radiator MAZDA 232 1990 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 93 of 677

E OUTLINE

OUTLINE

OUTttNE OF CONSTRUCTION

The cooling system in the 323 4WD model is basically the same as in the 323 2WD model.

Although there is no fundamental change from the BP DOHC of the 2WD model, the coolant circulation

path has been changed to direct coolant to the water-cooied turbocharger.

A two-stage thermostat is used in the BP DUHC turbocharged engine to stabilize the engine coolant tem-

peratu re.

The radiator and cooling fan specifications are different. The BP DOHC turbocharged engine of the 4WD

model uses a two-speed electric cooling fan.

93GOEX-704

COOLANT FLOW CHART (BP DOHC TURBO)

E-4

Page 94 of 677

![MAZDA 232 1990 Suplement User Guide SPECIFICATlONS

-

km

Cootlng system

Coolant camacltv

EnginelTtansaxte

lrters [US Qt. Imo at)

8P SOHC ] 8P DOW Turbo

MTX ATX

I MTX

Water-cooled, forced crrculation

5.0 (5.3, 4.4)

I 6.0 t&3,5 MAZDA 232 1990 Suplement User Guide SPECIFICATlONS

-

km

Cootlng system

Coolant camacltv

EnginelTtansaxte

lrters [US Qt. Imo at)

8P SOHC ] 8P DOW Turbo

MTX ATX

I MTX

Water-cooled, forced crrculation

5.0 (5.3, 4.4)

I 6.0 t&3,5](/img/28/57056/w960_57056-93.png)

SPECIFICATlONS

-

km

Cootlng system

Coolant camacltv

EnginelTtansaxte

lrters [US Qt. Imo at)

8P SOHC ] 8P DOW Turbo

MTX ATX

I MTX

Water-cooled, forced crrculation

5.0 (5.3, 4.4)

I 6.0 t&3,5.3) -

1 Type

Water puma 1

I Water seal Centrifugal

Unified mechanical

seal

: Type I Wax,single stage”‘, Wax, two-stage*’ 1 Wax, two-stage

80.5-83.5 (177-182)“1

Opening temperature

“C (OF)

Main: 86.5-89.5 (188-l 93) *’ Main: 86.5-89.5 (lSS--193)

The:mosta! 1 Sub : 83.5-86.5 (182-188) Sub 83.G86.5 (182-188)

1 Full-open temperature OC

(OF) 95 (203)*‘, 100 (212)*’ i 100 (212)

L I

“...Except cold area, *2...Cotd area only

1 r 1 93GOEX-706 j Full-open lift mm (in) 8.5 (0.335) or more’l

Main: 8.0 (0.31).mln.‘2

Sub : 1.5 10.061 min * Main: 8.0 (0.31) min.

Sub : I.5 (0.06) mm.

Radiator 1 Type

Cap vaive opening-pressure ’

kPa (kglcm2, psi) Corrugated fin

74-l 03 (0.75-I .05, 11-l 5) j Tvm?

EIectnc I

Coohg fan f Outer drameter mm (in) 320 (12.6) 340 (13.4)

Blade

Number 4 5

Motor

/ Current A

6.6 * 1 Hi : 13.3 + 10% max.

Lo: 8.8 + 10% max. E-5

Page 95 of 677

E OUTlANE

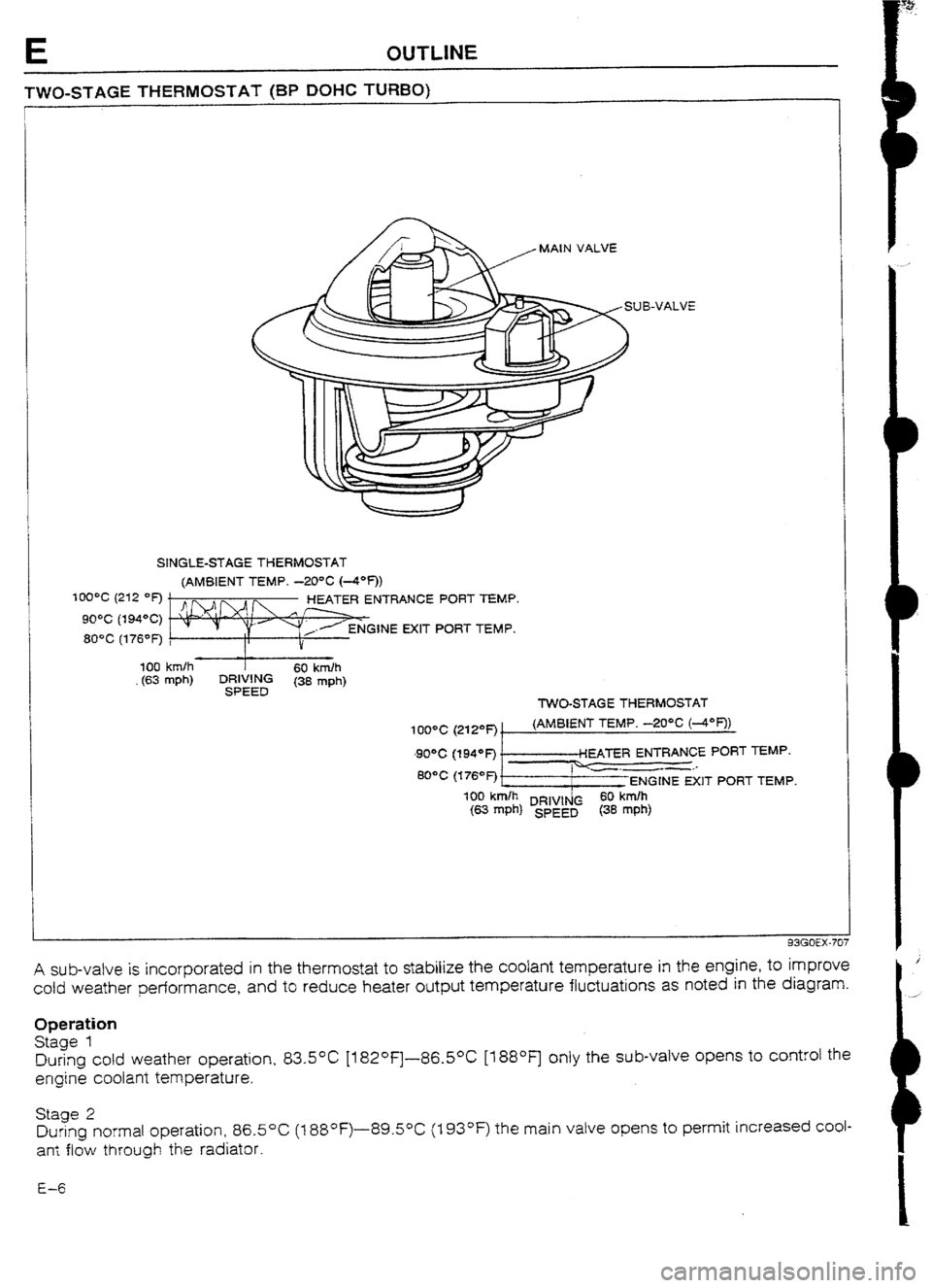

TWO-STAGE THERMOSTAT (BP DOHC TURBO)

MAIN VALVE

SINGLE-STAGE THERMOSTAT

(AMBIENT fEMP. -20% (4*f))

NTRANCE PORT TEMP

GINE EXIT PORT TEMP.

- 100 km/h

60 kndh

(63 mph) ~~~~~ (38 mph)

TWO-STAGE THERMOSTAT

A sub-valve is incorporated in the thermostat to stabilize the coolant temperature in the engine, to improve

cold weather performance, and to reduce heater output temperature fluctuations as noted in the diagram.

Operation

Stage 1

During cold weather operation, 83.5*C [182°F]-86.50C [t 88OF] only the sub-valve opens to control the

engine coolant temperature.

Stage 2

During normal operation, 86.5OC (1 88°F)-89.50C (I 93OF) the main valve opens to permit increased coul-

an: flow through the radiator.

E-6

Page 96 of 677

RADIATOR AND COOLING FAN

The radiator and cooling fan specifications are revised.

Specifications

r

EnginelTransaxle BP SOHC 1 BP DOHC Turbo

ATX I

Item MTX MTX 1 Radiator I

Width 647 +

+

Core size

mm (in) H etght 390 t *-

Depth 16 25 e

Fm pnch

mm (in) 1.3 t c

Heat dissipaton capacity kcallh

38,800 43,800 C

Type -

Double tube - Transaxle oil cooler

Heat dissipation capacity

-

kcal/h I 1,650 -

Cooling fan

Number of biades

4 5 +

Outer drameter

mm (in> 320

340 C

Capacity

w-v 80-12 160-12 c

Current

A

1 I 6.6 * 1 Hi : 13.3 + 7 0% max. + Lo: 8.8 + 10% max.

93GOEX-708

OIL COOLER (ATX

;ECTION A-A

4WD MODEL ZWD MODEL

I

DEPTH E-7

Page 97 of 677

E OUTLINE

ELECTRIC COCUNG FAN SYSTEM (BP DOHC TURBO)

System Circuit

I I

WITH A/C

r----‘-- -___- ---------.--------;

ADDITIONAL

FAN

MOTOR

I

II 1 A/C RELAY

RAD1ATdTHERMOSWITCH

ABOVE 105% I221 OF-): ON +IIAGNOSlS

CONNECTOR

WATER

THERMOSWlTCH

ABOVE 97% (207OF): ON

Operation 1. When the coolant temperature exceeds 97OC (207*F), the water thermoswitch turns ON to close the No.7

relay, and connects the + I and -1 terminals of the fan motor

connector. The fan motor turns at low

speed (about 1,660 rpm).

2. When the coolant temperature exceeds 105OC (221 OF), the radiator thermoswitch turns ON, to close the

No.2 and No.3 relays, and connects

the +2 and -2 terminals of the fan motor connector. The fan mo-

tor turns at high speed (about 2,200 rpm).

3. if the vehicle is equipped with air conditioning, the cooling fan motor operates whenever the

NC switch

and the blower switch are on, regardless of

the coolant temperature. Also, when the A/C switch and the blower switch are on, the A/C retay closes

to operate the additional fan

motur.

Note

l The water thermoswitch and the cooling fan reIay are normally-open switches.

Checking cooling fan operation 1. Jump across the TFA and the GND terminals

of the diagnosis connector with a jumper wire.

2. Turn the ignition switch to ON and verify that the cooling fan operates smoothly.

Note

l When the water thermoswitch connector is disconnected, the cooling fan wiif not operate.

E-8

Page 98 of 677

SUPPLEMENTAL SERVICE INFORMAT1ON, THERMOSTAT E

SUPPLEMENTAL SERVICE INFURMATtON

The following points in the section are changed in comparison with Workshop Manual [Europe (1203-l 0-89F),

Australia (I 204-I 0-89f)].

Thermostat (BP DUHC Turbo only)

l Inspection

Electric cooling fan system (BP DOHC Turbo only)

l System inspection

Fan motor

l 1 nspection

Water thermoswitch (BP DOHC Turbo only)

l tnspection

Radiator thermoswitch (BP DOHC Turbo only)

l Removal I Inspection I Installation

Fan relay (BP DOHC Turbo only)

l Removal ! Inspection 93GOEX-710

-

THERMOSTAT (BP DOHC TURBO)

SUB-V E

‘A

/ INSPECTKM

1. Visually check that the thermostat valve is airtight.

2. Place the thermostat and a thermometer in water.

3. Heat the water and check the following:

Initial-opening temperature:

Main: 86.5-89.5% (188--t93°F)

Sub : 83.5-86.5OC (f82--f88QF)

Full-open temperature: 100°C (212°F)

Full-open lift

Main: 8.Umm CU.31 in) min.

Sub : f.5mm (0.06 in) min.

E-9

Page 99 of 677

E ELECTRIC COOLING FAN SYSTEM

ELECTRIC COOLING FAN SYSTEM (BP

DUHC TURBO)

SYSTEM ClRCUIT

r

WITH A/C

r-- _______ ------

I ADDITIONAL

1 FAN

I PRESSL

SWITCH

I WATER

THERMOSWfTCtl

ABOVE 87OC (207OF): ON

RADlATOjl THERMOSWITCH

ABOVE 105*C (221 “I=): ON

8 93GOEX-719

-

%

J--- QY- -THERMOME?ERsi-=i

--

--------L-

93GOEX-7 i 2

E-10 SYSTEM INSPECTION

1. Jump across the test fan (TFA) terminal and the ground

(GN D) terminal of the diagnosis connector.

2. Turn the ignition switch ON and verify that the fan operates.

If the fan does not operate, inspect the cooling fan system

components and wiring harness.

3. Remove the radiator cap and place a thermometer in the

radiator filler neck.

4. Start the engine.

5. Verify that the fan operates when the coolant temperature

reaches approx. 97*C (207°F).

If it does, check the water thermoswitch.

(Refer to page

E--i I.)

Page 101 of 677

E RADIATOR THERMUSWlTCki

RADIATOR THERMOSWITCH (BP DUHC TURBO)

REMOVAL I INSPECTION I INSTALLATION

I. Disconnect the negative battery cable.

2. Remove in the order shown in the figure.

3. Install in the reverse order of removal, referring to InstaHation Note.

7.8-13 H-m

(80-l 10 cm-kg, 69-95 h-lb)

(80-110 cm-kg,

69-95In4b)

REPLACE 1. Resonance chamber

2. Radiator cowling mounting bolts

3. Radiator thermoswitch connector

03WEX-027 4. Radiator thermoswitch

Inspection . . . . . . . . * . . . . . . . . . . . . . ..-. -.*,.a..- . . . . . . .I. below

Installation Note _.,............................._. below

1NSPECTlON 1. Place the switch and a thermometer in engine oil.

Warning

l Do not heat the engine oil above 12O*C (248OF) 2. Heat the engine oil gradually and check continuity of the

switch with

an ohmmeter.

Engine oil temperature “C (*F) Continuity

More than 105 (221) Yes I

t Less than 96 (205) No

1

3. If not as specified, replace the radiator thermoswitch.

Installation Note

Radiator thermoswitch

Caution

l Do not use an impact wrench for installation. 1. Install the radiator thermoswitch along with a new gasket.

Tightening torque: 5.9-12

Nom (60-120 cm-kg, 52-104 in-lb) 93GOEX.721 E-12

Page 121 of 677

F2 OUTUNE

OUTLINE OF CONSTRUCTION

The fuel and emission control system of the new 323 4WD model is basically the same as that of the new

323 2WD modet; however, a turbocharger and knock control system are added to the BP TURBO model

and the fuel tank is designed

with separate right and left sections due to the installation of the propeller shaft

for the 4-wheel-drive system. A transfer pump is also equipped to pump the fuel from the left

to the right

(fuel pump side) section of the fuel tank.

The major points of difference between the 2WD model and 4WD model are as shown below.

93GOF2-705

Difference

Component 2WD 4WD

BP SUHC BP OOHC BP SOHC BP TURBU Remark

INTAKE AG! 1 Resonance duct 0 0 0 - -

SYSTEM

Resonance chamber 0

0 G -

VICS .-

ui- - -

Turbocharger - - -

0 Refer to page

FZ-12

I ntercooler - - -

0 Refer to page FZ-14

Air bypass valve - - -

0 Refer to page F2-14

FUEL SYSTEM Fuel pump control - - -

0 Refer to page F2-16

Transfer pump - -

0 0 Refer to page F2-18

Operating time for BP

Pressure regulator control 0 0 0 0

TURBO is different

(Refer to page F2-23)

Fuel pump reststorlrelay - - -

0 Refer to page F2-18

EVAPORATIVE

EMISSION

Fuel vapor vatve - -

CONTROL 0 0 Refer to page F2-16

SYSTEM

CONTROL

SYSTEM Point type

0 0

Throttle sensor 0 (MTX) -

-

Variable type - -

0 W-x) 0

Without heater

0 0 0 -

Oxygen sensor F

With heater - -

- 0 Refer to page F2-23

Water thermoswitch (on radiator)

-

Knock control system -

Overboost wami ng buzzer -

Turbocharge Indicator - -

C @TX) - NC cut-off system

- - 0

Refer to page F2-22

- -

0 Refer to page F2-21

- - 0 Refer to page F2-21

93GOF2-706

Page 141 of 677

F2 CONTROLSYSTEM

AK CUT-OFF SYSTEM (AI-X)

To improve the retiability of the engine at high temperature condition, the water thermoswitch on the radiator

is switched OFF above approx. II I “C (232OF) and stops the A/C operation.

ECU

NC OPERATION BLOWER FAN

WATER

THERMOSWITCH

IABOVE

111 OC (232OF): OFF]

NC SWITCH

IGNITION

T

l 1

BLOWER SWITCH

MAGNET

CLUTCH

93GOF2-73

F2-24