wheel torque MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 13 of 677

GI IDENTIFICATION NUMBER LOCATIONSIUNITSIABBREVlATlONS

IDENTIFICATCON NUMBER LOCATIONS

I

VEHKZLE IDENTIFICATION NUMBER @‘IN) AUTOMATIC TRANSAXLE MODEL AND NUM8ER

ENGINE MODEL AND NUMBER

UNlTS

N-m (m-kg or cm-kg,

ft-lb or in-lb) . . . . . .._.......... Torque

rpm ._._..._.. . . . . . . .._.._.._. . .._. Revolutions per minute

A . . .._._._...__.._.._.._. .__...._. . . Ampere(s)

v .._.... .* .*... ..__.._...*. ..*. .*. ,. Volt(s)

0 I.._._............**..-.-*..-....... Ohm(s) (resistance)

Wa (kg/cm2, psi) . . . . . . . . . . Pressure

(usually positive)

mmlig (inHg) . . . . . . .._.._... Pressure

(usually negative)

w . . . ..*.....e*.-..-..-.....*.e..... Watt

liters (US qt, imp qt) .._. Volume

mm (in) ,_._.._._..._.,_. .~. . ..__ Length

89UOGX-006

ABBREVIATIONS

AB.DC ........................... After bottom dead

center

A/C _ .............................. Air conditioner

ACC ............................. Accessories

ATX ............................. Automatic transaxte

ATDC ......................... Afier top dead center

ATF .............................. Automatic transmission

ftuid

BAC ........................... Bypass air control

BBDC.. ......................... Before bottom dead

center

BTDC ........................... Before top dead center

CPU ............................. Central processing unit t EC-AT ........................... Ekctronically-controlled

automatic transmission

ECU ............................. Engine control unit

EGI ............................... Electronic gasotine

injection

EL ................................ Electricaf toad

EX ................................ Exhaust

IC ................................. Integrated circuit

IGN ............................... Ignition

IN ................................. Intake

tNT ............................... Intermittent

ISC ............................. Idle speed control

LH ................................ Left hand

M .................................. Motor

MIL ............................... Malfunction indicator

lamp

tb4TX. ............................. Manual transaxle

OD. ............................... Overdrive

OFF .............................. Switch off

ON ................................ Switch on PCV .............................. Positive crankcase

ventilation

PRC.. ............................ Pressure regulator

control

P/S ................................ Power steering

P/W .............................. Power wtndow

RH.. .............................. Right hand

SST ............................... Special service tool

ST .................................

Start

SW . . .............................. Switch

TDC. ............................. Top dead center

4VVD ............................. 4-wheel drive

Page 203 of 677

H CLUTCH FLUID (WITH ABS)

CLUTCH FLUID (WITH ABS)

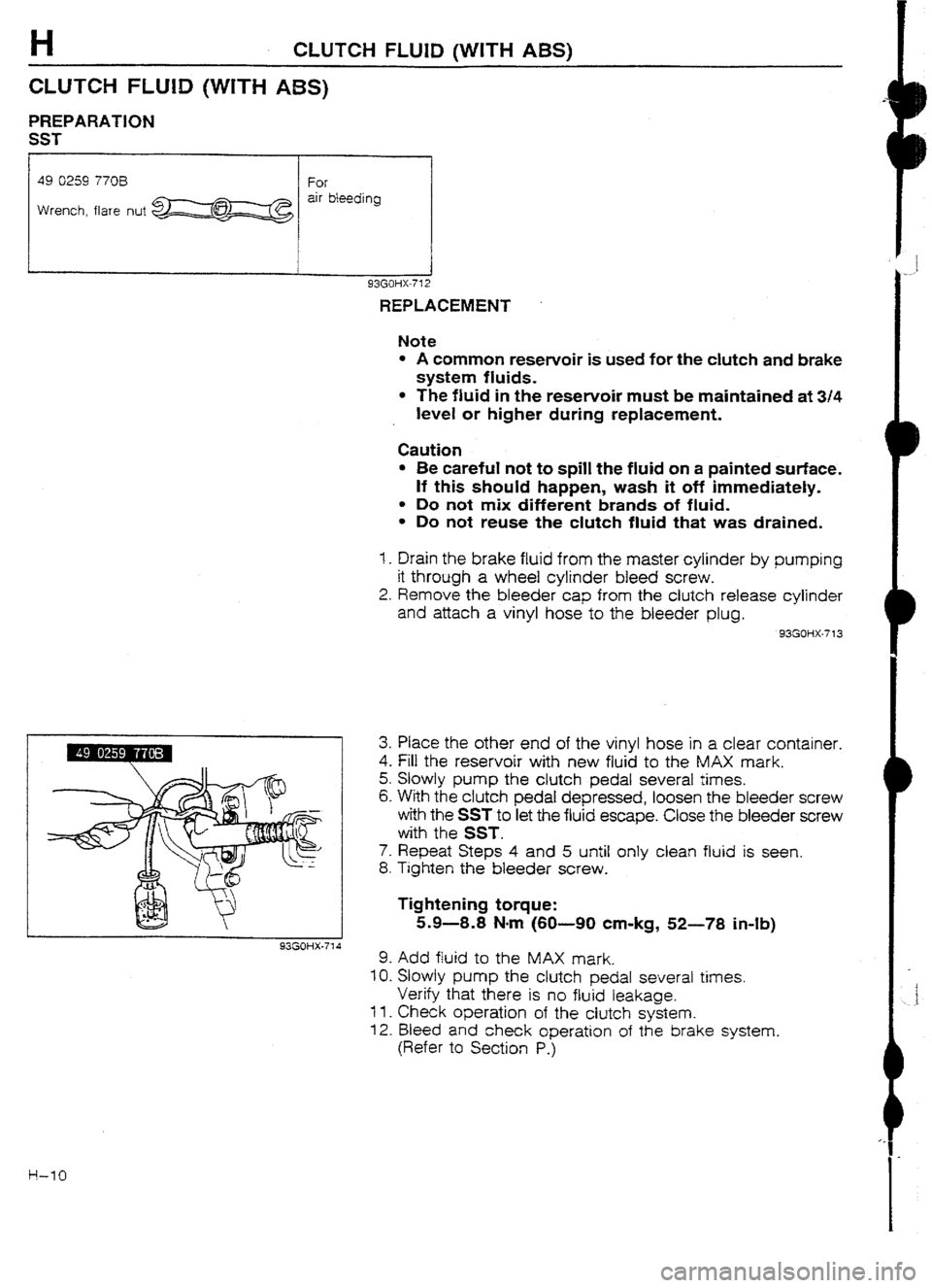

PREPARATION

SST

49 0259 770B

For

Wrench, flare nut

m air

bleeding

1

93GOHX-714 93GOHX-712

REPLACEMENT

Note

l A common reservoir is used for the clutch and brake

system fluids.

l The fIuid in the reservoir must be maintained at 314

tevet or higher during replacement.

Caution

l Be careful not to spill the fluid on a painted surface.

If this should happen, wash it off immediately.

l Do not mix different brands of fluid.

l Do not reuse the clutch fluid that was drained.

1. Drain the brake fluid from the master cylinder by pumping

it through a wheel cylinder bleed screw.

2. Remove the bleeder cap from the clutch release cylinder

and attach a vinyl hose to the bleeder plug.

93GOHX-77 3

3. Place the other end of the vinyl hose in a clear container.

4. Fill the reservoir with new fluid to the MAX mark.

5. Slowly pump the clutch pedal several times.

6. With the clutch pedal depressed, loosen the bleeder screw

with the SST to let the fluid escape. Close the bleeder screw

with the SST.

7. Repeat Steps 4 and 5 until only clean fluid is seen.

8. Tighten the bleeder screw.

Tightening torque:

5.9-8.8 Nom (60-90 cm-kg, 52-78 in-lb)

9. Add fluid to the MAX mark.

IO. Slowly pump the clutch pedal several times.

Verify that there is no fluid leakage.

11.

Check operation of the clutch system.

12. Bleed and check operation of the brake system.

(Refer to Section PJ

Page 213 of 677

C1UTCf-f UNtT

9MUOHX-032

I

03UOf-lX-028

I

93GOHX-729

I

i

Removal Note

Clutch cover and disc

1. Install the SST.

2. Loosen each bolt one turn at a time in a crisscross pattern

until spring tension is released. Then remove the ciutch cov-

er and disc.

Pilot bearing

1. Remove the pilot bearing with the

SST if necessary.

Flywheel

Note

l After removing the flywheel, inspect for oil leakage

past the crankshaft rear oil seal.

If necessary, replace the oil seal.

1. Hold the flywheel with the SST.

2. Remove the flywheel.

Instalfation Note

Flywheel

1 -Wipe the bolts clean and apply sealant to the bolt threads.

2. Install the flywheel and SST.

3. Tighten the bolts evenly and gradually in the pattern shown.

Tightening torque:

96403 Nmm (9.8-10.5 m-kg, 71-76 ft.lb)

PiIot bearing

Note

l Install the pilot bearing ftush with the flywheeL

I_ Install the new bearing with the SST.

03UOHX-030

H-20

Page 214 of 677

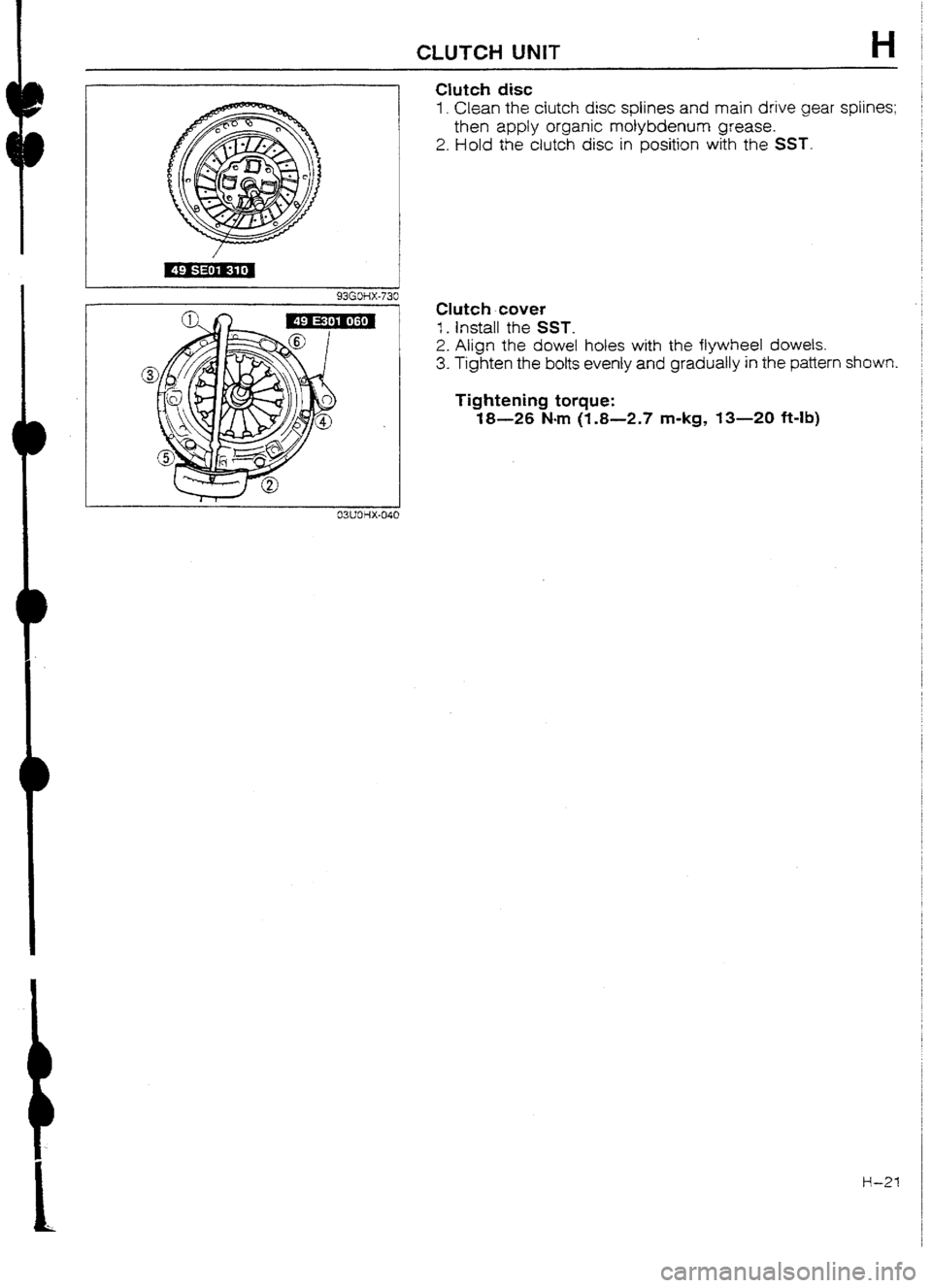

CLUTCW UNIT

Clutch disc

1. Clean the clutch disc splines and main drive gear spIines;

then apply organic molybdenum grease.

2. Hold

the clutch disc in position with the SST.

Clutch cover

1. Install the SST.

2. Align the

dowel holes with the flywheel dowels.

3. Tighten the

botts evenly and gradually in the pattern shown.

Tightening torque:

18-26 N-m (1.8-2.7 m-kg, 13-20 ft-lb)

EWOHX-040

Ii-21