fuel MAZDA 232 1990 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 158 of 677

I

F2

fNSPECTlON ACTION

I Check if cootrng system IS OK’

YES Go to next step

No Repair or reptace

l Thermostat l

l Electric cooling fan * l Radiator*

5 Try known good ECU and check if condltlon Yes Replace ECU * rnproves

NO Change fuel to another brand or use

higher octane fuel

l Refer to 323 Workshop Manual [1203-l O-89F (Europe) or It 204-I O-89F (Australia)]. %%‘3OF2-748 -

F2-4 I

Page 167 of 677

F2 FUEL SYSTEM

FUEL

SYSTEM

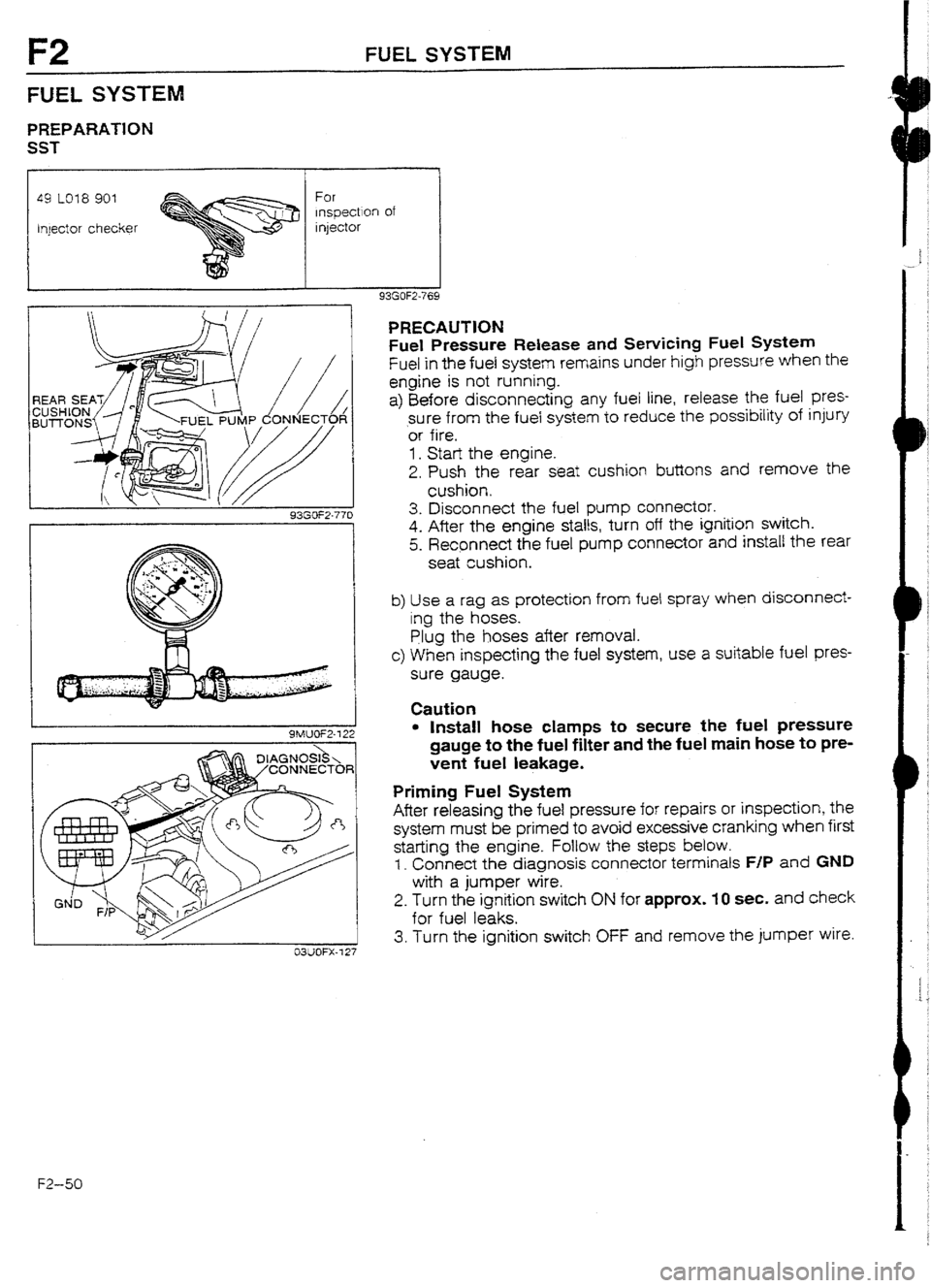

PREPARATlON

SST

49 LO18 901

Injector checker For

lnsgectlon of

injector

93GOF2.770

9MUOF2-722

03UOFX-7 27

F2-50

PRECAUTION

Fuel Pressure

Release and Servicing Fuel System

Fuel in the fuel system remains under high pressure when the

engine is not running.

a) Before disconnecting any fuel line, release the fuel pres-

sure from the fuel system to reduce the possibility of injury

‘or fife,

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion,

3. Disconnect the fuel pump connector.

4. After the engine stalts, turn off the ignition switch.

5. Recpnnect the fuel pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after

removal.

c) When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure the fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuet leakage.

Priming Fuel System

After releasing the fuel pressure for repairs or inspection, the

system must be primed to avoid excessive cranking when first

starting the engine. Follow the steps

below.

1. Connect the diagnosis connector terminals F/P and GND

with a jumper wire.

2. Turn the ignition switch

ON for approx. 10 set, and check

for fuel leaks.

3. Turn the ignition switch OFF and remove the jumper wire.

Page 168 of 677

FUEL SYSTEM F2

FUEL TANK

Removal I inspection / Instatlation

Warning

l Before performing the following operation, release the fue1 pressure from the fuet system to

reduce the possibitity of injury or fire. (Refer to page F2-50.)

l When removing the fuel tank, keep sparks, cigarettes, and open flames away from it.

l Before repairing the fuel tank, clean it throughly with steam to remove all explosive gas.

1. Remove in the order shown in the figure.

2. Inspect the fuel tank

components and repair or replace as necessary.

3. tnstall in the reverse order of removal, referring to Installation Note.

FUEL PUMP TRANSFER PUMP

0 SEAL RUBBER, REPLACE 7

A SSL

40-55 (4.1-56, 30-41)

N-m {m-kg, Mb)

93GOF2-771

F2-51

Page 169 of 677

F2 FUELSYSTEM

Note

l Drain the fuei from the fuel tank before removing the tank.

1. Fuel pump cover

2. FueI pump connector

3. Fuel hoses

Installation Note ..___........_.....__......_...._. below

4. Exhaust pipe

Removal / installation . . . . . . . .__._. . , . . . FZ-57, 58

5. Propeller shaft

Removal ! Installation .._._...._....._.._.. Section L 6. Fuel filier hose, breather hose, and

evaporation hoses

tnstal!ation Note ..m..,* . . . . ...*-. *..,- . . . . m...-e.. below

7. Fuel tank straps

8. Fuel tank

Inspect for cracks and corrosion

93GOF2-772

0 FUEL FILLER HOSE

03UOFX- 13! installation Nate

1. Push the ends of the main fuel hose, fuel return hose, and

evaporative hoses onto the fuel tank fittings at least 25mm

(1 .O in).

2. Push the fuel filler hose onto the fuel tank pipe and filler pipe

at least 35mm (1.4 in).

TRANSFER PUMP CONTROL SYSTEM

System Operation

I. Turn the ignition switch ON and verify that the fuel gauge

indicates more than half and that the transfer pump oper-

ating sound is heard.

Warning

l If the fuel level is less than one half, this inspec-

tion cannot be performed.

2. Ground the transfer pump connector terminai-wire (Y/L) with

a jumper wire and verify that the transfer pump stops.

3. Remove the jumper wire and verify that the transfer pump

begins operation after approx. IO sec.

4. If not as specified, check the following parts.

l Fuel pump control unit. [BP turboJ

(Refer to page F2-53.)

4x4 control unit [BP SOHC] (Refer to page Fl-12.)

l Transfer pump. (Refer to page F2-54.)

. Transfer pump switch. (Refer to page F2-54.)

93GOF2-774

F2-52

Page 170 of 677

![MAZDA 232 1990 Suplement Repair Manual FUELSYSTEM F2

FUEL PUMP CONTROL UNIT

I I 93GOF2-775

1

93GOF2-799

I 93GOF2-800

I 93GOF2.776

FUEL PUMP CONTROL UNIT [BP TURBO] l

Refer to page Fl-12 for BP SOHC model.

hspection

1. Remove the MAZDA 232 1990 Suplement Repair Manual FUELSYSTEM F2

FUEL PUMP CONTROL UNIT

I I 93GOF2-775

1

93GOF2-799

I 93GOF2-800

I 93GOF2.776

FUEL PUMP CONTROL UNIT [BP TURBO] l

Refer to page Fl-12 for BP SOHC model.

hspection

1. Remove the](/img/28/57056/w960_57056-169.png)

FUELSYSTEM F2

FUEL PUMP CONTROL UNIT

I I 93GOF2-775

1

93GOF2-799

I 93GOF2-800

I 93GOF2.776

FUEL PUMP CONTROL UNIT [BP TURBO] l

Refer to page Fl-12 for BP SOHC model.

hspection

1. Remove the fuel pump control unit.

2.

Disconnect the fuet pump controt unit connector.

3. Check ctintinuity between the fuel pump control unit con-

nector terminal B (Y/L) and a ground.

4. Perform the following inspection according to the results of

the continuity check.

Continuity exists

1. Turn the ignition switch ON.

2. Ground the fuel pump control unit terminal B (Y/L) with a

jumper wire and verify that the voltage at the fuel pump con-

trol unit terminal D (in’) is OV.

3. Remove the jumper wire and verify that the voltage at the

fuel pump control unit terminal D (L/Y) is approx. WV af-

ter approx. IO sec.

No continuity exists

1. Turn the ignition switch ON

and verify that the voltage at

the fuel pump control unit terminal D (L/Y) is OV.

2. Disconnect the transfer pump connector.

3. Turn the ignition switch ON and verify that the voltage at

the fuel pump control unit terminat D (LA’) is approx. t2V.

Replacement

1. Move the driver’s seat backward.

2.

Remove the bolts and remove the fuel pump control unit

and bracket as an assembly.

3. Remove the fuel pump control

unit from the bracket.

4. Install in the reverse

order of removal.

F2--53

Page 171 of 677

F2 FUELSYSTEM -.

03UOFX-82: 93GOF2-777

2

r

TRANSFER PUMP SWlTCH

Removal I Installation

1. Refer to replacement of the transfer pump.

(Refer to below.)

Inspection

1. Check continuity between transfer pump connector termi-

nal C and ground terminal.

r Float Dosition I Comnuity

I

I Down I Yes

I

2. If not as specified, reptace the transfer pump switch.

TRANSFER PUMP

Inspection

1. Remove the rear seat cushion.

03UOFX-823 2. Disconnect the transfer pump connector.

3. Check for continuity between transfer pump connector

terminal-wires (ES) and (t/V).

4. If no continuity exists, replace the transfer pump.

03UOFX-825

F2-54

Replacement

Warning

l When servicing the fuel system, keep sparks,

cigarettes, and open flames away from the fuel.

1. Remove the rear seat cushion.

Page 172 of 677

FUEL SYSTEM F2

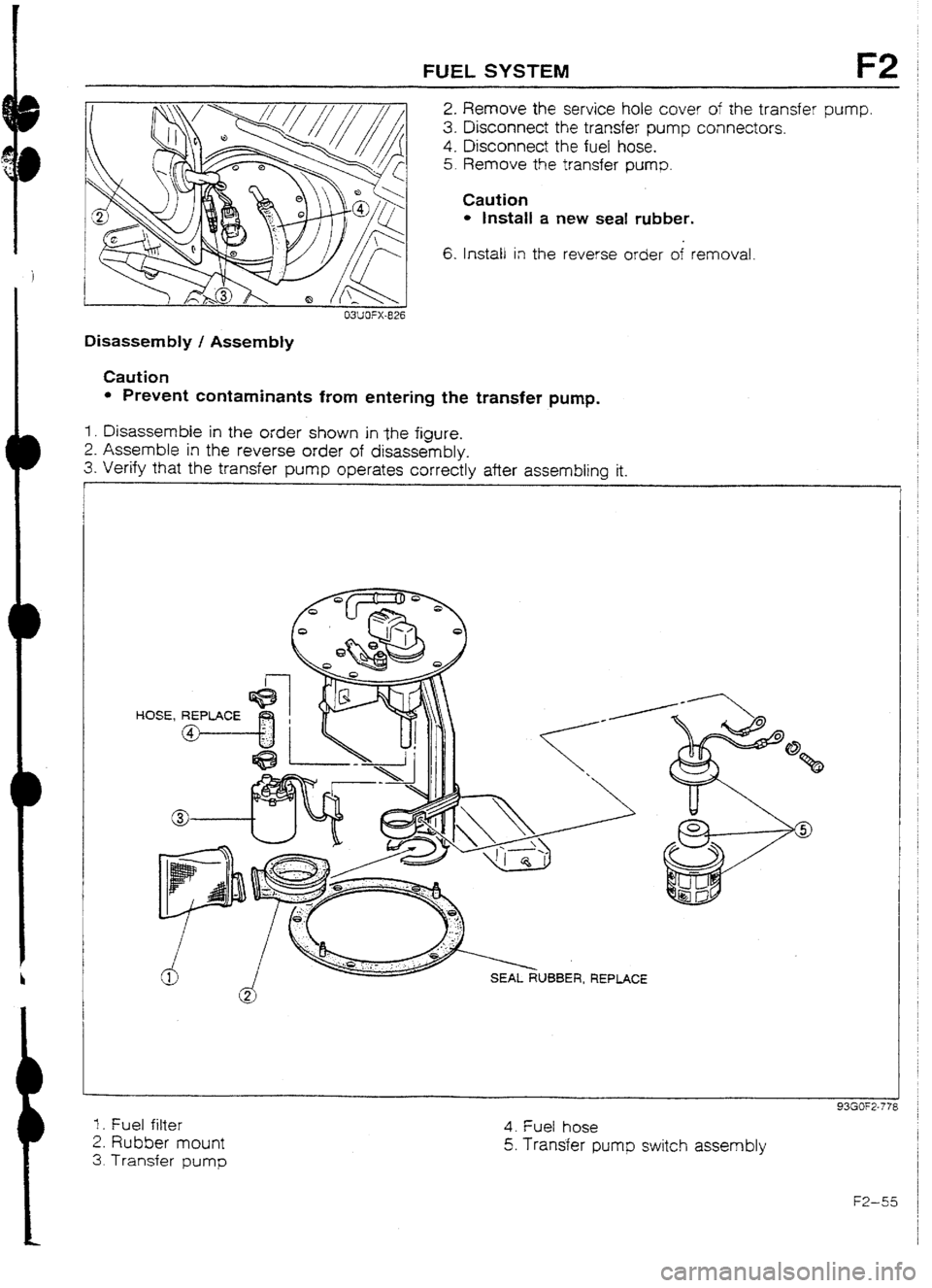

2. Remove the service hole cover of the transfer pump.

3. Disconnect the transfer pump connectors.

4. Disconnect the fuel hose,

5.

Remove the transfer pump.

6. Install in the reverse order of removal. Caution

l Install a new seat rubber.

03UOFX-826

Disassembly I Assembly

Caution

l Prevent contaminants from entering the transfer pump.

1. Disassemble in the order shown in ,the figure.

2. Assemble in the reverse order of disassembly.

3. Verify that the transfer pump operates correctly after assembling it.

HOSE, REPLACE

@

1. Fuel filter

2. Rubber mount

3. Transfer pump 4. Fuel hose

5. Transter pump switch assembly

93GOF2-77:

FZ-55

Page 173 of 677

F2 FUEL SYSTEM

93GOF2-775

1 93GOF2-78(

93GOF2-78:

1

93GOF2-78;

-

93GOF2-783

FUEL PUMP RESISTOR/RELAY

System Operation

I. Remove the rear seat cushion.

2,

Measure the voltage at the fuel pump connector terminal

A {G/O).

Voltage

r Crankinq Approx. 12V

I

I- Others t ACKXOX. I OV i

3. If not within specification, perform the following inspection,

and repair or replace if necessary.

l Fuel pump resistor/relay resistance. (Refer to below.)

l ECU II terminal voltage. (Refer to page F2-60.)

l Wiring harness and connector.

inspection

1.. Disconnect the connector.

2. Ground the fuel pump resister relay terminal D.

3. Apply 12V to terminal C and check for continuity between

terminals A and B.

Terminal C

12 applied

ov Continutty between A and B

NO

Yes

4. Measure the resistance between terminals E and F.

Resistance : 0.62-0.66Q [at 20% (68OF)l

INJECTOR

Volume Test

1. Remove the injectors with the delivery pipe.

2. Affix the injectors to the delivery pipe with wire.

Caution

l Affix the injectors firmly to the delivery pipe so that

no movement of the-injectors is possible.

Warning

l Be extremely careful when working with fuel.

Always work away from sparks or open flames.

3. Connect the SST to the battery and injector.

4. Check the injection volume with a graduated container.

Injection volume:

BP SUHC....44-47 cc (2.68-2.87 cu in)/15 sec.

BP Turbo

. ...87-105 cc (5.31 -6.41 cu in)/15 sec.

Caution

l When using the SST, make sure of the SST num-

ber and use correct one.

5. If nut correct, replace the injector(s).

Page 177 of 677

![MAZDA 232 1990 Suplement Repair Manual F2 CONTROL SYSTEM

Terminal voltage [BP TURBO]

eminal input Output , 1 Connected to Test condition Correct voltage Remark

IA - - Battery Constant Approx. 12V for backup

15 0 Main relay OFF Approx. MAZDA 232 1990 Suplement Repair Manual F2 CONTROL SYSTEM

Terminal voltage [BP TURBO]

eminal input Output , 1 Connected to Test condition Correct voltage Remark

IA - - Battery Constant Approx. 12V for backup

15 0 Main relay OFF Approx.](/img/28/57056/w960_57056-176.png)

F2 CONTROL SYSTEM

Terminal voltage [BP TURBO]

eminal input Output , 1 Connected to Test condition Correct voltage Remark

IA - - Battery Constant Approx. 12V for backup

15 0 Main relay OFF Approx. OV

(FUEL INJ relay) tgnltlon switch

-

ON Approx. 12V

1c 0 1 Ignition switch Wniie cranking Approx. 1 OV

-

(START)

lgnrtron switch ON Approx. OV

ID 0 Self -Diagnosis Test switch at “SELF-TEST” With Self-

Checker Lamp illuminated ior 3 sec. after ignition Approx. 5V Diagnosis Check-

(Monitor lamp) switch OFF* ON er and System

Lamp not illuminated after 3 sec. Approx. 12V Se’ector

Test switch at

“02 MONITOR” at idle

Monitor lamp illuminated Approx. 5V

Test switch at

“02 MONITOR” at idle

Monitor lamp not illumrnated Approx. 12’4

-lE - - - -

- -

1F 0 Self-Diagnosis Buzzer sounded for 3 sec. after ignition

Below 2.5V l With Self-

Checker switch OFF -+ ON Diagnosis

(Code Number)

Buzzer not sounded after 3 sec. Approx. 12V Checker and

Buzzer sounded Below 2.9 System Selector

l With System

Buzzer not sounded Approx. 12V Selector test

switch at

“SELF-TEST’ ’

I I 1G

0 Igniter

7H

0 Solenoid vahe

(Wastegate)

l!

0 Fuel pump

resistor/relay

I

lJ I r-Tcreiay Ignition switch ON

ld!e

Engine speed below 5,300 rpm

Engine speed above 5,300 rpm

While cranking

Idle

Ignition switch ON

AK switch ON at idle 1 Approx. OV

-

Approx. 0.2V

Approx. 12V

-

Below 1.5V

Approx. 1 OV

-

I3elow 15V

Approx. 12V

Below 2.5V

AIC switch OFF at idle Approx. 12V

-

IK 0 Diagnosis System Selector test switch at

connector

(TEN terminal)

1L - - -

- -

-

IM

t 0

1 Ground (Australia) Constant Below 1 .OV Not used

(Except Australia)

F2-60

Page 178 of 677

CONTROL SYSTEM F2

Incorrect voltage Possible cause

Always OV

l ROOM 10A fuse burned l Open circuit in wiring from ROOM 10A fuse to ECU termrnal IA

Always OV

I l Main relay maifunctlon l Open or short crrcu~t in wirrng from main relay to ECU termrnal 1 B

Always OV (Srarrer turns)

l Open or short circuit in wiring from ignition switch to ECU terminal 1C

Always UV

l Main relay (FUEL INJ relay} malfunctron l Open circuit in wiring from main relay to diagnosis connector terminal + B l Open or short circuit in wiring from dragnosls connector terminal MEN to

ECU terminal 1D

Always approx. 12V

I . Poor connection at ECU connector

l ECU matfunction

Always approx. 5V

l ECU malfunction

-

I -

Always below No disptay on Self- . Main relay (FUEL INJ retay) malfunction (Refer to page F3-142)

2.5V Diagnosis Checker l Open circuit in wiring from main relay to diagnosis connector termjnal + B

“88” displayed and

l Open or short circuit in wiring from diagnosis connector terminal FEN to

buzzer sounds con- ECU terminal 1 F

tinuously

Always approx. 12V

l Poor connection at ECU connector l ECU malfunction

Always OV

l Short circuit in wiring from igniter to ECU terminal tG

Atways OV or approx. 12V

l Refer to Code No.42 Troubleshooting (Refer to page F2-30)

Always approx. 12V

l Fuel pump resistor/relay malfunction

Always OV

l Open or short circuit in wiring from ECU terminal 1 I to resistor/retay

Always below

A/C does not operate

l AJC relay malfunction

23 l Open circuit in wiring from ignition switch to NC relay l Open circuit in wiring from A/C relay to ECU terminal IJ

A/C switch OFF but

l Short circuit in wiring from A/C relay to ECU terminal IJ

AIC operates

l ECU matfunction

Always approx. t2V

Always below 1 .OV

l Poor connection at ECU connector l ECU malfunction

l Short circurt in wiring from diagnosis connector terminal TEN to ECU termi-

nal 1K

Always approx. 12V

l Open circutt in wiring from diagnosis connector terminal TEN to ECU termi-

nal lK

l Open c~rcud in wiring from diagnosis connector terminal GND to ground

Always above 1 .OV

I

l Open circuit in wiring from ECU terminal 1 M to ground

F2-61