change wheel MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 33 of 677

BI OUTIAlE

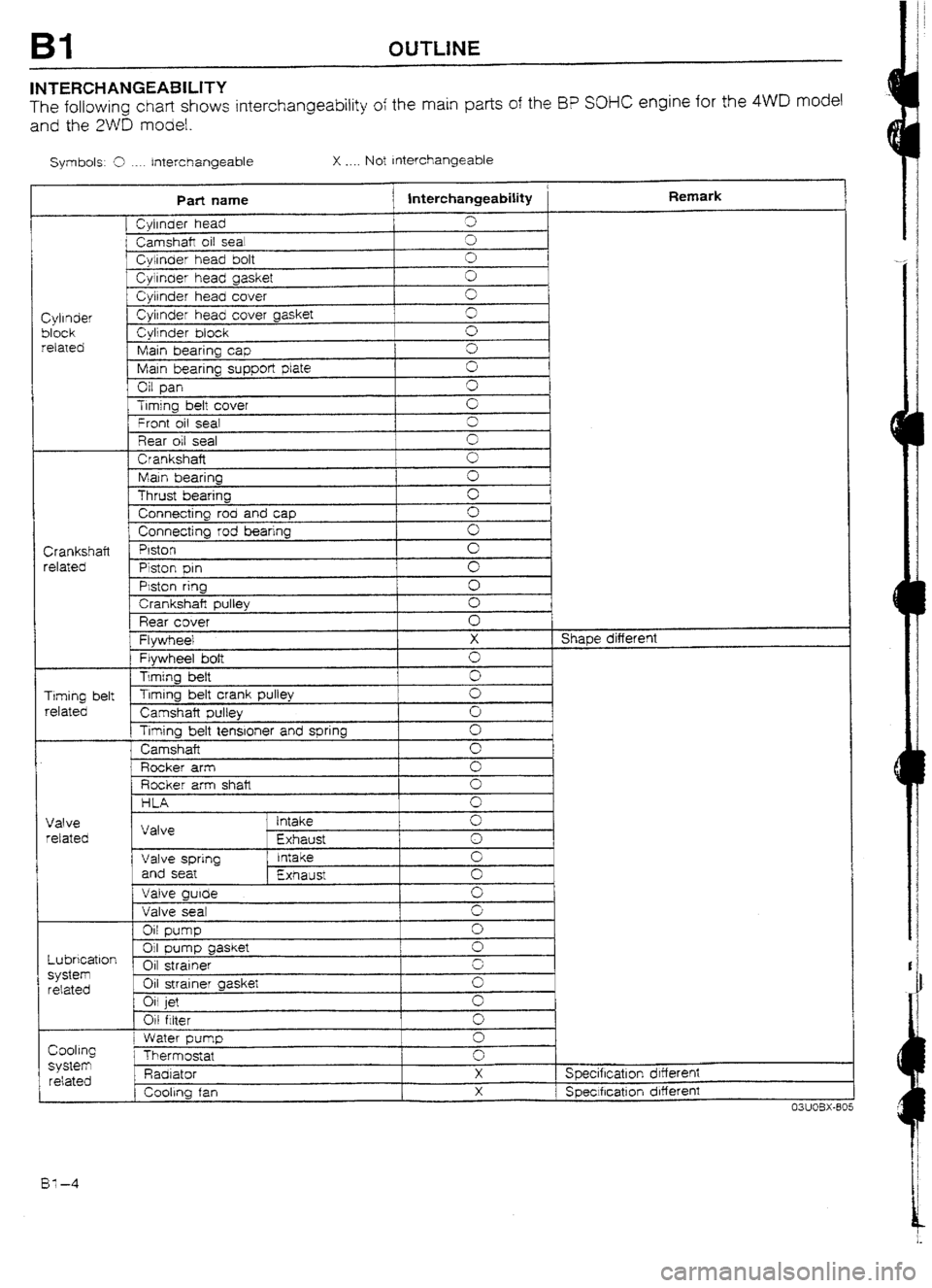

INTERCHANGEABILITY

The following chart shows interchangeability of the main parts of the I3P SOHC engine for the 4WD model

and the 2WD model.

Symbols: 9 ._.. Interchangeable X . . . . Not Interchangeable

Part name

j lnterchangeabiIity Remark

[ Cyirnder head 3

i Camshaft oil sea! cl

f Cylinder head bolt 0

Cyirnaer head gasket 0

Cylrnder head cover 0

Cylinder Cylrnder head cover gasket 3

block Cylinder block 0

related

Main bearing cap 0

Main bearing supper!

plate 0

Oil pan G

Trmjng bett cover

’ Front oil seal G

3

Rear oil seal 0

Crankshaft

0

Main bearing 0

Thrust bearing c

Connecting rod and cap 0

1 Connecting rod bearing 0

Crankshaft Piston

0

related

Piston pm cl

PMon ring

0

1 Crankshaft pulley 0

Rear cover 0

Flywheel X Shape different

Flywheel bolt 0

Timing heft

0

Timing belt Timing belt crank pulley

0

related

Camshaft pulley 0

Timing belt tenstoner and spring Cl

Camshaft

0

Rocker arm 0

Rocker arm shalt 0

HLA 0 I

Valve

retated

Lubrication

system

related Valve ’ intake

Exhaust 0

1

0

Valve spring Intake 0

and seat

Exhaust 0

Valve guide

0

Valve seat 9

Oil pump

0

01 gasket pump

0

Oil strainer r.

Oil strainer gasket G

Oil jet

0

Oil filter 0

Cooling

SyStem related

1 I Water pump

Thermostat

Padi ator

, Cooling fan 0

0

X

X Specification drffereni

1 Speclfrcatlon different

03UOBX-805

BY-4

Page 58 of 677

c

OUTLINE B2

INTERCHANGEABILITY

The following chart shows interchangeability of the main park of the BP DOHC Turbo engine for the 4WD

model and the BP DOHC Non-Turbo engine for the 2WD model.

Symbols: 5 . Interchangeabie X . . . . Not Interchangeable

Part name interchangeability Remark

1 Cylinder head Shape different

Camshaft oil sea! :

Cylinder head bolt

3

Cyijnder head gasket cl

C$rnder head cover 0

1

Cylinder Cylinder head cover gasket cl

I

Cylinder block 0

block

related Man bearing cap 0

Main bearing support plate 3

OrI pan x Shape different

Trming belt cuver cl

Seal plate 3

Front oil seal I

3

Rear oil seal cl

Crankshaft ‘3

Main bearing 0

Thrust bearing 0

Connecting rod and cap 0

Connecting rod bearing I

0

Crankshaft [ Prston Shape different

related

Piston pin +-- -

c Piston ring cl

Crankshaft pulley 0

Rear cover 3

I Flywheel X Shape different

Flywheel bolt 0

Timing belt

cl

Timing belt Timing belt crank pulley

cl

Camshaft pulley 0 I

related

f Timing belt tensioner and spring

i 0

1, ldter

Camshaft

; Valve timing different

I-LA

Valve I Make - cl

Valve Exhaust 0

related

Vaive sprtng Intake 0

and seat

Exhaust 0

Valve guide cl

Valve seal 0

Oil pump 0

Oil pump gasket 0

Lubrication Oil strainer

0

system Oil strainer gasket

0

related

Oil cooler

0

Oil jet

0

Oil fitter

0

Water pump cl

Cooling

Thermostat

X system Specificatron drfferent

related Radiator X Specificatron different

Cooling fan

X Specification different

^^-^-^ m^- Ix?-5

Page 106 of 677

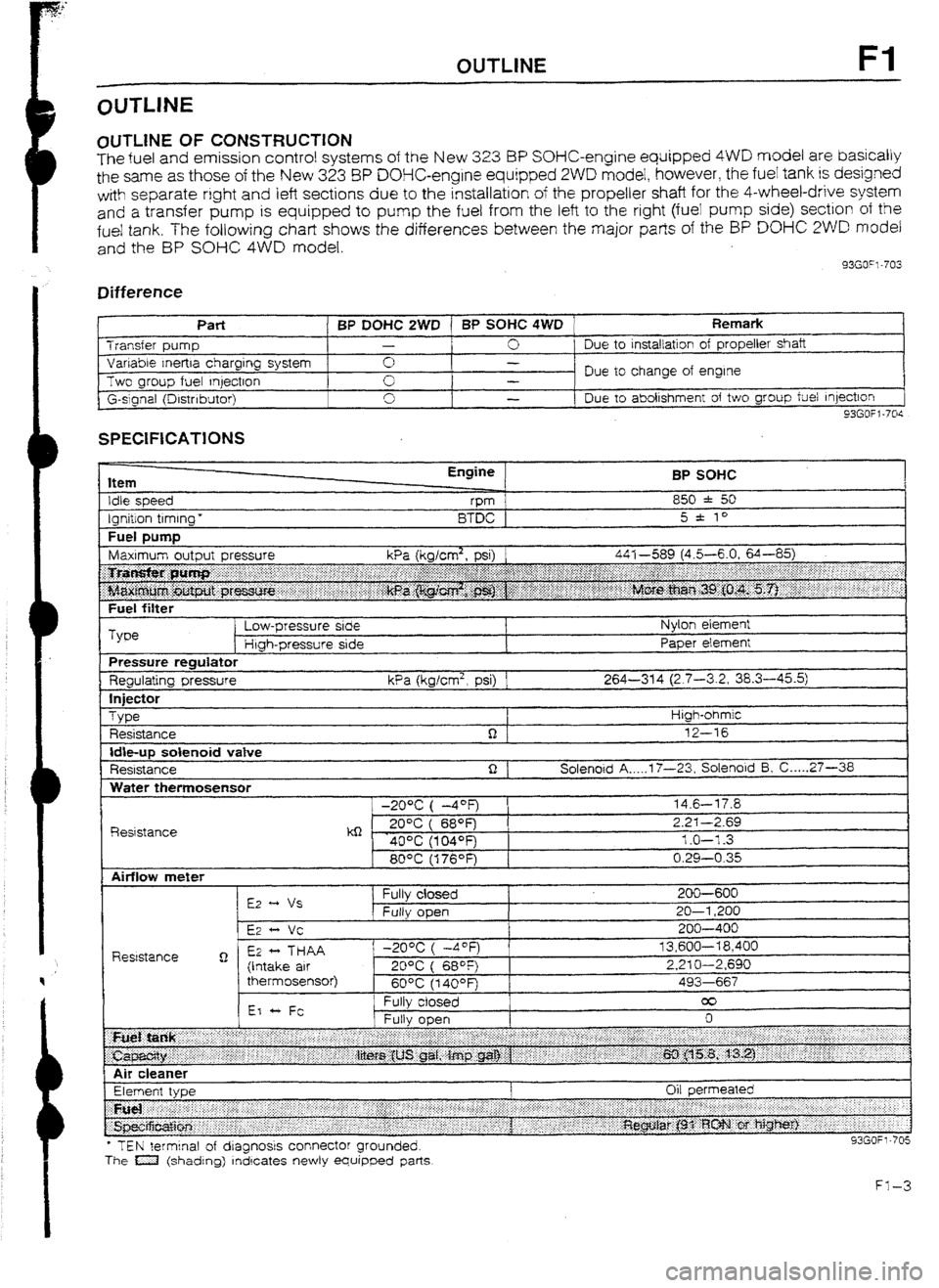

OUTLINE Fl

OlJTLlNE OF CONSTRUCTION

The fuel and emission control systems of the New 3.23 BP SOHC-engine equipped 4WD model are basically

the same as those of the New 323 8P DOHC-engine equipped 2WD model, however, the fuel tank is designed

with separate right

and left sections due to the installation of the propeller shaft for the 4-wheel-drive system

and

a transfer pump is equipped to pump the fuel from the left to the right (fuei pump side) section of the

fue! tank. The following chart shows the differences between the major parts of the BP DO% 2WD model

and the BP SOHC 4WD model.

33GO”l-703

Difference

I t

Part BP DOHC 2WD 1 BP SOHC 4WD Remark Transfer pump -

0 Due to

installation of propeller shaft

Variable Inertra charging system 0 -

Two group fuel qectron Due to change of engine

-

G-slgnal (Drstnbutor) 0

I -

Due to abolishment of two group fuel Injection

93GOfl-70s

SPECIFICATIONS

Item

Idle speed

Ignition timing * Engine

vm

BTDC BP SOHC

850 * 50

5 * to

Fuel DUtTlD I

Fuel filter

Type Low-pressure side

Htgh-pressure side Nylon element

Paper element

Pressure regulator

Regulating pressure kPa (kglcm2, psi) 1 264-314 (2.7-3.2, 38.3-45.5)

In

jfXt0r

Type

Resistance High-ohmic

12-16

Idbup solenoid vatve

Resistance Solenoid A _.._. 17-23, Solenoid 5, C ._... 27-36

Water themosensor

R&stance -20% ( -4OF)

kQ - . 20°C ( 689=)

40% (104OFj

80°C (176OF) 14.6-l 7.8

2.2-I -2.69

1.0-l -3

0.29-0.35

l TEN terminal of dragnosrs connector grounded.

The a (shading) rndrcates newly equipped parts

Page 197 of 677

H OUTLINE

OUTLINE

OUTLINE OF CONSTRUCTION

A hydraulic clutch control mechanism is used.

The basic construction is the same as that of 323 2WD model, but there is no interchangeability of parts

except for the release cylinder.

1. An assist/return spring is used on the BP DOHC Turbo model to reduce the required clutch pedal effort..

2. The hydraulic clutch master cylinder for the 8P DOl-lC Turbo model has a built-in check valve.

3. To improve clutch operation feeling and increased parts life, a friction plate and needle roller bearings

are used between the release fork and the release bearing.

93GOHX-704

SPECIFICATIONS

Hem

Clutch control Engine/Transaxle

BP SUHC BP DOHC Turbo

GSMX-R

Hydrautic

Clutch cover

Type

Set load

N (kg, lb) Diaphragm spring

3,846 (392, 862) 5,494 (560, I ,232)

Outer diameter 1

mm (in) 225 (8.858) 230 (9.055)

I 1 nner diameter mm (in)

I 150 (5.906)

I 155 (6.102) I

CI utch disc

Pressure plate side

mm {in) 4.1 (0.161) 3.2 (0.126)

Thickness f

Flywheel side

mm (in) 3.5 (0.138) 3.2 (0. f 26)

I Type I Suspended

I

Clutch pedal LHD 6.55 Pedal

ratio

RHD 6.7

Full stroke mm (in)

I 135 (5.32)

I

Height (With carpet) mm [in)

I I 96-204 (7.72-8.03)

I

Master cylinder Inner diameter

mm {in)

I 15.87 (0.625)

Release cylinder inner diameter

mm (in)

I - 19.05 (0.750)

I

Clutch fluid SAE J1703 or FMVSSI 16 DOT-3

93GOHX-705

H-4

Page 202 of 677

SUPPLEMENTAL SERVICE INFORMATION, TROU8LESHOOTlNG GUIDE H

SUPPLEMENTALSERVICE INFORMATION

The following points in this section are changed in comparison with 323 Workshop Manual (1206IO-89F).

Troubleshooting guide

Clutch fluid (with ABS)

l Replacement

Clutch pedal (BP DOHC Turbo) Clutch release cylinder (with ABS) l Air bleeding

Clutch unit

l Removal I Inspection I installation

Clutch master cylinder

(BP DOW Turbo or with ABS) l Removal I Inspection I installation

93GOHX-710

l Removal I Inspection I Installation (BP DUHC Turbo)

l Air bleeding (with ABS)

l Overhaul (BP DUHC Turbo)

TROUBLESHOOTING GUlDE

Problem

Possibte Cause Remedy Page

Slipping

Clutch disc facing worn excessively

Replace U-l 9

Clutch disc facing surface hardened or oifed

Repair or replace H-l 9

Pressure plate damaged Replace H-19

Diaphragm spring damaged or weakened

Replace H-l 9

Insufficient clutch pedal piay

Adjust H-12

Clutch pedal sticking

Repair or replace U-11

Flywheel damaged

Repair or replace H-19

Faulty

Excessive runout or damaged clutch disc

Replace H-19

disengagement

Clutch disc spiines rusted or worn ’

Remove rust or replace H-l 9

Clutch disc facing oiled

Repair or replace H-19

Diaphragm spring weakened

Reptace H-19

Excessive clutch pedal ptay

Adjust -

Insufficient clutch fluid

Add fluid H-10

Leakage of clutch fluid

Locate and repair or -

replace

Clutch vibrates

Clutch disc facing oiled

Repair or replace H-l 9

when accelerating

Torsion rubbers weakened

u-19 Clutch disc facing hardened or damaged Replace

Repair or replace H-19

Clutch disc facing rivets loose

Replace H-l 9

Pressure plate damaged or excessive runout

Replace H-l 9

Flywheel surface hardened or damaged

Repair or replace H-19

Loose or worn engine mount

Tighten or replace -

Clutch pedal

sticking Pedal shaft not properly lubricated

Lubricate or replace H-l 1

Asistireturn spring damaged or poor adjust

Replace or adjust H-11, 12

Abnormal noise

Clutch release bearing damaged

Replace N-1 9

Poor iubrication of release bearing sleeve

Torsion rubbers weakened Lubricate or replace H-19

Replace u-t9 Excessive crankshaft

end play

Repalr -

Pilot bearing worn or damaged

Replace H-79

Worn pivot points of reiease fork

Repair or replace H-19