Remove tire LINCOLN NAVIGATOR 2017 User Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2017, Model line: NAVIGATOR, Model: LINCOLN NAVIGATOR 2017Pages: 532, PDF Size: 3.9 MB

Page 315 of 532

Sometimes irregular tire wear can be

corrected by rotating the tires.

USING SNOW CHAINS WARNING

Snow tires must be the same size, load

index and speed rating as those

originally provided by Ford. Use of any tire

or wheel not recommended by Ford can

affect the safety and performance of your

vehicle, which could result in an increased

risk of loss of control, vehicle rollover,

personal injury and death. Additionally, the

use of non-recommended tires and wheels

can cause steering, suspension, axle, transfer

case or power transfer unit failure. Follow

the Ford recommended tire inflation pressure

found on the Safety Compliance Certification

Label (on the door hinge pillar, door latch

post or the door edge that meets the door

latch post, next to the driver seat), or Tire

Label on the B-Pillar or the edge of the driver

door. Failure to follow the tire pressure

recommendations can cause uneven

treadwear patterns and adversely affect the

way your vehicle handles. Note:

The suspension insulation and

bumpers will help prevent vehicle damage.

Do not remove these components from your

vehicle when using snow tires and chains.

The tires on your vehicle have all-weather

treads to provide traction in rain and snow.

However, in some climates, you may need

to use snow tires and cables. If you need to

use cables, it is recommended that steel

wheels (of the same size and specifications)

be used, as cables may chip aluminum

wheels.

Follow these guidelines when using snow

tires and chains:

• If possible, avoid fully loading your

vehicle.

• Use only cable type chains or chains

offered by Ford/Lincoln as an accessory

or equivalent. Other conventional link

type chains may contact and cause

damage to the vehicle's wheel house

and/or body.

• Do not install chains on the front tires as

this may interfere with suspension

components.

312

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and TiresE142548

Page 316 of 532

•

Only certain snow cables or chains have

been approved by Ford/Lincoln as safe

for use on your vehicle with the following

tires: 265/70R17 and 275/65R18.

• You should install snow cables or chains

that have been rated as SAE Class S.

• Install chains securely, verifying that the

chains do not touch any wiring, brake

lines, or fuel lines.

• Do not exceed 31 mph (50 km/h) or less

if recommended by the chain

manufacturer while using snow chains.

• Drive cautiously. If you hear the chains

rub or bang against your vehicle, stop

and retighten the chains. If this does not

work, remove the chains to prevent

damage to your vehicle.

• Remove the tire chains when they are no

longer needed. Do not use tire chains on

dry roads.

• Purchase chains or cables from a

manufacturer that clearly labels body to

tire dimension restrictions. The snow

chains or cables must be mounted in

pairs on the rear tires only. If you have any questions regarding snow

chains or cables, please contact your

authorized dealer.

TIRE PRESSURE MONITORING

SYSTEM

WARNING

The tire pressure monitoring system is

not a substitute for manually checking

tire pressures. You should periodically check

tire pressures using a pressure gauge.

Failure to correctly maintain tire pressures

could increase the risk of tire failure, loss of

control, vehicle rollover and personal injury. Each tire, including the spare (if

provided), should be checked

monthly when cold and inflated to

the inflation pressure recommended by the

vehicle manufacturer on the vehicle placard

or tire inflation pressure label. (If your vehicle

has tires of a different size than the size

indicated on the vehicle placard or tire

inflation pressure label, you should

determine the proper tire inflation pressure

for those tires.)

As an added safety feature, your vehicle has

been equipped with a Tire Pressure

Monitoring System (TPMS) that illuminates a

low tire pressure telltale when one or more

of your tires is significantly under-inflated.

Accordingly, when the low tire pressure

telltale illuminates, you should stop and

check your tires as soon as possible, and

inflate them to the proper pressure. Driving

on a significantly under-inflated tire causes

the tire to overheat and can lead to tire

failure. Under-inflation also reduces fuel

efficiency and tire tread life, and may affect

the vehicle ’s handling and stopping ability.

313

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 317 of 532

Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the

driver’

s responsibility to maintain correct tire

pressure, even if under-inflation has not

reached the level to trigger illumination of

the TPMS low tire pressure telltale.

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate when

the system is not operating properly. The

TPMS malfunction indicator is combined with

the low tire pressure telltale. When the

system detects a malfunction, the telltale will

flash for approximately one minute and then

remain continuously illuminated. This

sequence will continue upon subsequent

vehicle start-ups as long as the malfunction

exists.

When the malfunction indicator is illuminated,

the system may not be able to detect or

signal low tire pressure as intended. TPMS

malfunctions may occur for a variety of

reasons, including the installation of

replacement or alternate tires or wheels on

the vehicle that prevent the TPMS from functioning properly. Always check the TPMS

malfunction telltale after replacing one or

more tires or wheels on your vehicle to

ensure that the replacement or alternate tires

and wheels allow the TPMS to continue to

function properly.

The tire pressure monitoring system

complies with part 15 of the FCC rules and

with RSS-210 of Industry Canada. Operation

is subject to the following two conditions: (1)

This device may not cause harmful

interference, and (2) This device must accept

any interference received, including

interference that may cause undesired

operation.

This device complies with part 15 of the FCC

Rules and with Licence exempt RSS

Standards of Industry Canada. Operation is

subject to the following two conditions:

•

This device may not cause harmful

interference.

• This device must accept any interference

received, including interference that may

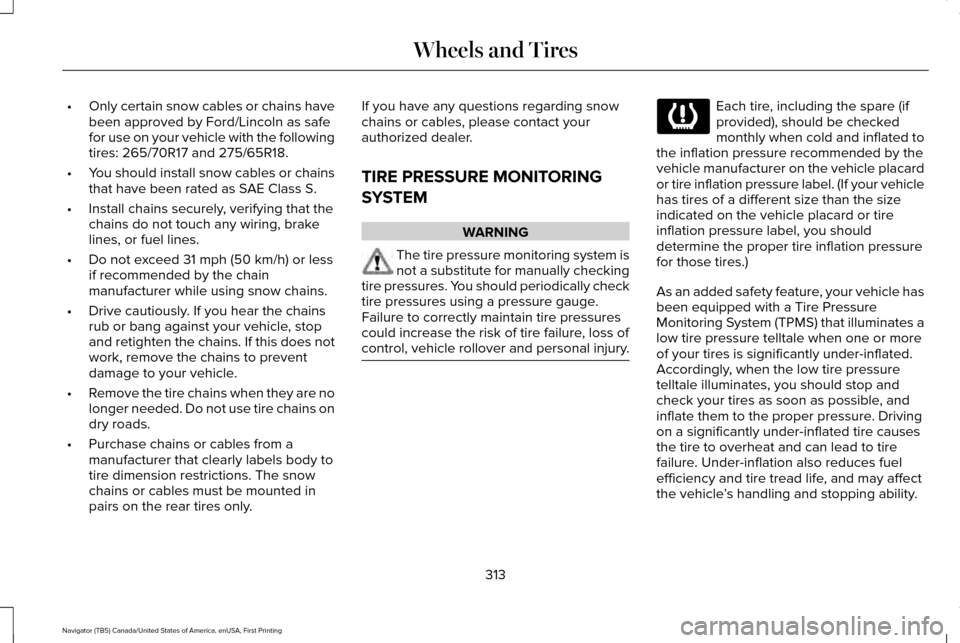

cause undesired operation. Changing Tires With a Tire Pressure

Monitoring System

Note:

Each road tire is equipped with a tire

pressure sensor located inside the wheel

and tire assembly cavity. The pressure

sensor is attached to the valve stem. The

pressure sensor is covered by the tire and

is not visible unless the tire is removed. Take

care when changing the tire to avoid

damaging the sensor.

You should always have your tires serviced

by an authorized dealer.

314

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and TiresE142549

Page 322 of 532

4.

Turn the hazard flashers on then off three

times. You must accomplish this within

10 seconds. If the reset mode has been

entered successfully, the horn will sound

once, the system indicator will flash and

a message is shown in the information

display. If this does not occur, please try

again starting at Step 2. If after repeated

attempts to enter the reset mode, the

horn does not sound, the system

indicator does not flash and no message

is shown in the information display, seek

service from your authorized dealer.

5. Train the tire pressure monitoring system

sensors in the tires using the following

system reset sequence starting with the

left front tire in the following clockwise

order: Left front (driver's side front tire),

Right front (passenger's side front tire),

Right rear (passenger's side rear tire), Left

rear (driver's side rear tire).

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds. Note:

The single horn chirp confirms that the

sensor identification code has been learned

by the module for this position. If a double

horn is heard, the reset procedure was

unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease the

air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained (driver's

side rear tire), the system indicator stops

flashing, and a message is shown in the

information display.

10. Turn the ignition off. If two short horn beeps are heard, the reset procedure

was unsuccessful and you must repeat

it. If after repeating the procedure and

two short beeps are heard when the

ignition is turned to off, seek assistance

from your authorized dealer. 11. Set all four tires to the recommended

air pressure as indicated on the Safety

Compliance Certification Label (affixed

to either the door hinge pillar,

door-latch post, or the door edge that

meets the door-latch post, next to the

driver's seating position) or Tire Label

located on the B-Pillar or the edge of

the driver's door.

CHANGING A ROAD WHEEL WARNINGS

The use of tire sealant may damage

your tire pressure monitoring system

and should only be used in roadside

emergencies. If you must use a sealant, the

Ford Tire Mobility Kit sealant should be used.

The tire pressure monitoring system sensor

and valve stem on the wheel must be

replaced by an authorized dealer after use

of the sealant. If the tire pressure monitor sensor

becomes damaged, it will no longer

function. See Tire Pressure Monitoring

System (page 313). 319

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 325 of 532

Tire Change Procedure

WARNINGS

When one of the front wheels is off the

ground, the transmission alone will not

prevent the vehicle from moving or slipping

off the jack. To help prevent the vehicle from

moving when you change a tire, be

sure to place the transmission in park (P), set

the parking brake and block (in both

directions) the wheel that is diagonally

opposite (other side and end of the vehicle)

to the tire being changed. Never get underneath a vehicle that is

supported only by a jack. If the vehicle

slips off the jack, you or someone else could

be seriously injured. Do not attempt to change a tire on the

side of the vehicle close to moving

traffic. Pull far enough off the road to avoid

the danger of being hit when operating the

jack or changing the wheel. WARNINGS

Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one provided

as original equipment with your vehicle,

make sure the jack capacity is adequate for

the vehicle weight, including any vehicle

cargo or modifications. Disable the power running boards

before jacking, lifting, or placing any

object under the vehicle. Never place your

hand between the power running board and

the vehicle as extended power running

boards will retract when the doors are

closed. Failure to follow these instructions

may result in personal injury. Failure to follow these instructions

when using the spare tire carrier could

cause loss of the wheel and tire and lead to

personal injury: Only use the spare tire carrier

to stow the tire and wheel combination

specified on the Tire Label or Safety

Compliance Certification Label on the B-Pillar

or the edge of the driver door. Other tire and

wheel combinations could cause the carrier

to fail if it does not fit securely or is too

heavy. Do not use impact tools or power WARNINGS

tools operating over 200 RPM, which may

cause winch malfunction and prevent a

secure fit. Override the winch at least three

times (there will be an audible click each

time) to ensure a tight secure fit of the wheel

and tire. Note:

Passengers should not remain in the

vehicle when the vehicle is being jacked.

Park on a level surface, activate the hazard

flashers and set the parking brake. Then,

place the transmission in park (P) and turn

the engine off.

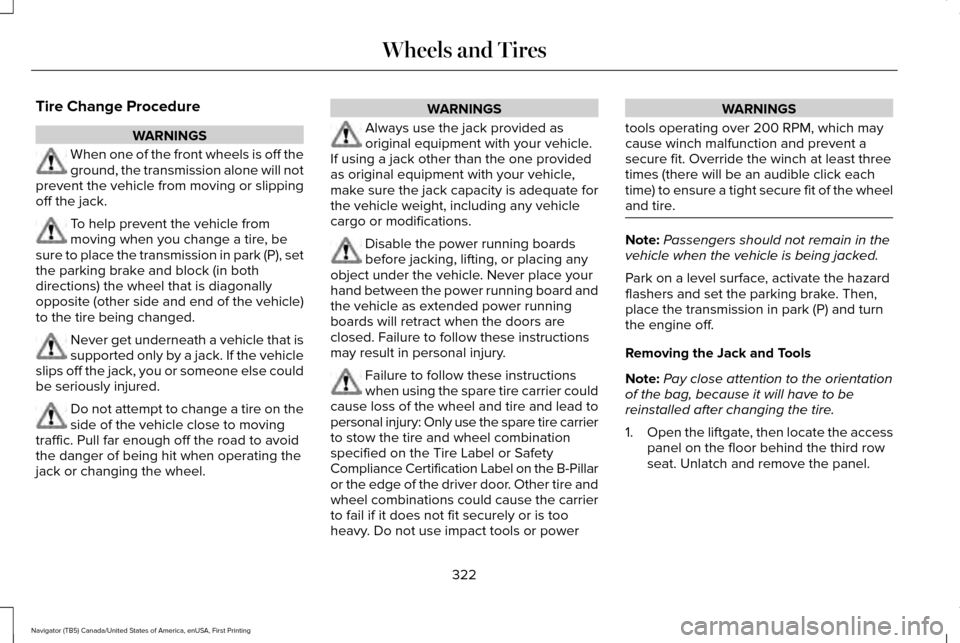

Removing the Jack and Tools

Note: Pay close attention to the orientation

of the bag, because it will have to be

reinstalled after changing the tire.

1. Open the liftgate, then locate the access

panel on the floor behind the third row

seat. Unlatch and remove the panel.

322

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 326 of 532

2.

Remove the jack and tools assembly tray

from the compartment by turning the

wing-nut counterclockwise. Remove the

bag from the jack and tools assembly tray

by loosening the strap.

3. Unsnap the wheel lug nut wrench, jack extension and handle from the plastic

tray.

4. Remove the hack from the tray assembly.

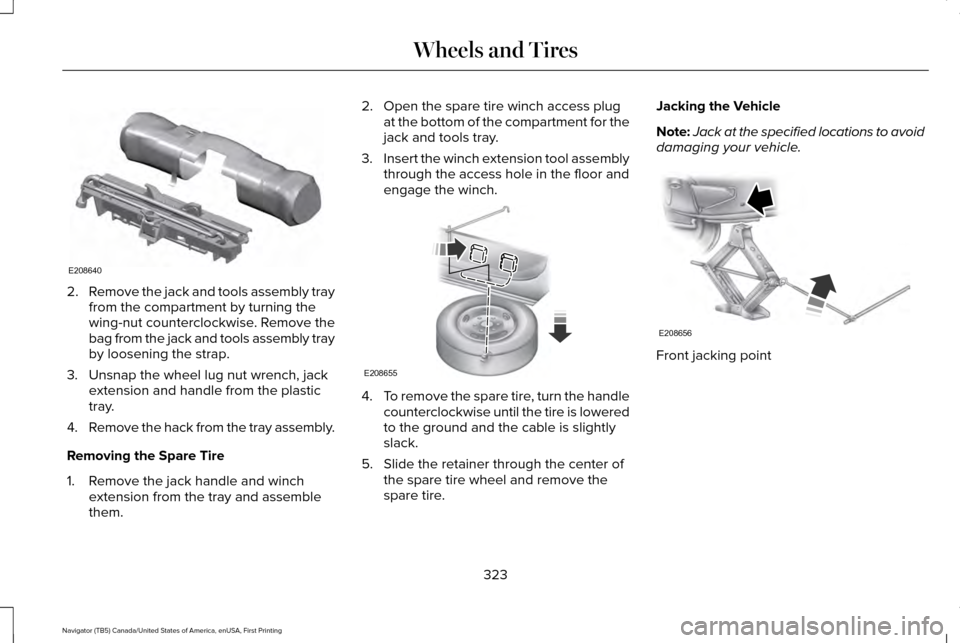

Removing the Spare Tire

1. Remove the jack handle and winch extension from the tray and assemble

them. 2. Open the spare tire winch access plug

at the bottom of the compartment for the

jack and tools tray.

3. Insert the winch extension tool assembly

through the access hole in the floor and

engage the winch. 4.

To remove the spare tire, turn the handle

counterclockwise until the tire is lowered

to the ground and the cable is slightly

slack.

5. Slide the retainer through the center of the spare tire wheel and remove the

spare tire. Jacking the Vehicle

Note:

Jack at the specified locations to avoid

damaging your vehicle. Front jacking point

323

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and TiresE208640 E208655 E208656

Page 327 of 532

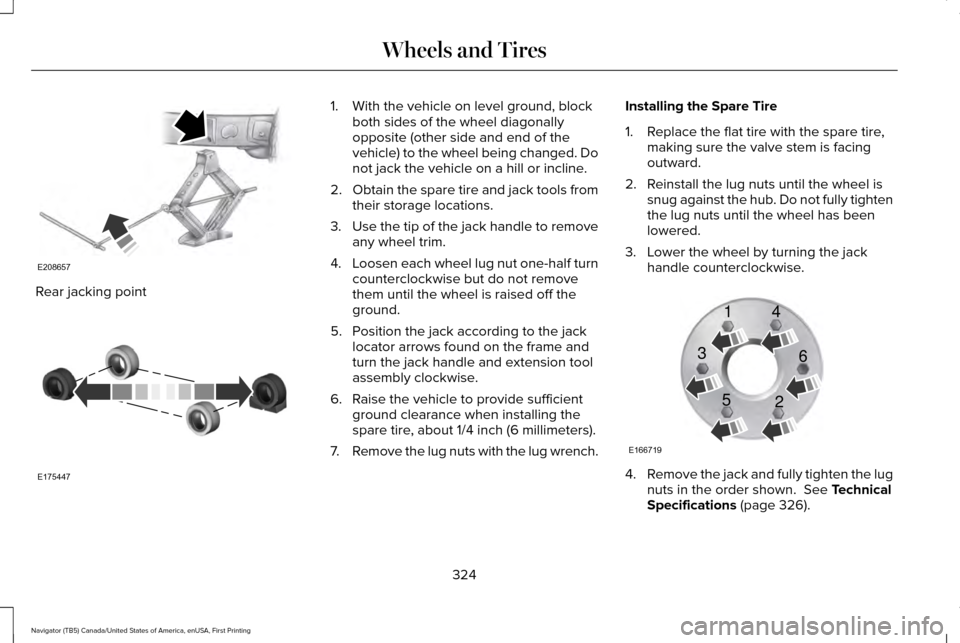

Rear jacking point 1. With the vehicle on level ground, block

both sides of the wheel diagonally

opposite (other side and end of the

vehicle) to the wheel being changed. Do

not jack the vehicle on a hill or incline.

2. Obtain the spare tire and jack tools from

their storage locations.

3. Use the tip of the jack handle to remove

any wheel trim.

4. Loosen each wheel lug nut one-half turn

counterclockwise but do not remove

them until the wheel is raised off the

ground.

5. Position the jack according to the jack locator arrows found on the frame and

turn the jack handle and extension tool

assembly clockwise.

6. Raise the vehicle to provide sufficient ground clearance when installing the

spare tire, about 1/4 inch (6 millimeters).

7. Remove the lug nuts with the lug wrench. Installing the Spare Tire

1. Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward.

2. Reinstall the lug nuts until the wheel is snug against the hub. Do not fully tighten

the lug nuts until the wheel has been

lowered.

3. Lower the wheel by turning the jack handle counterclockwise. 4.

Remove the jack and fully tighten the lug

nuts in the order shown. See Technical

Specifications (page 326).

324

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and TiresE208657 E175447 E166719

1

3

5 4

6

2

Page 328 of 532

Stowing the Flat or Spare Tire

1.

Lay the tire on the ground, near the rear

of the vehicle, with the valve stem side

facing up.

2. Slide the wheel partially under the vehicle and install the retainer through

the wheel center. If equipped, you may

have to remove the wheel center cap

prior to pushing the retainer through the

center of the wheel. To remove the

center cap, press it off with the jack tool

from the inner side of the wheel. Pull on

the cable to align the components at the

end of the cable. 3. Assemble the jack handle and winch

extension, then insert the winch

extension through the access hole

behind the third row seat and engage

the winch.

4. Turn the jack handle clockwise until the tire is raised to its stowed position

underneath the vehicle. The wrench will

become harder to turn and the spare tire

winch will rachet or slip when the tire is

raised to maximum tightness. A clicking

sound will be heard from the winch

indicating that the tire is properly stowed. 5. Disassembly the jack tool and winch

extension and snap them back into the

tool tray.

6. Reinstall the jack bag properly around the jack and tool assembly tray, making

sure the strap is fastened.

7. Close the access hole with the rubber plug.

8. Reinstall the tray into the vehicle and secure it with the wing nut.

325

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 329 of 532

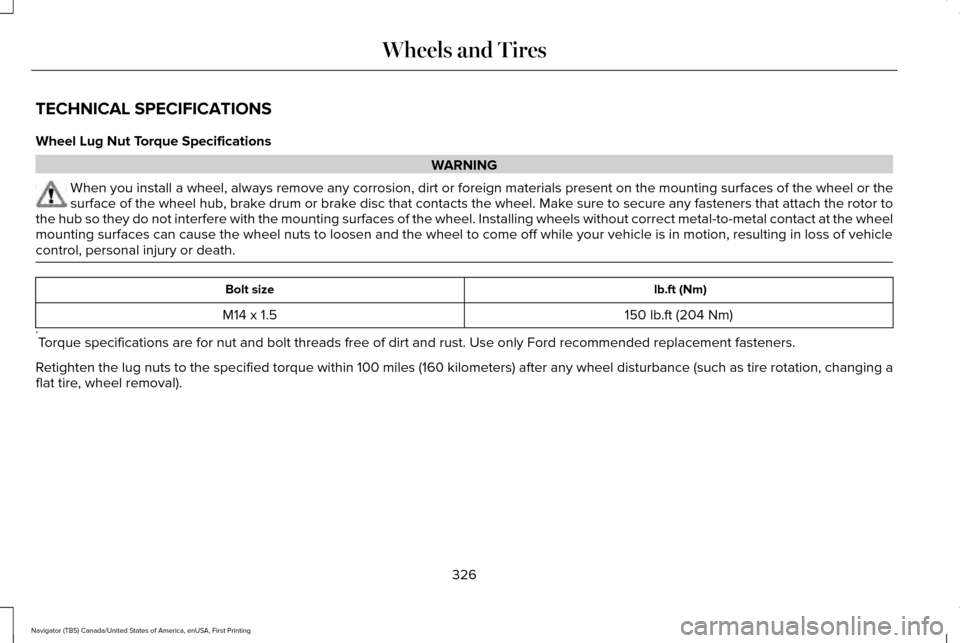

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When you install a wheel, always remove any corrosion, dirt or foreign m\

aterials present on the mounting surfaces of the wheel or the

surface of the wheel hub, brake drum or brake disc that contacts the wheel. Make sure to secure any fasteners that attach the rotor to

the hub so they do not interfere with the mounting surfaces of the wheel\

. Installing wheels without correct metal-to-metal contact at the wheel

mounting surfaces can cause the wheel nuts to loosen and the wheel to co\

me off while your vehicle is in motion, resulting in loss of vehicle

control, personal injury or death. lb.ft (Nm)

Bolt size

150 lb.ft (204 Nm)

M14 x 1.5

* Torque specifications are for nut and bolt threads free of dirt and rust.\

Use only Ford recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kil\

ometers) after any wheel disturbance (such as tire rotation, changing \

a

flat tire, wheel removal).

326

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 330 of 532

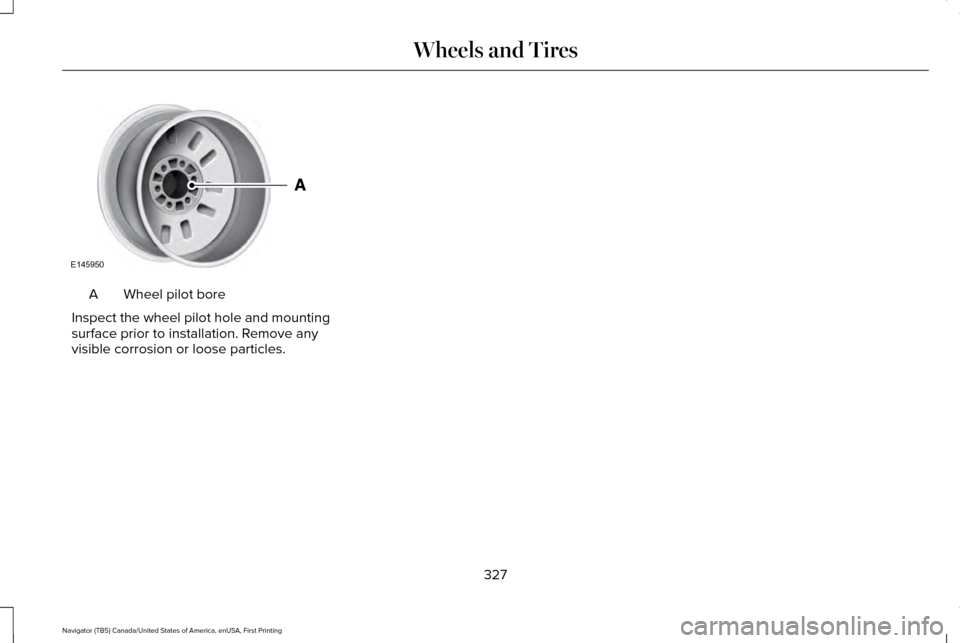

Wheel pilot bore

A

Inspect the wheel pilot hole and mounting

surface prior to installation. Remove any

visible corrosion or loose particles.

327

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and TiresE145950