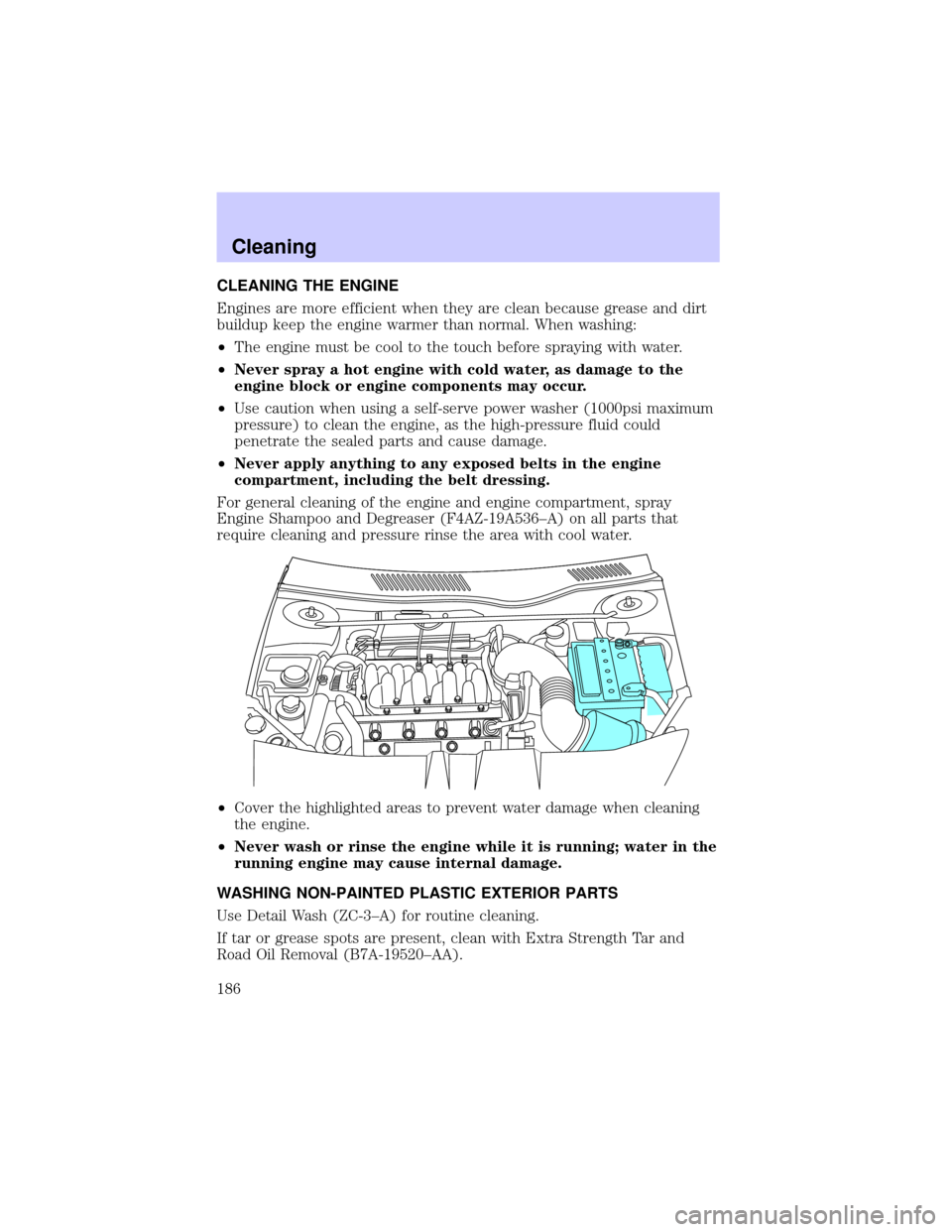

CLEANING THE ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

²The engine must be cool to the touch before spraying with water.

²Never spray a hot engine with cold water, as damage to the

engine block or engine components may occur.

²Use caution when using a self-serve power washer (1000psi maximum

pressure) to clean the engine, as the high-pressure fluid could

penetrate the sealed parts and cause damage.

²Never apply anything to any exposed belts in the engine

compartment, including the belt dressing.

For general cleaning of the engine and engine compartment, spray

Engine Shampoo and Degreaser (F4AZ-19A536±A) on all parts that

require cleaning and pressure rinse the area with cool water.

²Cover the highlighted areas to prevent water damage when cleaning

the engine.

²Never wash or rinse the engine while it is running; water in the

running engine may cause internal damage.

WASHING NON-PAINTED PLASTIC EXTERIOR PARTS

Use Detail Wash (ZC-3±A) for routine cleaning.

If tar or grease spots are present, clean with Extra Strength Tar and

Road Oil Removal (B7A-19520±AA).

Cleaning

186

Page 192 of 240

Working with the engine off

1. Set the parking brake, and ensure the gearshift is securely latched in

(P) park.

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Note:Do not start your engine with the air cleaner removed and do not

remove it while the engine is running.

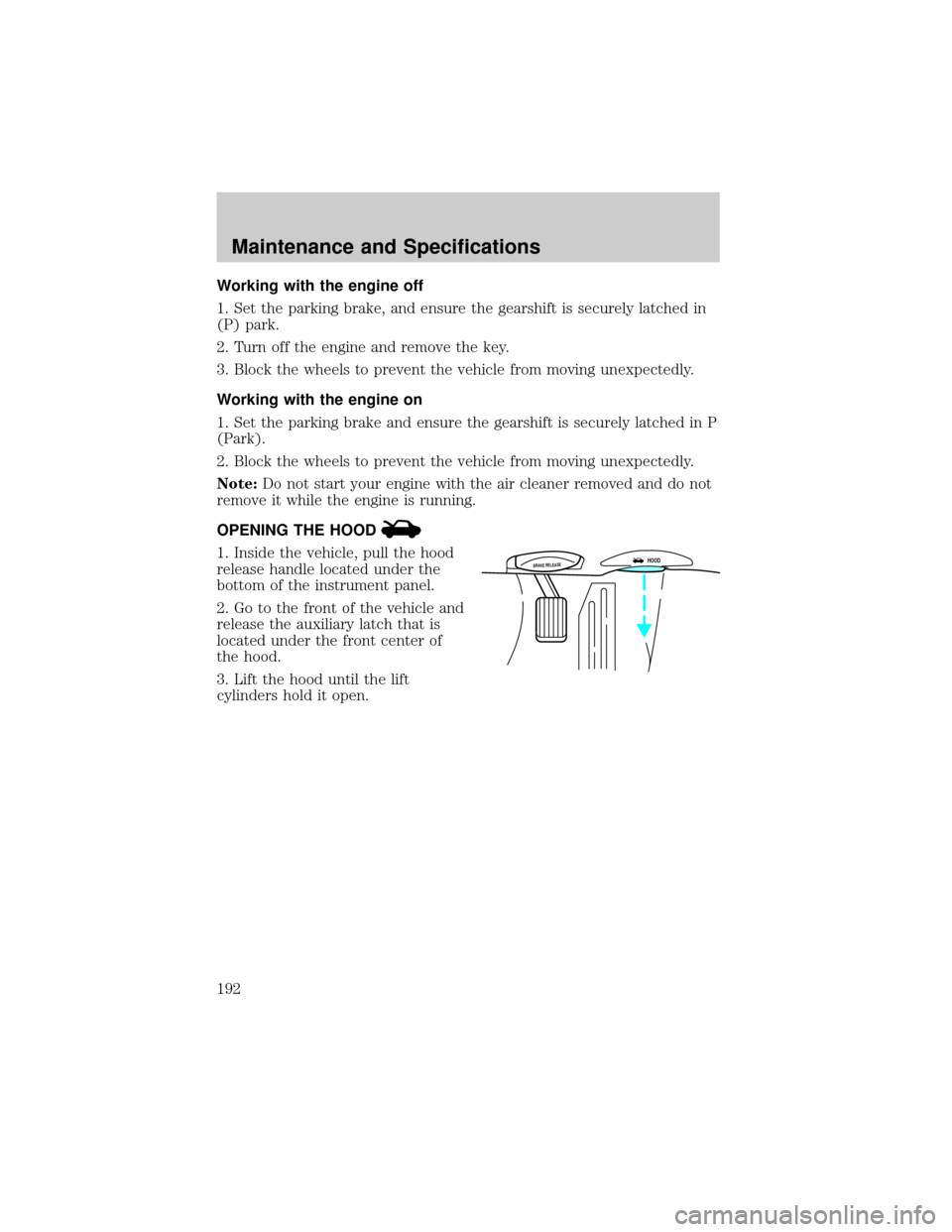

OPENING THE HOOD

1. Inside the vehicle, pull the hood

release handle located under the

bottom of the instrument panel.

2. Go to the front of the vehicle and

release the auxiliary latch that is

located under the front center of

the hood.

3. Lift the hood until the lift

cylinders hold it open.BRAKE RELEASEHOOD

Maintenance and Specifications

192

Page 196 of 240

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until three clicks are heard or until the cap is fully seated.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Engine oil and filter recommendations

Look for this certification

trademark.

SAE 5W-20 engine oil is recommended.

Only use oils ªCertified For Gasoline Enginesº by the American

Petroleum Institute (API). Use Motorcraft or an equivalent oil meeting

Ford specification WSS-M2C153±H.SAE 5W-20 oil provides optimum

fuel economy and durability performance meeting all

requirements for your vehicle's engine.

Do not use supplemental engine oil additives, oil treatments or engine

treatments. They are unnecessary and could, under certain conditions,

lead to engine damage which is not covered by your warranty.

Change your engine oil and filter according to the appropriate schedule

listed in the scheduled maintenance guide.

Ford production and aftermarket (Motorcraft) oil filters are designed for

added engine protection and long life. If a replacement oil filter is used

that does not meet Ford material and design specifications, start-up

engine noises or knock may be experienced.

It is recommended you use the appropriate Motorcraft oil filter (or

another brand meeting Ford specifications) for your engine application.

Maintenance and Specifications

196

Page 199 of 240

²The vehicle may need to be driven 16 km (10 miles) or more to

relearn the idle and fuel trim strategy.

²If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

If the battery has been disconnected or a new battery has been installed,

the clock must be reset once the battery is reconnected.

²Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

mileage intervals listed in the scheduled maintenance guide. The coolant

concentration should be maintained at 50/50 coolant and water, which

equates to a freeze point of -36É C (-34É F). Coolant concentration

testing is possible with a hydrometer or antifreeze tester (such as the

Rotunda Battery and Antifreeze Tester, 014±R1060). The level of coolant

should be maintained at the ªcold fullº of ªcold fill rangeº level in the

coolant reservoir. If the level falls below, add coolant per the instructions

in theAdding Engine Coolantsection.

Your vehicle was factory-filled with a 50/50 engine coolant and water

concentration. If the concentration of coolant falls below 40% or above

60%, the engine parts could become damaged or not work properly.A

50±50 mixture of coolant and water provides the following:

²Freeze protection down to -36É C (-34É F).

²Boiling protection up to 129É C (265É F).

²Protection against rust and other forms of corrosion.

²Enables calibrated gauges to work properly.

LEAD

RETURN

RECYCLE

Maintenance and Specifications

199