Seat LINCOLN MKZ 2016 Manual PDF

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2016, Model line: MKZ, Model: LINCOLN MKZ 2016Pages: 544, PDF Size: 5.77 MB

Page 282 of 544

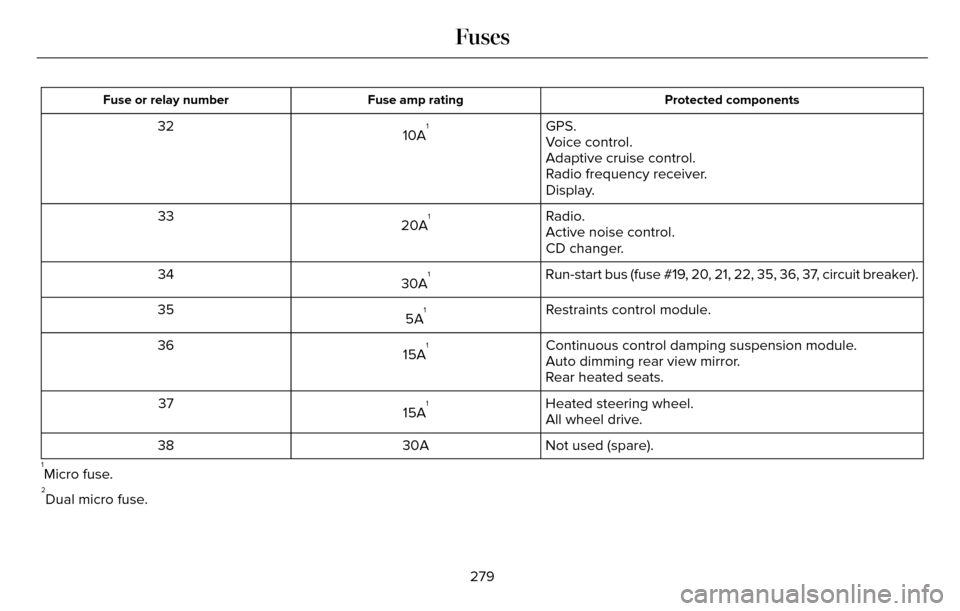

Protected components

Fuse amp rating

Fuse or relay number

GPS.

10A132

Voice control.

Adaptive cruise control.

Radio frequency receiver.

Display.

Radio.

20A

133

Active noise control.

CD changer.

Run-start bus (fuse #19, 20, 21, 22, 35, 36, 37, circuit breaker).

30A

134

Restraints control module.

5A

135

Continuous control damping suspension module.

15A

136

Auto dimming rear view mirror.

Rear heated seats.

Heated steering wheel.

15A

137

All wheel drive.

Not used (spare).

30A

38

1Micro fuse.2Dual micro fuse.

279

Fuses

Page 296 of 544

Refer to your scheduled maintenance

information for scheduled intervals for fluid

checks and changes. Your transmission does

not consume fluid. However, the fluid level

should be checked if the transmission is not

working properly. For example, if the

transmission slips or shifts slowly or if you

notice some sign of fluid leakage.

1. Drive the vehicle 20 miles (30 kilometers)or until it reaches normal operating

temperature

2. Park the vehicle on a level surface and engage the parking brake.

3. With the parking brake engaged and your foot on the brake pedal, start the engine

and move the gearshift lever through all

of the gear ranges. Allow a minimum of

10 seconds for each gear to engage.

4. Put the gearshift lever in P (Park) and leave the engine running.

Note: You will need to move the air filter

assembly to access the transmission

dipstick. 5. Remove the dipstick, wiping it clean with

a clean, dry lint free rag. If necessary,

refer to Under hood overview in this

chapter for the location of the dipstick.

6. Install the dipstick making sure it is fully seated in the filler tube by turning it to

the locked position.

7. Remove the dipstick and inspect the fluid level. The fluid should be in the

designated areas for normal operating

temperature.

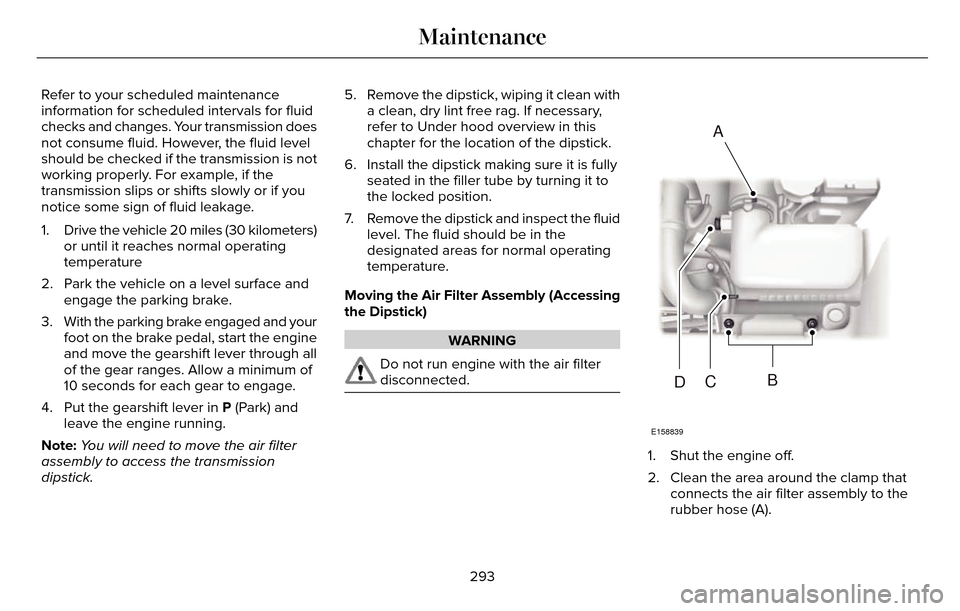

Moving the Air Filter Assembly (Accessing

the Dipstick)

WARNING

Do not run engine with the air filter

disconnected.

E158839

A

BCD

1. Shut the engine off.

2. Clean the area around the clamp that connects the air filter assembly to the

rubber hose (A).

293

Maintenance

Page 297 of 544

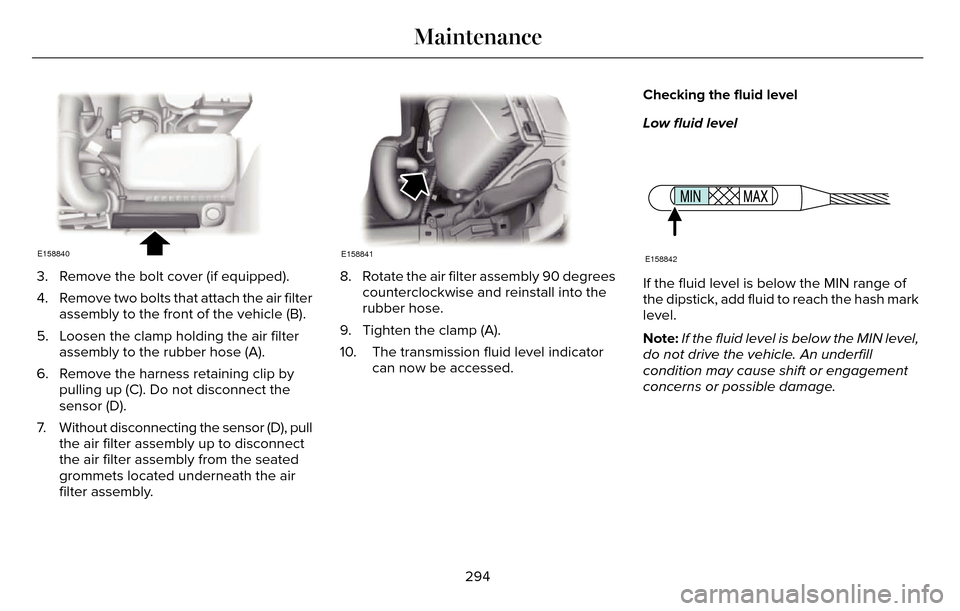

E158840

3. Remove the bolt cover (if equipped).

4. Remove two bolts that attach the air filterassembly to the front of the vehicle (B).

5. Loosen the clamp holding the air filter assembly to the rubber hose (A).

6. Remove the harness retaining clip by pulling up (C). Do not disconnect the

sensor (D).

7. Without disconnecting the sensor (D), pull the air filter assembly up to disconnect

the air filter assembly from the seated

grommets located underneath the air

filter assembly.

E158841

8. Rotate the air filter assembly 90 degreescounterclockwise and reinstall into the

rubber hose.

9. Tighten the clamp (A).

10. The transmission fluid level indicator can now be accessed. Checking the fluid level

Low fluid level

E158842

If the fluid level is below the MIN range of

the dipstick, add fluid to reach the hash mark

level.

Note:

If the fluid level is below the MIN level,

do not drive the vehicle. An underfill

condition may cause shift or engagement

concerns or possible damage.

294

Maintenance

Page 299 of 544

Do not use supplemental transmission fluid

additives, treatments or cleaning agents. The

use of these materials may affect

transmission operation and result in damage

to internal transmission components.

Reinstall the air filter assembly. After the fluid

level has been checked and adjusted as

necessary, do the following:

1. Shut the engine off.

2. Loosen the clamp holding the air filterassembly to the rubber hose.

3. Rotate the air filter assembly 90 degrees clockwise without disconnecting the

sensor.

4. Seat the air filter assembly back into the grommets by pushing down on the air

filter assembly.

5. Tighten the clamp.

6. Install and tighten two bolts that attach air filter assembly to the front of the

vehicle.

7. Install the bolt cover (if equipped).

8. Reinstall the harness retaining clip into the front of the air filter assembly.BRAKE FLUID CHECK

Fluid levels between the MIN and MAX lines

are within the normal operating range; there

is no need to add fluid. If the fluid levels are

outside of the normal operating range, the

performance of the system could be

compromised; seek service from your

authorized dealer immediately.

WASHER FLUID CHECK

WARNING

If you operate your vehicle in

temperatures below 40°F (5°C), use

washer fluid with antifreeze protection.

Failure to use washer fluid with antifreeze

protection in cold weather could result in

impaired windshield vision and increase the

risk of injury or accident.

Note: The front and rear washer systems

are supplied from the same reservoir. Add fluid to fill the reservoir if the level is low.

Only use a washer fluid that meets Ford

specifications. See Capacities and

Specifications (page 353).

State or local regulations on volatile organic

compounds may restrict the use of methanol,

a common windshield washer antifreeze

additive. Washer fluids containing

non-methanol antifreeze agents should be

used only if they provide cold weather

protection without damaging the vehicle’s

paint finish, wiper blades or washer system.

FUEL FILTER

Your vehicle is equipped with a lifetime fuel

filter that is integrated with the fuel tank.

Regular maintenance or replacement is not

needed.

296

Maintenance

Page 307 of 544

5. Install a new air filter element. Be carefulnot to crimp the filter element edges

between the air filter housing and cover.

This could cause filter damage and allow

unfiltered air to enter the engine if not

properly seated.

6. Install the air filter housing cover.

7. Engage the clamps to secure the air filter housing cover to the air filter housing.

304

Maintenance

Page 311 of 544

CLEANING THE INTERIOR

WARNINGS

Do not use cleaning solvents, bleach

or dye on the vehicle’s safety belts, as

these actions may weaken the belt webbing.

On vehicles equipped with

seat-mounted airbags, do not use

chemical solvents or strong detergents. Such

products could contaminate the side airbag

system and affect performance of the side

airbag in a collision.

Note: Follow the same procedure for

cleaning leather seats when cleaning leather

interior. See Cleaning Leather Seats (page

311). Note:

Do not use household cleaning

products or glass cleaners, which can stain

and discolor the fabric and affect the flame

retardant abilities of the seat materials.

For fabric, carpets, cloth seats, safety belts

and seats equipped with side airbags:

• Remove dust and loose dirt with a vacuum cleaner.

• Remove light stains and soil with Motorcraft Professional Strength Carpet

& Upholstery Cleaner.

For grease or tar stains:

• Spot clean the area with Motorcraft Spot and Stain Remover (Motorcraft

Multi-Purpose Cleaner in Canada).

• If a ring forms on the fabric after spot cleaning, clean the entire area

immediately (but do not oversaturate) or

the ring will set.

Cleaning Black Label Interior (If

Equipped)

Note: Alcantara microfiber cloth fabric is

made of polyester microfiber with

micro-porous polyurethane. Using

commercially available fabric cleaners can

cause permanent damage.

Note: Do not use commercially available

leather and vinyl cleaning products on

Alcantara microfiber cloth fabric.

Note: Lincoln Black Label vehicles may have

Alcantara microfiber cloth fabric on the

seats, headliner, floor mats and door panels.

Depending on the type of stain, use water,

lemon juice or pure ethyl alcohol when

cleaning. For cleaning Alcantara microfiber

cloth, refer to the following chart:

308

Vehicle Care

Page 313 of 544

CLEANING THE INSTRUMENT

PANEL AND INSTRUMENT

CLUSTER LENS

WARNING

Do not use chemical solvents or strong

detergents when cleaning the steering

wheel or instrument panel to avoid

contamination of the airbag system.

Note: Follow the same procedure as

cleaning leather seats for cleaning leather

instrument panels and leather interior trim

surfaces. See Cleaning Leather Seats (page

311).

Clean the instrument panel and cluster lens

with a clean, damp and soft cloth, then use

a clean, dry and soft cloth to dry these areas. • Avoid cleaners or polishes that increase

the gloss of the upper portion of the

instrument panel. The dull finish in this

area helps protect you from undesirable

windshield reflection.

• Do not use any household cleaning products or glass cleaners as these may

damage the finish of the instrument

panel, interior trim and cluster lens.

• Wash or wipe your hands clean if you have been in contact with certain

products such as insect repellent and

suntan lotion to avoid possible damage

to the interior painted surfaces.

• Do not allow air fresheners and hand sanitizers to spill onto interior surfaces.

If a spill occurs, wipe off immediately.

Your warranty may not cover these

damages.

If a staining liquid like coffee or juice has

been spilled on the instrument panel or on

interior trim surfaces:

1. Wipe up spilled liquid using a clean, soft cloth as quickly as possible. 2. Use Motorcraft Premium Leather and

Vinyl Cleaner or a commercially available

leather cleaning product for automotive

interiors. Test any cleaner or stain

remover on an inconspicuous area.

3. Alternatively, wipe the surface with a clean, soft cloth and a mild soap and

water solution. Dry the area with a clean,

soft cloth.

4. If necessary, apply more soap and water solution or cleaning product to a clean,

soft cloth and press it onto the soiled

area. Allow this to set at room

temperature for 30 minutes.

5. Remove the soaked cloth, then with a clean, damp cloth, use a rubbing motion

for 60 seconds on the soiled area.

6. Dry the area with a clean, soft cloth.

310

Vehicle Care

Page 314 of 544

CLEANING LEATHER SEATS (If

Equipped)

Note: Follow the same procedure as

cleaning leather seats for cleaning leather

instrument panels and leather interior trim

surfaces.

For routine cleaning, wipe the surface with

a soft, damp cloth and a mild soap and water

solution. Dry the area with a clean, soft cloth.

For cleaning and removing stains such as

dye transfer, use Motorcraft Premium Leather

and Vinyl Cleaner or a commercially available

leather cleaning product for automotive

interiors.

Note: Test any cleaner or stain remover on

an inconspicuous area.

You should:

• Remove dust and loose dirt with a vacuum cleaner.

• Clean and treat spills and stains as soon as possible. Do not use the following products as these

may damage the leather:

• Oil and petroleum or silicone-based

leather conditioners.

• Household cleaners.

• Alcohol solutions.

• Solvents or cleaners intended specifically for rubber, vinyl and plastics.

REPAIRING MINOR PAINT

DAMAGE

Authorized dealers have touch-up paint to

match your vehicle’s color. Your vehicle color

code is printed on a sticker on the front,

left-hand side door jamb. Take your color

code to your authorized dealer to make sure

you get the correct color.

Before repairing minor paint damage, use a

cleaner such as Motorcraft Bug and Tar

Remover to remove particles such as bird

droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout.

Always read the instructions before using

cleaning products.

CLEANING THE ALLOY WHEELS

Note: Do not apply a cleaning chemical to

warm or hot wheel rims and covers.

Note: Some automatic car washes may

cause damage to the finish on your wheel

rims and covers.

Note: Industrial-strength or heavy-duty

cleaners in combination with brush agitation

to remove brake dust and dirt, could wear

away the clear coat finish over a period time.

Note: Do not use hydrofluoric acid-based or

high caustic-based wheel cleaners, steel

wool, fuels or strong household detergents.

Note: If you intend parking your vehicle for

an extended period after cleaning the

wheels with a wheel cleaner, drive your

vehicle for a few minutes before doing so.

This will reduce the risk of increased

corrosion of the brake discs.

Alloy wheels and wheel covers are coated

with a clear coat paint finish. To maintain

their condition we recommend that you:

311

Vehicle Care

Page 322 of 544

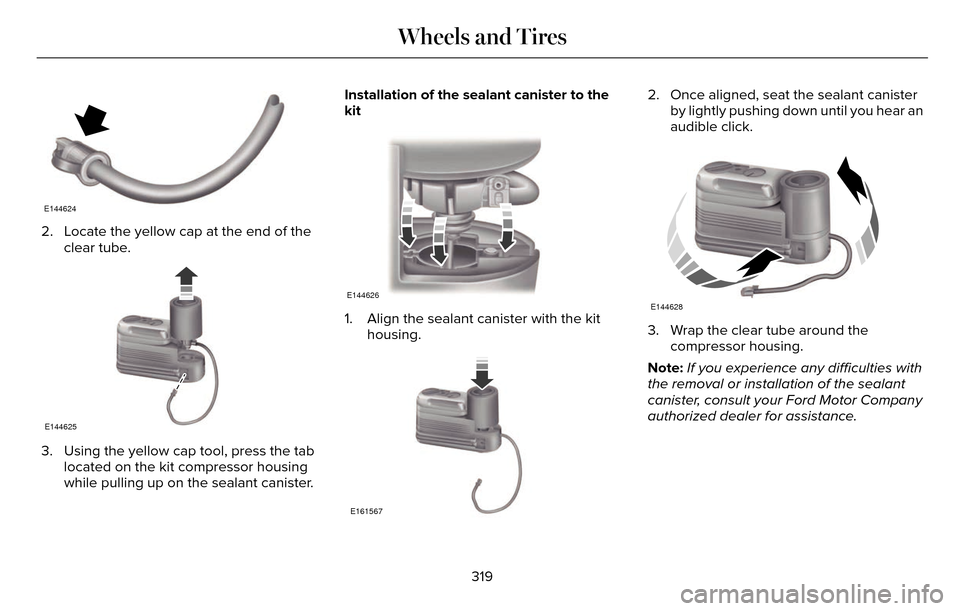

E144624

2. Locate the yellow cap at the end of theclear tube.

E144625

3. Using the yellow cap tool, press the tablocated on the kit compressor housing

while pulling up on the sealant canister. Installation of the sealant canister to the

kit

E144626

1. Align the sealant canister with the kit

housing.

E161567

2. Once aligned, seat the sealant canisterby lightly pushing down until you hear an

audible click.

E144628

3. Wrap the clear tube around thecompressor housing.

Note: If you experience any difficulties with

the removal or installation of the sealant

canister, consult your Ford Motor Company

authorized dealer for assistance.

319

Wheels and Tires

Page 329 of 544

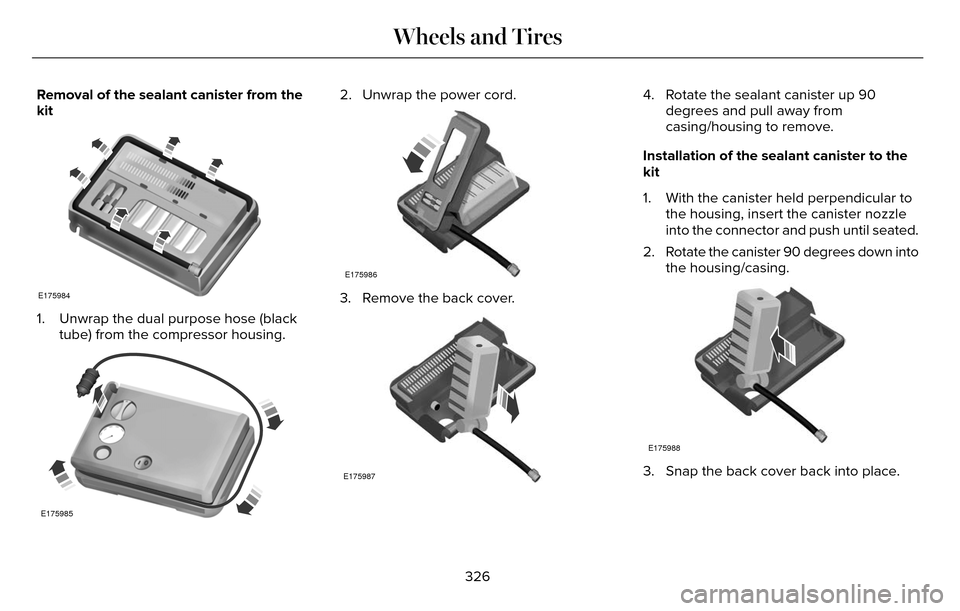

Removal of the sealant canister from the

kit

E175984

1. Unwrap the dual purpose hose (blacktube) from the compressor housing.

E175985

2. Unwrap the power cord.

E175986

3. Remove the back cover.

E175987

4. Rotate the sealant canister up 90degrees and pull away from

casing/housing to remove.

Installation of the sealant canister to the

kit

1. With the canister held perpendicular to the housing, insert the canister nozzle

into the connector and push until seated.

2. Rotate the canister 90 degrees down into the housing/casing.

E175988

3. Snap the back cover back into place.

326

Wheels and Tires