Specifications LINCOLN MKZ 2017 User Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2017, Model line: MKZ, Model: LINCOLN MKZ 2017Pages: 564, PDF Size: 5.54 MB

Page 314 of 564

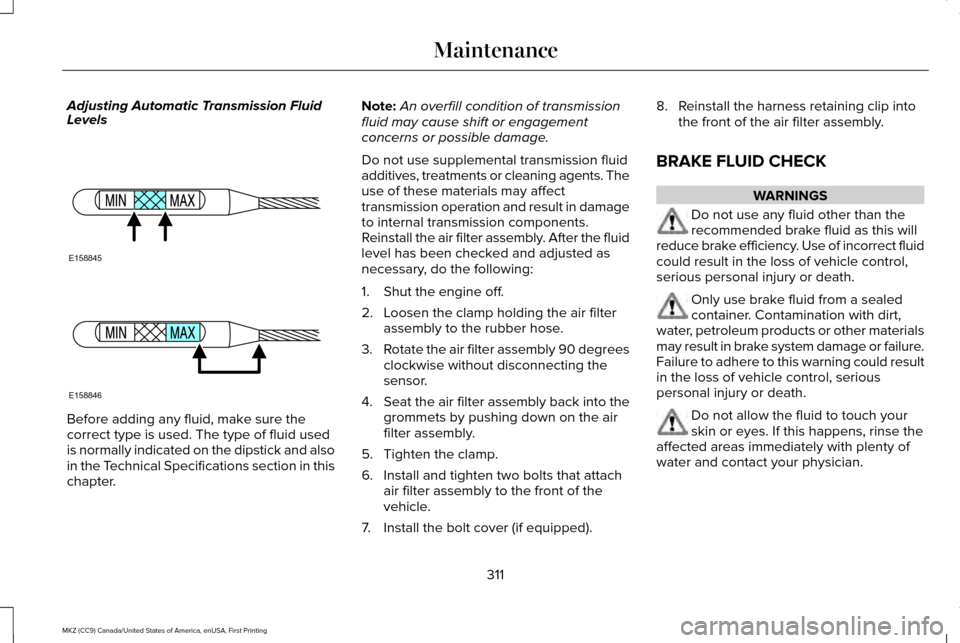

Adjusting Automatic Transmission Fluid

Levels

Before adding any fluid, make sure the

correct type is used. The type of fluid used

is normally indicated on the dipstick and also

in the Technical Specifications section in this

chapter. Note:

An overfill condition of transmission

fluid may cause shift or engagement

concerns or possible damage.

Do not use supplemental transmission fluid

additives, treatments or cleaning agents. The

use of these materials may affect

transmission operation and result in damage

to internal transmission components.

Reinstall the air filter assembly. After the fluid

level has been checked and adjusted as

necessary, do the following:

1. Shut the engine off.

2. Loosen the clamp holding the air filter assembly to the rubber hose.

3. Rotate the air filter assembly 90 degrees

clockwise without disconnecting the

sensor.

4. Seat the air filter assembly back into the

grommets by pushing down on the air

filter assembly.

5. Tighten the clamp.

6. Install and tighten two bolts that attach air filter assembly to the front of the

vehicle.

7. Install the bolt cover (if equipped). 8. Reinstall the harness retaining clip into

the front of the air filter assembly.

BRAKE FLUID CHECK WARNINGS

Do not use any fluid other than the

recommended brake fluid as this will

reduce brake efficiency. Use of incorrect fluid

could result in the loss of vehicle control,

serious personal injury or death. Only use brake fluid from a sealed

container. Contamination with dirt,

water, petroleum products or other materials

may result in brake system damage or failure.

Failure to adhere to this warning could result

in the loss of vehicle control, serious

personal injury or death. Do not allow the fluid to touch your

skin or eyes. If this happens, rinse the

affected areas immediately with plenty of

water and contact your physician.

311

MKZ (CC9) Canada/United States of America, enUSA, First Printing MaintenanceE158845 E158846

Page 315 of 564

WARNINGS

A fluid level between the MAX and

MIN lines is within the normal

operating range and there is no need to add

fluid. A fluid level not in the normal operating

range could compromise the performance

of the system. Have your vehicle checked

immediately. To avoid fluid contamination, the reservoir

cap must remain in place and fully tight,

unless you are adding fluid.

Only use fluid that meets Ford specifications.

See

Capacities and Specifications (page

367).

WASHER FLUID CHECK WARNING

If you operate your vehicle in

temperatures below 40°F (5°C), use

washer fluid with antifreeze protection.

Failure to use washer fluid with antifreeze

protection in cold weather could result in

impaired windshield vision and increase the

risk of injury or accident. Note:

The front and rear washer systems

are supplied from the same reservoir.

Add fluid to fill the reservoir if the level is low.

Only use a washer fluid that meets Ford

specifications.

See Capacities and

Specifications (page 367).

State or local regulations on volatile organic

compounds may restrict the use of methanol,

a common windshield washer antifreeze

additive. Washer fluids containing

non-methanol antifreeze agents should be

used only if they provide cold weather

protection without damaging the vehicle ’s

paint finish, wiper blades or washer system.

FUEL FILTER

Your vehicle is equipped with a lifetime fuel

filter that is integrated with the fuel tank.

Regular maintenance or replacement is not

needed. CHANGING THE 12V BATTERY WARNINGS

Batteries normally produce explosive

gases which can cause personal injury.

Therefore, do not allow flames, sparks or

lighted substances to come near the battery.

When working near the battery, always shield

your face and protect your eyes. Always

provide correct ventilation. When lifting a plastic-cased battery,

excessive pressure on the end walls

could cause acid to flow through the vent

caps, resulting in personal injury and damage

to the vehicle or battery. Lift the battery with

a battery carrier or with your hands on

opposite corners.

312

MKZ (CC9) Canada/United States of America, enUSA, First Printing Maintenance

Page 322 of 564

CHANGING THE ENGINE AIR

FILTER

WARNING

Do not start the engine with the air filter

removed. This can cause damage not

covered by the vehicle Warranty and can

result in serious injury. Only use the specified replacement air filter.

See Capacities and Specifications (page

367).

Change the air filter element at the correct

interval. See Scheduled Maintenance (page

495

).

When changing the engine air filter, do not

allow debris or foreign material to enter the

air induction system. The engine and

turbocharger are susceptible to damage from

even small particles. Note:

Failure to use the correct air filter

element may result in severe engine

damage. Resulting component damage may

not be covered by the vehicle Warranty. 1. Release the clamps that secure the air

filter cover to the housing.

2. Carefully lift the air filter housing cover.

3. Remove the air filter element from the air

filter housing.

4. Wipe any dirt or debris from the air filter housing and cover to make sure no dirt

gets in the engine and that you have a

good seal. 5.

Install a new air filter element. Be careful

not to crimp the filter element edges

between the air filter housing and cover.

This could cause filter damage and allow

unfiltered air to enter the engine if it is

not properly seated.

6. Install the air filter housing cover.

7. Engage the clips to secure the air filter housing cover to the air filter housing.

319

MKZ (CC9) Canada/United States of America, enUSA, First Printing MaintenanceE146427

Page 365 of 564

16. Remove the jack and fully tighten the

lug nuts in the order shown. See Technical Specifications (page 365).17.

To store the folded wrench on the jack,

engage the bracket of the jack base on

the wrench feature as shown. Swing

the wrench upward and adjust the

height of the jack until the pin engages

the hole. Tighten the hex nut clockwise

by hand until secure. 18. Put the flat tire, jack and lug wrench

away. Make sure the jack is fastened

securely before you drive.

19. Unblock the wheel.

362

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and TiresE176165

Page 368 of 564

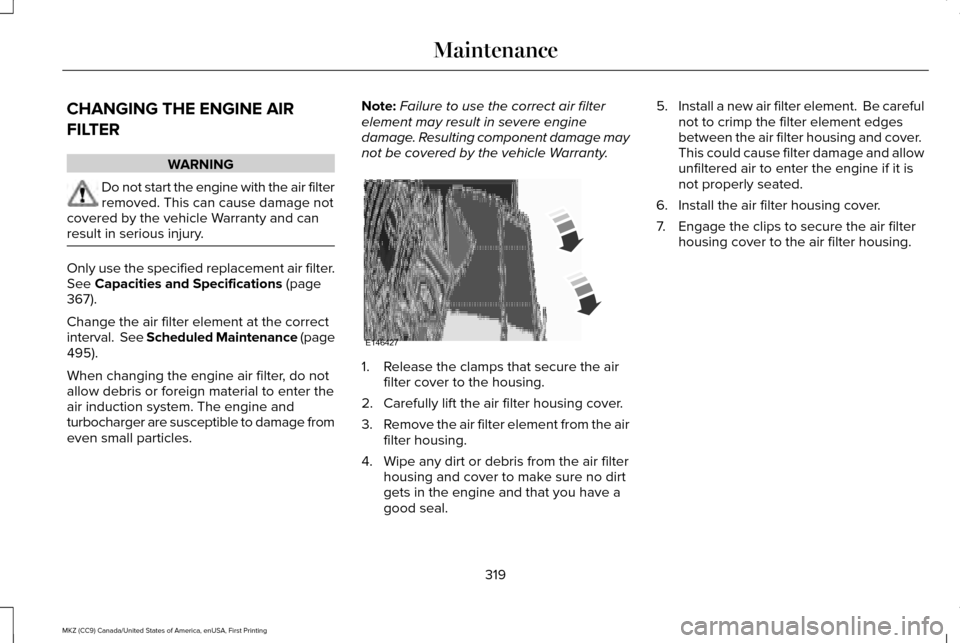

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign \

materials present on the mounting surfaces of the wheel or the

surface of the wheel hub, brake drum or brake disc that contacts the wheel. Make sure that any fasteners that attach the rotor to the

hub are secured so they do not interfere with the mounting surfaces of t\

he wheel. Installing wheels without correct metal-to-metal contact at

the wheel mounting surfaces can cause the wheel nuts to loosen and the w\

heel to come off while your vehicle is in motion, resulting in loss

of control. lb.ft (Nm)

Bolt size

150 lb.ft (204 Nm)

M14 x 1.5

* Torque specifications are for nut and bolt threads free of dirt and rust.\

Use only Ford recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kil\

ometers) after any wheel disturbance (such as tire rotation, changing \

a

flat tire, wheel removal).

365

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 369 of 564

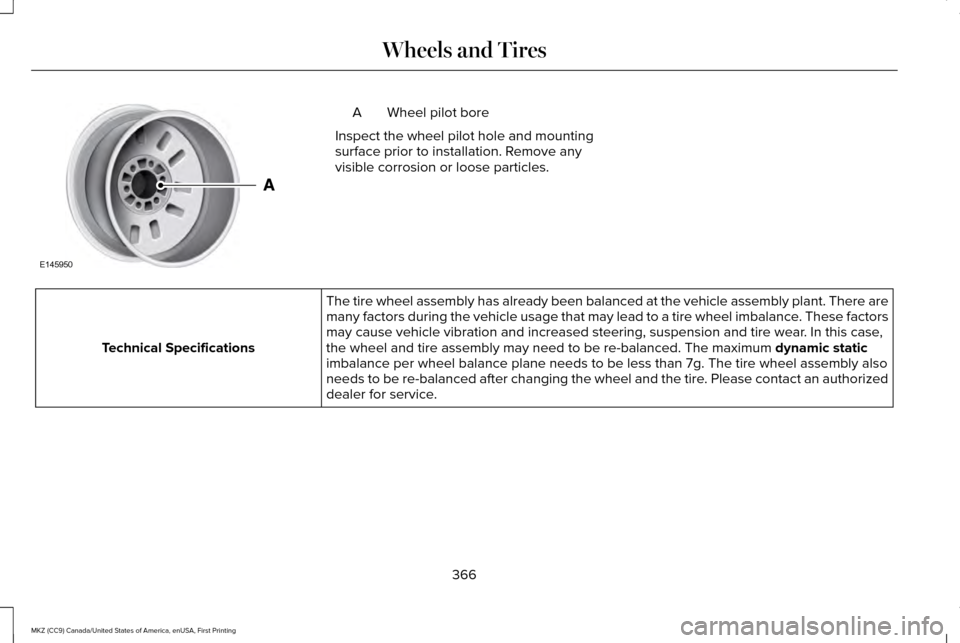

Wheel pilot bore

A

Inspect the wheel pilot hole and mounting

surface prior to installation. Remove any

visible corrosion or loose particles. The tire wheel assembly has already been balanced at the vehicle assembl\

y plant. There are

many factors during the vehicle usage that may lead to a tire wheel imba\

lance. These factors

may cause vehicle vibration and increased steering, suspension and tire \

wear. In this case,

the wheel and tire assembly may need to be re-balanced. The maximum dynamic static

imbalance per wheel balance plane needs to be less than 7g. The tire whe\

el assembly also

needs to be re-balanced after changing the wheel and the tire. Please contact an authorized

dealer for service.

Technical Specifications

366

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and TiresE145950

Page 370 of 564

ENGINE SPECIFICATIONS - 2.0L

2.0L engine

Engine

122

Cubic inches

1-3-4-2

Firing order

Coil on plug

Ignition system

9.3:1

Compression ratio

0.027-0.031 in. (0.70-0.80 mm)

Spark plug gap

367

MKZ (CC9) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 371 of 564

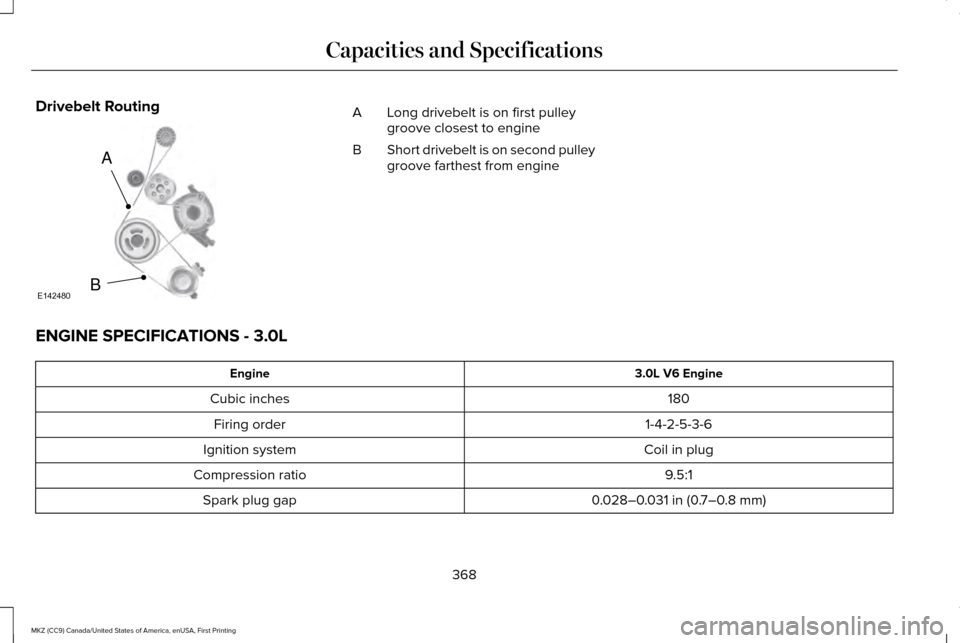

Drivebelt Routing

Long drivebelt is on first pulley

groove closest to engine

A

Short drivebelt is on second pulley

groove farthest from engine

B

ENGINE SPECIFICATIONS - 3.0L 3.0L V6 Engine

Engine

180

Cubic inches

1-4-2-5-3-6

Firing order

Coil in plug

Ignition system

9.5:1

Compression ratio

0.028–0.031 in (0.7–0.8 mm)

Spark plug gap

368

MKZ (CC9) Canada/United States of America, enUSA, First Printing Capacities and SpecificationsA

BE142480

Page 372 of 564

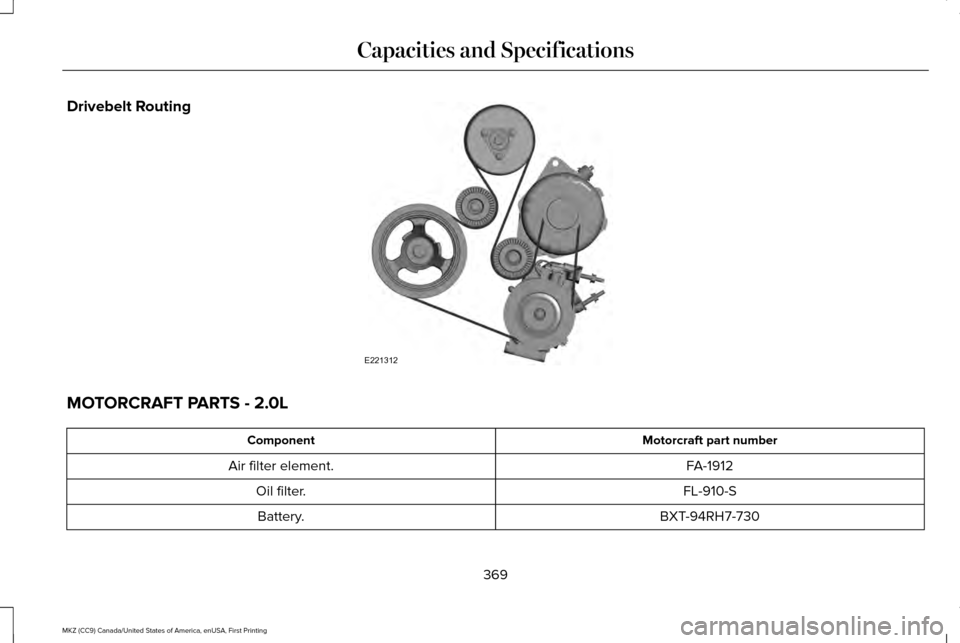

Drivebelt Routing

MOTORCRAFT PARTS - 2.0L

Motorcraft part number

Component

FA-1912

Air filter element.

FL-910-S

Oil filter.

BXT-94RH7-730

Battery.

369

MKZ (CC9) Canada/United States of America, enUSA, First Printing Capacities and SpecificationsE221312

Page 373 of 564

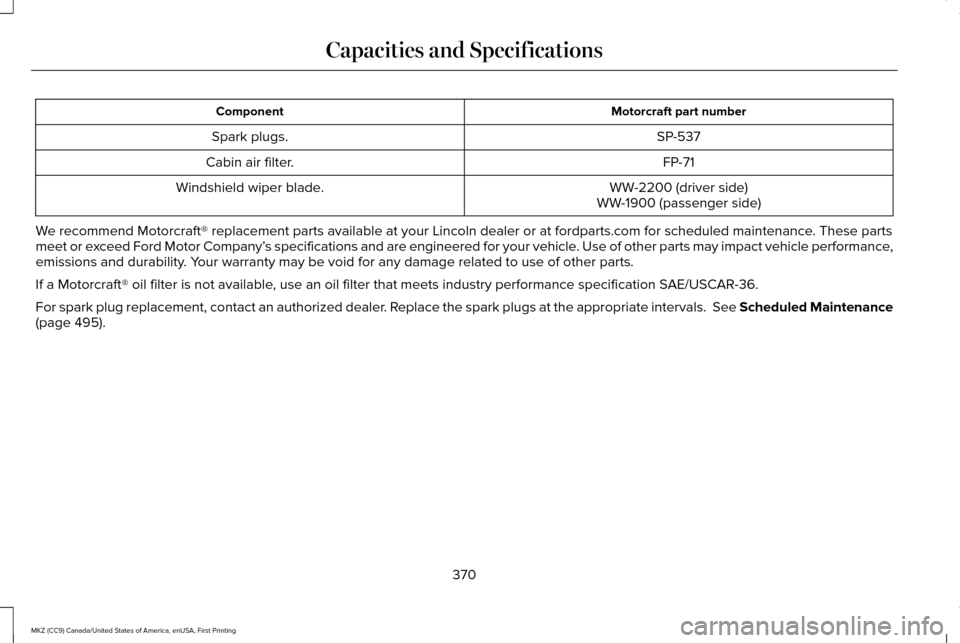

Motorcraft part number

Component

SP-537

Spark plugs.

FP-71

Cabin air filter.

WW-2200 (driver side)

Windshield wiper blade.

WW-1900 (passenger side)

We recommend Motorcraft® replacement parts available at your Lincoln d\

ealer or at fordparts.com for scheduled maintenance. These parts

meet or exceed Ford Motor Company’ s specifications and are engineered for your vehicle. Use of other parts may impact vehicle performance,

emissions and durability. Your warranty may be void for any damage related to use of other parts.

If a Motorcraft® oil filter is not available, use an oil filter that meets industry performance specification SAE/USCAR-36.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the appropriate intervals. See Scheduled Maintenance

(page 495).

370

MKZ (CC9) Canada/United States of America, enUSA, First Printing Capacities and Specifications