diagram MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 2 of 677

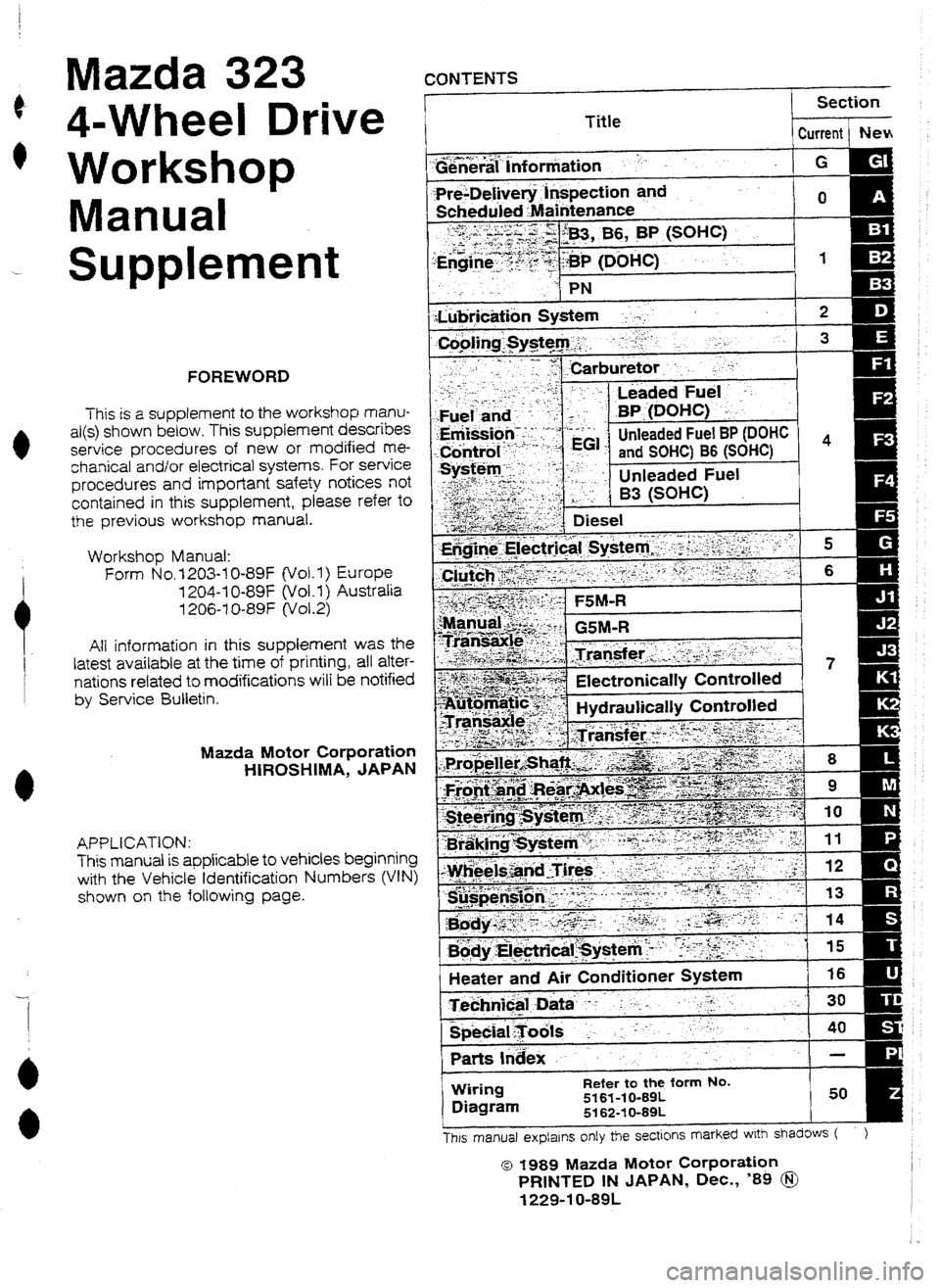

Mazda 323

4-Wheel Drive

Workshop

Manual CONTENTS

Title Section

Current ) NeH

Supplement

FOREWORD

This is a supplement to the workshop manu-

al(s) shown below. This supplement describes

service procedures of new or modified me-

chanical and/or electrical systems. For service

procedures and important safety notices not

contained in this supplement, please refer to

the previous workshop manual.

Workshop Manual:

Form No. 1203-I O-89F (Vol. I> Europe

1204-I O-89F (vol. I > Australia

I ZM-1 o-89F (vol.2)

Ali information in this supplement was the

latest available at the time of printing, all alter-

nations related to modifications wili be notified

by Service Bulletin.

Mazda Motor Corporation

HIROSHlMA, JAPAN

APPLlCATlON:

This manual is applicable to vehicles beginning

with the Vehicle Identification Numbers (UN)

shown on the following page. Electronically Controlled

Wiring

Diagram

Refer to the form No. 5161-l O-89L

5162-t O-89L

Thrs manual explarns only the sectIons marked with shadows ( ) 0 1989 Mazda Motor

Corporation

PRlNTED IN JAPAN, Dec., ‘88 @$ 1229-l O-891

Page 95 of 677

E OUTlANE

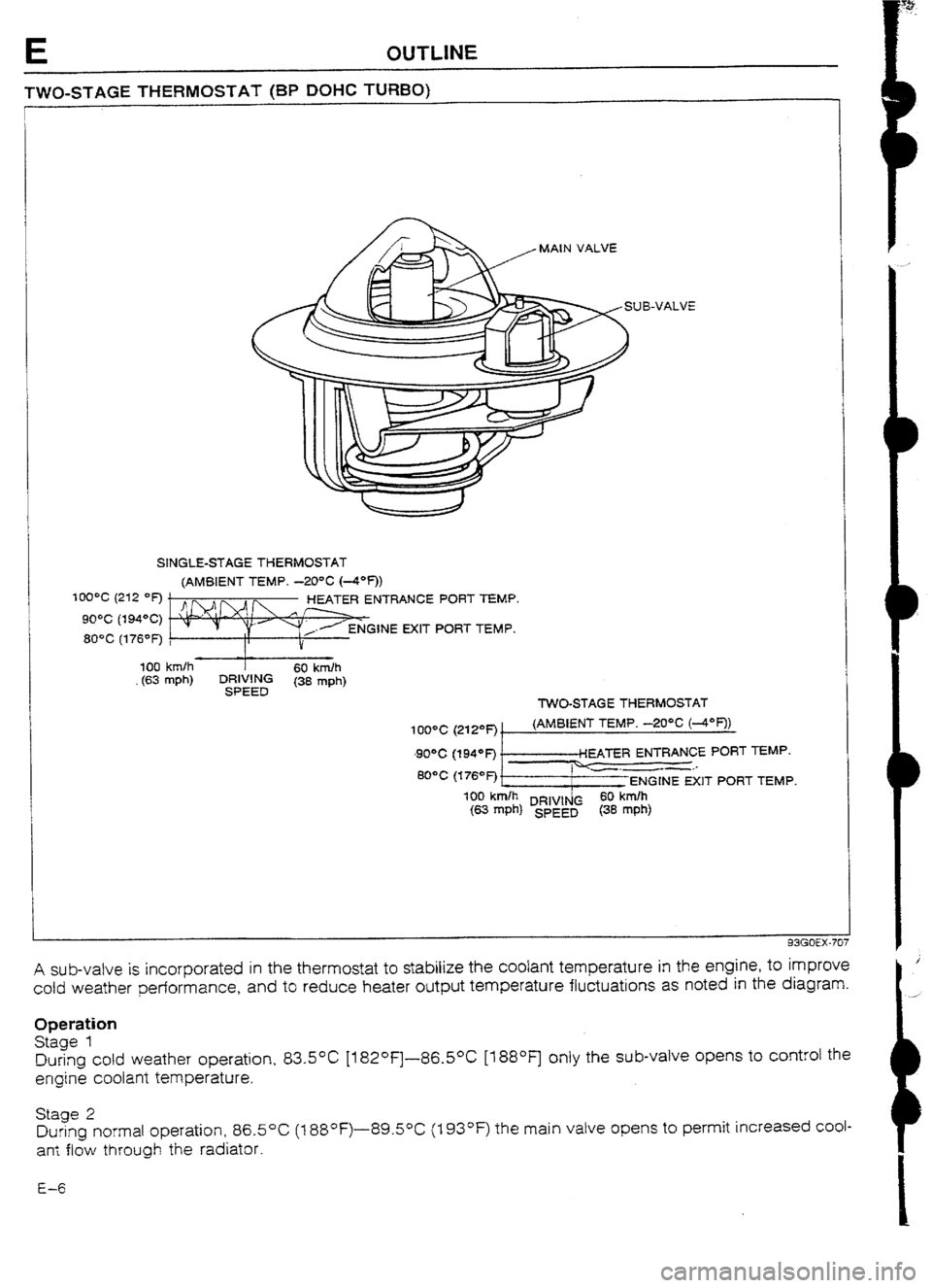

TWO-STAGE THERMOSTAT (BP DOHC TURBO)

MAIN VALVE

SINGLE-STAGE THERMOSTAT

(AMBIENT fEMP. -20% (4*f))

NTRANCE PORT TEMP

GINE EXIT PORT TEMP.

- 100 km/h

60 kndh

(63 mph) ~~~~~ (38 mph)

TWO-STAGE THERMOSTAT

A sub-valve is incorporated in the thermostat to stabilize the coolant temperature in the engine, to improve

cold weather performance, and to reduce heater output temperature fluctuations as noted in the diagram.

Operation

Stage 1

During cold weather operation, 83.5*C [182°F]-86.50C [t 88OF] only the sub-valve opens to control the

engine coolant temperature.

Stage 2

During normal operation, 86.5OC (1 88°F)-89.50C (I 93OF) the main valve opens to permit increased coul-

an: flow through the radiator.

E-6

Page 104 of 677

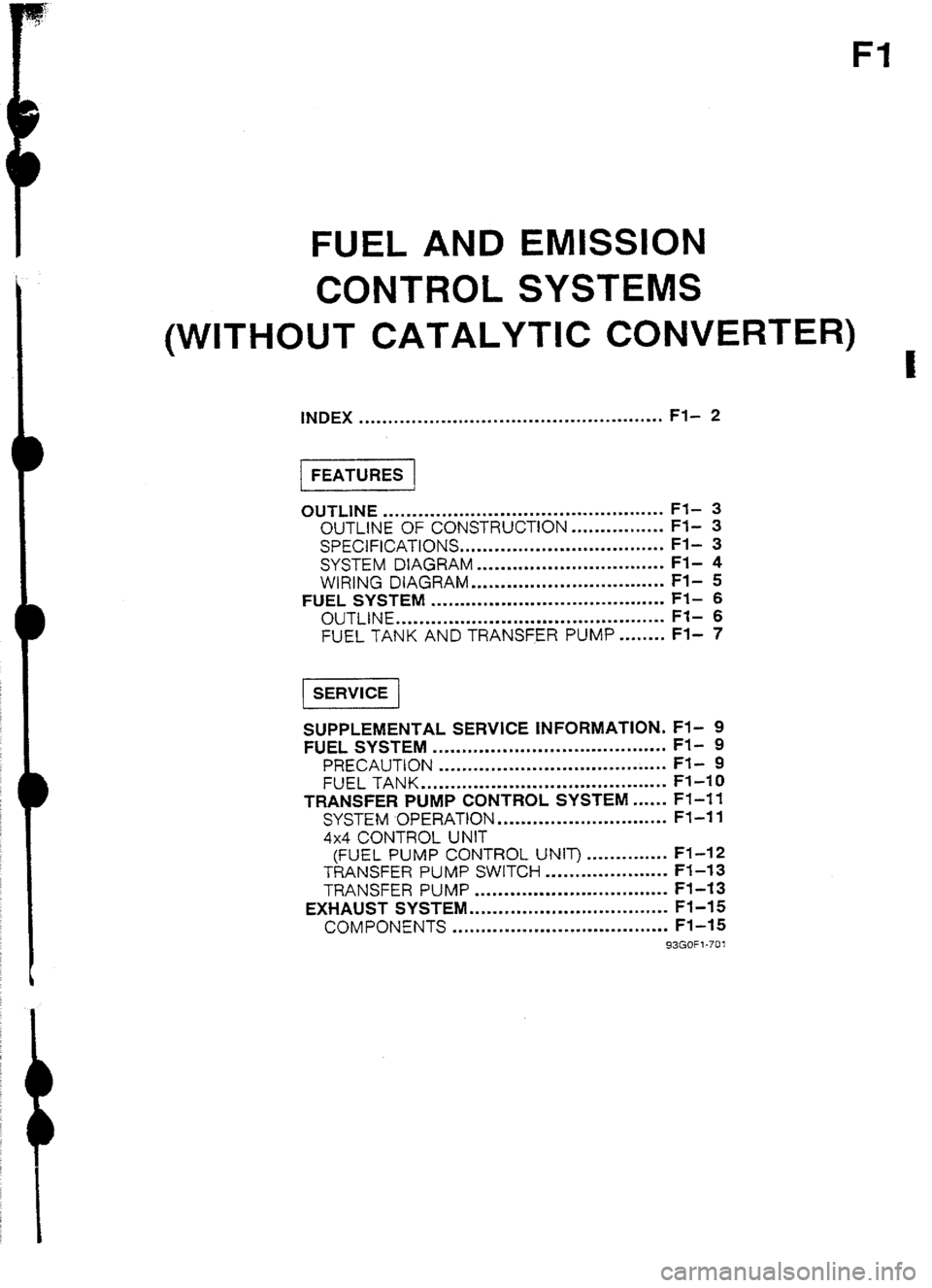

Fl

FUEL AND EMISSION

CONTROL SYSTEMS

(WITHOUT CATALYTIC CONVERTER)

I

INDEX . . . ..*.....*....**..............................~... Fl- 2

1 FEATURES 1

OUTLINE ................................................ Fl- 3

OUTLINE OF CONSTRUCTION ................ Ff- 3

SPECIFICATIONS ................................... Fl- 3

SYSTEM DIAGRAM

................................ FI- 4

WIRING DIAGRAM

................................. Fl- 5

FUEL SYSTEM

........................................ Fl- 6

OUTLINE .............................................. Fl- 6

FUEL TANK AND TRANSFER PUMP.. ...... Fl- 7

1 SERVICE j

SUPPLEMENTAL SERVICE INFORMATION. Fl- 9

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . ..I.... . . . . . . . . . . . . Fl- 9

PRECAUTION . . . . . . . ..,.. . ..*...... . . . . . . . . . . . . . . ..I Fl- 9

FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..I.. ..I Fl-ICI

TRANSFER PUMP CONTROL SYSTEM ..I... Ff-If

SYSTEM OPERATION . . . . . . . . . ..I................. Fl-11

4x4 CONTROL UNIT

(FUEL PUMP CONTROL UNIT-j . . . . . . ..I..... FI-12

TRANSFER PUMP SWITCH . . . . . . . . . . . . . . . . . . . . . F1-13

TRANSFER PUMP . . . . . . . . . ..l..................... Fl-13

EXHAUSTSYSTEM

. . . . ..I....... l . . . . . . . . . . . . . a. I... Ff-15

COMPONENTS . ..a.. . . . . . . . . . . . . . . . . . I..... . . . . . . . . Fl-15

93GOFf -701

Page 120 of 677

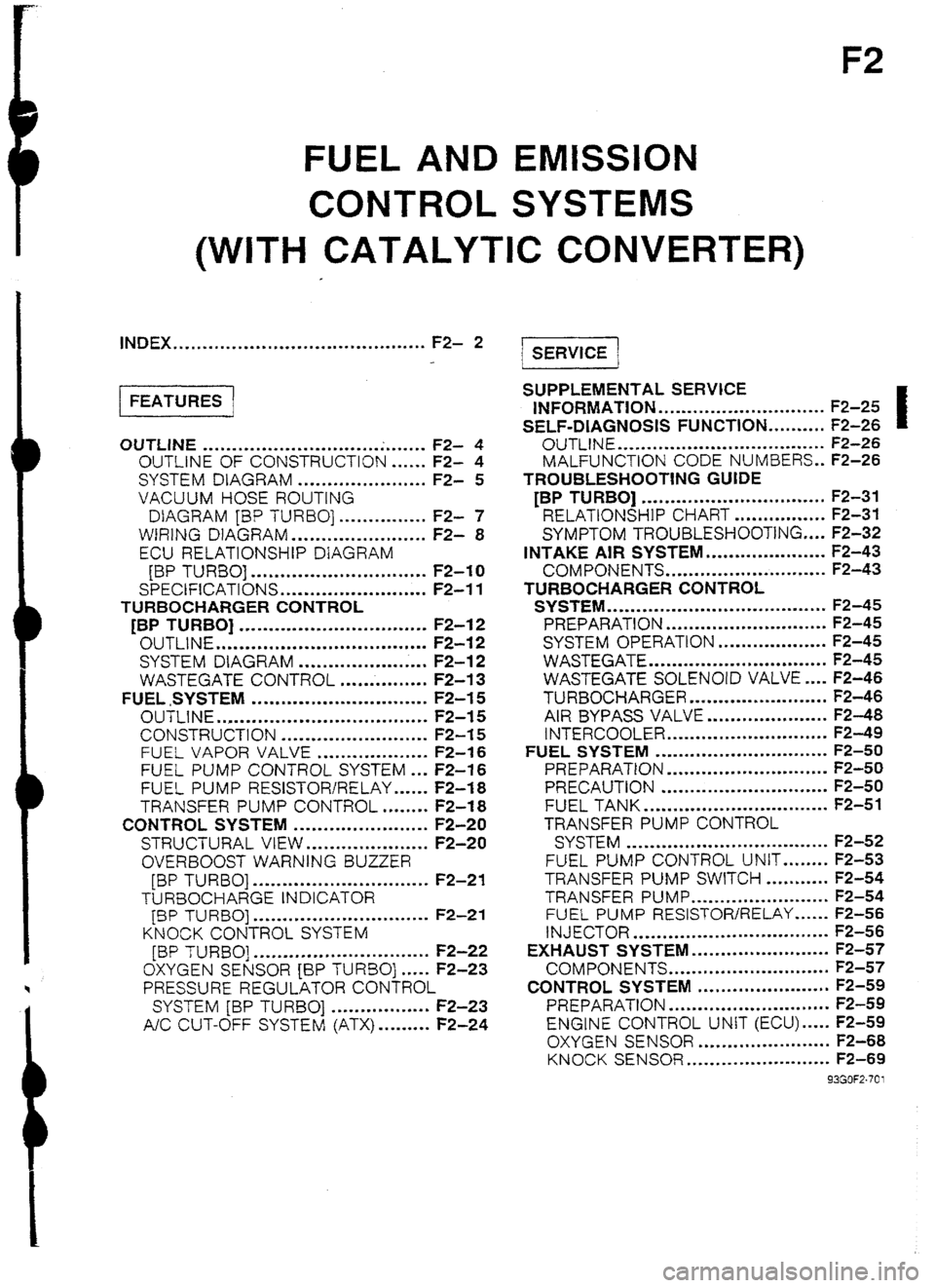

F2

FUEL AND EMISSION

CONTROL SYSTEMS

(WITH CATALYTIC CONVERTER)

.

INDEX ..*.........**.*.........*..........*...... F2- 2

OUTLINE ...................................... F2- 4

OUTLINE OF CONSTRUCTION.. .... F2- 4

SYSTEM DIAGRAM ...................... F2- 5

VACUUM HOSE ROUTING

DIAGRAM [BP TURBO] ............... F2- 7

WIRING DlAGRAM.. ..................... FZ- 8

ECU REtATlONSHIP DIAGRAM

[BP TURBO] .............................. F2-10

SPEClFtCATlONS. ........................ F2-11

TURBOCHARGER CONTROL

[BP TURBO] ................................ F2-I 2

OUTLINE .................................... F2-I 2

SYSTEM DIAGRAM ................. .; ... F2-12

WASTEGATE CONTROL ...............

F2-13

FUEL,SYSTEM

.............................. F2-15

OUTLINE

.................................... F2-15

CONSTRUCTlON ......................... F2-15

FUEL VAPOR VALVE ................... F2-16

FUEL PUMP CONTROL SYSTEM.. . F2-16

FUEL PUMP RESISTOR/RELAY ...... F2-18

TRANSFER PUMP CONTROL. ....... F2-I 8

CONTROL SYSTEM ....................... F2-20

STRUCTURAL VIEW.. ................... F2-20

OVERBOOST WARN!NG BUZZER

[BP TURBO] .............................. F2-21

TURBOCI-IARGE INDICATOR

[BP TURBO] .............................. F2-21

KNOCK CONTROL SYSTEM

[BP TURBO] .............................. F2-22

OXYGEN SENSOR [BP TURBO]. .... F2-23

PRESSURE REGULATOR CONTROL

SYSTEM [BP TURBO] ................. F2-23

A/C CUT-OFF SYSTEM (ATX) .........

F2-24 SUPPLEMENTAL SERVICE

INFORMATION ............................. F2-25

SELF-DIAGNOSIS FUNCTION .......... F2-26

OUTLINE

.................................... F2-26

MALFUNCTION CODE NUMBERS . . F2-26

TROUBLESHOOTtNG GUIDE

[BP TURBO1

................................ F2-31

RELATlONSHlP CHART ................ F2-31

SYMPTOM TRUUBLESH0OTlNG .... F2-32

tNTAKE AIR SYSTEM ..................... F2-43

COMPONENTS ............................ F2-43

TURBOCHARGERCONTROL

SYSTEM ...................................... F2-45

PREPARATION ............................ F2-45

SYSTEM OPERATION ................... F2-45

WASTEGATE ............................... F2-45

WASTEGATE SOLENOID VALVE.. .. F2-46

TURBOCHARGER ........................ F2-46

AIR BYPASS VALVE ..................... F2-48

INTERCOOLER ............................ F2-49

FUEL SYSTEM .............................. F2-50

PREPARATION ............................ F2-50

PRECAUTION ............................. F2-50

FUEL TANK

................................ F2-51

TRANSFER PUMP CONTROL

SYSTEM ................................... F2-52

FUEL PUMP CONTROL UNIT ........ F2-53

TRANSFER PUMP SWITCH ........... F2-54

TRANSFER PUMP.. ...................... F2-54

FUEL PUMP RESISTOR/RELAY ...... F2-56

INJECTOR

.................................. F2-56

EXHAUST SYSTEM

COMPONENTS .................................................... ;ff;

CONTROL SYSTEM ....................... F2-59

PREPARATION

............................ F2-59

ENGINE CONTROL UNIT (ECU) ..... F2-59

OXYGEN SENSOR ....................... F2-68

KNOCK SENSOR ......................... F2-69

93GOF2.701

Page 124 of 677

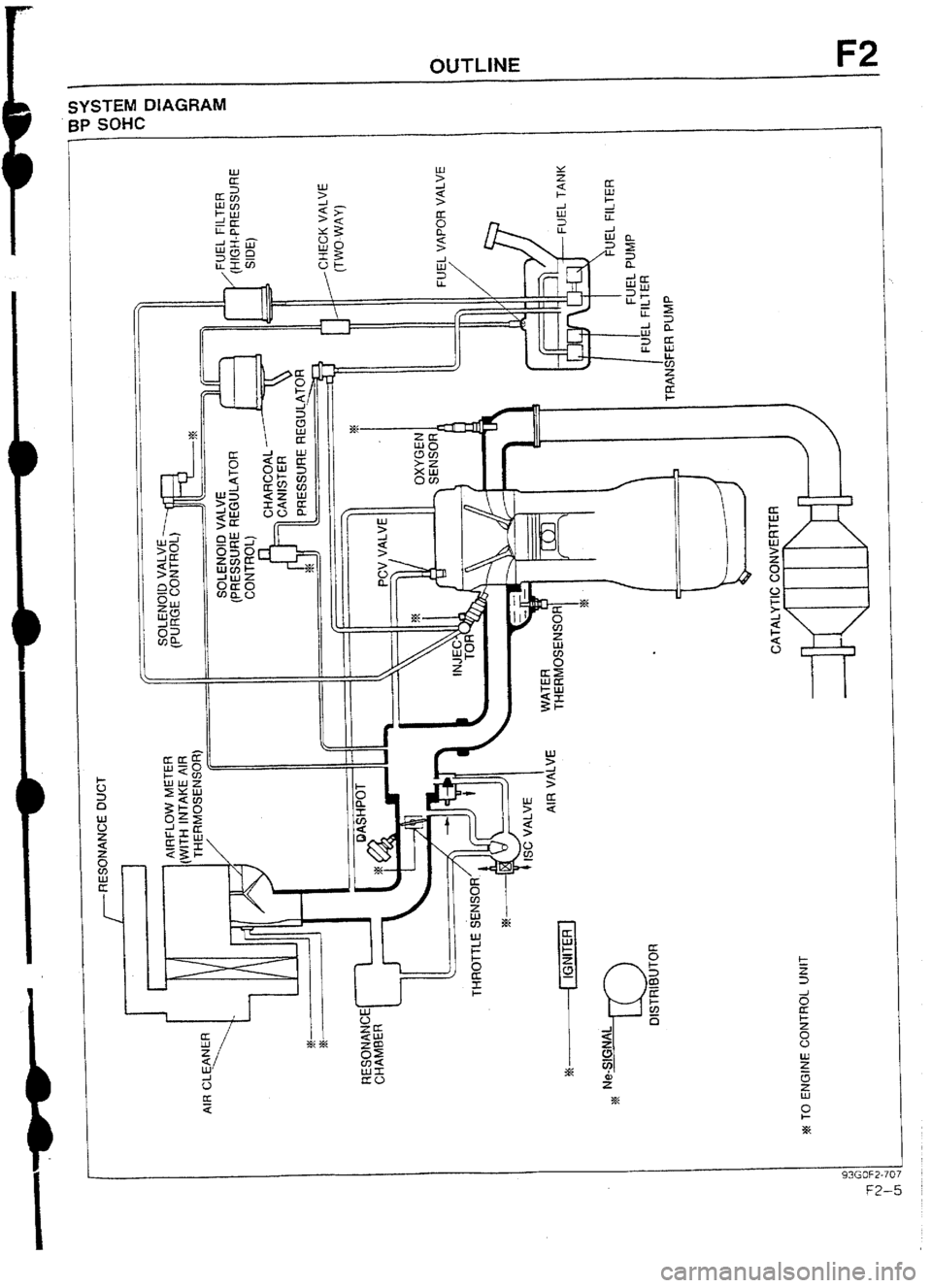

OUTLINE F2

SYSTEM DIAGRAM

BP SOHC

1

J

I

U

”

a

1

93GOF2-707

m-5

Page 125 of 677

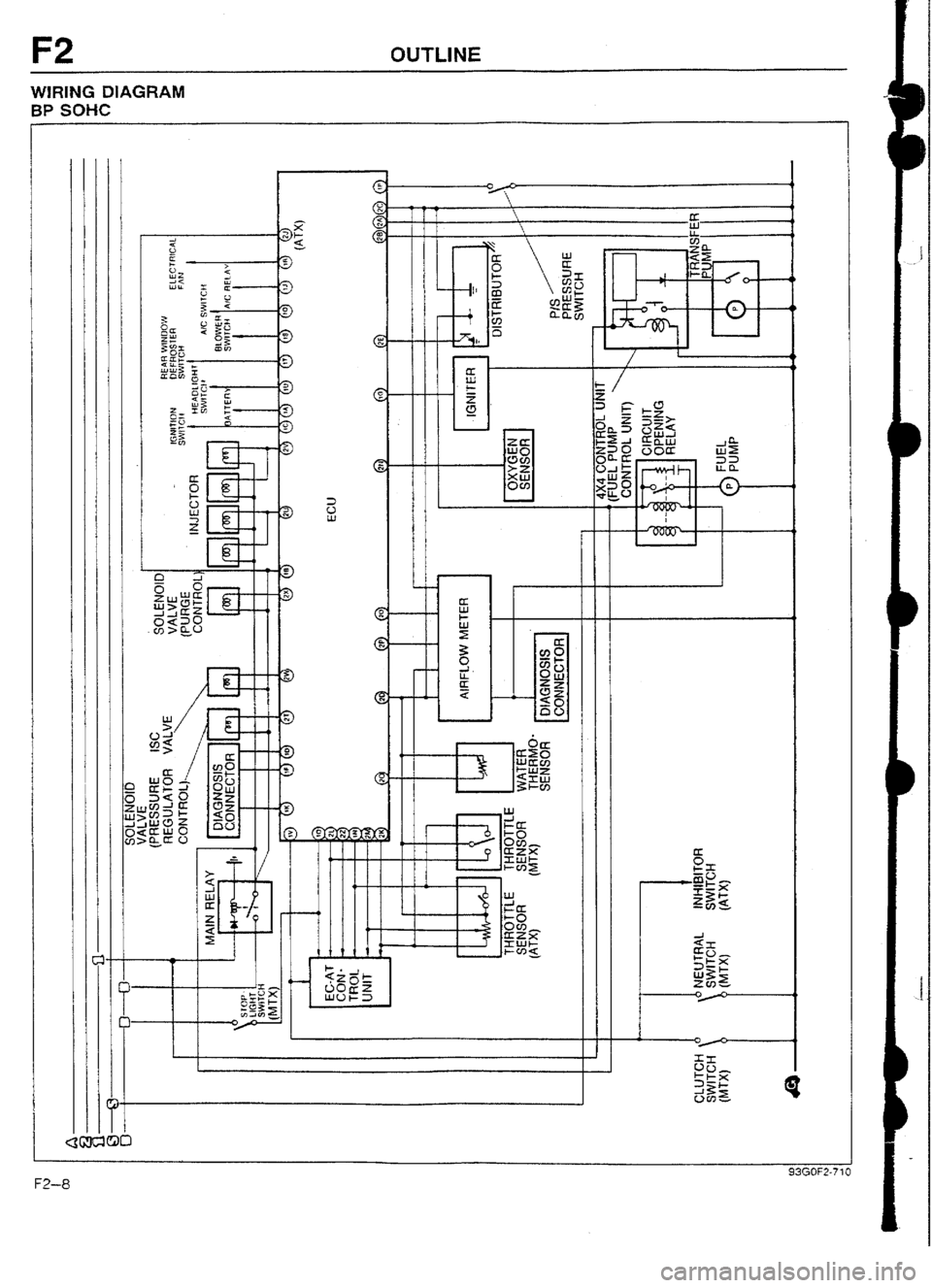

OUTLINE

WtRlNG DIAGRAM

BP SOHC

r-

-

93GOF2-71, FZ-8

Page 129 of 677

![MAZDA 232 1990 Workshop Manual Suplement F2 TURBOCHARGER CONTROL [BP TURBO]

TURBOCHARGER CONTROL [BP TURBO]

OUTLINE

l The air-to-air intercooler is adopted to lower intake air temperature and to improve engine performance.

l With additio MAZDA 232 1990 Workshop Manual Suplement F2 TURBOCHARGER CONTROL [BP TURBO]

TURBOCHARGER CONTROL [BP TURBO]

OUTLINE

l The air-to-air intercooler is adopted to lower intake air temperature and to improve engine performance.

l With additio](/img/28/57056/w960_57056-128.png)

F2 TURBOCHARGER CONTROL [BP TURBO]

TURBOCHARGER CONTROL [BP TURBO]

OUTLINE

l The air-to-air intercooler is adopted to lower intake air temperature and to improve engine performance.

l With addition of the wastegate control system, engine torque at higher rpm is increased.

AIR BYPASS VALVE

WASTEGATE

SOLENOID VALVE

TURBOCHAR

ACTUATOR

-

SYSTEM DIAGRAM

AIR BYPASS VALVE 1

t

!NTERCOOLER

n Ii Y7rzFes-~ m I

-

TUREiOCHARGER

WASTEGATE SOLENO1D VALVE

93GOF2-7 7

FZ-12

Page 130 of 677

![MAZDA 232 1990 Workshop Manual Suplement TURBOCHARGER CONTROL [BP TURBO] F2

WASTEGATE CONTROL

The engine control unit controls the wastegate solenoid valve to give higher boost to the engine in the higher

rpm range, increasing engine torq MAZDA 232 1990 Workshop Manual Suplement TURBOCHARGER CONTROL [BP TURBO] F2

WASTEGATE CONTROL

The engine control unit controls the wastegate solenoid valve to give higher boost to the engine in the higher

rpm range, increasing engine torq](/img/28/57056/w960_57056-129.png)

TURBOCHARGER CONTROL [BP TURBO] F2

WASTEGATE CONTROL

The engine control unit controls the wastegate solenoid valve to give higher boost to the engine in the higher

rpm range, increasing engine torque

and power.

System

Diagram

I

t

1 ECU

i i

AIRFLOW METER ACTUATOR

WASTEGATE

WASTEGATE

SOLENOID VALVE

r ACTUATOR

WASTEGATE SOLENOID VALVE

: OFF (VALVE CLOSED)

ACTUATOR

BOOST

PRESSURE

WASTEGATE SULENOlD VALVE

: ON (VALVE OPEN) Operation

Engine speed below 5,300 rpm

The

wastegate solenoid valve is OFF. Boost pressure is ap-

plied directly to the actuator and the wastegate opens when

the boost pressure exceeds 49 kPa (0.5 kg/cm , 7.1

psi).

Engine speed above 5,300 rpm

The wastegate

solenoid valve is UN. Some boost pressure is

bypassed to the intake manifold, limiting the opening of the

wastegate to increase boost pressure and

improve engine per-

formance.

F2-13

Page 145 of 677

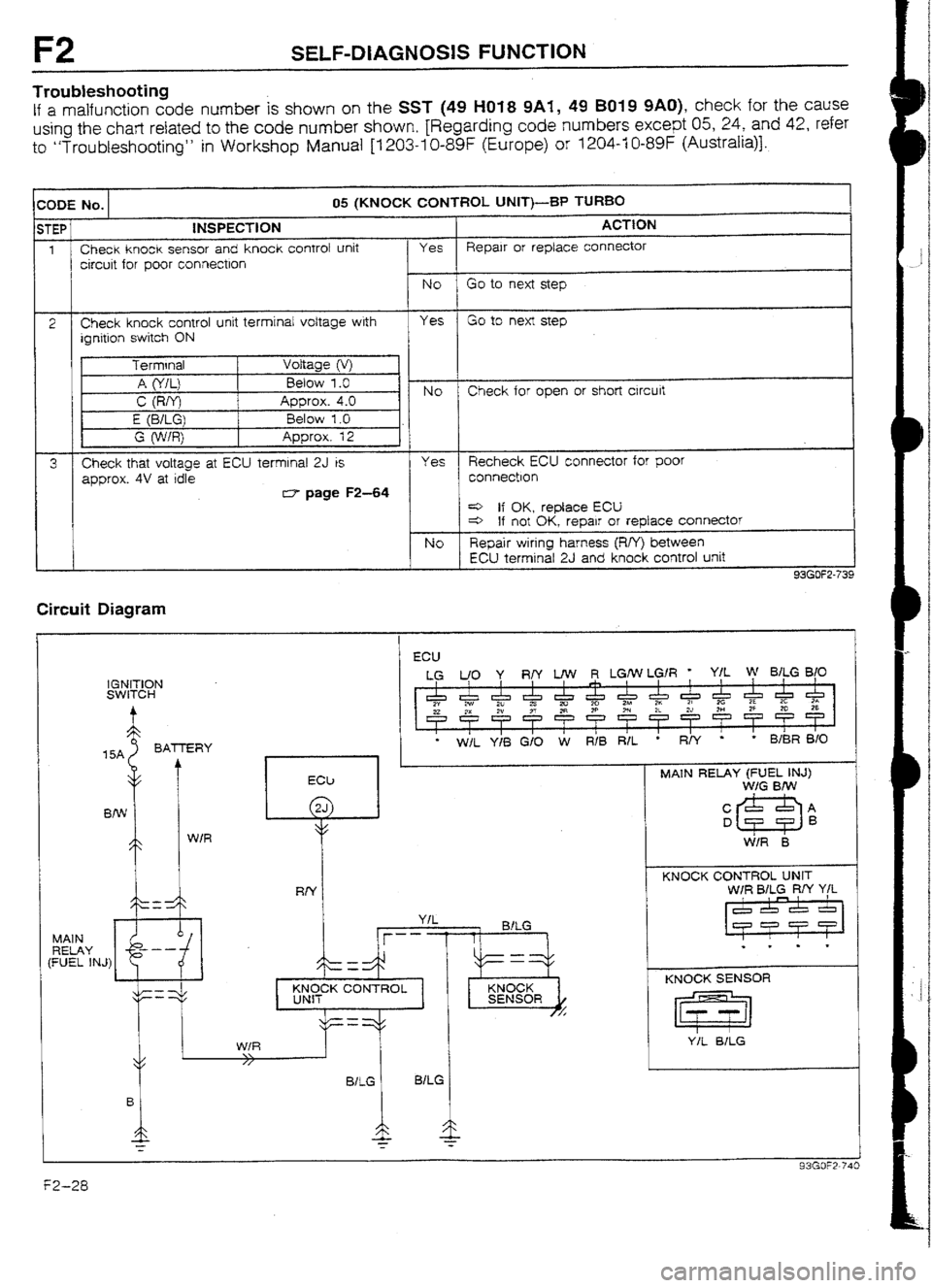

F2 SELF-DIAGNOSlS FUNCTION

Troubleshooting

If a malfunction code number is shown on the SST (49 l-l01 8 9Ai, 49 B019 9AO), check for the cause

using the chart related to the code number shown, [Regarding code numbers except 05, 24, and 42, refer

to “Troubleshooting” in Workshop Manual [I 203-I O-89F (Europe) or 1204-f 0-89F (Australia)].

r C :ODE No. 05 (KNOCK CONTROL UNIT)-BP TUR80

;TEP

2

3 I INSPECTION

Check knock sensor and knock control unit

circuit for poor connectlon ACTtON

Yes Repalr or replace connector

Check knock control unit terminal voltage with

ignition switch ON

Check that voltage at ECU terminal 2J is

approx. 4V at idle

rs7 page F2-64 Yes Recheck ECU connector for poor

connection

4 If OK, replace ECU

4 If not OK, repair or replace connector

NO Repair wiring harness (R/Y) between

ECU terminal 2J and knock control unit

93GOF2-7:

Circuit Diagram

I

ECU

IGNITION

SWITCH

15A BATTERY

MAIN

RELAY

(FUEL 1N.J)

l W/L Y/i3 G/O W RIB R/L

YIL

jr- -- - - 1 BlLG

-

-

MCK CONTROL

I

. :

MAIN RELAY (FUEL INJ)

W/G BIW

C&=&A

KNOCK CONTROL UNIT

W/R EMLG RN Y/L

1

KNOCK SENSOR

Page 146 of 677

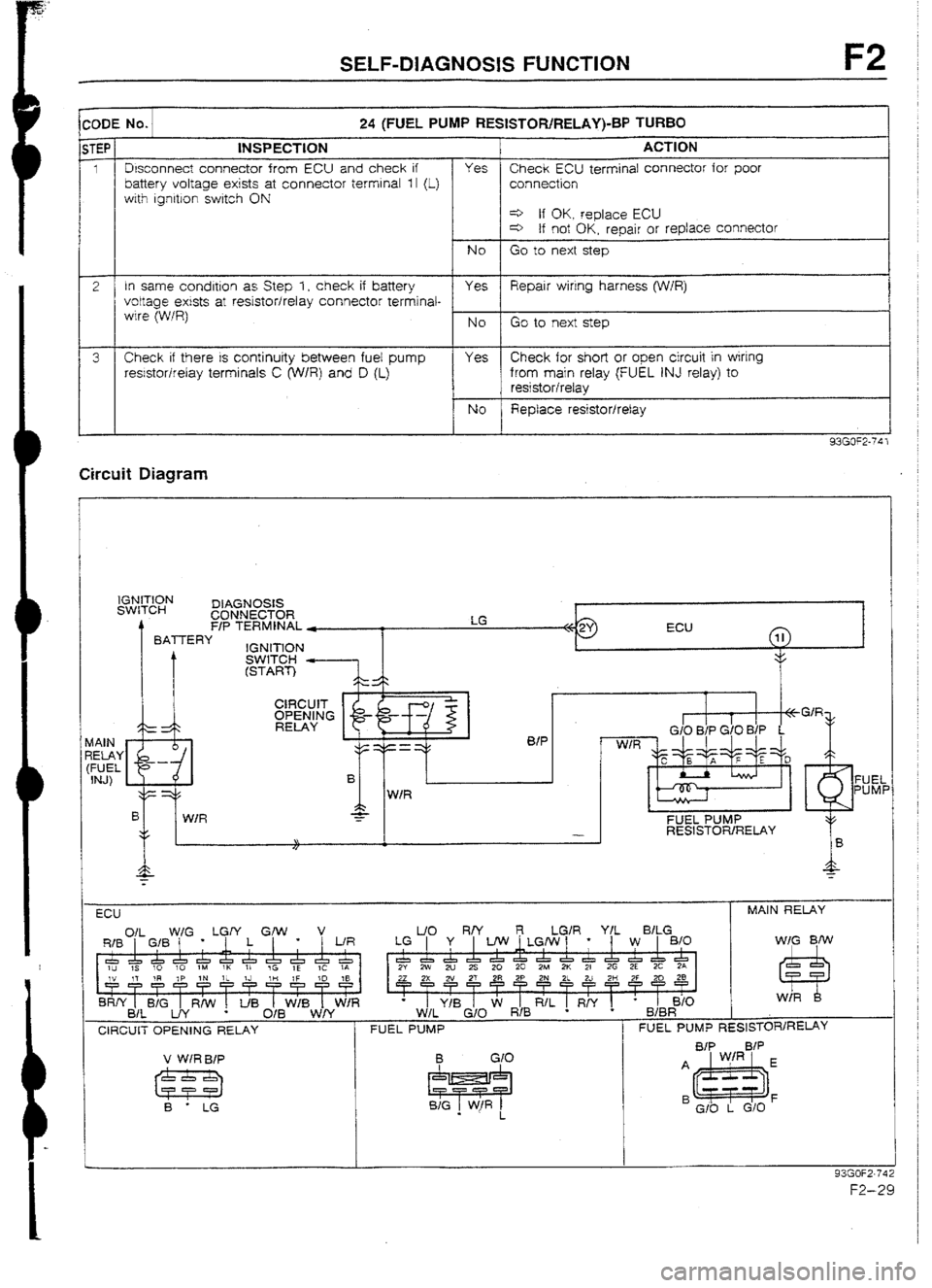

SELF-DIAGNOSIS FUNCTION F2

:UDE No. 24 (FUEL PUMP RESISTOR/RELAY)-BP TURBO

STEP INSPECTION ACTtON

1 1 Disconnect connector from ECU and check if

1 battery voltage exists at connector terminal 1 I (L) Yes Check ECU terminal connector for poor

connection

with ignition switch ON

e If OK. replace ECU

c=> If not OK, repair or replace connector

NO Go to next step

2 In same condltlon as Step 1, check if battery

Yes Repair wiring harness (W/R)

voltage exists at resistor/relay connector terminai- I

wire (W/R)

NO Go to next step

3 Check if there is continuity between fuel pump

Yes Check for short or open circuit

in wiring

res!stor/relay terminals C (‘W/R) and D (L) from main relay (FUEL INJ relay) to

t resistor/relay

NO Replace resistor/relay

93GOF2-74 1 Circuit Diagram

IGNITION

SWITCH DIAGNOSIS

CONNECTOR

rl

F/P TERMINAL *

BATTERY

IGNlTlON

0fP

W/R

FUEL

PUMF

B

c W/R 7

FUEL PUMP

- RESISTOR/RELAY

\I

I/

ECU MAIN RELAY

Of1

W/G . LGrf Grw l v L/O R/Y LGlR YfL B/LG

RIB 1

I GIB J 1 1 [ WR LG ] Y , UW~LGIw/ * 1 W ] 810 WIG BfW

I

I I I

1 I I

I

&J,~&&&l&&c!zr5& &l~&cLa~~c!zch&&&&~

1~ IS 10 10 IM 1K II tC 1E 1C IA 2Y 2w 2u 2s 20 20 28.4 2K 21 2G 2E 2C 2A

IV 17 ?R IP 1N 1~ IJ III IF ro :8

rrrrrT?rrTT

BRff t BIG 1 R/W ! t/B 1 WIB 1 W/R

BIL UY O/B WN

CIRCUIT OPENING RELAY

FUEL PUMP FUEL PUMP RESlSTOR/RE~Y

v WIRBIP

B - LG

93GOF2.74

F2-29