Boost LINCOLN MKC 2016 User Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2016, Model line: MKC, Model: LINCOLN MKC 2016Pages: 432, PDF Size: 4.89 MB

Page 52 of 432

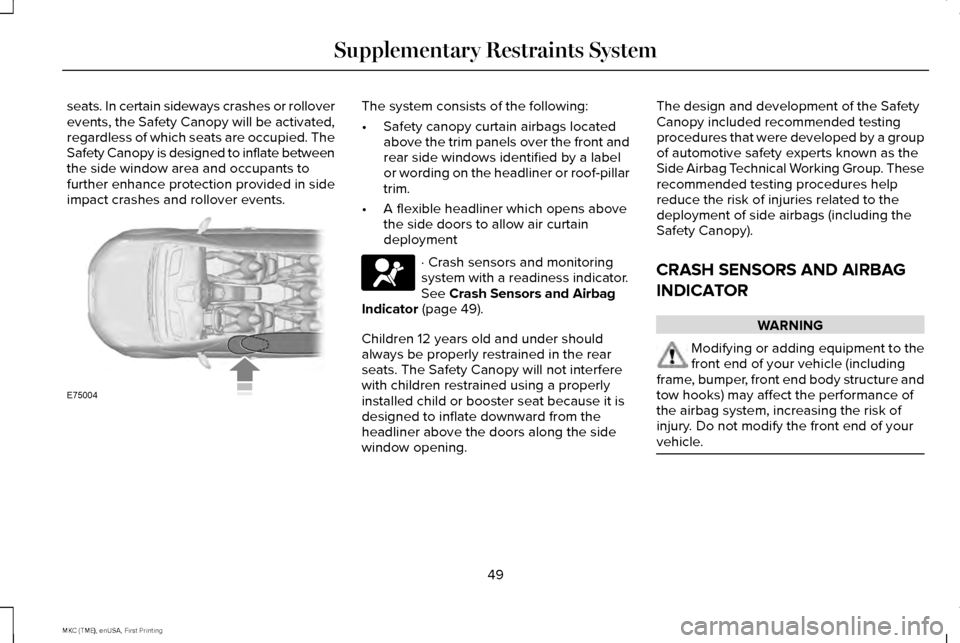

seats. In certain sideways crashes or rollover

events, the Safety Canopy will be activated,

regardless of which seats are occupied. The

Safety Canopy is designed to inflate between

the side window area and occupants to

further enhance protection provided in side

impact crashes and rollover events. The system consists of the following:

•

Safety canopy curtain airbags located

above the trim panels over the front and

rear side windows identified by a label

or wording on the headliner or roof-pillar

trim.

• A flexible headliner which opens above

the side doors to allow air curtain

deployment · Crash sensors and monitoring

system with a readiness indicator.

See Crash Sensors and Airbag

Indicator (page 49).

Children 12 years old and under should

always be properly restrained in the rear

seats. The Safety Canopy will not interfere

with children restrained using a properly

installed child or booster seat because it is

designed to inflate downward from the

headliner above the doors along the side

window opening. The design and development of the Safety

Canopy included recommended testing

procedures that were developed by a group

of automotive safety experts known as the

Side Airbag Technical Working Group. These

recommended testing procedures help

reduce the risk of injuries related to the

deployment of side airbags (including the

Safety Canopy).

CRASH SENSORS AND AIRBAG

INDICATOR

WARNING

Modifying or adding equipment to the

front end of your vehicle (including

frame, bumper, front end body structure and

tow hooks) may affect the performance of

the airbag system, increasing the risk of

injury. Do not modify the front end of your

vehicle. 49

MKC (TME), enUSA, First Printing Supplementary Restraints SystemE75004

Page 167 of 432

•

Fuels can also be harmful if absorbed

through the skin. If fuel is splashed on

the skin, clothing or both, promptly

remove contaminated clothing and wash

skin thoroughly with soap and water.

Repeated or prolonged skin contact with

fuel liquid or vapor causes skin irritation.

• Be particularly careful if you are taking

“Antabuse ” or other forms of disulfiram

for the treatment of alcoholism. Breathing

gasoline vapors, or skin contact could

cause an adverse reaction. In sensitive

individuals, serious personal injury or

sickness may result. If fuel is splashed on

the skin, promptly wash skin thoroughly

with soap and water. Consult a physician

immediately if you experience an adverse

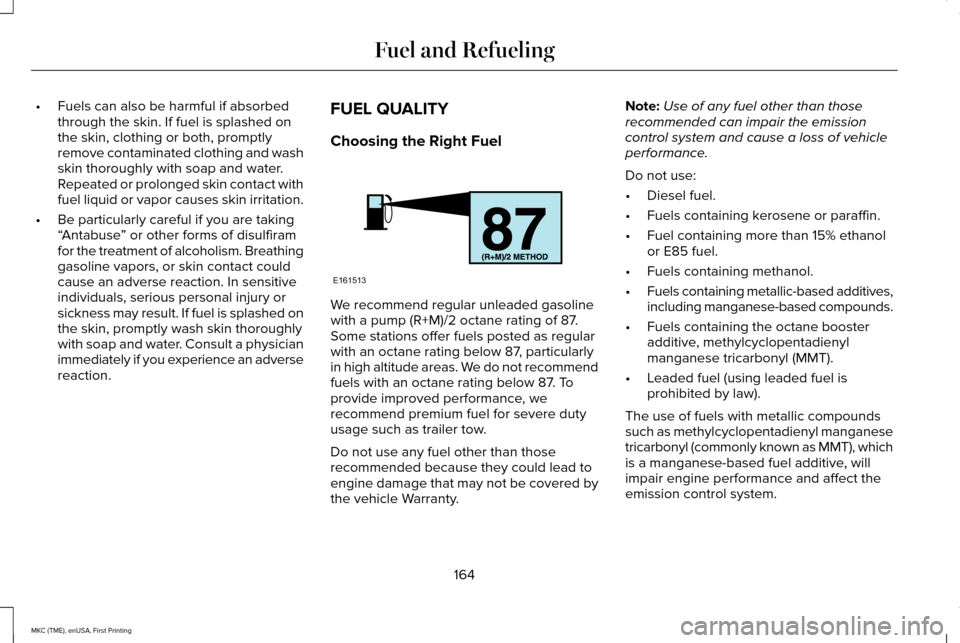

reaction. FUEL QUALITY

Choosing the Right Fuel We recommend regular unleaded gasoline

with a pump (R+M)/2 octane rating of 87.

Some stations offer fuels posted as regular

with an octane rating below 87, particularly

in high altitude areas. We do not recommend

fuels with an octane rating below 87. To

provide improved performance, we

recommend premium fuel for severe duty

usage such as trailer tow.

Do not use any fuel other than those

recommended because they could lead to

engine damage that may not be covered by

the vehicle Warranty.Note:

Use of any fuel other than those

recommended can impair the emission

control system and cause a loss of vehicle

performance.

Do not use:

• Diesel fuel.

• Fuels containing kerosene or paraffin.

• Fuel containing more than 15% ethanol

or E85 fuel.

• Fuels containing methanol.

• Fuels containing metallic-based additives,

including manganese-based compounds.

• Fuels containing the octane booster

additive, methylcyclopentadienyl

manganese tricarbonyl (MMT).

• Leaded fuel (using leaded fuel is

prohibited by law).

The use of fuels with metallic compounds

such as methylcyclopentadienyl manganese

tricarbonyl (commonly known as MMT), which

is a manganese-based fuel additive, will

impair engine performance and affect the

emission control system.

164

MKC (TME), enUSA, First Printing Fuel and RefuelingE161513

Page 189 of 432

1.

Pull the switch and hold it in this position.

2. Drive your vehicle, then release the switch when you notice that the engine

has developed sufficient driving force.

Automatic release - drive away release

Your vehicle will automatically release the

parking brake if all of the following conditions

exist:

• The driver door is closed.

• The vehicle is accelerated.

• There are no faults detected in the

parking brake system.

Note: The driver door must be closed and

the driver safety belt must be fastened

before this feature will operate.

Note: If the electric parking brake warning

lamp stays illuminated, the electric parking

brake will not automatically release. You

must release the electric parking brake using

the electric parking brake switch.

Note: The engine must be running and the

accelerator pedal must be pressed before

the drive away release feature will operate. The brake system warning lamp will go off

to confirm that the electric parking brake has

been released.

Note:

The electric parking brake drive away

release makes starting on a hill easier. This

feature will release the parking brake

automatically when the vehicle has sufficient

drive force to move up the hill. To assure

drive away release when starting uphill,

press the accelerator pedal quickly.

Battery With No Charge WARNING

You will not be able to apply or release

the electric parking brake if the battery

is low or has no charge. If the battery is low or has no charge, use

jumper cables and a booster battery.HILL START ASSIST WARNINGS

The system does not replace the

parking brake. When you leave your

vehicle, always apply the parking brake and

shift the transmission into park (P) (automatic

transmission) or first gear (1) (manual

transmission). You must remain in your vehicle once

you have activated the system.

During all times, you are responsible

for controlling your vehicle, supervising

the system and intervening, if required. If the engine is revved excessively, or

if a malfunction is detected, the system

will be deactivated. The system makes it easier to pull away

when your vehicle is on a slope without the

need to use the parking brake.

186

MKC (TME), enUSA, First Printing Brakes

Page 257 of 432

Should your vehicle shut off after a collision,

you may restart your vehicle. For vehicles

equipped with a key system:

1. Switch off the ignition.

2. Switch on the ignition.

3. Repeat Steps 1 and 2 to re-enable the

fuel pump.

For vehicles equipped with a push button

start system:

1. Press the START/STOP button to switch

off the ignition.

2. Press the brake pedal and press the START/STOP button to switch on the

ignition.

3. Remove your foot from the brake pedal and press the

START/STOP button to

switch off the ignition.

4. You can either attempt to start the engine

by pressing the brake pedal and the

START/STOP

button, or switch on the

ignition only by pressing the

START/STOP

button without pressing

the brake pedal. Both ways re-enable the

fuel system. Note:

When you try to restart your vehicle

after a fuel shutoff, the vehicle makes sure

that various systems are safe to restart.

Once your vehicle determines that the

systems are safe, then the vehicle will allow

you to restart.

Note: In the event that your vehicle does not

restart after your third attempt, contact an

authorized dealer.

JUMP STARTING THE VEHICLE WARNINGS

The gases around the battery can

explode if exposed to flames, sparks,

or lit cigarettes. An explosion could result in

personal injury or vehicle damage. Batteries contain sulfuric acid which

can burn skin, eyes and clothing, if

contacted. Use only an adequate-sized cable with

insulated clamps. Preparing Your Vehicle

Note:

Do not attempt to push-start your

automatic transmission vehicle. Automatic

transmissions do not have push-start

capability. Attempting to push-start a vehicle

with an automatic transmission may cause

transmission damage.

Note: Use only a 12-volt supply to start your

vehicle.

Note: Do not disconnect the battery of the

disabled vehicle as this could damage the

vehicle's electrical system.

Park the booster vehicle close to the hood

of the disabled vehicle, making sure the two

vehicles do not touch. Turn all accessories

off.

254

MKC (TME), enUSA, First Printing Roadside Emergencies

Page 258 of 432

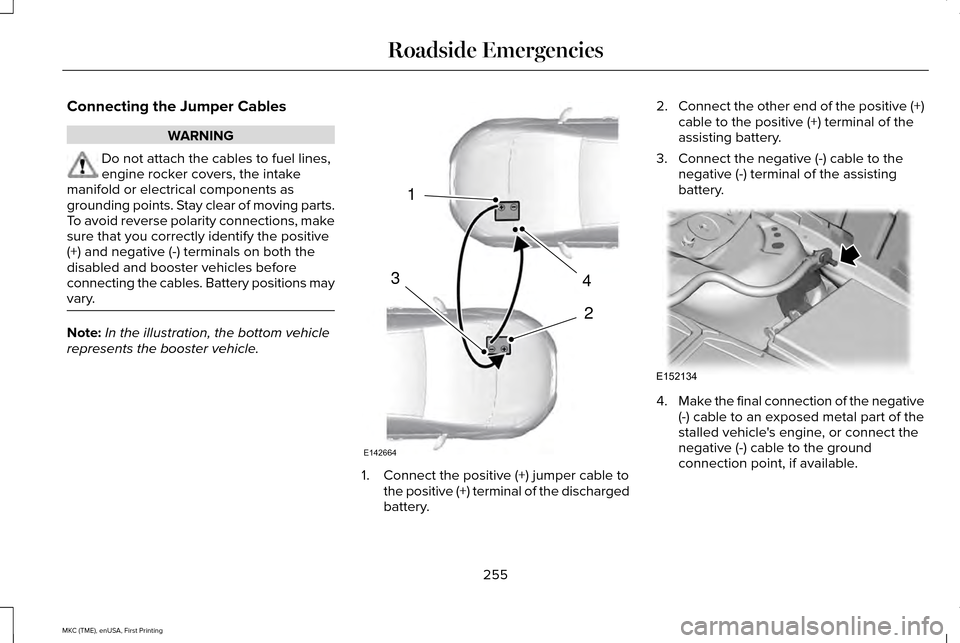

Connecting the Jumper Cables

WARNING

Do not attach the cables to fuel lines,

engine rocker covers, the intake

manifold or electrical components as

grounding points. Stay clear of moving parts.

To avoid reverse polarity connections, make

sure that you correctly identify the positive

(+) and negative (-) terminals on both the

disabled and booster vehicles before

connecting the cables. Battery positions may

vary. Note:

In the illustration, the bottom vehicle

represents the booster vehicle. 1. Connect the positive (+) jumper cable to

the positive (+) terminal of the discharged

battery. 2.

Connect the other end of the positive (+)

cable to the positive (+) terminal of the

assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the assisting

battery. 4.

Make the final connection of the negative

(-) cable to an exposed metal part of the

stalled vehicle's engine, or connect the

negative (-) cable to the ground

connection point, if available.

255

MKC (TME), enUSA, First Printing Roadside Emergencies4

2

1

3

E142664 E152134

Page 259 of 432

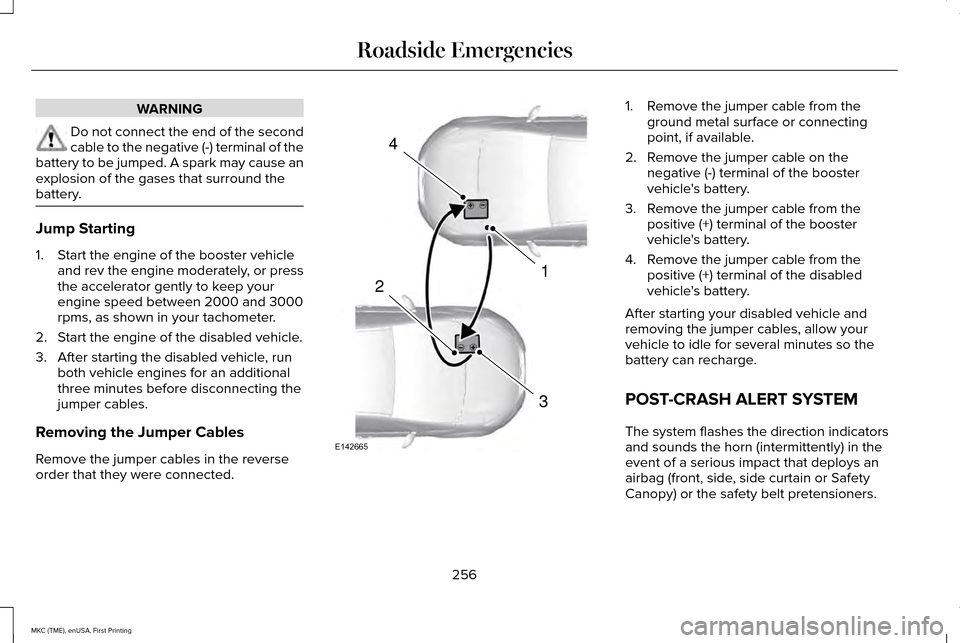

WARNING

Do not connect the end of the second

cable to the negative (-) terminal of the

battery to be jumped. A spark may cause an

explosion of the gases that surround the

battery. Jump Starting

1. Start the engine of the booster vehicle

and rev the engine moderately, or press

the accelerator gently to keep your

engine speed between 2000 and 3000

rpms, as shown in your tachometer.

2. Start the engine of the disabled vehicle.

3. After starting the disabled vehicle, run both vehicle engines for an additional

three minutes before disconnecting the

jumper cables.

Removing the Jumper Cables

Remove the jumper cables in the reverse

order that they were connected. 1. Remove the jumper cable from the

ground metal surface or connecting

point, if available.

2. Remove the jumper cable on the negative (-) terminal of the booster

vehicle's battery.

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle's battery.

4. Remove the jumper cable from the positive (+) terminal of the disabled

vehicle's battery.

After starting your disabled vehicle and

removing the jumper cables, allow your

vehicle to idle for several minutes so the

battery can recharge.

POST-CRASH ALERT SYSTEM

The system flashes the direction indicators

and sounds the horn (intermittently) in the

event of a serious impact that deploys an

airbag (front, side, side curtain or Safety

Canopy) or the safety belt pretensioners.

256

MKC (TME), enUSA, First Printing Roadside Emergencies4

1

3

2

E142665

Page 287 of 432

UNDER HOOD OVERVIEW - 2.0L ECOBOOST™

284

MKC (TME), enUSA, First Printing MaintenanceABCDEF

GHE171684

Page 289 of 432

UNDER HOOD OVERVIEW - 2.3L ECOBOOST™

286

MKC (TME), enUSA, First Printing MaintenanceABCDEF

GHE171685

Page 305 of 432

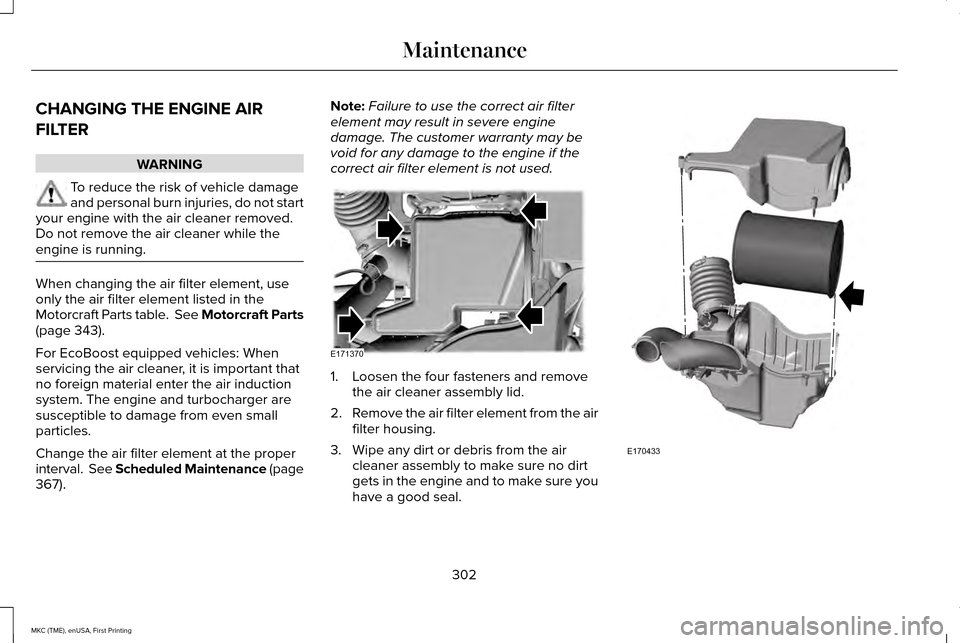

CHANGING THE ENGINE AIR

FILTER

WARNING

To reduce the risk of vehicle damage

and personal burn injuries, do not start

your engine with the air cleaner removed.

Do not remove the air cleaner while the

engine is running. When changing the air filter element, use

only the air filter element listed in the

Motorcraft Parts table. See Motorcraft Parts

(page 343).

For EcoBoost equipped vehicles: When

servicing the air cleaner, it is important that

no foreign material enter the air induction

system. The engine and turbocharger are

susceptible to damage from even small

particles.

Change the air filter element at the proper

interval. See Scheduled Maintenance (page

367

). Note:

Failure to use the correct air filter

element may result in severe engine

damage. The customer warranty may be

void for any damage to the engine if the

correct air filter element is not used. 1. Loosen the four fasteners and remove

the air cleaner assembly lid.

2. Remove the air filter element from the air

filter housing.

3. Wipe any dirt or debris from the air cleaner assembly to make sure no dirt

gets in the engine and to make sure you

have a good seal. 302

MKC (TME), enUSA, First Printing MaintenanceE171370 E170433

Page 345 of 432

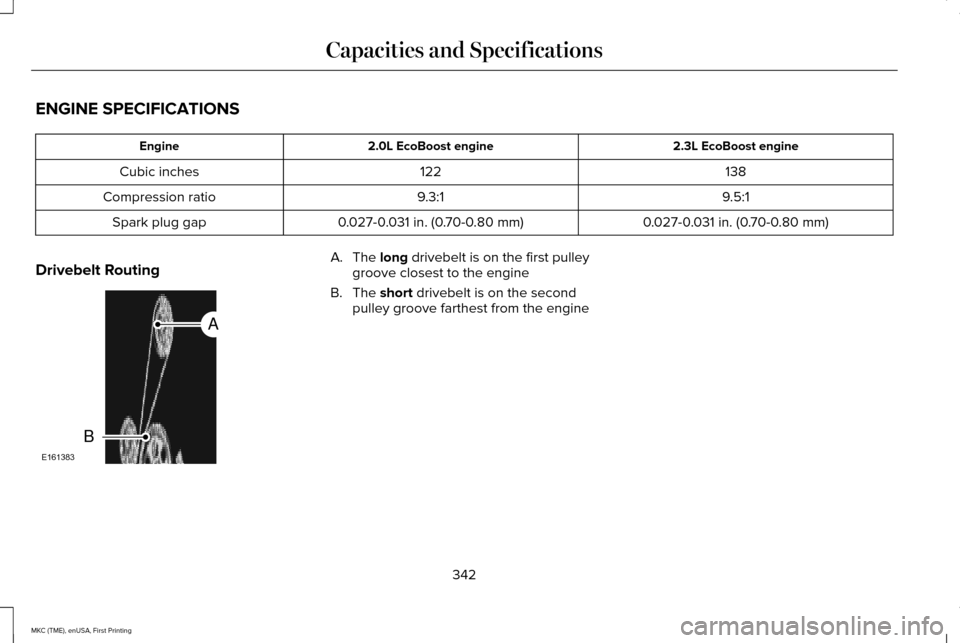

ENGINE SPECIFICATIONS

2.3L EcoBoost engine

2.0L EcoBoost engine

Engine

138

122

Cubic inches

9.5:1

9.3:1

Compression ratio

0.027-0.031 in. (0.70-0.80 mm)

0.027-0.031 in. (0.70-0.80 mm)

Spark plug gap

Drivebelt Routing A. The long drivebelt is on the first pulley

groove closest to the engine

B. The

short drivebelt is on the second

pulley groove farthest from the engine

342

MKC (TME), enUSA, First Printing Capacities and SpecificationsE161383

A

B