spark plugs MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 21 of 677

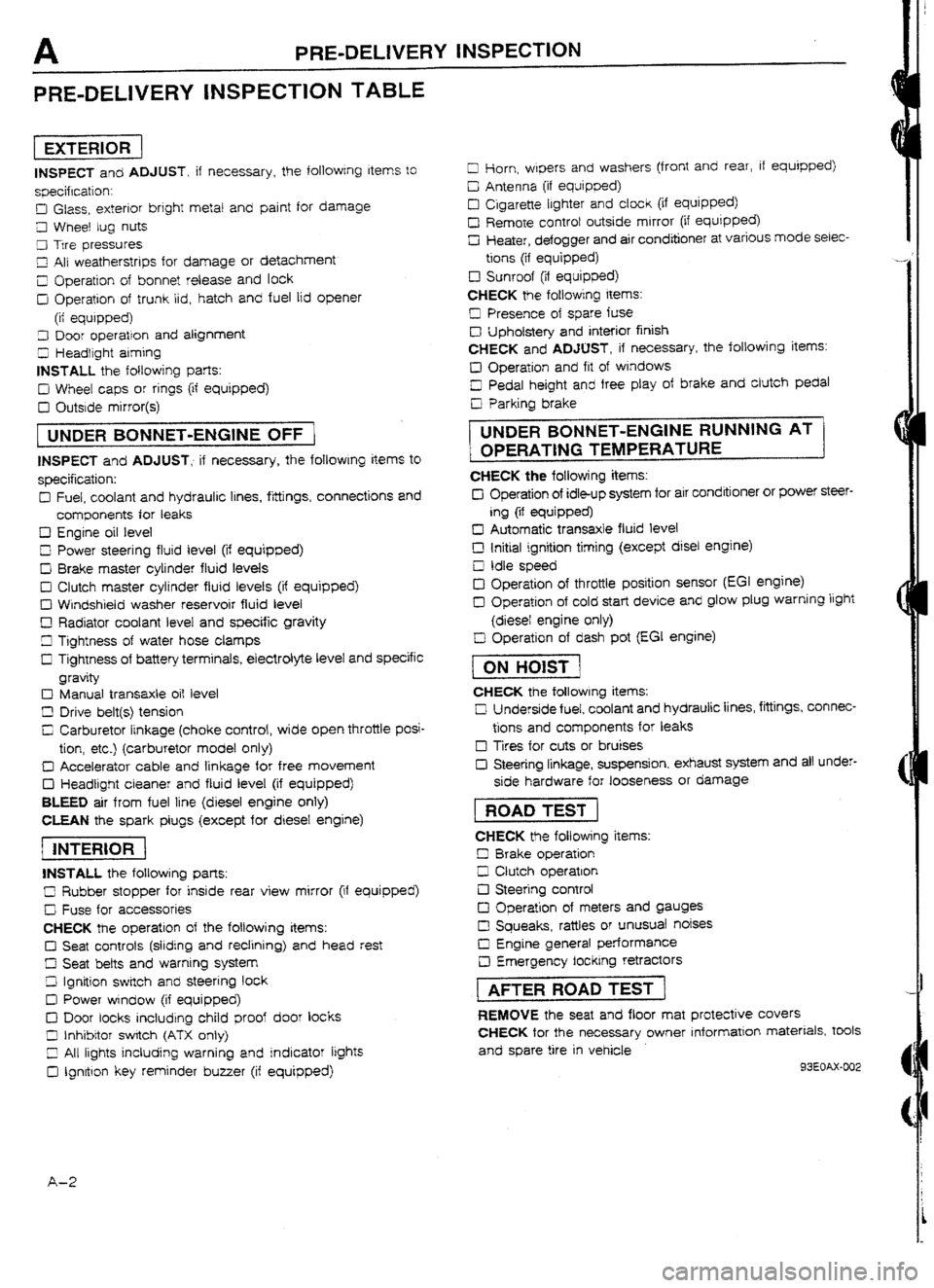

A PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

pieziG-

INSPECT and ADJUST, if necessary, the following Items to

specification:

D Glass, exterior bright metal and paint for damage

Cl Wheel tug nuts

9 Trre pressures

LII All weatherstrips for damage or detachment

Z Operation of bonnet release and lock

D Operation of trunk lid, hatch and fuel lid opener

(it equipped)

3 Door operation and alignment

5 Headlight aiming

INSTALL the following parts:

D Wheel caps or rings (if equipped)

D Outside mirror(s)

[ UNDER BONNET-ENGINE OFF )

INSPECT and ADJUST, if necessary, the foIlowIng items to

specification:

Cl Fuel, coolant and hydraulrc lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level (if equipped)

D Brake master cylinder fluid levels

0 Clutch master cylinder fluid levels (if equipped) q

Windshield washer reservoir fluid level

D Radiator coolant level and specific gravity

Ll Tightness of water hose clamps

I3 Tightness of battery terminals, electrolyte level and specific

gravity

c) Manual transaxle oit level

D Drive belt(s) tension

C; Carburetor linkage (choke control, wide open throttle posi-

tion, etc.) (carburetor model only)

D Accelerator cable and linkage for free movement

D Headlight cleaner and fluid level (if equipped)

BLEED air from fuel line (diesel engine only)

CLEAN the spark plugs (except for diesef engine)

piicis-1

INSTALL the foflowing parts:

C Rubber stopper for inside rear view mirror (if equipped)

c! Fuse for accessories

CHECK the operation of the following items:

Cl Seat controls (sliding and redining) and head rest

ci Seat belts and warnrng system

Z! Ignition swrtch and steering lock

III Power window {if equipped)

0 Door locks including child proof door locks

0 Inhibitor switch

(ATX only)

Z All lights including warning and indicator lights

0 Ignrtron key reminder buyer (if equipped) Cl Horn, wipers and washers (front and rear, if equipped)

D Antenna (if equipped} q

Cigarette lighter and clock (if equipped)

I2 Remote controt outside mirror

(if equipped) q

Heater, defogger and air conditioner at various mode selec-

tions (if equipped)

c3 Sunroof (if equipped)

CHECK

the fotiowing items: q

Presence of spare fuse

c3 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

Cl Operation and fit of windows

D Pedal height and free ptay of brake and clutch pedal

Cl Parking brake

i UNDER BONNET-ENGtNE RUNNING AT ]

1 OPERATtNG TEMPERATURE

CHECK the following items:

Cl Operation of idle-up system for air conditioner or power steer-

ing (if equipped)

13 Automatic transaxle fluid level

D Initial ignition timing

(except disel engine) q

Idle speed

El Operation of throttle position sensor (EGI engine)

13 Operation of cold start device and glow plug warning light

(diesel engine only)

D Operation of dash pot [EGI engine)

t

ON HOtST 1

CHECK the following items:

U Underside fuel, coolant and hydraulic lines, fittings, connec-

tions and components for leaks q

Tires for cuts or bruises

Cl Steering linkage, suspension, exhaust system and all under-

side hardware for

looseness or damage

1 ROAD TEST 1

CHECK the foliowing items:

II Brake operation

D Clutch operation

0 Steering control

c3 Operation of meters and gauges

0 Squeaks, rattles or unusual noises q

Engine general performance

c3 Emergency Iocking retractors

rAFTER ROAD TEST 1

REMOVE the seat and floor mat protective covers

CHECK for the necessary

owner information materials, tools

and spare tire in vehicle

93EOAX-002

A-2

Page 23 of 677

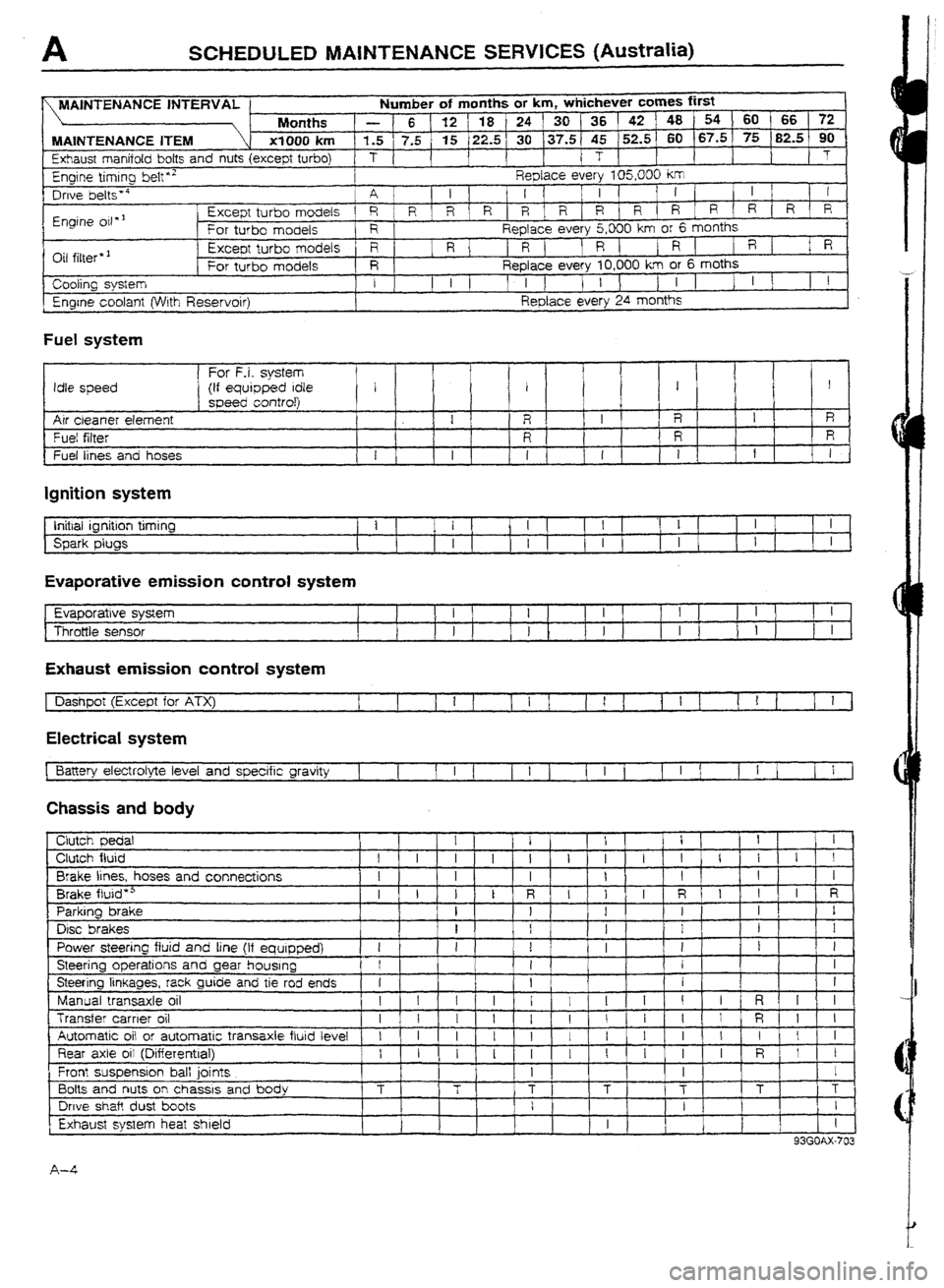

A SCHEDULED MAINTENANCE SERVICES (Australia)

lumber of months or km, whichever cumes first

P

_ 48 54 60 1 66 72

5

60 67.5 75 90 .--- .-- -

.-m-w --v-w _ _ -_-- - - _ _ - -

_ -- - - --- __-

_-

-- -- (82.5

Exhaust manifold bolts and nuts (except turbo) T 1

I i T 1

1 T

Engine timlrtg belt”’ Replace every 105,000 km

Drwe belts * a

A I 1 I 1 1 I 1

! ’ I I 1 1

Engine oil * ’ Except turbo models 1 RIR\R/RIRIRIR R R,R R R/R

For turbo models R

Replace every 5,000 km or 6 months

r-k:1 c:t+*-* 1 Except turbo models

R 1 R 1 1 R ( ) R ( 1 R ( 1

R 1 f R

-

1 VII IIIIc;I 1 For turbo models I R 1 ReDlace everv IO.000 km or E

Engine coolant (Wrth Reservoir)

Fuel

system

Replace e&y 24 months

For F-i. system

Idle speed (if equipped Idle 1 1 1 I

I speed controf)

Air cleaner element 1

R , I R I R

Fuet filter

I I? R R

~ Fuel lines and hoses

1 I 1 I I 1 I I 1 1

Ignition system

t Initial ignition timing

Spark plugs i I I I -1 I I

I I I I I

f

Evaporative emission control system

Evaporative system

Throttle sensor

Exhaust emission contra! system

[ Dashpot

(Except for ATX) I 1 I

1 1 I 1 1 t 1 1 1 1 1 ! 1 1 I 1

Electrical system

Battery electrolyte level and specific gravity ]

I 1 1 I 1 t I ’ 1 1 I 1 f I ( 1

I 1

Chassis and body

Brake lines, hoses and connections

Brake fluid * a

Parking brake

Disc brakes

1 Power steering fluid and line Ilf &uiDDedl

I 1 1 I I I

I 1 1 III II

I ’

I I

Steering operations and gear housing

I

1 1 I --r--j- 1 I

I

Steerino linkanes. rack auide and tie rod pnds .-- --

----.“.a ..‘-~--, J- -.-- _.- .-- -..-- I I I t I 1 1 I I I I I I I 1

Manual transaxle oil I \\!‘I rl\jl I 1 I R III

1 Transfer Automatic carrier oil or 09 automatic transaxle fluid level

1 1 I 1 111 I 1 I l 1 I 1 I 1[11i t I 1 I 1 I I 1 I

R 1 Iii 1 I

1 Rear axle oil (Differential) 1 t I I I I I I I I

t ’ I r . ’ 1 . I I I I I R I 1

I

I I

i T

1 T T T 1 T [ T I 1 T

Front suspension ball joints

Bolts and nuts on chassis and body

I I I . I ! ,

I 1 I . I 1 ’ I I ’

Drive shaft dust boots

I

I 1 I 1

I 1 1 I

~~

- - ’ C1utcl-1 pedat

Clutch fluid

1

A-4

Page 25 of 677

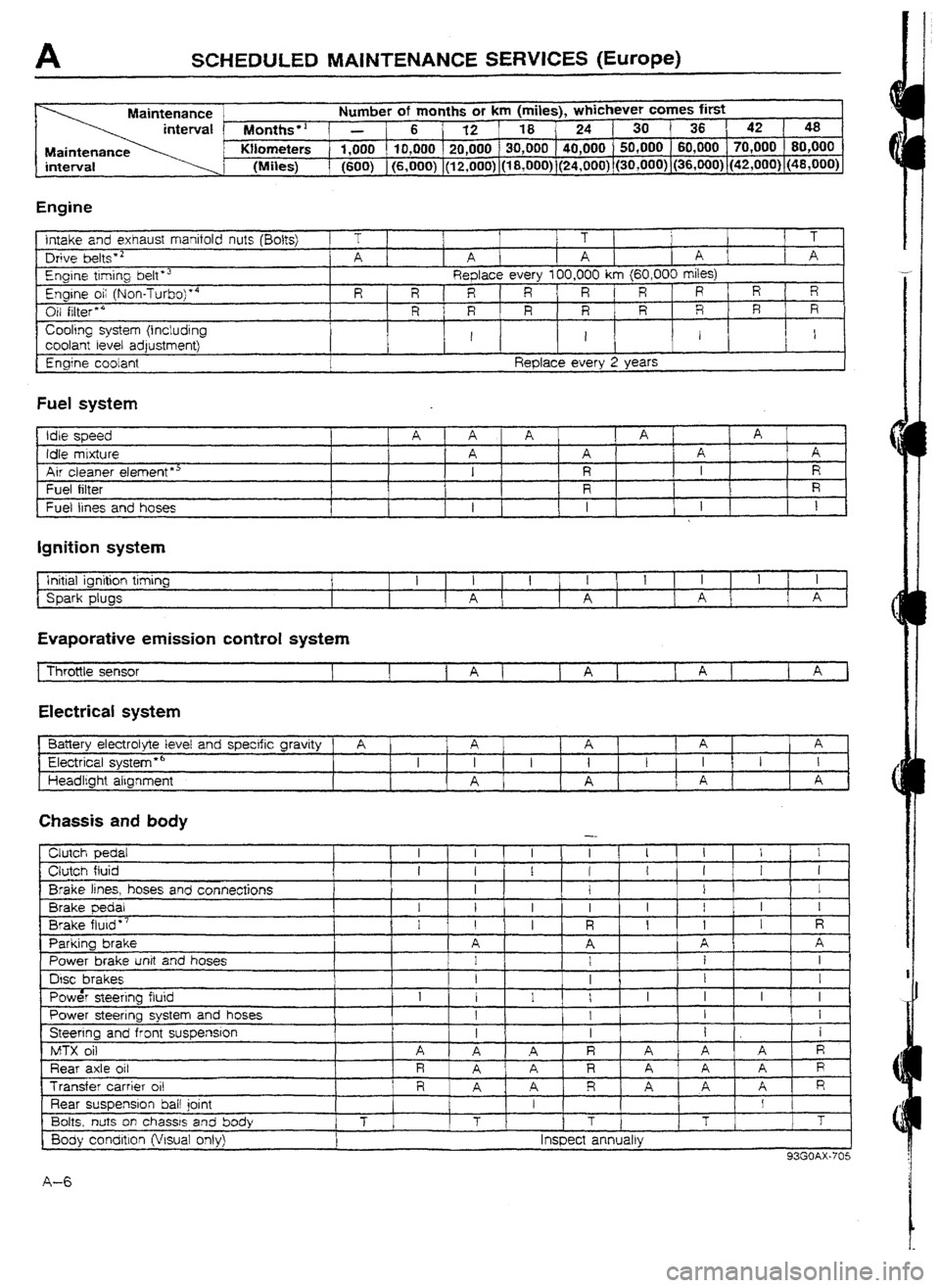

SCHEDULED MAlNTENANCE SERVICES (Europe)

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 1 12 18 24 1 30

36 1 42 48

Maintenance Wometers 1,000 10,000 20,000 30,000 40,000 50,000 60,000 1 70,000 80,000

interval

(Miles) (600) (6,000) (12,000) (18,000) (24,000) (30,000) (36,000)~(42,000) (48,000)

Engine Intake

and exhaust manifold nuts (Bolts) Drive belts * 2

Engine ttming belt *’

Engine oi; (Non-Turboj’4

Oil filter * 4

Cooling system (Including coolant

level adjustment)

Enaine coolant T

1 1 1

1 1 ’

A

[ A I A 1 A ] [ A

Replace every t 00,000 km (60,000 miles)

R

R R R R R R R 1 R

R R R R R R R R

I I 1 I

Reolace everv 2 Years

Fuel system

Idle speed

Idle mixture

Air cleaner element *’ Fuel

filter

Fuel lines and hoses

I A I * A 1 A 1 A

I

A A A A

I R I R

R

I R I

1 I

t I 1 [ I

Ignition system

Initial ignition timing

Spark plugs I t I I 1 I 1 I

A A ( A A

Evaporative emission control system

Electrical system

Ejattery electrolyte level and specific gravity A

A 1 A A 1 A

Electrical system

l 6

I I I

I t I 1 I I

Headlight algnment

A A f A 1 A

Chassis and body

Clutch pedal

Clutch fluid

Brake lines, hoses and connections

Brake pedal

Brake flutd *7

Parking brake

Power brake unit and hoses

DGC brakes

Pow& steering fluid

Power steering system and hoses

Steering and front suspension

MTX oil

Rear axle oil

Transfer carrier

ui!

Rear suspension bail joint

Bolts, nuts on chassis and body

8ody condltlon (Visual onty)

-

I I I I I I I I

1 I I I I I I I

I

1 I I

i

1 I I I I I I

I I I

R I 1 I R

A A A 1 A

1

1 i 1 I

I

I I

I

I

I I I I I I I

I 1 I I

I 1 I 1 i

1 A

A R A A A R

iR,i A R A A A R

R ’

A . A R A A A R

f I

T

T T T

T

I Inspect annually

93GOAX-705

A-6

Page 28 of 677

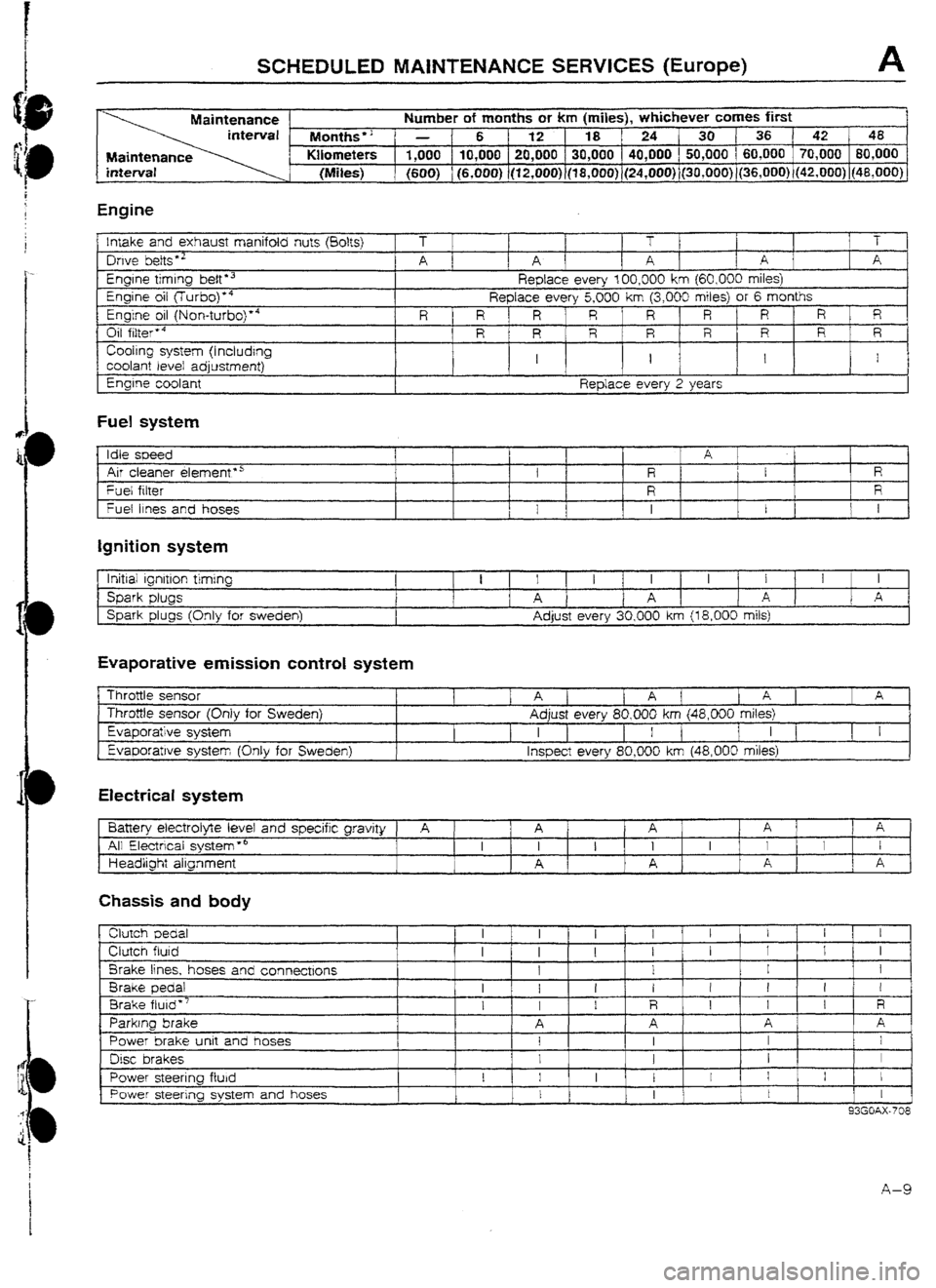

SCHEDULED MAtNTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 1 12 18 ‘24 30136 42 48

Maintenance Kilometers 1,000 10,000 20,000 30,000 40,000 50,000 ( 60,000 70,000 80,000

(Miles) (600) (6,000) (12,OOO)~(l8,0~0) (24,000) (3O,UOO))(36,000) (42,000) j48,OOU)

Engine

!nrake and exhaust manifold nuts (80&j

Owe belts *’

Engrne timing belt l 3

Engine oil flurbo)‘4

Engine oil (Non-turbo)“4

Oil filter’4

Cooling system (I ncludrng

coolant level adjustment)

Engine coolant T 1 T T

A 1 1 A A 1 A A

Reptace every 100,000 km

{60,000 miles)

Replace every 5,000 km (3,000 miles) or 6 months

R R 1 R R R R ‘ R R R

R R R R R R R ’ R

I I I I

Replace every 2 years

Fuel system

Idle soeed

I A 1

Air cleaner elemenf*5 I f R E

R

Fuel fitter

R R

fuel 11~s and hoses 1

t 1 I I I I

Ignition system

lrritiai ignition timing

Spark plugs

Spark plugs (Only for Sweden) 1 I I I 1 I I 1 I I 1 I

A 1 A A 1 A

Adjust every 30,000 km {

18,000 mils)

Evaporative emission control system

Throttle sensor

Throttle sensor (Only for

Sweden)

Evaporative system Evaporatwe system Khlv

for Sweden) 1 1 Aj 1 A ( [ A ] 1 A

Adjust every 80,000 km (48,000 miles)

I 1 I [ I 1

I I [ 1 I

lnsoect everv 80.000 km (48.000 miles)

Electrical system

Battery electrolyte level and specific gravity

A 1 A A ’ 1 A ; A *

All Electrical system *’ I I 1 I I I I I I

Headlight alignment A A A I

c I A ,

Chassis and body

clutch Dedal

Clutch fluid

Brake lines, hoses and connectrons

Brake pedal

Brake fluid”’

Parking brake

Power brake unit and hoses

Disc brakes

Power steering fluid

Power steering system and hoses I

I I 1 1 1 I I

I I

I

I I I I 1 1 I

1

1 I I

I I I I t ! I I

I I I R I 1 I R

A A A A

I I I I

I 1 I 1

I 1 I I I I j I ,

I

I 1 I 1

I

93GOAX-708

A-9

Page 64 of 677

D

D

SUPPLEMENTAL SERVICE iNFORMATION, COMPRESSION 82

SUPPLEMENTAL SERVICE INFORMATION

The following points in this section are changed in comparison with Workshop Manual [Europe (7 203~IO-899,

Australia (I 204-1 U-89F) 1.

Compression

l Inspection

Engine

l Removal

l Engine stand mounting

l Engine stand dismounting

l Ins:attaIion 93GQ32-77 I

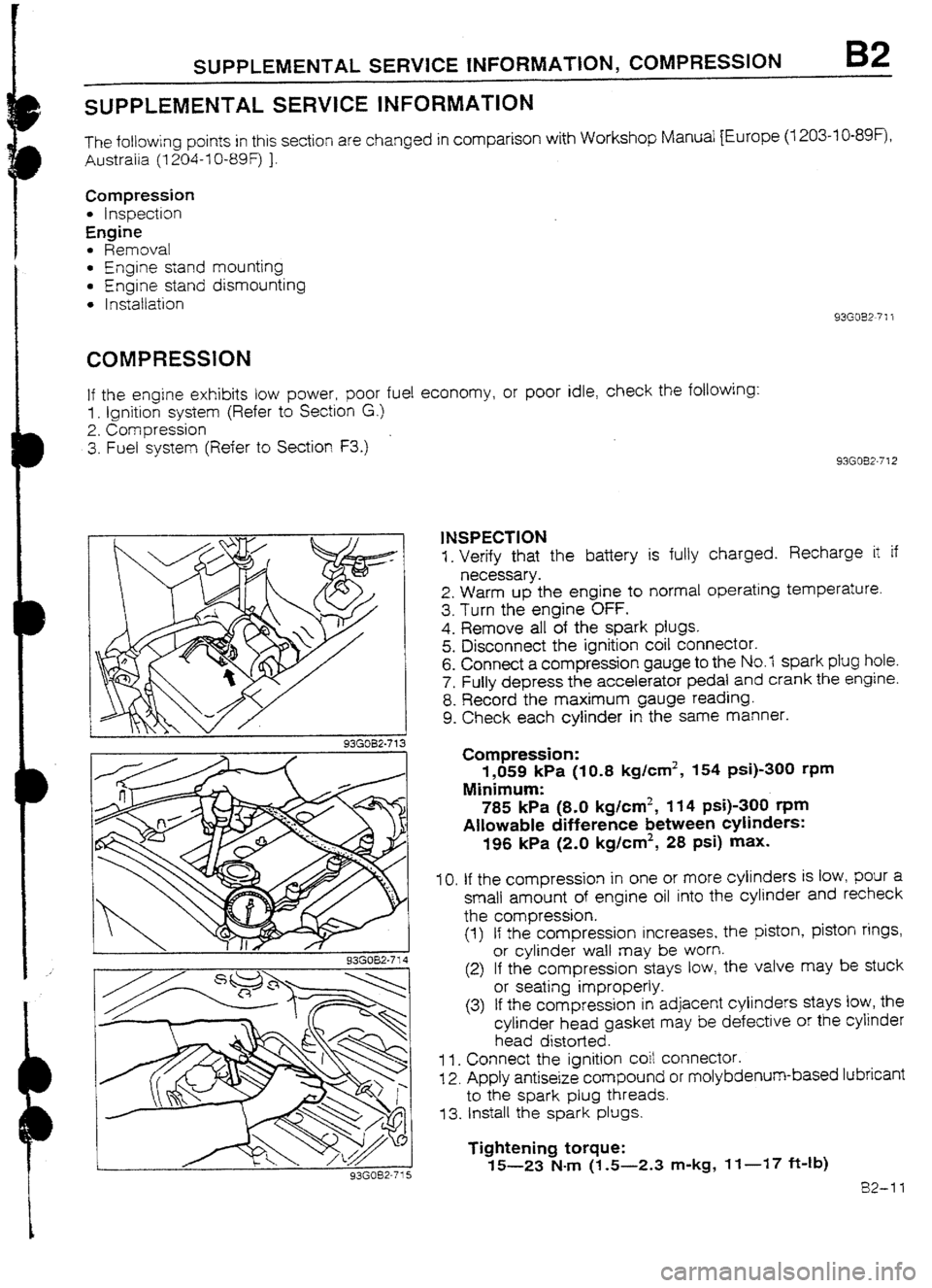

COMPRESStON

If the engine exhibits low power, poor fuel economy, or poor idle, check the following:

1. Ignition system (Refer to Section G.)

2. Compression

3. Fuel system (Refer to Section F3.)

93G032-774 93GO32-712

1NSPECTION

1. Verify that the battery is fully charged. Recharge it if

necessary.

2. Warm up the engine to normal operating temperature.

3. Turn the engine OFF.

4. Remove all of the spark plugs.

5. Disconnect the ignition coil connector.

6. Connect a compression gauge to the No.7 spark plug hole.

7. Fully depress the accelerator pedal and crank the engine.

8. Record the maximum gauge reading.

9. Check each cylinder in the same manner.

Compression:

1,059 kPa (IO.8 kg/cm2, 154 psi)-300 rpm

Minimum:

785 kPa (8-O kg/cm2, 114 psi)-300 t-pm

Allowable difference between cylinders:

196 kPa (2.0 kglcm2, 28 psi) max.

IO. If the compression in one or more cylinders is low, pour a

small amount of engine oil into the cylinder and recheck

the compression.

(1) If the compression increases, the piston, piston rings,

or cylinder waII may be worn.

(2) If the compression stays tow, the valve may be stuck

or seating improperly.

(3) If the compression in adjacent cylinders stays low, the

cylinder head gasket may be defective or the cylinder

head distorted.

1 I. Connect the ignition coit connector.

12. Apply antiseize compound or molybdenum-based lubricant

to the spark plug threads.

73. Install the spark plugs.

Tightening torque:

15-23 N-m (1.5-2.3 m-kg, If-17 ft-Ib)

82-11