lock MAZDA 232 1990 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 49 of 677

91 1NSTALLATION

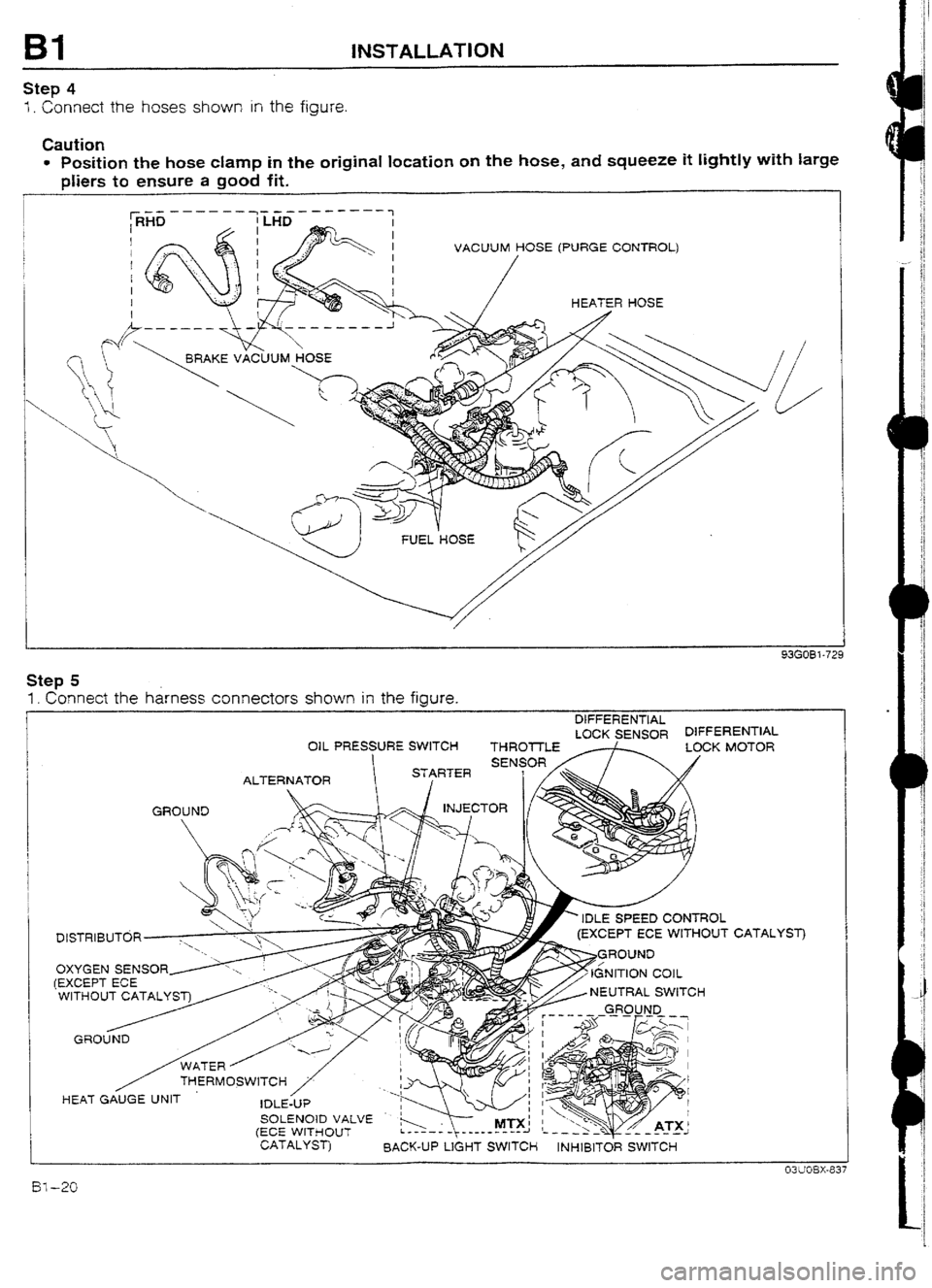

Step 4

1. Connect the hoses shown in the figure.

Caution

l Position the hose clamp in the original location on the hose, and squeeze it lightly with large

pliers to ensure a good fit.

Step 5

1. Connect the harness connectors shown in the figure.

OIL PRESSURE SWITCH

Df STRlBUTdR

OXYGEN SENSOR

(EXCEPT ECE

WITHOUT CATALYST) lVFFFRFh!TIAI

-.I I -4 m-m. I -r-h LOCK SENSOR DIFFERENTIAL

THRO77LE

/--+I / LOCK MOTOR

AC. .A--

r IDLE SPEED CONTROL

r

dz k

/NEUTRAL SWITCH

“Rou2ydy __

HEAT GAUGE UNIT ’

IDLE-UP

SOLENOID VALVE

IECE WlTl-tOUT

‘CATALYST-)

BACK-UP LIGHT SWITCH INHlBlTdR SWITCH

G3UOBX-837

E3i -20

Page 54 of 677

B2

ENGINE

(DOHC)

INDEX . . . . . . . ..**......... . . . . . . . ...* . . . . . . . . . . . . . . . . . . . l . BZ- 2

OUTLINE

................................................ BZ- 3

OUTLINE OF CONSTRUCTION.. .............. BZ- 3

SPEClFlCATlONS .................................. BZ- 4

INTERCHANGEABiLITY

.......................... BZ- 5

CYLINDER HEAD

.................................. BZ- 6

CYLINDER BLOCK AND OIL PAN ........... BZ- 7

PISTON ............................................... BZ- 8

FtYWtiEEL .......................................... BZ- 9

CAMSHAFT .......................................... BZ-10

SUPPLEMENTAL SERVICE INFORMATION BZ-11

COMPRESSION

....................................... 82-I 1

INSPECTION ........................................ B2-11

REMOVAL .............................................. BZ-12

PROCEDURE ........................................ BZ-12

ENGINE STAND MOUNTING.. ................... BZ-20

PROCEDURE ........................................ BZ-20

ENGINE STAND DISMOUNTING.. ..............

BZ-21

PROCEDURE ........................................ 82-21

INSTALLATION

....................................... BZ-23

PROCEDURE ........................................ BZ-23

93GOB2-701

Page 58 of 677

c

OUTLINE B2

INTERCHANGEABILITY

The following chart shows interchangeability of the main park of the BP DOHC Turbo engine for the 4WD

model and the BP DOHC Non-Turbo engine for the 2WD model.

Symbols: 5 . Interchangeabie X . . . . Not Interchangeable

Part name interchangeability Remark

1 Cylinder head Shape different

Camshaft oil sea! :

Cylinder head bolt

3

Cyijnder head gasket cl

C$rnder head cover 0

1

Cylinder Cylinder head cover gasket cl

I

Cylinder block 0

block

related Man bearing cap 0

Main bearing support plate 3

OrI pan x Shape different

Trming belt cuver cl

Seal plate 3

Front oil seal I

3

Rear oil seal cl

Crankshaft ‘3

Main bearing 0

Thrust bearing 0

Connecting rod and cap 0

Connecting rod bearing I

0

Crankshaft [ Prston Shape different

related

Piston pin +-- -

c Piston ring cl

Crankshaft pulley 0

Rear cover 3

I Flywheel X Shape different

Flywheel bolt 0

Timing belt

cl

Timing belt Timing belt crank pulley

cl

Camshaft pulley 0 I

related

f Timing belt tensioner and spring

i 0

1, ldter

Camshaft

; Valve timing different

I-LA

Valve I Make - cl

Valve Exhaust 0

related

Vaive sprtng Intake 0

and seat

Exhaust 0

Valve guide cl

Valve seal 0

Oil pump 0

Oil pump gasket 0

Lubrication Oil strainer

0

system Oil strainer gasket

0

related

Oil cooler

0

Oil jet

0

Oil fitter

0

Water pump cl

Cooling

Thermostat

X system Specificatron drfferent

related Radiator X Specificatron different

Cooling fan

X Specification different

^^-^-^ m^- Ix?-5

Page 60 of 677

OUTLINE B2

CYLfNDER BLOCK AND OIL PAN

I BP TURBO

I CONtiECTOR BOLT

BP TURBO

A CYLINDER BLOCK

BLIND PLUG

OIL RtiURN

PIPE

1

93GCB2-7C

The cylinder block is no different. But in conjunction with the newly provided turbocharger, the coolant, and

Mxication oil passages on the cylinder block are used.

Tfie oil pan has a provision for oil to return from the turbocharger.

BZ-7

Page 75 of 677

B2 ENGINE STAND DISMOUNTING

93GOB2-7%

93AOB2-077

05WOBX-25

82-22 Water Bypass Pipe

1. Apply a small amount of engine coolant to the new O-ring.

2. install the O-ring on the pipe.

3. InstaIi the water bypass pipe.

A/C Compressor Bracket (if equipped)

1. Install the A/C compressor bracket.

Tightening torque

@: 19-25 N&m (1.9-2.6 m-kg, 14-19 ft-lb)

@: 37-52 Nom (3.8-5.3 m-kg, 27-38 ft-fb)

Exhaust Manifold and Turbocharger Assembly

I= Remove all foreign material from the exhaust manifold con-

tact surfaces.

2. Install a new gasket.

3. Instatl the exhaust manifold and turbocharger assembly.

Tightening torque:

38-46 N-m (3.9-4.7 m-kg, 28-34 ft-lb)

4. Connect the water hose to the water bypass pipe.

5. Connect the water hose and the oil pipe to the cylinder

block.

Tightening torque

@: 12-18 N-m (I -2-l .8 m-kg,

6. Connect the oil return hose to the oi 8.7-13 ft-lb)

I pan.

Exhaust Manifold Insulator

1. Install the exhaust manifold insulator.

Tightening torque:

7.8-I 1 Mm (80-I IO cm-kg, 69-95 in-lb)

Page 81 of 677

INSTALLATION

I

1 93EOB2-061

03 UOBX-848

93EOBZ07E

93GOB2-760

93GOB2-737

E32-28

4. Install the joint shaft.

5. Tighten the bolts in the order shown.

Tightening torque: 42-62

N=m (4.3-6.3 m-kg, 31-46 ft-lb)

Tie-rod end

1. Install the tie-rod end to the

knuckle.

Tightening torque: 42-57

Nmm (4.3-5.8 m-kg, 31-42 ft-lb)

Z.-Install a new cotter pin.

StabiIiter

I. Install and adjust the stabilizer.

Dimension A: 17.19mm (0.67-0.75 in)

Tightening torque:

f 6-23 Nm (I .6-2.3 m-kg, 12-17 ft-lb)

Exhaust pipe

I. InstaIl the exhaust pipe along with

a new gasket,

tighten locknuts @:

Loose1 y tighten brat ket

Tighten locknuts @

nuts @

and loosely

2.

3.

Tightening torque:

31-46 Mm (3.2-4.7 m-kg, 23-34 ft.lb) 4.

Tighten bracket nuts @,

Tightening torque: 21-27

Nm (2.1-2.8 m-kg, 15-20 ft-lb)

Select and

shift cables

1. Install the select cable and the spring pin.

2. Install the shift cable and the spring pin,

Page 216 of 677

![MAZDA 232 1990 Suplement User Guide J3

MANUAL TRANSAXLE AND

TRANSFER UNIT (GSMX-R)

INDEX .........................................

J3- 2

/FEATURES] I

OUTLINE .....................................

J3- 4

OUTLINE OF CONSTRUCTION .. MAZDA 232 1990 Suplement User Guide J3

MANUAL TRANSAXLE AND

TRANSFER UNIT (GSMX-R)

INDEX .........................................

J3- 2

/FEATURES] I

OUTLINE .....................................

J3- 4

OUTLINE OF CONSTRUCTION ..](/img/28/57056/w960_57056-215.png)

J3

MANUAL TRANSAXLE AND

TRANSFER UNIT (GSMX-R)

INDEX .........................................

J3- 2

/FEATURES] I

OUTLINE .....................................

J3- 4

OUTLINE OF CONSTRUCTION ..... J3- 4

SPECIFlCATtUNS ....................... J3- 5

TRANSAXLE AND TRANSFER UNIT J3- 5

STRUCTURAL VIEW.. ................. J3- 6

TRANSAXLE ................................ J3- 8

DOUBLE CONE SYNCHRU

MECHANlSM ........................... J3- 8

SHIFT FORKS AND SHIFT RODS . . J3- 10

iNTERLUCK MECHANISM ......... ., J3- 11

TRANSFER UNtT

.......................... J3- 12

CENTER DIFFERENTIAL ............. J3- 14

VISCOUS COUPLING

(BP DOHC TURBO). .................. J3- 20

CENTER DlFFERENTIAL LUCK

SYSTEM (MANUAL) .................. J3- 23

CENTER DIFFERENTIAL LOCK

SYSTEM (ELECTRICAL) ............. J3- 24

CENTER DIFFERENTIAL LOCK

CONTROL SWITCH ................... J3- 28

CENTER DIFFERENTIAL LUCK

ASSEMBLY

.............................. J3- 29

CENTER DIFFERENTIAL LOCK

SENSOR SWlTCH.. ................... J3- 31

IDLER GEAR SHAFI- ................... J3- 33

POWERFLOW .............................. J3- 34

TROUBLESHOOTING GUIDE ......... J3- 35 TRANSAXLE OIL .......................... J3- 36

INSPECTlON ............................. 33- 36

REPLACEMENT.. ....................... J3- 36

TRANSFER CARRIER CM .............

339 36

INSPECTION ............................. J3- 36

REPLACEMENT. ........................ J3- 36

TRANSAXLE AND

TRANSFER UNIT ........................ J3- 38

PREPARATION .......................... J3- 38

REMOVAL ................................. J3- 42

DISASSEMBLY

........................... J3- 48

INSPECTION ............................. J3- 72

ASSEMBLY ............................... J3- 75

INSTALLATION

.......................... J3-I I2

SHIFT MECHANISM.. .................... J3-119

OVERHAUL ............................... J3-119

CENTER DIFFERENTIAL

LOCK SYSTEM ........................... J3-121

SYSTEM DIAGRAM ..................... J3-121

INSPECTION ............................. J3-122

CENTER DIFFERENTIAL

LOCK MOTOR ............................ J3-123

INSPECTDN ............................. J3-123

REPLACEMENT ......................... J3-123

4x4 CONTROL UNIT.. ................... J3-126

INSPECTION ............................. 53-l 26

REPLACEMENT.. ....................... 53-l 26

CENTER DIFFERENTIAL

LOCK SWITCH ........................... J3-126

INSPECTION ............................. J3-126

REPLACEMENT ......................... J3-127

CENTER DIFFERENTIAL

LUCK SENSOR SWITCH ............. J3-127

INSPECTION ............................. J3-127

REPLACEMENT ......................... J3-127

93GOJ3-701

Page 217 of 677

J3 INDEX

JNDEX

LHD

// /

vIscOsIn:

ALL SEASON DEXRON-II, \_\;/ M-III

ABOVE -18OC @OF): ?5W-90

CAPACITY: 2.6 liters

(2.7 us qt, 2.2 Imp qt) ABOVE -18OC (UOF): 90

BELOW --t8OC (UOF): 8UW

CAPACITY: 0.5 liter

IO.53 US qt, 0.44 Imp qt 1. Transaxle oil

Inspection.. ._._.. . . . . . . . . . . . . . . . . . . . . . . . . page J3- 36

Replacement -.._.......-............... page J3- 36

2. Transfer carrier oi!

Inspection

. . . ..-*..-.*a. . . . . * . . . . . . . . . . . . . page J3- 36

Replacement . . ..-...Ir.....*....~......

page J3- 36 3. Transaxle and transfer unit

Removal . . . . . . . ..-.-........-._._._....... page J3- 42

Disassembly, .._. . . .-. ._. .-. . . . . . . . . . . . . page J3- 48

Inspection.. . . . . . . ._. .-. .-. .-. . ._. . . . ._. . . page J3- 72

Assembly _.._..._.__._......._._..._...._ page J3- 75

Installation _.._.._.._._..._. . . . . . . . . .._.._ page J3-1 I 2

4. Shift mechanism

Overhaul ,._.._... . . . . . . . . . . . ._..._......_ page

J3-1 19 J3-2 Inspection . . . . . . . . . . . . . .._......._._...... 5. Center differential lock motor

page J3-I 23 Replacement .,-.....,..._..............

page J3-123 6.4x4 Control unit

Inspection ,.......... ~ ....._._._........I- page J3-I 26

Replacement ..*...** . . . . *.*...- . . . . . . . - page J3-126 7. Center differential lock switch

1 nspection ..,....*.....*.. *.*.* . . . . -.- . . . . page J3-126

Replacement ..~ ..,....._.........._,... page 33-l 26

8.

Center differential lock sensor switch

Inspection.. . . . . . . _ _ _ . . . _. . . _. _ _ _. __. . . . _ _ page J 3- 128

Replacement ..,.. . . . . . . . . . . . . . .._...... page J3-128

Page 218 of 677

t

1

lNDEX J3

GRADE: API SERVICE GL-5

ABOVE -18OC (OOF): 90

BELOW -18°C (OOf): 80W

CAPACITY: 0.5 liter

(0.53 us qt, 0.44 Imp qt)

SERVICE, SECTiON T

GRADE: API SERVICE Gt4

ALL SEASON DEXRON-II, M-D

ABOVE -18OC (OOF): 75W-90

CAPACITY: 2.6 liters

(2.7 US qt, 2.2 Imp qt)

I. Transaxle oil

Inspection . . . . .._........_................ page J3-

36

Reptacement . . . . . . . . . _,. . . . ._. . . . . . . . . .

page J3-

36

2. Transfer carrier oil

Inspection.. . .._. . . .._ ._. ._.. . . . . . . . . . . . . .

page

J3- 36

Replacement . . . . . . . . . . ..l._............ page J3-

36

3. TransaxIe and transfer unit

Removal .I...............~.......~......__

page J3- 42

Disassembly .**.,.--......-.**.....,.._.

page J3- 48

t nspection . . .._........*...*I.-..-........

page J3- 72

Assembly . .._....._.....--......-........ page J3- 75

lnstaliation . . . . ._. . . _ .-. . . . . . ..-. . . .._., . _ page J3-I 12

4. Shift mechanism

Overhaul . . . ..*..-.*._.........-..........

pageJ3-119 5. Center differential lock motor

Inspection . . . . . . . . . . . . . . . . . . .._..._....... page J3-123

Replacement . . . _ , . . . . . . *. . . . . _ . _. . . . _ . .

page J3- 123

6. 4x4 Control unit

Inspection . . . . . . . . . . . . .._...._......._....

page J3-126

Replacement . . . .._......_........ . . . . . .

page J3-126

7. Center differential lock switch

Inspection.. . _ . _ . _. _. . _. . . . . _ . . . _ . . . . . . . . .

page J3-f 27

Replacement . . . . . .._...._........_..... page 33-l 27

8. Center differential lock sensor switch

Inspection . . . . . . . . . . . . . . ** .-... 1*..**-.I..

pageJ3-128

Replacement

. . ..=......-.... -* . . . . -..-. page J3-I 28

J3-3

Page 219 of 677

J3 OUTLtNE

OUTLINE OF CONSTRUCTION

l Full-time 4-wheel drive, incorporating a viscous coupling is used on the BP DUHC Turbo model. BP SUHC

engine equipped models are fitted with an electronically controlled, lockable center differential.

With this system all driving conditions are easily contended with; from good roads to bad roads and

ad-

verse weather conditions.

l The transaxle and transfer unit were developed based on the GSM-R type transaxle.

The transaxle, center differential, viscous coupling, and front differentia! are a single, compact unit.

l The center differential employs a planetary carrier. system and a viscous coupling, and functions to distrib-

ute the driving force to the front and rear differentials as needed.

Through the use of this center differential, tire scuffing common to 4-wheel drive vehicles during tight cor-

nering, is eliminated.

l The speedometer driven gear (for detection of vehicle speed) is installed in the transfer carrier and detects

the speed of the rear wheels.

l Lubrication oil of the transaxle and transfer unit and of the carrier is contained separately.

93GOJ3-704

J3-4