lock LOTUS ELISE 2005 Owner's Manual

[x] Cancel search | Manufacturer: LOTUS, Model Year: 2005, Model line: ELISE, Model: LOTUS ELISE 2005Pages: 205, PDF Size: 4.51 MB

Page 65 of 205

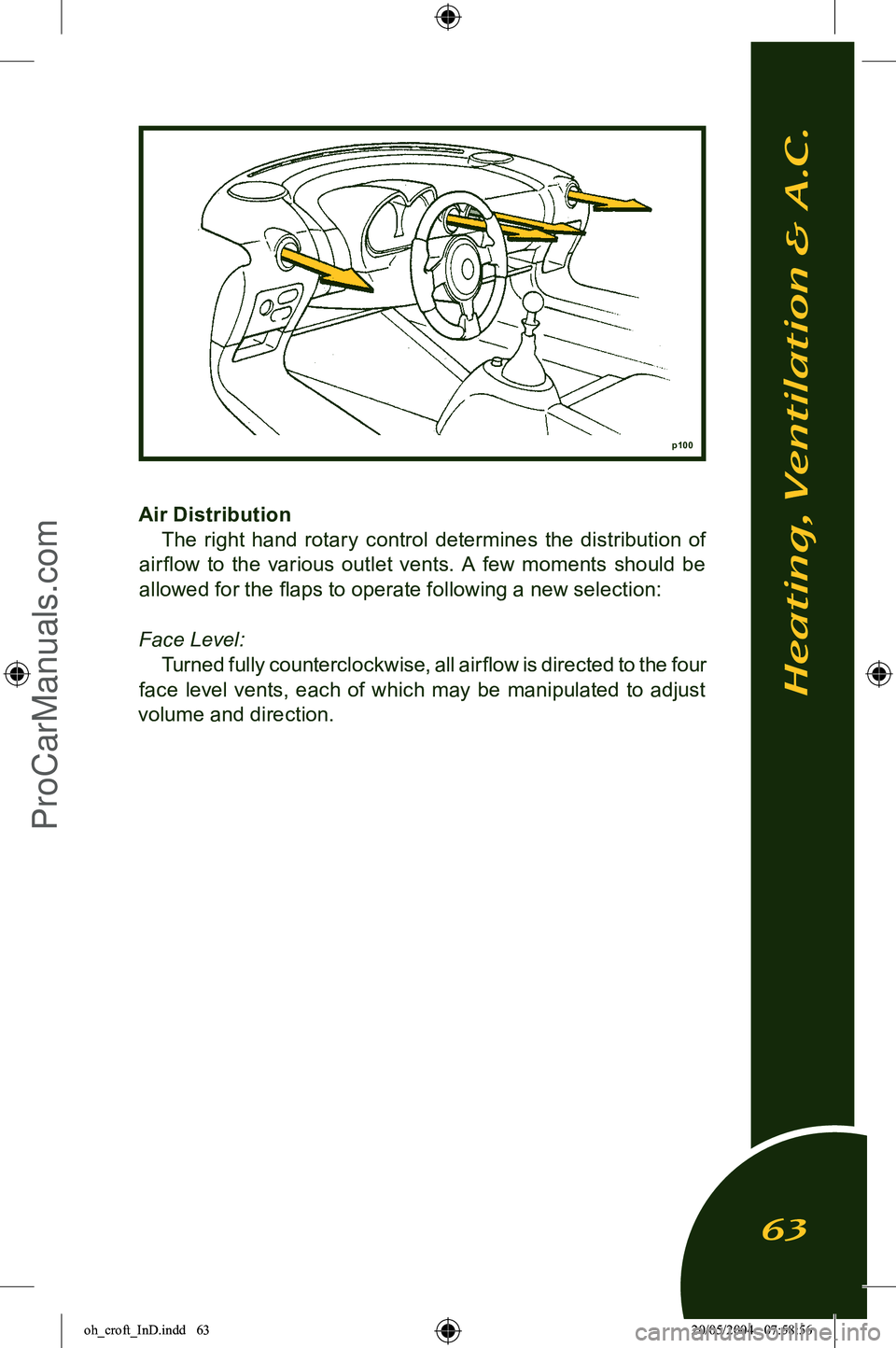

Air DistributionThe right hand rotary control determines the distribution of

air flow to the various outlet vents. A few moments should be

allowed for the flaps to operate following a new selection:

Face Level: Turned fully counterclockwise, all airflow is directed to the four

face level vents, each of which may be manipulated to adjust

volume and direction.

p100

Heating, Ventilation & A.C.

63

oh_croft_InD.indd 6320/05/2004 07:58:56ProCarManuals.com

Page 66 of 205

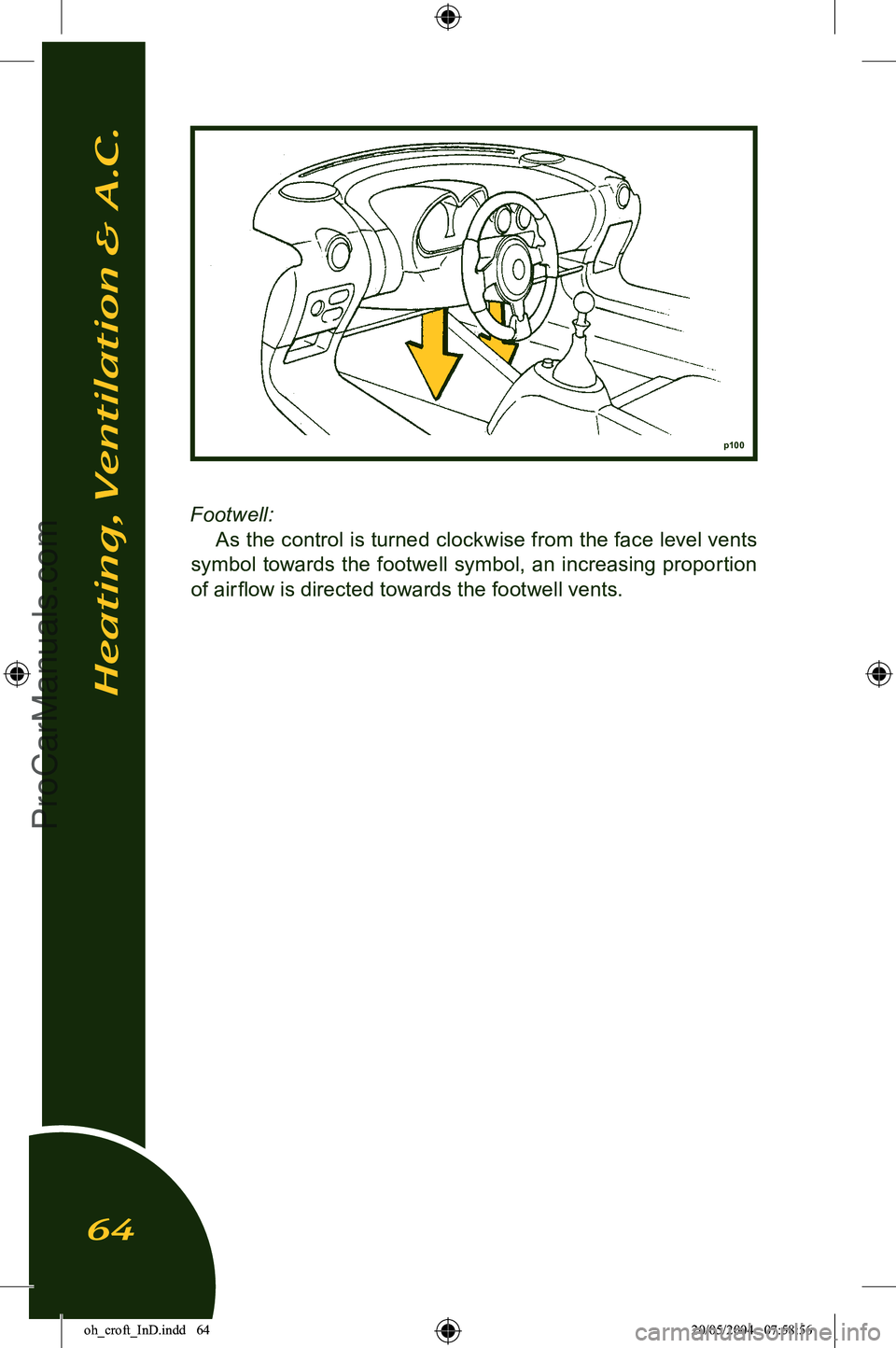

Footwell:

As the control is turned clockwise from the face level vents

symbol towards the footwell symbol, an increasing proportion

of air flow is directed towards the footwell vents.

p100

Heating, Ventilation & A.C.

64

oh_croft_InD.indd 6420/05/2004 07:58:56ProCarManuals.com

Page 67 of 205

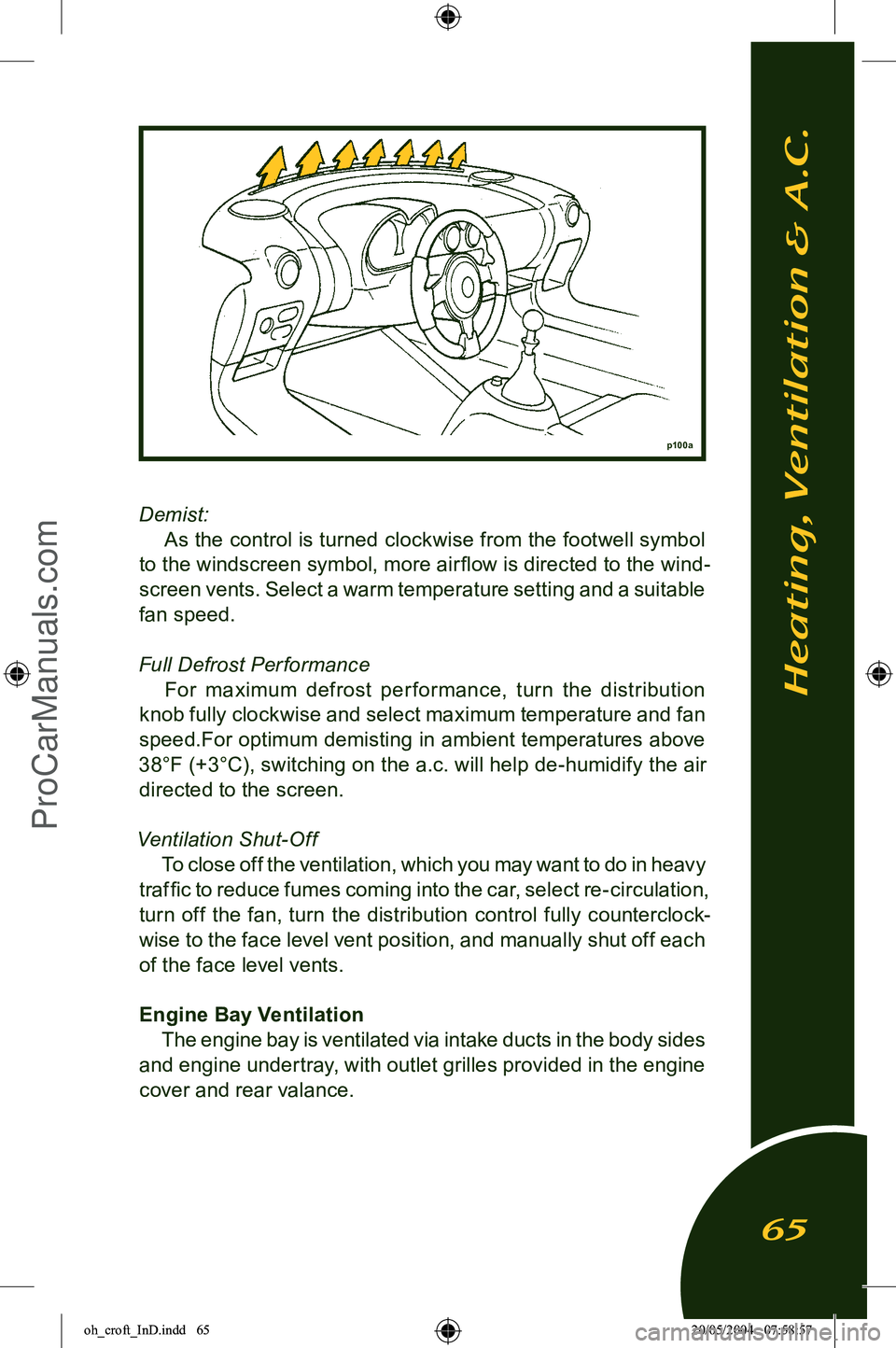

Demist:

As the control is turned clockwise from the footwell symbol

to the windscreen symbol, more air flow is directed to the wind

-

screen vents. Select a warm temperature setting and a suitable

fan speed.

Full Defrost Per formance For maximum defrost per formance, turn the distribution

knob fully clockwise and select maximum temperature and fan

speed.For optimum demisting in ambient temperatures above

38°F (+3°C), switching on the a.c. will help de-humidify the air directed to the screen.

Ventilation Shut-Off To close off the ventilation, which you may want to do in heavy

traffic to reduce fumes coming into the car, select re-circulation,

turn off the fan, turn the distribution control fully counterclock

-

wise to the face level vent position, and manually shut off each of the face level vents.

Engine Bay Ventilation The engine bay is ventilated via intake ducts in the body sides

and engine undertray, with outlet grilles provided in the engine

cover and rear valance.

p100a

Heating, Ventilation & A.C.

65

oh_croft_InD.indd 6520/05/2004 07:58:57ProCarManuals.com

Page 69 of 205

FootbrakeVentilated disc brakes are fitted to all four wheels of the

Elise. These are operated by separate front and rear hydraulic

circuits, supplied from a tandem master cylinder with vacuum

servo. Anti-lock control is provided by a microprocessor based

electro-hydraulic unit, integrated into the base braking system. The braking system is designed to provide good pedal feed

-

back, with efficient disc cooling to inhibit brake fade. With a

new car, or new brake system components, maximum braking

efficiency will be achieved if, for the first few hundred miles, needless heavy braking is avoided. Allow the brake pads and discs to ‘bed in’ fully before using the brakes to their full potential.

Pedal effort will reduce as the brakes are bedded in, and as they

are warmed from cold to normal working temperature. Note that

the hard grade pad material may give rise to a certain amount of brake noise under some conditions; such noise is not harmful

and does not affect the life or efficiency of the brakes.

WARNING:

• After driving through a ford, or a flooded road, some loss of braking response may be experienced until the brakes

have dried out. As soon as it is safe to do so after such an encounter, apply the brakes until normal operation

is restored. Failure to do so may result in an accident in

which you or others may be killed or seriously injured.

• The brake assistance servo uses vacuum supplied from the engine intake plenum, such that assistance is avail

-

able only when the engine is running. Never coast down

-

hill with the engine stopped. If this situation accidently arises, avoid repeated application of the brakes, or the

stored vacuum supply will be rapidly used up. Greater

pedal pressures will be required. This may adversely affect performance of the brakes which may result in an

accident in which you or others may be killed or seriously

injured.

Anti-lock Brake System The Anti-lock Brake System (ABS) is used to optimise brake

performance in extreme conditions and reduce the potential

for any wheel to lock up. Under most conditions, the maximum braking force is provided by a wheel which is rotating at about

90% of road speed. Apart from the likelihood of increasing the

Driving Controls

67

oh_croft_InD.indd 6720/05/2004 07:58:57ProCarManuals.com

Page 70 of 205

stopping distance, a locked wheel provides little or no steering

force, such that with both front wheels locked, movement of the steering wheel has no effect on car direction. With the anti-lock

system, even panic braking results in controlled deceleration and the retention of steering response. ABS is especially ad

-

vantageous when braking on slippery road surfaces and in bad driving conditions, but it is important to realise that the ABS

cannot increase the friction level at the road surface, but can only make optimum use of the grip available.

WARNING: When driving in adverse weather, or on poor road sur

-

faces, always be alert to the possibility of slippery condi

-

tions and make the necessary allowance for increased stop

-

ping distances. Failure to do so may result in an accident in which you or others may be killed or seriously injured.

Normal braking, controlled by the pressure applied to the

brake pedal, occurs when the road conditions allow for decel

-

eration to be achieved without danger of wheel lock. The relative

speeds of the four wheels are continuously monitored by the

ABS when the brakes are applied, and if one or more wheels begin to lock, the brake pressure to that wheel(s) is modulated

by the ABS to help keep the wheel rotating and provide the

maximum controlled braking force. The wheels may appear

to lock momentarily as the wheel speed rapidly changes, and some tire noise (intermittent screeching) may be heard which is normal and will vary with road and tire conditions. Note that the

ABS does not function at speeds below 5 mph (7 km/h). When the ABS is activated, the driver is will feel a ‘pulsing’

sensation at the brake pedal as the fluid pressure is modulated, and also by audible clicking sounds. These signals indicate to

the driver that maximum braking is occuring, and that driving style should be modified to suit the conditions.

The minimum stopping distance is achieved by applying the

brakes firmly and steadily, and allowing the ABS to modulate

hydraulic pressure. The driver should not attempt to emulate

this process by ‘pumping’ the brake pedal, as modulation at the pedal will treat all four wheels similarly, rather than the individual

wheel control allowed by the electronics. An ABS tell tale lamp in the instrument panel is provided

to warn of any problems in the system and to indicate that the

Driving Controls

68

oh_croft_InD.indd 6820/05/2004 07:58:57ProCarManuals.com

Page 71 of 205

integral self diagnostics have switched out the anti-lock function.

See ‘ABS tell tale lamp’.

WARNING:

• The increased control that ABS provides should not induce you to take more risks with your safety. ABS will

not prevent a skid caused by abrupt steering movements,

or attempting to corner too quickly.

• Always maintain a safe following distance from other cars relative to the road surface and weather conditions.

Obey all traffic laws.

• Risk of accidents due to inappropriate speed cannot be reduced even by ABS. The driver is responsible for the

judgement of safe speed.

• The control unit of the ABS is set for standard tire size. If non-standard Tires are fitted, the control unit may mis-

interpret the speed of the car, because of the variant data

it receives from the wheel speed sensors. Fitting non standard tires would seriously affect the performance of

your ABS.

• The amber ABS tell tale in the instrument panel should light for about 4 seconds following ignition switch on, and

then go out. If the lamp remains lit, or comes on whilst driving, a fault in the anti-lock brake system is indicated.

The base brake system will continue to operate normally,

but without ABS. The car can be driven but should be

checked and repaired at the earliest opportunity.

• Activation of the ABS will vary according to the level of grip available at the Tires. On dry surfaces, activation

will occur only with a high pedal pressure. On slippery

surfaces, only a low pressure will be needed.

• On loose or uneven surfaces, such as gravel or snow, a car with ABS may need a longer stopping distance. Allow

a greater distance between cars in these conditions.

Driving Controls

69

oh_croft_InD.indd 6920/05/2004 07:58:57ProCarManuals.com

Page 74 of 205

STARTING PROCEDURE & ENGINE BREAK-IN

WARNING:CARBON MONOXIDE - Be aware of the danger of carbon

monoxide! Never run the engine in an enclosed space. The

exhaust gases contain carbon monoxide, a deadly gas

which is particularly dangerous, as being colourless odour

-

less and tasteless, its presence is very difficult to detect.

Before starting the engine, always check that the parking

brake is firmly applied, the transmission is in neutral, and as

an extra precaution, depress the clutch pedal. Switch off any

unnecessary electrical loads.

Starting a Cold or Warm Engine

The fuel injection and engine management system controls fuel delivery and engine settings under all normal operating conditions.

i) Insert the key into the steering lock/ignition switch and turn to

position ‘l’ to unlock the column. Before turning on the igni

-

tion; if the security tell tale in the tachometer face is flashing, mobilise the engine by pressing once, and for a full second,

the larger of the two buttons on the transmitter fob.

ii) Turn the key to position ‘II’ to switch on the ignition, and pause

for a moment to allow the fuel system to prime.

iii) Depress the clutch pedal as a precaution, and without moving

the accelerator, press the ‘Start’ button at the left hand end of

the dashboard to engage the starter motor. Release the button

as soon as the engine starts. Allow a cold engine to idle for

10 seconds before driving off, but if ambient temperatures are below freezing, allow the engine and screen heating systems

to warm up for a few minutes before driving.

iv) If the engine fails to start within 15 seconds, stop cranking

and pause for 10 seconds before a second attempt.

v) If further efforts are unsuccessful, contact your dealer or seek

other expert help.

WARNING:

An unattended car with a running engine is potentially

hazardous. Turn off the engine before leaving the car.

Starting & Engine Break-In

72

oh_croft_InD.indd 7220/05/2004 07:58:58ProCarManuals.com

Page 79 of 205

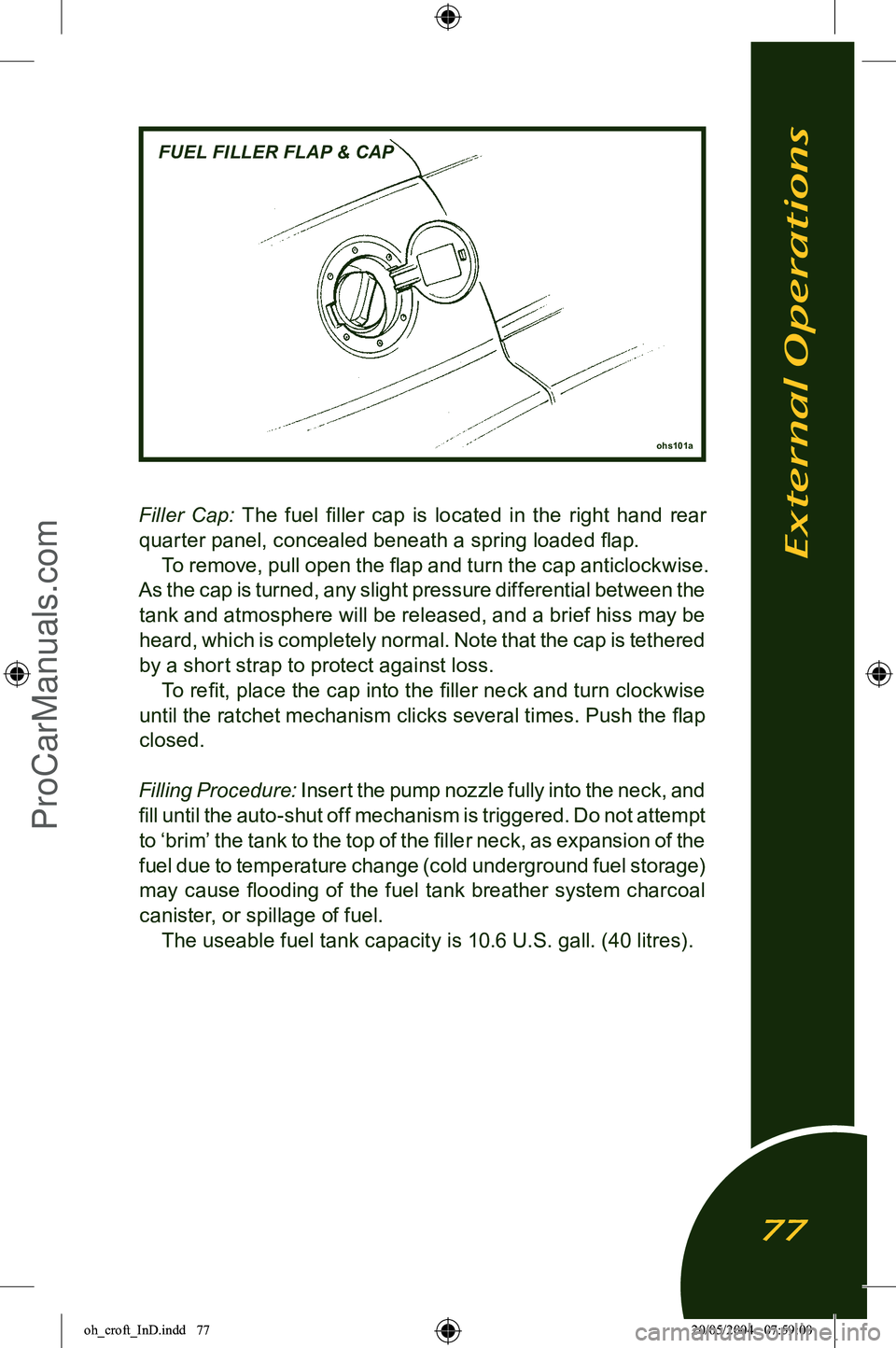

Filler Cap: The fuel filler cap is located in the right hand rear

quarter panel, concealed beneath a spring loaded flap. To remove, pull open the flap and turn the cap anticlockwise.

As the cap is turned, any slight pressure differential between the tank and atmosphere will be released, and a brief hiss may be heard, which is completely normal. Note that the cap is tethered by a short strap to protect against loss.

To refit, place the cap into the filler neck and turn clockwise

until the ratchet mechanism clicks several times. Push the flap closed.

Filling Procedure:

Insert the pump nozzle fully into the neck, and

fill until the auto-shut off mechanism is triggered. Do not attempt to ‘brim’ the tank to the top of the filler neck, as expansion of the

fuel due to temperature change (cold underground fuel storage) may cause flooding of the fuel tank breather system charcoal

canister, or spillage of fuel. The useable fuel tank capacity is 10.6 U.S. gall. (40 litres).

ohs101a

FUEL FILLER FLAP & CAP

External Operations

77

oh_croft_InD.indd 7720/05/2004 07:59:00ProCarManuals.com

Page 81 of 205

Engine Cover/Trunk LidThe engine cover/trunk lid provides access to the engine and

rear luggage compartment.

To open the lid: Insert the key into the lock and turn clockwise. When released, a spring plunger will lift the lid sufficiently to allow it to be raised fully by hand. Support the lid by engaging

the prop provided on the trunk bulkhead, in the slotted plate adjacent to the latch mechanism.

WARNING:

• When using the rear luggage compartment, beware of any hot surfaces exposed in the engine bay. Touching hot

surfaces could cause serious burns.

• Before closing the lid, ensure that no persons or objects

will be trapped.

• If necessary, protect and/or secure heavy objects as required.

To close: Stow the support prop in its bulkhead clip, and, keeping

fingers well clear of entrapment, and ensuring that no obstruction is present, lower the lid. Fully engage the latch mechanism by pressing down on the lid just forward of the key lock, NOT at

the extreme rear end of the panel.

ohs92a

REAR LID RELEASE

External Operations

79

oh_croft_InD.indd 7920/05/2004 07:59:00ProCarManuals.com

Page 85 of 205

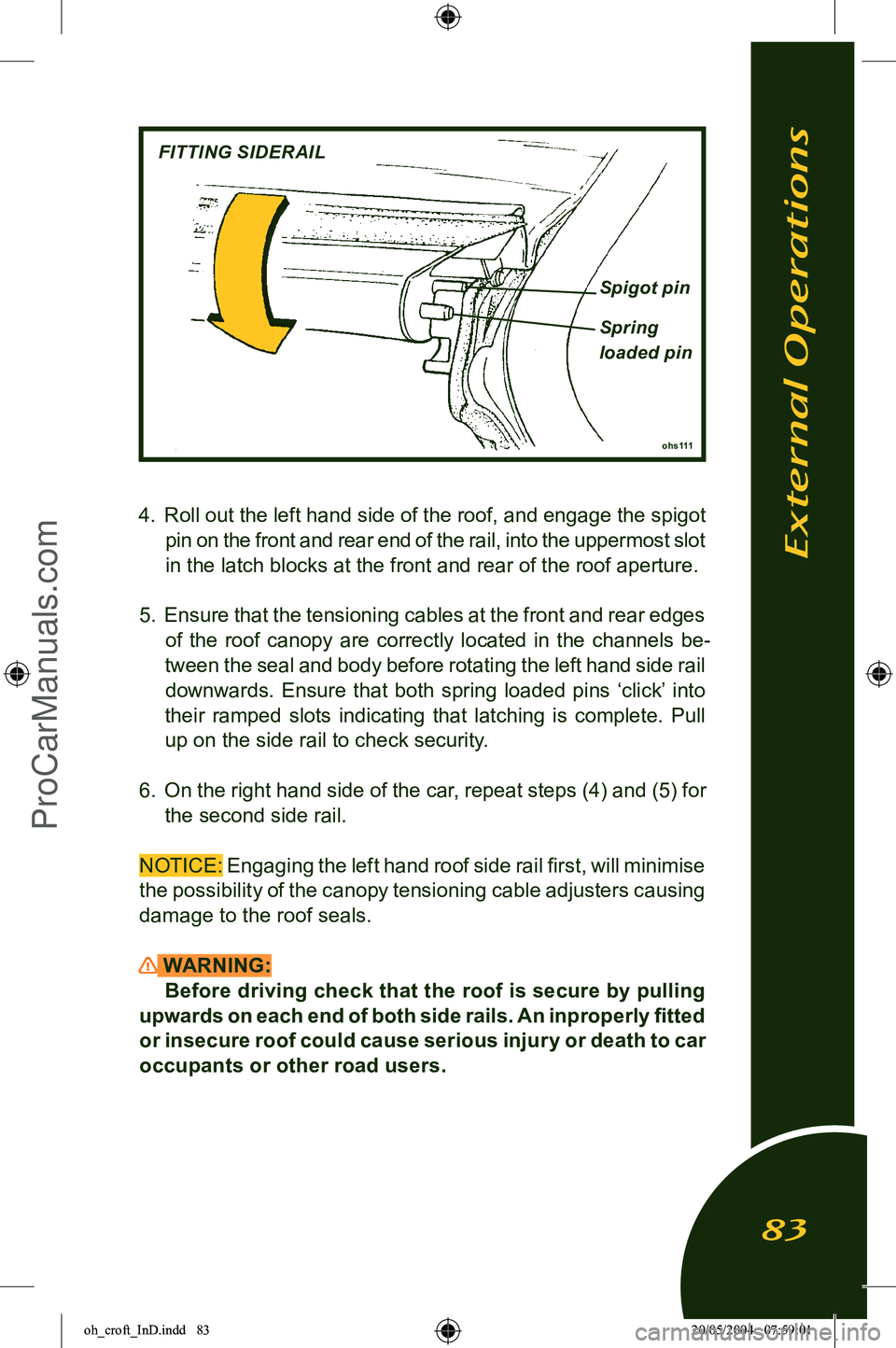

4. Roll out the left hand side of the roof, and engage the spigot

pin on the front and rear end of the rail, into the uppermost slot

in the latch blocks at the front and rear of the roof aperture.

5. Ensure that the tensioning cables at the front and rear edges of the roof canopy are correctly located in the channels be

-

tween the seal and body before rotating the left hand side rail downwards. Ensure that both spring loaded pins ‘click’ into

their ramped slots indicating that latching is complete. Pull up on the side rail to check security.

6. On the right hand side of the car, repeat steps (4) and (5) for

the second side rail.

NOTICE: Engaging the left hand roof side rail first, will minimise

the possibility of the canopy tensioning cable adjusters causing damage to the roof seals.

WARNING: Before driving check that the roof is secure by pulling

upwards on each end of both side rails. An inproperly fitted

or insecure roof could cause serious injury or death to car

occupants or other road users.

External Operations

83

ohs111

FITTING SIDERAIL

Spigot pin

Spring

loaded pin

oh_croft_InD.indd 8320/05/2004 07:59:01ProCarManuals.com