light MAZDA 232 1990 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 49 of 677

91 1NSTALLATION

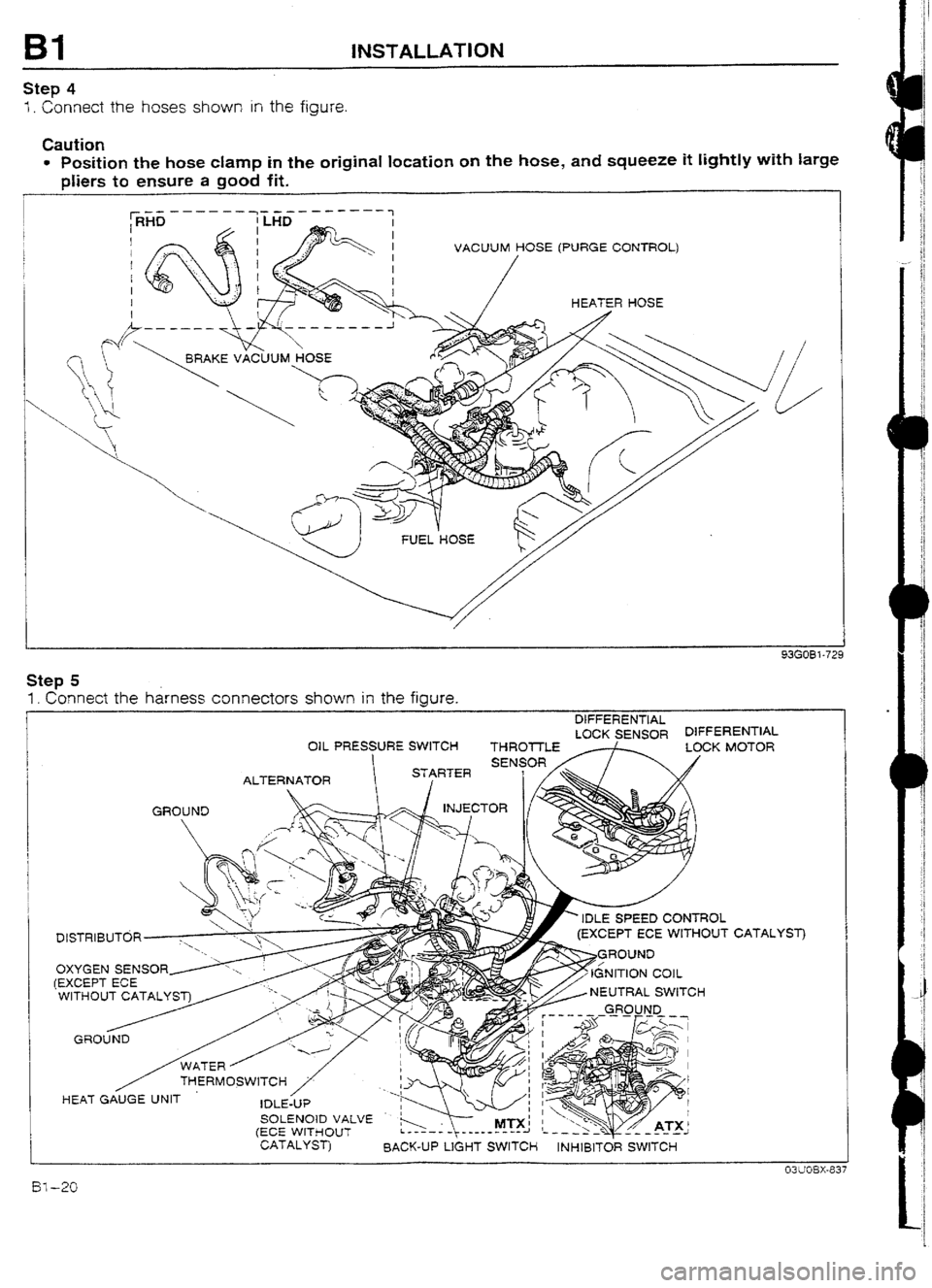

Step 4

1. Connect the hoses shown in the figure.

Caution

l Position the hose clamp in the original location on the hose, and squeeze it lightly with large

pliers to ensure a good fit.

Step 5

1. Connect the harness connectors shown in the figure.

OIL PRESSURE SWITCH

Df STRlBUTdR

OXYGEN SENSOR

(EXCEPT ECE

WITHOUT CATALYST) lVFFFRFh!TIAI

-.I I -4 m-m. I -r-h LOCK SENSOR DIFFERENTIAL

THRO77LE

/--+I / LOCK MOTOR

AC. .A--

r IDLE SPEED CONTROL

r

dz k

/NEUTRAL SWITCH

“Rou2ydy __

HEAT GAUGE UNIT ’

IDLE-UP

SOLENOID VALVE

IECE WlTl-tOUT

‘CATALYST-)

BACK-UP LIGHT SWITCH INHlBlTdR SWITCH

G3UOBX-837

E3i -20

Page 82 of 677

INSTALLATION 82

RIGHT-HAND DRIV

Step 4

1. Connect the hoses shown in the figure. Speedometer cable

I_ Connect the speedometer cable.

Caution

l Position the hose clamp in the original location on the hose, and squeeze it lightly with large

pliers to ensure a good fit. .

93G082-76 ‘I

B2-29

Page 86 of 677

INSTALLATION

93G082-7ti

HERE

/+Ju 7

93GOB2-74!

Caution

l Position the hose clamp in the original location on

the hose, and squeeze it lightly with large pliers to

ensure a good fit.

Accelerator cable

1. Install the accelerator

cable.

Tightening torque

@): 7.8-l 1 N4m (80-l 10 cm-kg, 69-95 in-lb)

2. Adjust the cable deflection by turning nuts @ .

Deflection: I-3mm (U&4--0.12 in)

Battery carrier and battery

1 . Install the battery carrier.

Tightening torque:

7.8-l 1 N4m (80-I IO cm-kg, 69-95 in-lb)

2. Install the battery and the battery cover.

3. Install the battery bracket.

Tightening torque:

2.9-5.9 N.m (30-60 cm-kg, 26-52 in-lb)

4. Connect the positive battery cable.

Air cleaner assembly

1. Install the air cleaner assembly.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

2. Connect the airflow sensor connector.

3. Connect the hoses shown in the figure.

Strut tower bar

I. Instail the strut tower bar.

Tightening torque:

88-108 Narn (9.0-11 .U m-kg, 65-80 ft-lb)

Undercover and side cover

1. Install the undercovers and side covers.

93GOB2-746

82-33

Page 127 of 677

![MAZDA 232 1990 Suplement User Guide F2 OUTLINE

ECU RELATIONSHIP DlAGRAM [BP TURBO]

INPUT DEVICE KNOCK SENSOR

KNOCK

i( CONTROL

DlSTRlBUTOR ,-, UNIT

NC SWITCH

--k/L SWITCHS

{REAR WINDOW DEFROSTER SWITCH.

HEADLIGHT SWITCH, BLOWER MAZDA 232 1990 Suplement User Guide F2 OUTLINE

ECU RELATIONSHIP DlAGRAM [BP TURBO]

INPUT DEVICE KNOCK SENSOR

KNOCK

i( CONTROL

DlSTRlBUTOR ,-, UNIT

NC SWITCH

--k/L SWITCHS

{REAR WINDOW DEFROSTER SWITCH.

HEADLIGHT SWITCH, BLOWER](/img/28/57056/w960_57056-126.png)

F2 OUTLINE

ECU RELATIONSHIP DlAGRAM [BP TURBO]

INPUT DEVICE KNOCK SENSOR

KNOCK

i( CONTROL

DlSTRlBUTOR ,-, UNIT

NC SWITCH

--k/L SWITCHS

{REAR WINDOW DEFROSTER SWITCH.

HEADLIGHT SWITCH, BLOWER SWITCH,

ELECTRICAL FAN SWITCH)

BATTERY A

THRO77LE

SENSOR

NEUTRAL/ IDENTIFICATION

CLUTCH SWITCH

DIAGNOSIS

CONNECTOR

(TEN TERMINAL) INTAKE AIR

THERMOSENSOR

OUTPUT DEVICE

CIRCUIT

OPENING

SOLENOID VALVE

(PRESSURE REGULATOR

WASTEGATE

SOLENOID VALVE

RESISTOR/RELAY

SOLENOID VALVE

(PURGE CONTROL)

93GOFZ-71

F2-10

Page 137 of 677

F2 CONTROL SYSTEM

CONTROL

SYSTEM

STRUCTURAL VIEW

OXL STOPLIGHT SWITCH CLUTCH SWITCH

INJECTOR

P/S PRESSURE

SWITCH

‘GEN SE877

DtSTRIBUTOR

/ PUMP

CONTROL UNll

CONTROL UNIT

CONNECTOR

P REStSTORlRELAY

FUEL tNJ RELAY (MAIN RELAY)

AIRFLOW METER

SOLENOID VALVE

I NEUTRAL SWITCH

(PRESSURE REGULATOR)

WATER THERMOSENSOR

93GOf2.729

Page 139 of 677

![MAZDA 232 1990 Suplement User Guide F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTAL MAZDA 232 1990 Suplement User Guide F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTAL](/img/28/57056/w960_57056-138.png)

F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTALLED BETWEEN No.2 AND

No.3 CYLINDER)

IGNITER

KNOCK iX?NTROL

UNIT

Operation

When the engine vibrates, the knock sensor generates a slight voltage signal that is the sent to the knock

control unit. The knock control unit determines whether the signal is a knocking signal. If it is a knocking

signal, the ignition spark is retarded according to the intensity of the knock to a maximum of 4O.

Inhibition of spark retardation

In order to improve drivability and fuel economy, the ECU inhibits the above spark retardation when the

‘engine load Ls light, the coolant temperature is below O°C (32OF), the engine is cranking during engine test

conditions.

Note

l The knock ~ensur and knock control unit cannot be inspected individually.

When a matfunction code number 05 is indicated, replace the knock controt unit or sensor

only after inspecting the related wiring and connectors.

F2-22

Page 140 of 677

![MAZDA 232 1990 Suplement User Guide CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid hea MAZDA 232 1990 Suplement User Guide CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid hea](/img/28/57056/w960_57056-139.png)

CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid heating ceramic heater to detect the air/fuel ratio,

PRESSURE REGULATOR CONTROL SYSTEM [BP TURBO]

PRESSURE

REGULATOR

I SOLENOID VALVE

(PRESSURE REGULATOR CONTROL)

FUEL

+ (FROM

DELIVERY PIPE1

II

FUEL INJ I

RELAY

(MAIN REU\Y)

I

II Ir

-__. _ - -’ VACUUM

CT0 DYNAMIC

Ill

CHAMBER)

BATTERY -

c

FUEL

(TO FUEL TANK)

nme*rn -.-a

To prevent percolation of the fuel during hot restart idle, vacuum to the pressure regulator k cut for 180

sec., and the fuel injection pressure is increased to slightly more than 284 kPa (2.90 kg/cm’, 41.2 psi).

Operating condition

l Coolant temperature: Above 90°C (194OF)

l Intake air temperature: Above 58OC (136OF)

g No-load condition

FZ-23

Page 148 of 677

![MAZDA 232 1990 Suplement User Guide TRUUBLESHOOT1NG GUIDE

TROUBLESHOOTING GUIDE [BP TURBO]

RELAT1ONSt-W CHART

,

i OUTPUT DEVICE

INPUT DEVfCE

KNOCK SENSOR

1

I

-

I-

3 DIAGNOSIS CONNECTOR

(TEN TERMfNAL)

IGNITION SWITCH

(STAR MAZDA 232 1990 Suplement User Guide TRUUBLESHOOT1NG GUIDE

TROUBLESHOOTING GUIDE [BP TURBO]

RELAT1ONSt-W CHART

,

i OUTPUT DEVICE

INPUT DEVfCE

KNOCK SENSOR

1

I

-

I-

3 DIAGNOSIS CONNECTOR

(TEN TERMfNAL)

IGNITION SWITCH

(STAR](/img/28/57056/w960_57056-147.png)

TRUUBLESHOOT1NG GUIDE

TROUBLESHOOTING GUIDE [BP TURBO]

RELAT1ONSt-W CHART

,

i OUTPUT DEVICE

INPUT DEVfCE

KNOCK SENSOR

1

I

-

I-

3 DIAGNOSIS CONNECTOR

(TEN TERMfNAL)

IGNITION SWITCH

(START POSITION)

0 0 0 Cl

EIL SIGNAL * ’

0 0

0 0

P/S PRESSURE SWITCH

0

1

0 0 A/C SWITCH

0 0 0 0 NEUTRAt AND CLUTCH

SWfTCHES 0 0

0

STOPLIGHT SWITCH

0

0

0 0 0 ATMOSPHERIC PRESSURE

SENSOR (IN ECU) 0

0

THROTTLE SENSOR 0 0 0 0 0

0 INTAKE AfR THERMOSENSOR 0

AlRFLOW METER 0 0

I------ i

0 OXYGEN SENSOR

WATER THERMOSENSOR 0

0 0

O G-SIGNAL

DISTRIBUTOR

I---- Ne-SIGNAL I-L 0 0 L-

0

0

L.- 0 0

L 0 0

93GOF2-i45

*I E/L SIGNAL: Slower fan control switch Second position or higher, cooSing fan operating? headlights ON, or rear wtn-

dow defroster switch ON

Page 179 of 677

F2 CONTROLSYSTEM

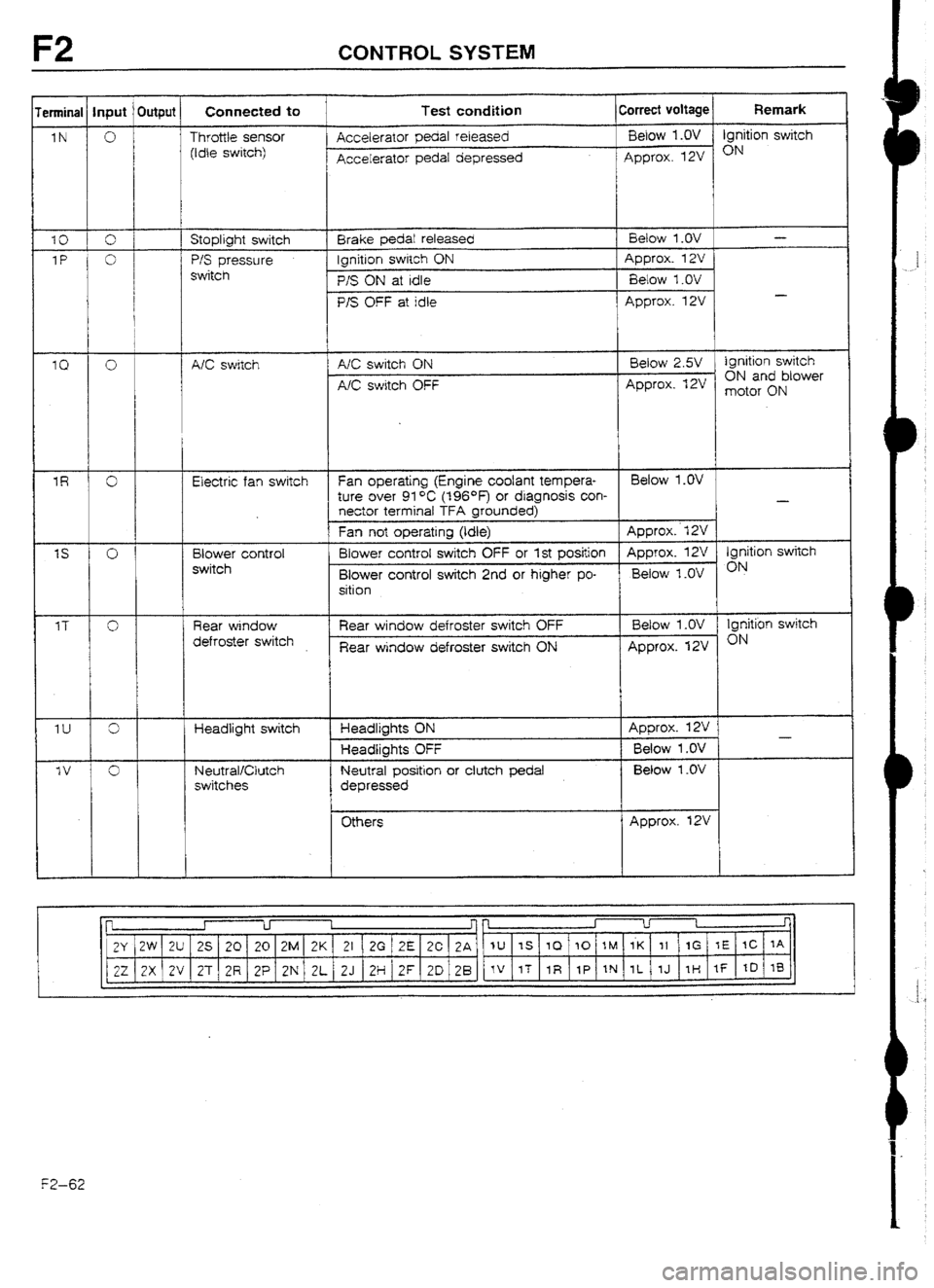

erminat Input ’ Output Connected to Test condition Correct voltage Remark

1N 0 I Throttle sensor Accelerator pedal released &low l.OV j Ignition switch

(Idle switch)

Accelerator pedal depressed Approx. 12V *N

IO I 0 j [ Stoplight switch Brake pedal released Betow 1 .OV -

1P j 0 1 i P/S pressure lgnitlon switch ON Approx. 12V

I

switch

f/S ON at idle Below 1 .UV

I

P/S OFF at idle Approx. 12V -

I

to 0 A/C switch A/C switch ON

NC switch OFF Beiow 2.W ignition switch

ON and blower

Approx* t2V motor ON

i

1R 0 Electric fan switch Fan operating (Engine coolant tempera- Betow l.OV

ture over 91 *C (t96*F) or diagnosis con-

-

nector terminal TFA grounded)

Fan not operating (Idle) Approx.. f 2V

IS 0 Blower control Blower controf switch OFF or 1st position Approx. 13 Ignition switch

switch

Blower control switch 2nd or higher po- Below 7 .OV ON

sition

IT

Cl Rear window

defroster switch Rear window defroster switch OFF

Rear window defroster switch ON Below 1 .OV Ignition switch

Approx. 12V ON

1u 3 Headlight switch Headlights ON Approx. 12V

-

Headlights OFF Below 1 .OV

-Iv Cl ’ Neutral/Clutch

Neutral position or clutch pedal Below I .OV

switches

depressed

Others Approx. 12V

l-7 I r

f

2V 2W 2U 25 20 20 2M 2K 21 2G IZE 2C 2A IU IS 10 10 IM 1K 11 1G rE tC IA

22 2X (2V 2T 2R 2P 2N 2L 2J 2H’ZF 20 2B fV 1T 1R IP IN 1L 7J III If ItI 1B l F2-62

Page 180 of 677

CONTROL SYSTEM F2

Incorrect voltage

Always below 1 .OV Possible cause

l Throttle sensor misadjustment l Short circuit in wiring from throttle sensor to ECU terminal IN l ECU malfunction

Always approx. f 2V

Atways below 1 .OV (Stopfights OK)

Always below 1 .OV

l Throttle sensor misadjustment l Open circuit in wiring from throttle sensor to ECU terminal IN l Open ctrcuit in wiring from throttle sensor to ECU terminal 20

l Open crrcurt in wiring from stoplight switch to ECU terminal 10

l P/S pressure switch malfunction l Short circuit in wirrng from P/S pressure switch to ECU termrnai 1 P

l ECU malfunction

Always approx. 12V

Atways below 2.5V (Btower fan OK) . P/S pressure switch malfunction

l Open circuit in wiring from P/S pressure switch to ECU terminal I P l Open circuit in wiring from P/S pressure switch to ground

l A/C switch malfunction l Short circuit in wiring from A/C switch to ECU terminal 1 Q l Poor connection at ECU connector l ECU malfunction

Always approx. 12V (Blower fan OK)

l ’ A/C switch malfunction l Open c~rcurt in wiring from NC switch to ECU terminal 1Q l ken circuit H-I winnu from A/C switch to blower control switch

Always below 1.W

l Open or short circuit in wiring from fan relay to ECU terminal IR

(Electrkal cooling fan UK} l ECU malfunctron

Always below 1 .OV (Blower fan OK)

l Short crrcutt in wiring from blower control swrfch to ECU terminal IS l Poor connection at ECU connector l ECU malfunction

Always approx. 12V (Blower fan OK)

Always below Illumination lamp

1.w ON when rear

window defroster

switch ON 1

l Open circurt in wrring from blower control switch to ECU terminat IS

I

l Open or short circuit rn wiring from rear window defroster switch to ECU

terminal 1 T

ftlumination lamp

never ON

l Open circuit in wiring from ignition switch to rear window defroster switch

l Rear window defroster switch malfunction I

Always below 1 .OV (Headlights OK)

l Open or short circurt in wiring from headlight relay to ECU termtnal 1 U

Always below 1 .OV

Always approx. l2V

l Neutral switch malfunction l Clutch switch malfunction l Short circuit in wiring from ECU terminal IV to neutral or clutch switch

l Neutral switch maifunctton l Clutch switch malfunction l Open circuit in wiring from ECU terminal IV to neutral or clutch swttch

l Poor connection at ECU connector

93GOFZ789

F2-63