air condition MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 13 of 677

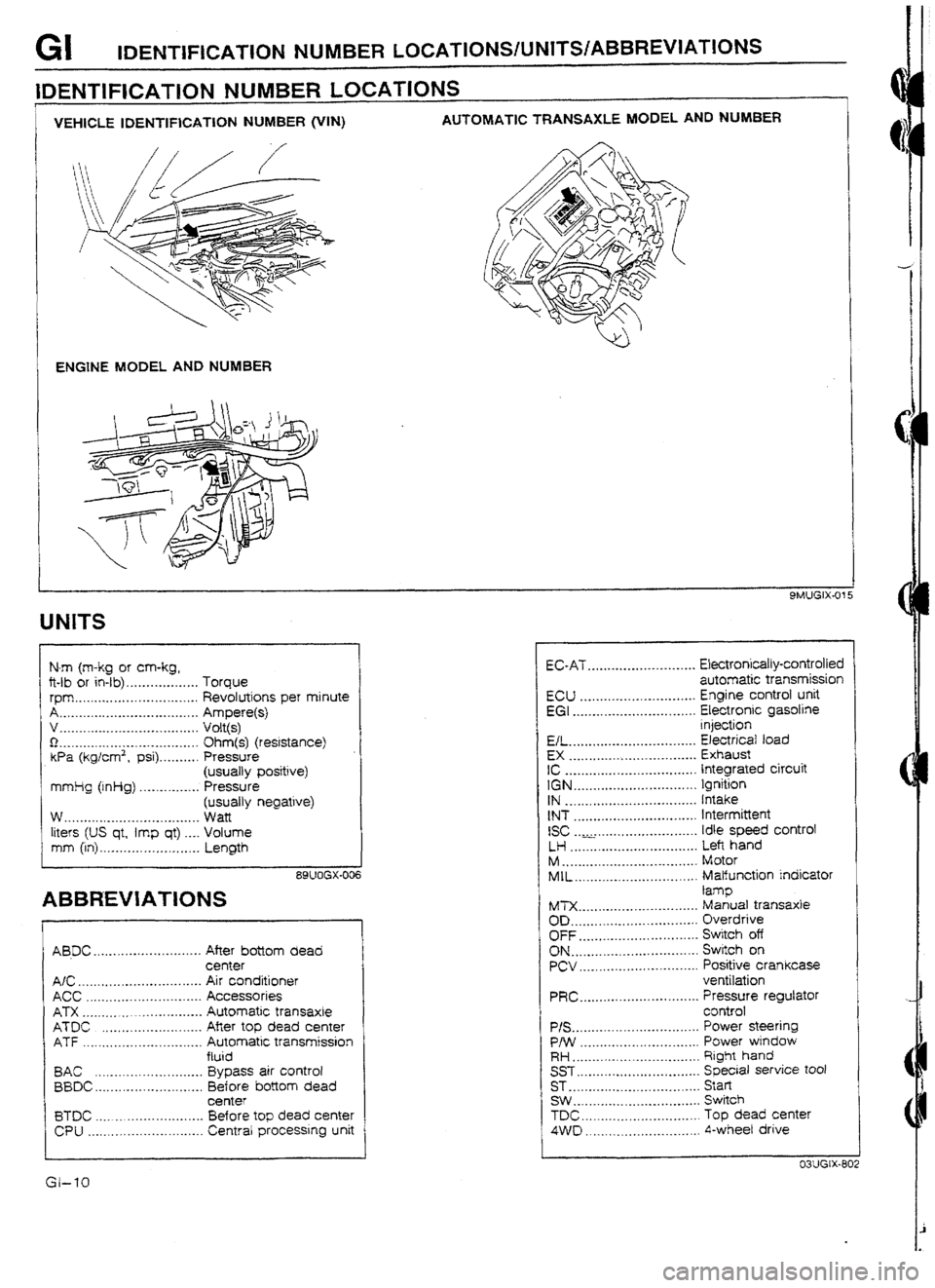

GI IDENTIFICATION NUMBER LOCATIONSIUNITSIABBREVlATlONS

IDENTIFICATCON NUMBER LOCATIONS

I

VEHKZLE IDENTIFICATION NUMBER @‘IN) AUTOMATIC TRANSAXLE MODEL AND NUM8ER

ENGINE MODEL AND NUMBER

UNlTS

N-m (m-kg or cm-kg,

ft-lb or in-lb) . . . . . .._.......... Torque

rpm ._._..._.. . . . . . . .._.._.._. . .._. Revolutions per minute

A . . .._._._...__.._.._.._. .__...._. . . Ampere(s)

v .._.... .* .*... ..__.._...*. ..*. .*. ,. Volt(s)

0 I.._._............**..-.-*..-....... Ohm(s) (resistance)

Wa (kg/cm2, psi) . . . . . . . . . . Pressure

(usually positive)

mmlig (inHg) . . . . . . .._.._... Pressure

(usually negative)

w . . . ..*.....e*.-..-..-.....*.e..... Watt

liters (US qt, imp qt) .._. Volume

mm (in) ,_._.._._..._.,_. .~. . ..__ Length

89UOGX-006

ABBREVIATIONS

AB.DC ........................... After bottom dead

center

A/C _ .............................. Air conditioner

ACC ............................. Accessories

ATX ............................. Automatic transaxte

ATDC ......................... Afier top dead center

ATF .............................. Automatic transmission

ftuid

BAC ........................... Bypass air control

BBDC.. ......................... Before bottom dead

center

BTDC ........................... Before top dead center

CPU ............................. Central processing unit t EC-AT ........................... Ekctronically-controlled

automatic transmission

ECU ............................. Engine control unit

EGI ............................... Electronic gasotine

injection

EL ................................ Electricaf toad

EX ................................ Exhaust

IC ................................. Integrated circuit

IGN ............................... Ignition

IN ................................. Intake

tNT ............................... Intermittent

ISC ............................. Idle speed control

LH ................................ Left hand

M .................................. Motor

MIL ............................... Malfunction indicator

lamp

tb4TX. ............................. Manual transaxle

OD. ............................... Overdrive

OFF .............................. Switch off

ON ................................ Switch on PCV .............................. Positive crankcase

ventilation

PRC.. ............................ Pressure regulator

control

P/S ................................ Power steering

P/W .............................. Power wtndow

RH.. .............................. Right hand

SST ............................... Special service tool

ST .................................

Start

SW . . .............................. Switch

TDC. ............................. Top dead center

4VVD ............................. 4-wheel drive

Page 21 of 677

A PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

pieziG-

INSPECT and ADJUST, if necessary, the following Items to

specification:

D Glass, exterior bright metal and paint for damage

Cl Wheel tug nuts

9 Trre pressures

LII All weatherstrips for damage or detachment

Z Operation of bonnet release and lock

D Operation of trunk lid, hatch and fuel lid opener

(it equipped)

3 Door operation and alignment

5 Headlight aiming

INSTALL the following parts:

D Wheel caps or rings (if equipped)

D Outside mirror(s)

[ UNDER BONNET-ENGINE OFF )

INSPECT and ADJUST, if necessary, the foIlowIng items to

specification:

Cl Fuel, coolant and hydraulrc lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level (if equipped)

D Brake master cylinder fluid levels

0 Clutch master cylinder fluid levels (if equipped) q

Windshield washer reservoir fluid level

D Radiator coolant level and specific gravity

Ll Tightness of water hose clamps

I3 Tightness of battery terminals, electrolyte level and specific

gravity

c) Manual transaxle oit level

D Drive belt(s) tension

C; Carburetor linkage (choke control, wide open throttle posi-

tion, etc.) (carburetor model only)

D Accelerator cable and linkage for free movement

D Headlight cleaner and fluid level (if equipped)

BLEED air from fuel line (diesel engine only)

CLEAN the spark plugs (except for diesef engine)

piicis-1

INSTALL the foflowing parts:

C Rubber stopper for inside rear view mirror (if equipped)

c! Fuse for accessories

CHECK the operation of the following items:

Cl Seat controls (sliding and redining) and head rest

ci Seat belts and warnrng system

Z! Ignition swrtch and steering lock

III Power window {if equipped)

0 Door locks including child proof door locks

0 Inhibitor switch

(ATX only)

Z All lights including warning and indicator lights

0 Ignrtron key reminder buyer (if equipped) Cl Horn, wipers and washers (front and rear, if equipped)

D Antenna (if equipped} q

Cigarette lighter and clock (if equipped)

I2 Remote controt outside mirror

(if equipped) q

Heater, defogger and air conditioner at various mode selec-

tions (if equipped)

c3 Sunroof (if equipped)

CHECK

the fotiowing items: q

Presence of spare fuse

c3 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

Cl Operation and fit of windows

D Pedal height and free ptay of brake and clutch pedal

Cl Parking brake

i UNDER BONNET-ENGtNE RUNNING AT ]

1 OPERATtNG TEMPERATURE

CHECK the following items:

Cl Operation of idle-up system for air conditioner or power steer-

ing (if equipped)

13 Automatic transaxle fluid level

D Initial ignition timing

(except disel engine) q

Idle speed

El Operation of throttle position sensor (EGI engine)

13 Operation of cold start device and glow plug warning light

(diesel engine only)

D Operation of dash pot [EGI engine)

t

ON HOtST 1

CHECK the following items:

U Underside fuel, coolant and hydraulic lines, fittings, connec-

tions and components for leaks q

Tires for cuts or bruises

Cl Steering linkage, suspension, exhaust system and all under-

side hardware for

looseness or damage

1 ROAD TEST 1

CHECK the foliowing items:

II Brake operation

D Clutch operation

0 Steering control

c3 Operation of meters and gauges

0 Squeaks, rattles or unusual noises q

Engine general performance

c3 Emergency Iocking retractors

rAFTER ROAD TEST 1

REMOVE the seat and floor mat protective covers

CHECK for the necessary

owner information materials, tools

and spare tire in vehicle

93EOAX-002

A-2

Page 22 of 677

SCHEDULED MAINTENANCE SERVICES (Australia) A

SCHEDULED MAINTENANCE SERVICES (Australia)

Chart symbols:

I : Inspect: Visual examination or functiona! measurement of a system’s operation (Performance)

A: Adjust

R: Replace or change

T : Tighten

Note

l As the result of visual examination or functional measurement of a system’s operation (Per-

formance), correct, clean or replace as required.

REMARKS:

After 90,000 km or 72 months, continue to follow

the described maintenance items and intervals periodically.

As

“I

*2

*3

“4

l 5 for *

marked items in this maintenance chart please pay attention to the following points.

If the vehicfe is operated under the foltowing conditions, it is suggested that

the engine oil and oil f&r

be changed more often that at usual recommended intervals.

a> Driving in dusty condrt,ons.

b) Extended periods of idling

or low speed operation.

c) Driving for a prolonged period iti coid temperatures or driving only short distances regularly.

Replacement of the timing belt is required at every 105,000 km. failure to replace the timing belt may

result in damage to the engine.

If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, repface more often

than at usual recommended intervals.

Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid shotlid be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-702

-

A-3 i

Page 24 of 677

!

i

i

I

i

t-

I

i

i

e

-1

SCHEDULED MAfNTENANCE SERVICES (Europe) A

MAINTENANCE TABLE (Leaded Fuel Model)

Chart symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80.000 km or 48 months, continue to foltow the described maintenance at the recommended intervals.

As

*I

*2

“3

*4

*5

*6

*7 for *’

marked items in this’ maintenance chart, note the following points.

Major service interval at 12 months!ZO,OOO km (I 2,000 miles).

Lubrication service based on distance only, 10,000 km (6,000 miles), not time.

Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

ii equipped.

Replacement of the timing belt is required every ICQOUO km (60,000 miles). Failure to replace the timing

belt may result in damage to the engine.

If the vehicle is operated under any of the following conditions, it is suggested that the engine

oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for prolonged periods in cold temperatures or regularly driving only short distances.

If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than the recommended intervals.

This is a full function check of all electrical systems, i.e, afl lights, washers (inctuding condition of blades)

electric windows sunroof, horn, etc.

Replace every two years.

tf there has been continuous hard driving, mountain driving, or it the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-704

A-5

Page 27 of 677

A SCHEDULED MAINTENANCE sERvw3 (Europe)

SCHEDULED MAfNTENANCE SERWCES (Europe)

MAWTENAN CE TABLE (Unlead Fuel Model)

Chati symbols:

I : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

* 1 Major service interval at 12 months120,OOO km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

*2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

“3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). failure to replace the tim-

ing belt may result in damage to the engine.

“4 If the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the &commended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c> Driving for a prolonged periods in cold temperatures or regularly driving only short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more oten

than at usual recommended intervals.

*6 This is a full function check of all electrical systems, i.e, all lights, washers (including condition of blades)

electric windows, sunroof, horn etc.

“7 Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-707

A-8

Page 97 of 677

E OUTLINE

ELECTRIC COCUNG FAN SYSTEM (BP DOHC TURBO)

System Circuit

I I

WITH A/C

r----‘-- -___- ---------.--------;

ADDITIONAL

FAN

MOTOR

I

II 1 A/C RELAY

RAD1ATdTHERMOSWITCH

ABOVE 105% I221 OF-): ON +IIAGNOSlS

CONNECTOR

WATER

THERMOSWlTCH

ABOVE 97% (207OF): ON

Operation 1. When the coolant temperature exceeds 97OC (207*F), the water thermoswitch turns ON to close the No.7

relay, and connects the + I and -1 terminals of the fan motor

connector. The fan motor turns at low

speed (about 1,660 rpm).

2. When the coolant temperature exceeds 105OC (221 OF), the radiator thermoswitch turns ON, to close the

No.2 and No.3 relays, and connects

the +2 and -2 terminals of the fan motor connector. The fan mo-

tor turns at high speed (about 2,200 rpm).

3. if the vehicle is equipped with air conditioning, the cooling fan motor operates whenever the

NC switch

and the blower switch are on, regardless of

the coolant temperature. Also, when the A/C switch and the blower switch are on, the A/C retay closes

to operate the additional fan

motur.

Note

l The water thermoswitch and the cooling fan reIay are normally-open switches.

Checking cooling fan operation 1. Jump across the TFA and the GND terminals

of the diagnosis connector with a jumper wire.

2. Turn the ignition switch to ON and verify that the cooling fan operates smoothly.

Note

l When the water thermoswitch connector is disconnected, the cooling fan wiif not operate.

E-8

Page 138 of 677

![MAZDA 232 1990 Workshop Manual Suplement CONTROL SYSTEM

WE~DOST WARNlNG BUZZER [BP TURBO]

To improve engine reliability, the overboost warning buzzer installed in the instrument cluster sounds during

overboost conditions as detected by en MAZDA 232 1990 Workshop Manual Suplement CONTROL SYSTEM

WE~DOST WARNlNG BUZZER [BP TURBO]

To improve engine reliability, the overboost warning buzzer installed in the instrument cluster sounds during

overboost conditions as detected by en](/img/28/57056/w960_57056-137.png)

CONTROL SYSTEM

WE~DOST WARNlNG BUZZER [BP TURBO]

To improve engine reliability, the overboost warning buzzer installed in the instrument cluster sounds during

overboost conditions as detected by engine

speed and intake air amount caiculations within the ECU. The

driver is thus warned to reduce engine

speed.

DETECTtON

OVERBOOST

BUZZER

TURBOCHARGE INDICATOR [BP TURBO]

When the turbocharger boost pressure calcul’ated by intake air amount and engine speed reaches the predeter-

mined level and the transaxle is in gear, the turbocharge indicator illuminates to inform the driver of turbocharge

operation.

1

AIRFLOW METER

DISTRI BUTUR

rd” i

4 NEUTRAUCLUTCH

SWITCH ECU

* CALCULATION

-, OF

BOOST

PRESSURE

TURBOCHARGE

INDICATOR

Page 140 of 677

![MAZDA 232 1990 Workshop Manual Suplement CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid hea MAZDA 232 1990 Workshop Manual Suplement CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid hea](/img/28/57056/w960_57056-139.png)

CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid heating ceramic heater to detect the air/fuel ratio,

PRESSURE REGULATOR CONTROL SYSTEM [BP TURBO]

PRESSURE

REGULATOR

I SOLENOID VALVE

(PRESSURE REGULATOR CONTROL)

FUEL

+ (FROM

DELIVERY PIPE1

II

FUEL INJ I

RELAY

(MAIN REU\Y)

I

II Ir

-__. _ - -’ VACUUM

CT0 DYNAMIC

Ill

CHAMBER)

BATTERY -

c

FUEL

(TO FUEL TANK)

nme*rn -.-a

To prevent percolation of the fuel during hot restart idle, vacuum to the pressure regulator k cut for 180

sec., and the fuel injection pressure is increased to slightly more than 284 kPa (2.90 kg/cm’, 41.2 psi).

Operating condition

l Coolant temperature: Above 90°C (194OF)

l Intake air temperature: Above 58OC (136OF)

g No-load condition

FZ-23

Page 147 of 677

F2 SELF-DIAGNOSlS FUNCTION

XIDE No. 1 42 (SOLENOID VALVE - WASTEGATE)-BP TURBO STEP

tNSPECTiON

ACTION

1

Disconnect connector from ECU and check if Yes Check ECU terminal connector for poor

battery voltage exists at connector terminal f H connection

(O/B) with Ignition switch ON

e If OK, replace ECU

4 tf not OK, repalr or replace connector

No Go to next step

2 in same condition as Step 1, check if battery Yes Repair wiring harness voltage extsts at solenoid valve connector

terminal-wire

NO Go to next step

3 Check if solenoid valve is OK

Yes Check for short or open circuit in wiring

.r3 page F2-46 from main relay (FUEL INJ relay) to

solenoid valve

NO Replace solenoid valve

Circuit Diagram

BA-iTERY

15A k

IGNITION SWITCH v /\: ./

WIG

B/w O/B

‘L a,

d

MAIN RELAY

(FUEL INJ)

WASTEGATE

SOtENOlD VALVE

ECU

WASTEGATE MAIN RELAY (FUEL INJ)

SOLENOfD VALVE

RIB 011 GIB WIG * LGIY L GM,

l v L/R

I

A WIG %fw

W/R

1u

10 1M 1K 71 B O/B

I I

i

B&Y B/L B;G UY Rh’ * I

I

IJB d/B WiB Wff W/R W/R B

F2-30

Page 149 of 677

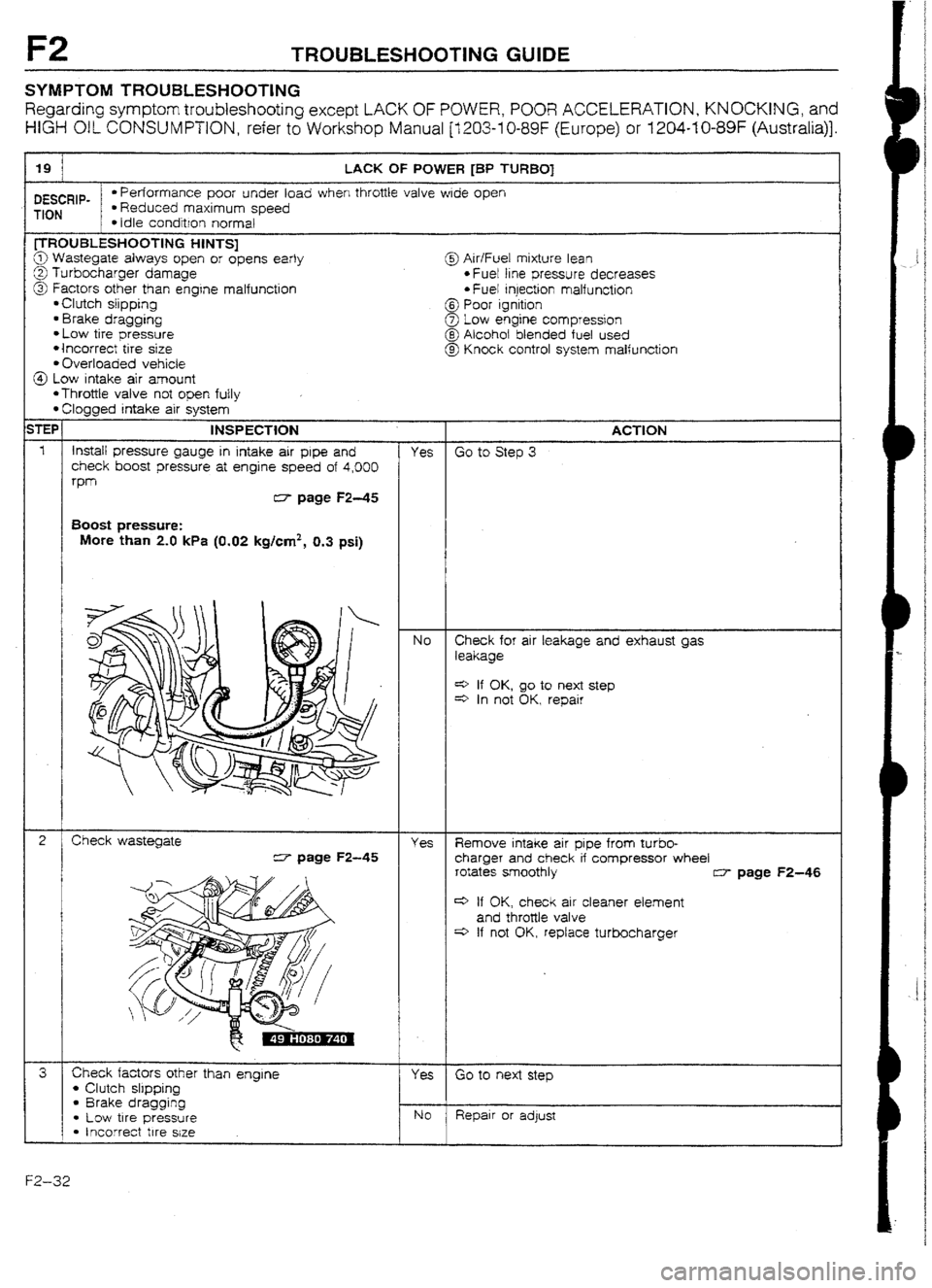

F2 TROUBLESt=iUUTlNG GUIDE

SYMPTOM TROUBLESHOOTING

Regarding symptom troubleshooting except LACK OF POWER, POOR XCELERATION, KNOCKING, and

HIGH UIL CONSUMPTION, refer to Workshop Manual [I 203-l O-89F (Europe) or 1204-l O-89F (Australia)].

19 LACK OF POWER [BP TIJR801

DESCRIP- *Performance poor under load when throttle valve wide open

TION *Reduced maximum speed

l Idle condition normal

[TROUBLESHOOTING HINTS1

3 Wastegate always open or opens early

3 Turbocharger damage

@ Factors other than engine malfunction

*Clutch sllpping

l Brake dragging

*Low tire pressure

l Incorrect tire size l Overloaded vehicle

@ Low intake air amount

*Throttle valve not open fully

*Clogged intake air system

TEP INSPECTlON

1

Install pressure gauge in intake air pipe and

check boost pressure at engine speed of

4,000

wm

CT page F2-45

Boost pressure:

More than 2.0 kPa (0.02 kglcm2, 0.3

psi)

@ Air/Fuel mixture lean

l Fuel iine pressure decreases l Fuel injection malfunction

@ Poor ignrtjon

@ Low engine compression

@ Alcohol blended fuel used

@ Knock control system malfunction

ACTION

Yes Go to Step 3

NO Check for air leakage and exhaust gas

leakage

4 If OK, go to next step

4 In not OK, repair

2 Check wastegate

Yes Remove intake air pipe from turbo-

f7 page F2-45 charger and check if compressor wheel

rotates smoothly t7 page F2-46

4 If OK, check air cleaner element

and throttle valve

+ If not OK, replace turbocharger

3 Check factors other than engrne Yes

l Clutch slipping Go to next step

1 8rake dragging

’

l Low tire pressure NO Repair or adjust

l Incorrect tire srze

FZ-32