light MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 5 of 677

GI IMPORTANT tNFORMATlUN

IMPORTANT INFORMATION

1

.ftl

1

BASIC ASSUMPTIONS

This workshop manual assumes that you have certain special tools that are necessary for the safe and effi-

cient performance of service operations on Mazda vehicles and that you know how to use

them properly.

It also assumes that you are familiar with automobile

systems and basic service and repair procedures. You

should

not attempt to use this manual unless these assumptions are correct and you understand the conse-

quences described below.

SAFETY RlSK

This manual contains certain notes, warnings, and other precautionary information that you should carefully

read and follow to reduce the risk of personal injury to yourself or others and the risk of improper service

that may damage the vehicle

or render it unsafe. If there is no such information in regard to any specific

service method, this does not mean there is no possibility that personal safety or vehicle safety will be

jeopardized by the use of incorrect methods or toots.

POSSIBLE LOSS OF WARRANTY

The manufacturer’s warranty on Mazda vehicles and engines can be voided if improper service or repairs

are performed by persons other than those at an Authorized Mazda Dealer.

WARNING ON LUBRICANTS AND GREASES ’

Avoid all prolonged and repeated contact with mineral oils, especially used oils. Used 08s contaminated

during service (e.g., engine sump oils) are more irritating and more likely to cause serious effects, including

skin cancer, in the event of gross and prolonged skin contact.

Wash skin thoroughly after work involving oil.

Protective hand cleaners may be of value provided they can be removed from the skin with water. Do not

use gasoline, paraffin, or other solvents to remove oil from the skin.

Lubricants and greases may be slightly irritating to the eyes.

Repeated or prolonged skin contact should be avoided by wearing protective clothing if necessary. Particu-

lar care should be taken with used oils and greases containing lead. Do not allow work clothing to be con-

taminated with oil. Dry clean or launder such clothing at regular intervafs.

9MUGiX-502

Page 15 of 677

GI CAUTKN

SMUGIX-a21

I VOLTMETER

1 9MUGlX-021

POWER SOURC

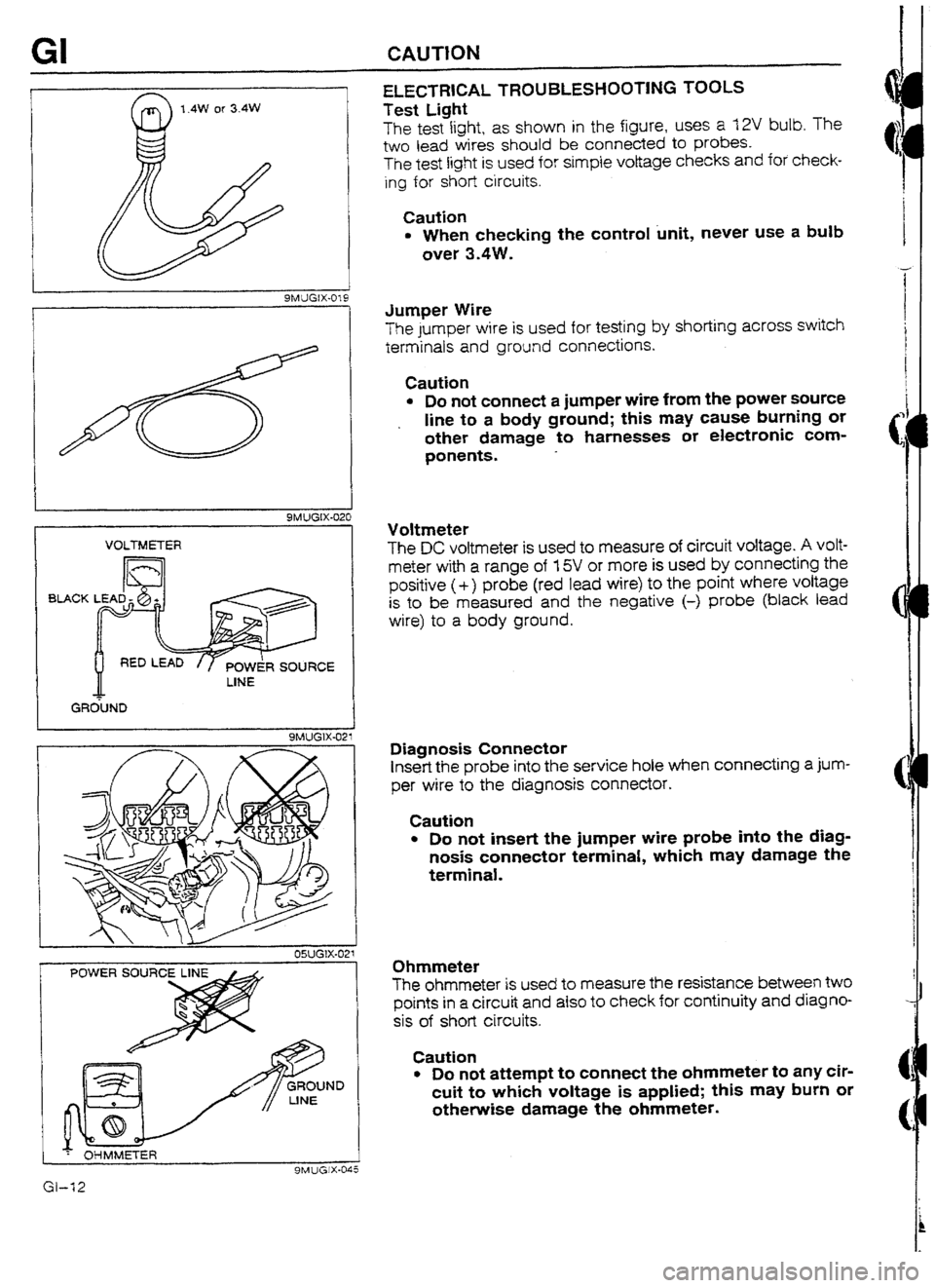

ELECTRICAL TROUBLESHOOTING TOOLS

Test Light

The test light, as shown in the figure, uses a f2V bulb. The

two lead wires should be connected to

probes.

The test light is used for simple voltage checks and for check-

ing for short circuits.

Caution

l When checking the control unit, never use a butt,

over 3.4w.

Jumper Wire

The jumper wire is used for testing by shorting across switch

terminals and ground connections.

Caution

l Do not connect a jumper wire from the power source

, line to a body ground; this may cause burning or

other damage to harnesses or electronic com-

ponents. -

Voltmeter

The DC voltmeter is used to measure of circuit

voltage. A volt-

meter with a range of 15V or more is used by connecting the

positive ( + ) probe (red lead wire) to the point where voltage

is to be measured and the negative (-1 probe (black lead

wire) to a body ground.

Diagnosis Connector

Insert the probe into the service hole when connecting a jum-

per wire to the diagnosis connector.

Caution

l Do not insert the jumper wire probe into the diag-

nosis connector terminal, which may damage the

terminal.

Ohmmeter

The ohmmeter is used to measure the resistance between two

points in a circuit and atso to check for continuity and diagno-

sis of short circuits.

Caution

l Do not attempt to connect the ohmmeter to any cir-

cuit to which voltage is applied; this may burn or

otherwise damage the ohmmeter.

Page 17 of 677

I OWGIX-028

1 SMUG IX-027

gMi)GlX-03

GI-i4

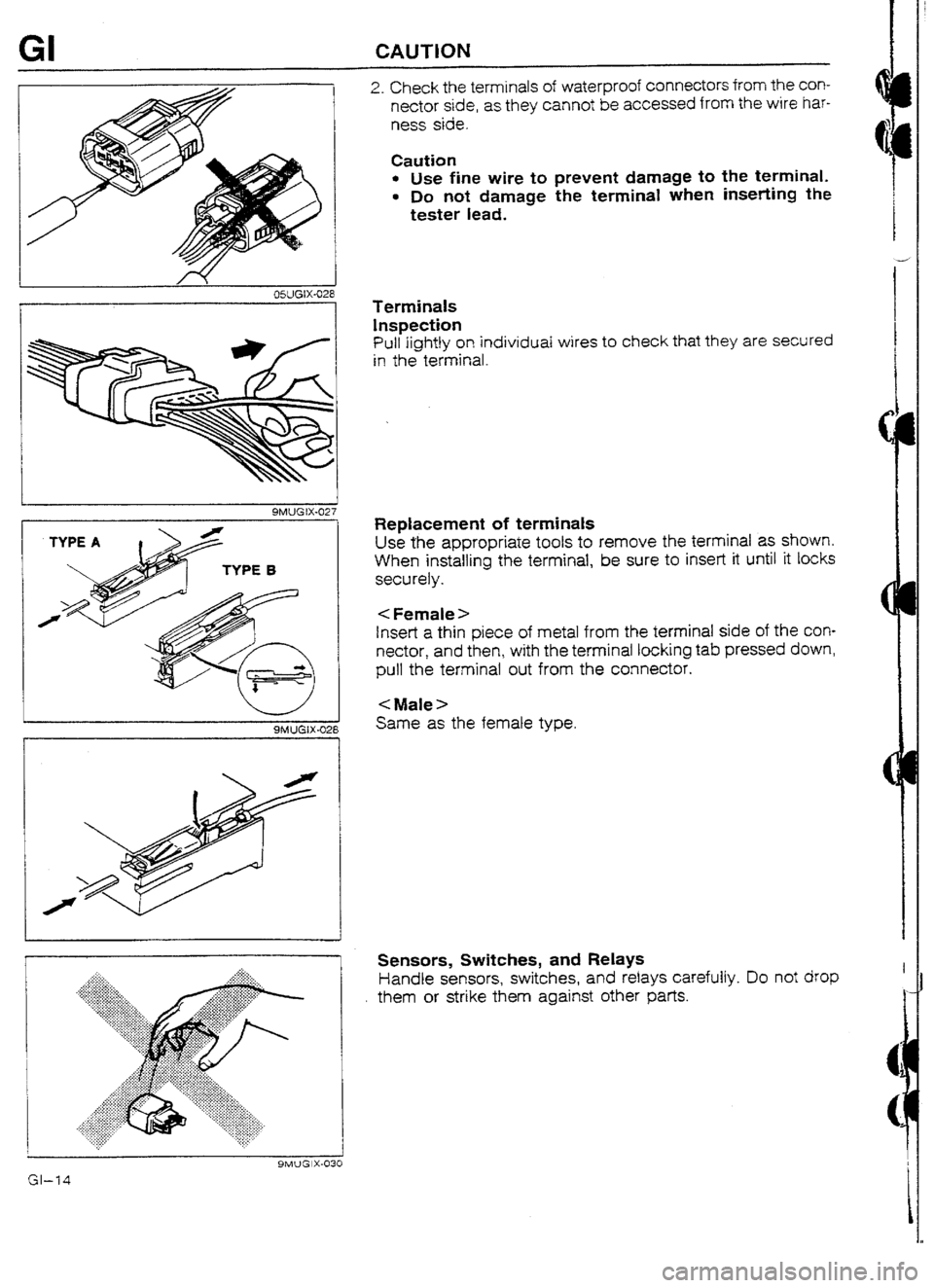

2. Check the terminals of waterproof connectors from the con-

nector side, as they cannot be accessed from the wire har-

ness side.

Caution l

Use fine wire to prevent damage to the terminal. l

Do not damage the terminal when inserting the

tester lead.

Terminals

Inspection

Pull lightly on individual wires to check that they are secured

in the terminal.

Replacement of terminals

Use the appropriate tools to remove the terminal as shown.

When installing the terminal, be sure to insert it until it locks

securely.

Insert a thin piece of metal from the terminal side of the con-

nector, and then, with the terminal locking tab pressed down,

pull the terminal out from the connector.

< Male >

Same as the female type,

Sensors, Switches, and Relays

Handle sensors, switches, and relays carefully. Do not drop

them or strike them against other parts.

4 I

i c

Page 18 of 677

CAUTION GI

I 9MUGIX-031

PULLER

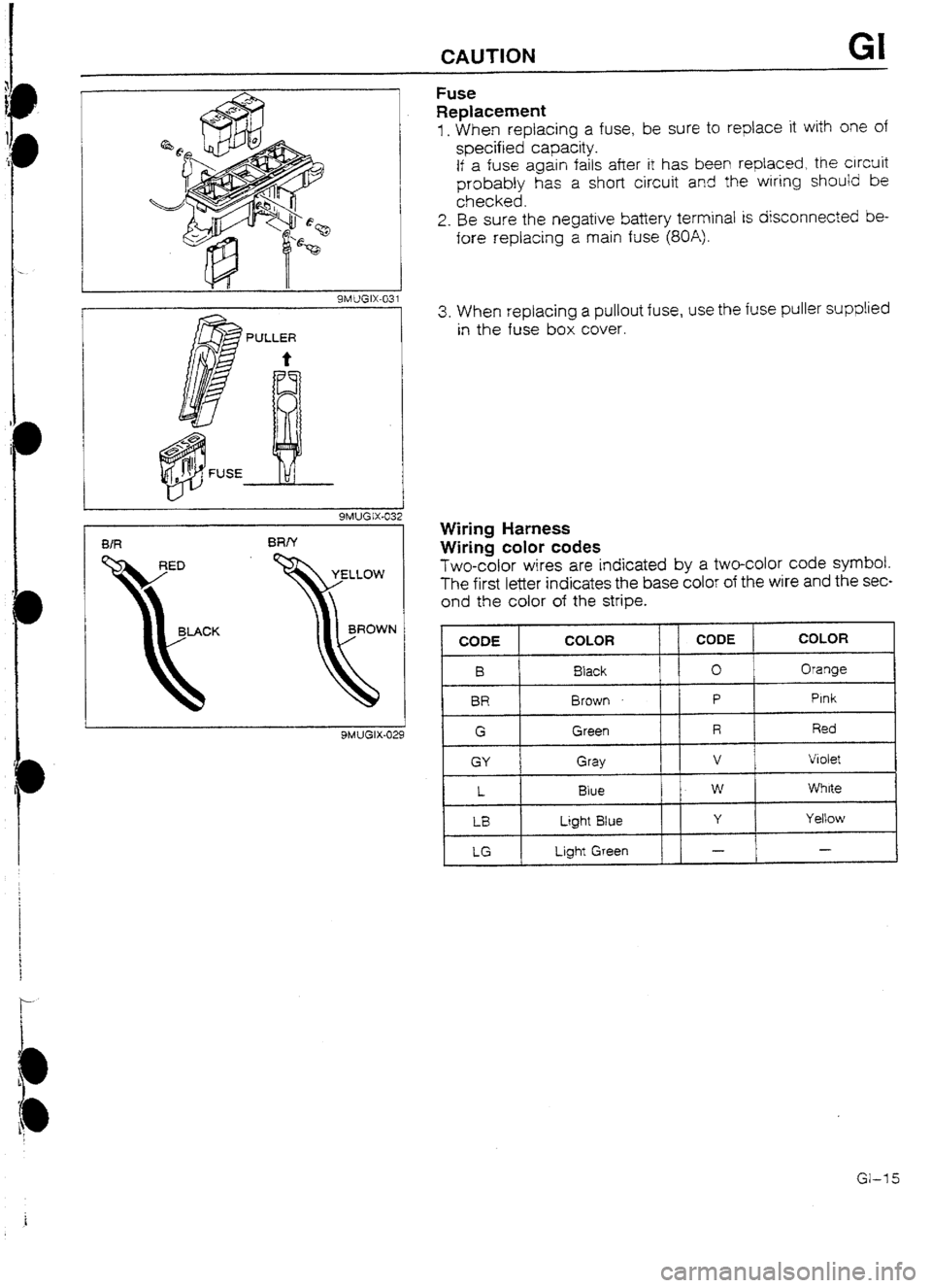

t Fuse

Replacement

1. When replacing a fuse, be sure to replace it with one of

specified capacity.

If a fuse again fails after it has been reptaced, the circuit

probably has a short circuit and the wiring should be

checked.

2. Be sure the negative battery terminal i

fore replacing a main fuse @A).

3. When replacing a pullout fuse, use the

in the fuse box cover. ; disconnected be-

use puller supplied

Wiring Harness

Wiring color codes

Two-color wires are indicated by a two-color code symbol.

The first letter indicates the

base color of the wire and the sec-

ond the color of the stripe.

1 9MUGIX-029

LG Light Green - - CODE

B COLOR

Black CODE )

0 COLOR

Orange

BR Brown P Pink

1

G

GY

t

LB Green

Gray

Blue

Light Blue R

! Red

V Violet

W White

Y Yellow

Gl-15

Page 21 of 677

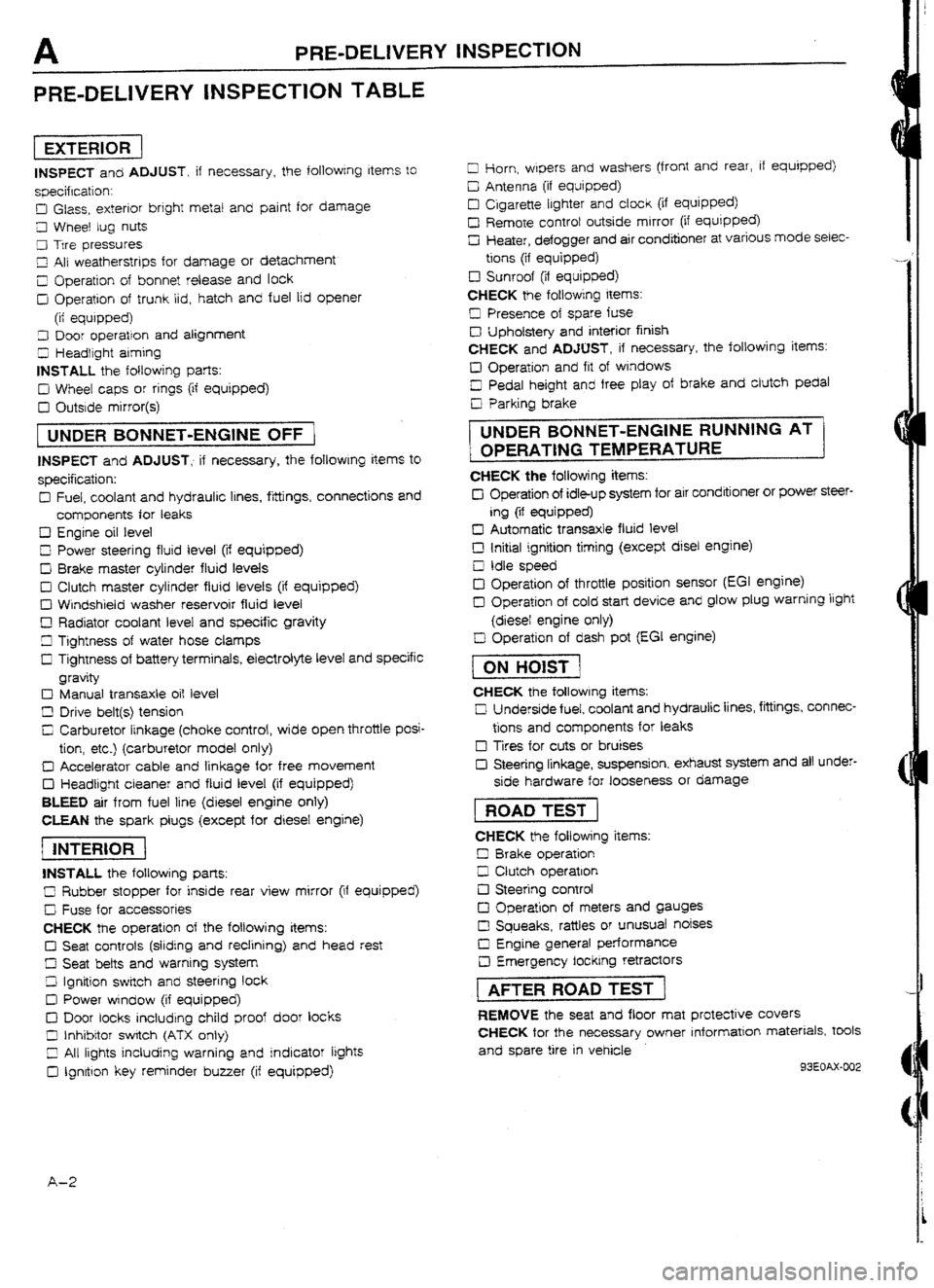

A PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

pieziG-

INSPECT and ADJUST, if necessary, the following Items to

specification:

D Glass, exterior bright metal and paint for damage

Cl Wheel tug nuts

9 Trre pressures

LII All weatherstrips for damage or detachment

Z Operation of bonnet release and lock

D Operation of trunk lid, hatch and fuel lid opener

(it equipped)

3 Door operation and alignment

5 Headlight aiming

INSTALL the following parts:

D Wheel caps or rings (if equipped)

D Outside mirror(s)

[ UNDER BONNET-ENGINE OFF )

INSPECT and ADJUST, if necessary, the foIlowIng items to

specification:

Cl Fuel, coolant and hydraulrc lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level (if equipped)

D Brake master cylinder fluid levels

0 Clutch master cylinder fluid levels (if equipped) q

Windshield washer reservoir fluid level

D Radiator coolant level and specific gravity

Ll Tightness of water hose clamps

I3 Tightness of battery terminals, electrolyte level and specific

gravity

c) Manual transaxle oit level

D Drive belt(s) tension

C; Carburetor linkage (choke control, wide open throttle posi-

tion, etc.) (carburetor model only)

D Accelerator cable and linkage for free movement

D Headlight cleaner and fluid level (if equipped)

BLEED air from fuel line (diesel engine only)

CLEAN the spark plugs (except for diesef engine)

piicis-1

INSTALL the foflowing parts:

C Rubber stopper for inside rear view mirror (if equipped)

c! Fuse for accessories

CHECK the operation of the following items:

Cl Seat controls (sliding and redining) and head rest

ci Seat belts and warnrng system

Z! Ignition swrtch and steering lock

III Power window {if equipped)

0 Door locks including child proof door locks

0 Inhibitor switch

(ATX only)

Z All lights including warning and indicator lights

0 Ignrtron key reminder buyer (if equipped) Cl Horn, wipers and washers (front and rear, if equipped)

D Antenna (if equipped} q

Cigarette lighter and clock (if equipped)

I2 Remote controt outside mirror

(if equipped) q

Heater, defogger and air conditioner at various mode selec-

tions (if equipped)

c3 Sunroof (if equipped)

CHECK

the fotiowing items: q

Presence of spare fuse

c3 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

Cl Operation and fit of windows

D Pedal height and free ptay of brake and clutch pedal

Cl Parking brake

i UNDER BONNET-ENGtNE RUNNING AT ]

1 OPERATtNG TEMPERATURE

CHECK the following items:

Cl Operation of idle-up system for air conditioner or power steer-

ing (if equipped)

13 Automatic transaxle fluid level

D Initial ignition timing

(except disel engine) q

Idle speed

El Operation of throttle position sensor (EGI engine)

13 Operation of cold start device and glow plug warning light

(diesel engine only)

D Operation of dash pot [EGI engine)

t

ON HOtST 1

CHECK the following items:

U Underside fuel, coolant and hydraulic lines, fittings, connec-

tions and components for leaks q

Tires for cuts or bruises

Cl Steering linkage, suspension, exhaust system and all under-

side hardware for

looseness or damage

1 ROAD TEST 1

CHECK the foliowing items:

II Brake operation

D Clutch operation

0 Steering control

c3 Operation of meters and gauges

0 Squeaks, rattles or unusual noises q

Engine general performance

c3 Emergency Iocking retractors

rAFTER ROAD TEST 1

REMOVE the seat and floor mat protective covers

CHECK for the necessary

owner information materials, tools

and spare tire in vehicle

93EOAX-002

A-2

Page 24 of 677

!

i

i

I

i

t-

I

i

i

e

-1

SCHEDULED MAfNTENANCE SERVICES (Europe) A

MAINTENANCE TABLE (Leaded Fuel Model)

Chart symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80.000 km or 48 months, continue to foltow the described maintenance at the recommended intervals.

As

*I

*2

“3

*4

*5

*6

*7 for *’

marked items in this’ maintenance chart, note the following points.

Major service interval at 12 months!ZO,OOO km (I 2,000 miles).

Lubrication service based on distance only, 10,000 km (6,000 miles), not time.

Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

ii equipped.

Replacement of the timing belt is required every ICQOUO km (60,000 miles). Failure to replace the timing

belt may result in damage to the engine.

If the vehicle is operated under any of the following conditions, it is suggested that the engine

oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for prolonged periods in cold temperatures or regularly driving only short distances.

If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than the recommended intervals.

This is a full function check of all electrical systems, i.e, afl lights, washers (inctuding condition of blades)

electric windows sunroof, horn, etc.

Replace every two years.

tf there has been continuous hard driving, mountain driving, or it the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-704

A-5

Page 25 of 677

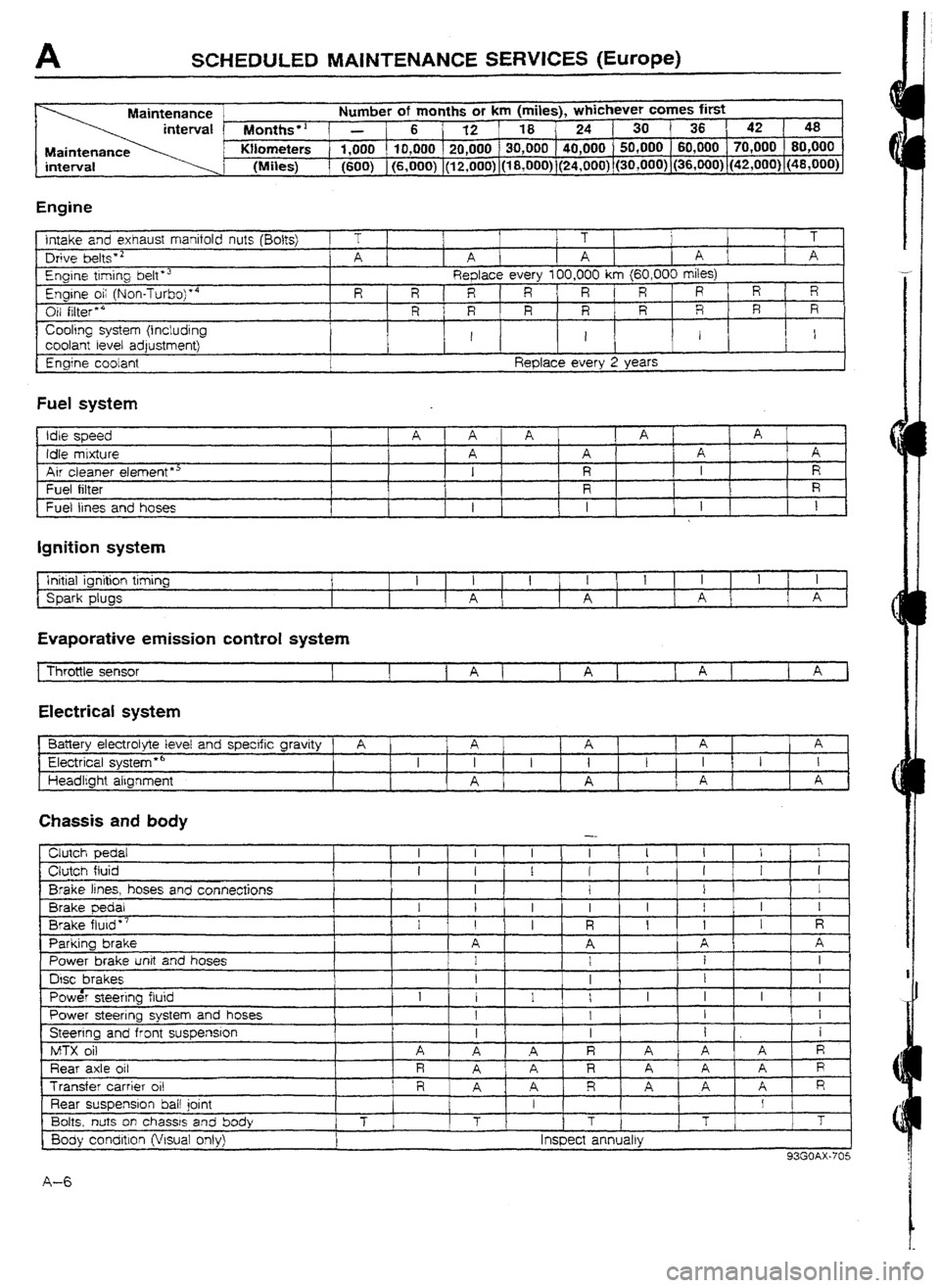

SCHEDULED MAlNTENANCE SERVICES (Europe)

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 1 12 18 24 1 30

36 1 42 48

Maintenance Wometers 1,000 10,000 20,000 30,000 40,000 50,000 60,000 1 70,000 80,000

interval

(Miles) (600) (6,000) (12,000) (18,000) (24,000) (30,000) (36,000)~(42,000) (48,000)

Engine Intake

and exhaust manifold nuts (Bolts) Drive belts * 2

Engine ttming belt *’

Engine oi; (Non-Turboj’4

Oil filter * 4

Cooling system (Including coolant

level adjustment)

Enaine coolant T

1 1 1

1 1 ’

A

[ A I A 1 A ] [ A

Replace every t 00,000 km (60,000 miles)

R

R R R R R R R 1 R

R R R R R R R R

I I 1 I

Reolace everv 2 Years

Fuel system

Idle speed

Idle mixture

Air cleaner element *’ Fuel

filter

Fuel lines and hoses

I A I * A 1 A 1 A

I

A A A A

I R I R

R

I R I

1 I

t I 1 [ I

Ignition system

Initial ignition timing

Spark plugs I t I I 1 I 1 I

A A ( A A

Evaporative emission control system

Electrical system

Ejattery electrolyte level and specific gravity A

A 1 A A 1 A

Electrical system

l 6

I I I

I t I 1 I I

Headlight algnment

A A f A 1 A

Chassis and body

Clutch pedal

Clutch fluid

Brake lines, hoses and connections

Brake pedal

Brake flutd *7

Parking brake

Power brake unit and hoses

DGC brakes

Pow& steering fluid

Power steering system and hoses

Steering and front suspension

MTX oil

Rear axle oil

Transfer carrier

ui!

Rear suspension bail joint

Bolts, nuts on chassis and body

8ody condltlon (Visual onty)

-

I I I I I I I I

1 I I I I I I I

I

1 I I

i

1 I I I I I I

I I I

R I 1 I R

A A A 1 A

1

1 i 1 I

I

I I

I

I

I I I I I I I

I 1 I I

I 1 I 1 i

1 A

A R A A A R

iR,i A R A A A R

R ’

A . A R A A A R

f I

T

T T T

T

I Inspect annually

93GOAX-705

A-6

Page 27 of 677

A SCHEDULED MAINTENANCE sERvw3 (Europe)

SCHEDULED MAfNTENANCE SERWCES (Europe)

MAWTENAN CE TABLE (Unlead Fuel Model)

Chati symbols:

I : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

* 1 Major service interval at 12 months120,OOO km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

*2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

“3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). failure to replace the tim-

ing belt may result in damage to the engine.

“4 If the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the &commended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c> Driving for a prolonged periods in cold temperatures or regularly driving only short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more oten

than at usual recommended intervals.

*6 This is a full function check of all electrical systems, i.e, all lights, washers (including condition of blades)

electric windows, sunroof, horn etc.

“7 Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-707

A-8

Page 28 of 677

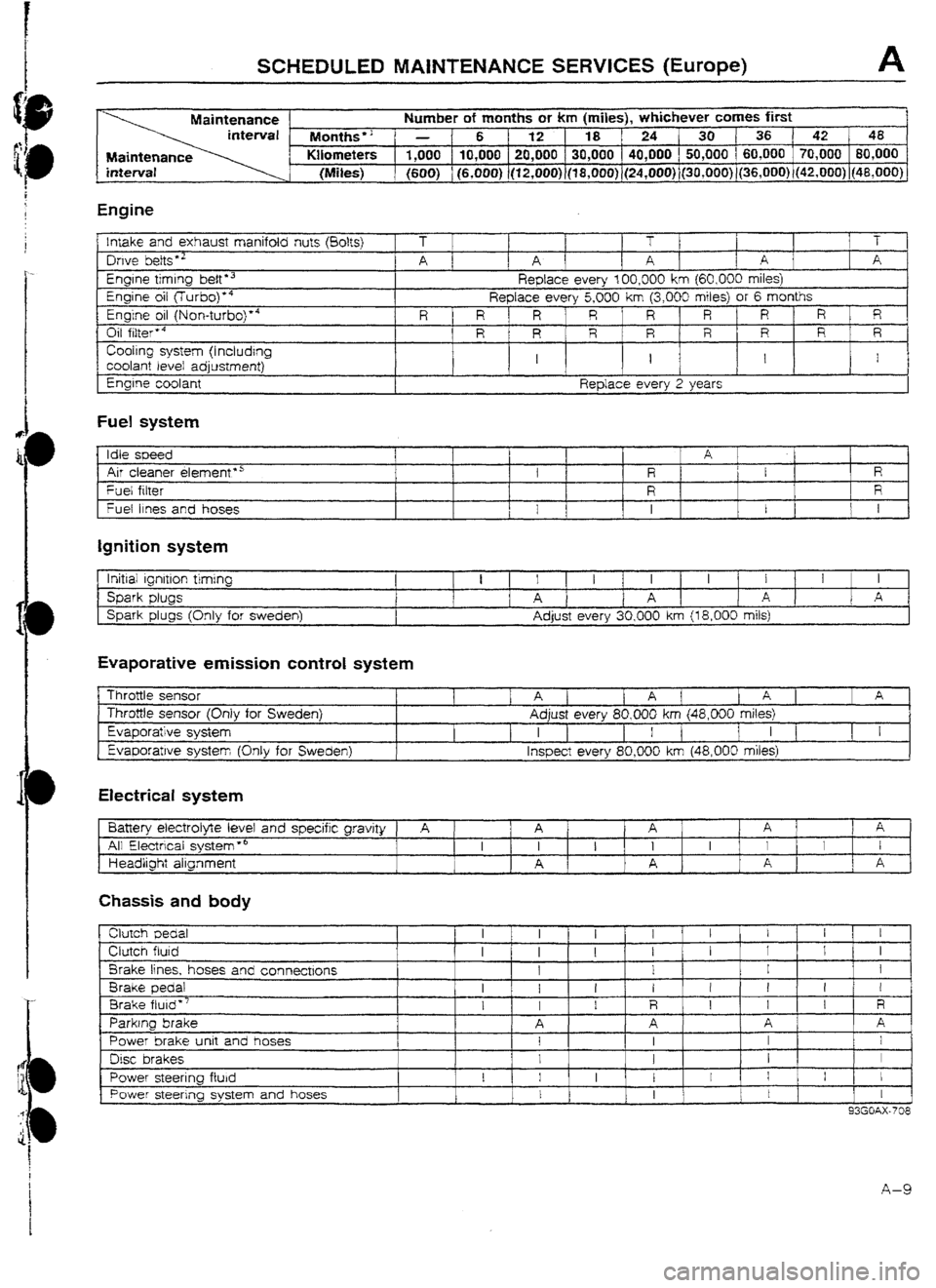

SCHEDULED MAtNTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 1 12 18 ‘24 30136 42 48

Maintenance Kilometers 1,000 10,000 20,000 30,000 40,000 50,000 ( 60,000 70,000 80,000

(Miles) (600) (6,000) (12,OOO)~(l8,0~0) (24,000) (3O,UOO))(36,000) (42,000) j48,OOU)

Engine

!nrake and exhaust manifold nuts (80&j

Owe belts *’

Engrne timing belt l 3

Engine oil flurbo)‘4

Engine oil (Non-turbo)“4

Oil filter’4

Cooling system (I ncludrng

coolant level adjustment)

Engine coolant T 1 T T

A 1 1 A A 1 A A

Reptace every 100,000 km

{60,000 miles)

Replace every 5,000 km (3,000 miles) or 6 months

R R 1 R R R R ‘ R R R

R R R R R R R ’ R

I I I I

Replace every 2 years

Fuel system

Idle soeed

I A 1

Air cleaner elemenf*5 I f R E

R

Fuel fitter

R R

fuel 11~s and hoses 1

t 1 I I I I

Ignition system

lrritiai ignition timing

Spark plugs

Spark plugs (Only for Sweden) 1 I I I 1 I I 1 I I 1 I

A 1 A A 1 A

Adjust every 30,000 km {

18,000 mils)

Evaporative emission control system

Throttle sensor

Throttle sensor (Only for

Sweden)

Evaporative system Evaporatwe system Khlv

for Sweden) 1 1 Aj 1 A ( [ A ] 1 A

Adjust every 80,000 km (48,000 miles)

I 1 I [ I 1

I I [ 1 I

lnsoect everv 80.000 km (48.000 miles)

Electrical system

Battery electrolyte level and specific gravity

A 1 A A ’ 1 A ; A *

All Electrical system *’ I I 1 I I I I I I

Headlight alignment A A A I

c I A ,

Chassis and body

clutch Dedal

Clutch fluid

Brake lines, hoses and connectrons

Brake pedal

Brake fluid”’

Parking brake

Power brake unit and hoses

Disc brakes

Power steering fluid

Power steering system and hoses I

I I 1 1 1 I I

I I

I

I I I I 1 1 I

1

1 I I

I I I I t ! I I

I I I R I 1 I R

A A A A

I I I I

I 1 I 1

I 1 I I I I j I ,

I

I 1 I 1

I

93GOAX-708

A-9

Page 36 of 677

REMOVAL Bl

/

/

93G05? -72t

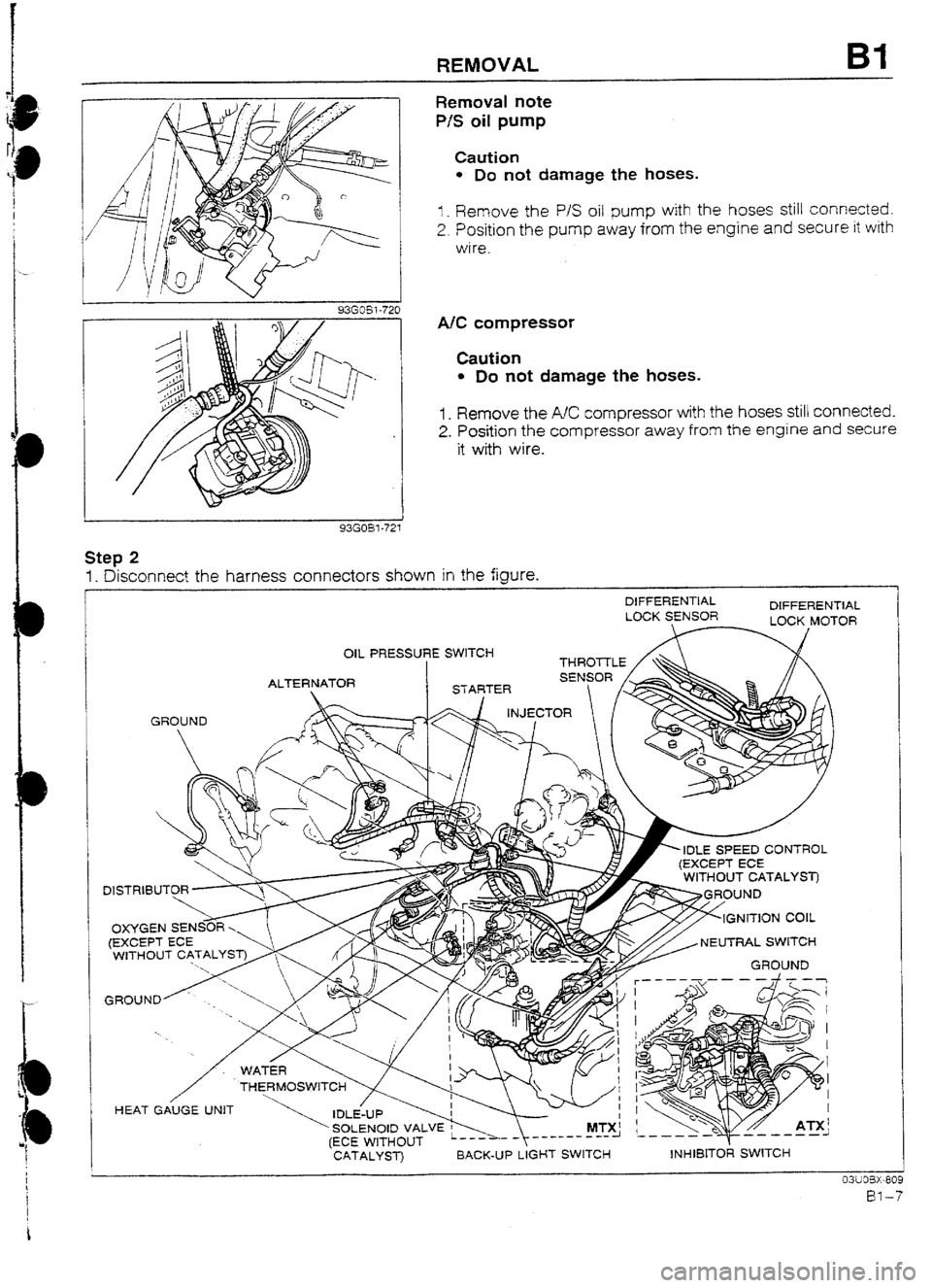

Removal note

P/S oil pump

Caution

l Do not damage the hoses.

I _ Remove the P/S oil pump with the hoses still connected.

2. Position the pump away from the engine and secure it with

wire.

A/C compressor

Caution

l Do not damage the hoses.

1. Remove the AC compressor with the hoses still connected.

2. Position the compressor away from the engine and secure

it with wire.

Step 2

1. Disconnect the harness connectors shown in the figure.

DIFFERENTIAL

DIFFERENTIAL

LUCK SENSOR

OIL PRESSURE SWITCH --- -

GROUND

r, IDLE SPEED CONTROL

NEUTRAL SWITCH

’ SOLENOID VALVE w MTX!

(ECE WITHOUT _--------I

CATALYST) BACK-UP LIGHT SWITCH

\‘C

Y ~55 ATX’

d ---a-- ,-,---1

INHIBITOR SWITCH