oil MAZDA 323 1992 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 28 of 279

![MAZDA 323 1992 Suplement User Guide B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 1 MAZDA 323 1992 Suplement User Guide B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 1](/img/28/57055/w960_57055-27.png)

B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 11 .Omm

IO.650 in 1 below 10.433 in 1 below

oil rmg groove. oil ring groove.

COOLING CHANNEL

*IL YTLET

OIL t NiET

l The piston skirt is shortened for reduced weight and friction. l A cast iron ring carrier is installed in the piston to reduce piston-ring groove wear. l A cooling channel is incorporated in the body of the piston. The 011 jet squirts oil into this cootrng channel

and the or! absorbs

the heat from around the ring lands, reducing piston ring and cylinder wat! wear

Bz-4

Page 53 of 279

F3 TRUUBtESHOOTlNG GUIDE

IDIAGNOSTiC tNDEX

No. TFtOUBLESHOOTtNG ITEM DESCRIPTtON PAGE

1.

WI/I not crank or cranks slowly Refer to Engine Electrrcal System ‘1

2 Cranks normally but No combustion Engine cranks at normal speed but shows no sign of F3-22

will not start flrlng

3 Partial corn bustlon- Engine cranks at normal speed but shows only par- ‘1

When engine cold tial combustion and will not continue to run

4 Partial combustron- Engine cranks at normal speed and shows partial F3-25

After warm-up combustion but ~111 not continue runnrng after being

hot soaked

Cranks normally but Always Engine cranks at normal speed but rqurres exces- ‘1

hard to start sive cranktng time before starting

When engine cold Same condition as No. 5 when engine IS cold ‘1

Restarts normally after warm-up

After warm-up Same condition as No. 5 after running and betng hot F3-27

soaked

Starts normaNy when cold

1 8 1 Rough idle/

tsl Engine stalls at idle 1 Always [ Engine stalls or vibrates excessively at idle

r - 1 F3-29

r

Before warm-up 1 Engine stalls or vibrates excessively at idle during

I ‘1

10

11

12 After warm-up

When A/C, P/S,

or IX ON

Rough rdle/Englne stalts lus: after starting warm-up

Engine runs normally at idle during warm-up but

stalls or vibrates excessively atter warm-up

Engrne stalls or vtbrates excessrvely at idle when

NC, P/S, or E/L ON

Engine stalts or vibrates excessively lust after starting

tacceleratton from Idle1 F3-3 f

‘1

‘1

I I ’ I

I 13 High Idle speed after warm-up tdle speed excessively hrgh after warm-up ‘1

14 Idle moves up and down/idle hunts Engine speeds up and down periodically at Idle

F3-33

15 Engme stalls on deceleratron Engine unexpectedly stops running durrng or after

F3-35

deceleration

16 Engine statts suddenly (intermrttent) Engine intermittently stops runnrng

F3-36

17 Hesitates/Stumbles on acceleratton Flat spot occurs just after accelerator is depressed,

‘1

or m/Id ierkina occurs dunna acceleration

L I I

t 18 1 Surges while crulsng

1 Unexpected change In engine speed that is usually 1 ‘1

1 repetrtive

19 tack of power

20 Poor acceleration

21 Runs rough durrng deceleration/Backfire

22 Knocktng

23 Fuel odor Performance poor under load when throttle valve IS

wide open

Maximum speed reduced

Performance poor during acceleration

Engtne runs rough during deceleratron, and abnor-

mal combustion occurs in exhaust system

Abnormal combust!on accompanied by audible

“pinging” noise

( Gasoline odor in cabln ‘2

‘2

‘1

‘2

+1

24 Exhaust sulfur smell Exhaust gas has an unusual odor

25 High oil consumption Oil consumption excessive

b

26 Poor fuel economy Fuel economy unsatisfactory

27 A/C does not work

Blower fan operates, but magnetic clutch does not

l 1.. .Refet to 323 Workshop Manual (t 203-l O-89F). l 2...Re#er to 323 4-Wheet Drive Workshop Manual (1229-IO-89L). ‘1

‘2

‘1

l 1

13EOFS327

F3-20 -..

REAR I

--

--

Page 68 of 279

![MAZDA 323 1992 Suplement User Guide TROUBLESHOOTING GUiDE F3

15 ENGINE STALLS ON DECELERATION

IESCRIP-

l Engrne unexpectedly stops running dunng or after deceleration

[iON l Idle condition normal.

TROUBLESHOOT1NG HtNTS]

ingrne spe MAZDA 323 1992 Suplement User Guide TROUBLESHOOTING GUiDE F3

15 ENGINE STALLS ON DECELERATION

IESCRIP-

l Engrne unexpectedly stops running dunng or after deceleration

[iON l Idle condition normal.

TROUBLESHOOT1NG HtNTS]

ingrne spe](/img/28/57055/w960_57055-67.png)

TROUBLESHOOTING GUiDE F3

15 ENGINE STALLS ON DECELERATION

IESCRIP-

l Engrne unexpectedly stops running dunng or after deceleration

[iON l Idle condition normal.

TROUBLESHOOT1NG HtNTS]

ingrne speed drops too much when releasrng accelerator

3 Idle-speed misadjustment @I Loose connector disconnected by force of deceleration

3 Fuel-cut contrd malfunction

TEP lNSPECTlON ACTION

1 1s idle condition normal? Yes Go to next step

tdle speed: 800 f 50 rpm (in neutral)

NO Adjust or perform Troubleshooting, Nos.

8-I 1 “ROUGH IDLE”

(Refer to Workshop Manual

(1203-I o-89F))

2 Is “00” displayed on Self-Diagnosis Checker Yes Go to next step

with ignition switch ON?

SYSTEM SELECT: 1 NO Service Code No. displayed

Check for cause (Refer to specified

check sequence) ET page F3-16

“88” flashes

Check ECU termrnal 1 F voltage

Voltage: Battery voltage

(ignition switch ON) r;r page F346

W:SELFTEST

e If OK, replace ECU CI page F3-3

4 If not OK, check wirtng

(ECU - Self-Diagnosis Checker)

3 Does Self-Diagnosis Checker Monitor Lamp with Yes Go to next step

lgnttlon switch UN show that switches operate

correctly?

NO Lamp not ON or OFF with specified

switch

Check for cause (Refer to specified

check sequence)

W: SEtF TEST Lamp slways ON

Check wiring between

(ECU terminal 1 D - Self-Diagnosis

Checker)

4 Are ECU ?erminal voltages OK? Yes Go to next step

(especially IV, 20, 20, ZU, 2V.

and 20) v page F346 No

Check for cause

5 Check for poor connection of foltowing parts YC?S Repair or replace

l ignrtion coil l Igniter l Olstribdor l High-tension lead

NO Go to next step l Injector. l Injector resistor l Ctrcuit-opening relay . l ECU

F3-35

Page 69 of 279

F3 TROUBLESHOOTING GUIDE

STEP INSPECTION ACTlON

6 Is dashpot correctly adjusted? Yes Go to next step

c

Dashpot set speed: Approx. 3,500 rpm

No Adjust dashpot

7

Try known good ECU; does condition

Improve?

w page F3-3

13EOF3-336

16 ENGINE STALLS SUDDENLY (INTERMITTENT)

DESCRIP.

l Engine intermittently stops running

TION l Before stalling, engine conditron is OK

TROUBLESHOOTING HINTS]

@ intermittently no spark or no fuel injection caused by ve-

hlcle vibratron, acceleratton, or deceleration

l Poor connectlon in wiring harness

iTEP INSPECTION ACTfON

1 Is “00” displayed on Self-Oiagnoss Checker Yes Go to next step

with lgnltlon swrtch ON?

NO Service Code No. displayed

Check for cause (Refer to speclfled

check sequence).

Note CT page F3-16

l When checking wiring harness and

connectors, tap, move, and wiggle

suspect sensor and/or harness to

recreate problem

“88” flashes ’

Check ECU terminal IF voltage

Voltage: Battery voltage

{ignition swttch ON) w page F3-45

4 If OK, replace ECU

4 If not OK, check wiring

(ECU - Self-Diagnosis Checker)

2 Check for poor connection of foliowrng parts

Yes Reparr or replace

l lgnltfon coil l Igniter l Distributor l t-flgh-tensron lead

No Go to next step l Injector l Injector reststor l Circutt-opening relay l ECU

3 Are ECU terminal voltages OK? Yes Go to Troubleshbotrng No. 2

(especially 16, 2A, 2B, and 2C) .“CRANKS NORMALLY BUT WILL NOT

w page F3-45 START (NO COMBUSTION)”

w page F3-20

Note

. No Check for cause

l When. checking voltages, tap, move, and

wiggle harness and connector to recreate

problem

* lrlrl m-7

F3-36

7.8-l

Page 70 of 279

F3 II TURBOCHARGER CONTROL SYSTEM ‘1

1’

:j

TURBOCHARGER CONTROL

SYSTEM

TURBOCHARGER

Re’inovaf / Installation

Caution

l Be careful of the following points after turbocharger removal.

l Do not carry the turbocharger by the actuator rod or actuator hose.

l Do not drop the turbocharger.

l Set the turbocharger down with the turbine shaft horizontat.

l Cover the intake, exhaust, and oil passages to prevent dirt or other material from entering

the turbocharger.

l Use the specified new studs when installing the turbocharger.

1, Disconnect the negative battery cable.

2. Raise the vehicle and support it on safety stands.

3. Remove the undercover.

4. Orain the engine coolant.

5. Remove in the order shown in the figure, referring to Removal Note.

6. Install in the reverse order of removal, referring to Installation Note.

I-- 7.8-1 1 N-m ~80-110 kgfcm. 69-96 idbf j

3946 13.94.7, 2% 3842 13.94.3, 28-

31--46 13.2-4.7, 23-341

T, REPLACE .

12-18 1 f-2-1.8, 8.7-13 I

GASKET, REPLACE

19-26 1 t .9-2.6, 14-19 1

7.6-11 Mm t80-?lO kgfcm, 69-95 hlbfl

~-t-n 1 kgf-m, Wlbt]

13EOF3 3.31

F3-3i

Page 71 of 279

F3 TURBOCHARGERCONTROLSYSTEM

1. Radiator

2. Insulator 3. Air hose, and air pipe

4. Oxygen sensor connector

5. Front exhaust pipe

13EOF534

F3-38 6. Water hose

7. Oil pipe

8. Exhaust manifold and turbocharger

Removal Note ,.........I.....f.~.~l....... II.I.... below

Installation Note . . . . , , l.. . . . . . . , ,.. ,..*, , . . . . . . . . . below

13EOF3-339

Removal Note Exhaust

manifold and turbocharger 1. Remove the exhaust manifold and the turbocharger as an

assembly.

2. Separate the turbocharger assembly from the exhaust

manifold.

Installation Note

Exhaust manifold and turbocharger’ I I Remove .all old gaskets and

sealant. 2. Install new gaskets.

3. Supply 25 cc ( 1.5 cu in ] of oil through the oil passage

of the turbocharger.

4. Mount the turbocharger assembly to the exhaust manifold.

5. Install the turbocharger and the exhaust manifold assem-

bly to the engine and loosely tighten the nuts.

6. Install the bracket and the front exhaust pipe, and tighten

the turbocharger mounting nut%

WASTEGATE SOLENOD VALVE

Caution

l The wastegate solenoid valve must be replaced with

the turbocharger, it cannot be replaced by itself.

Inspection 1. Disconnect the connector.

2. Measure the resistance of the solenoid valve.

Resistance: 35-45 !‘l (at 20°C f68OFj) 3. M not as specified, replace the wastegate solenoid valve and

turbocharger as an assembly, if necessary.

(Refer to page F3-37.)

3. Instc

Page 88 of 279

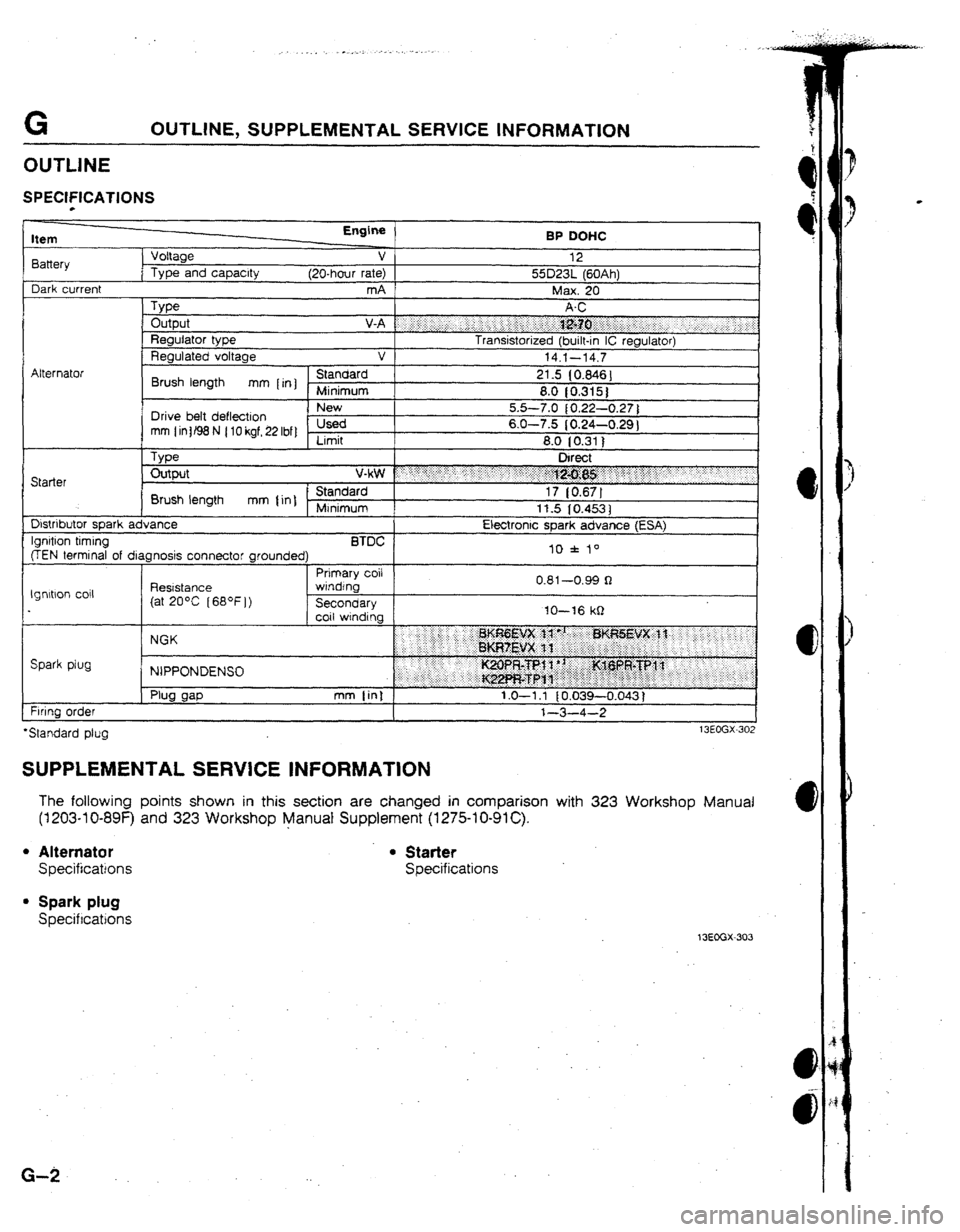

G OUTLINE, SUPPLEMENTAL SERVICE INFORMATION

SPECIFfCATfUNS

Item

8attery

Dark current Voltage

Type and capacity Engine

v

(20-hour rate)

mA BP DOHC

12

55D23L (60Ah)

Max. 20

Type Output V-A f “‘i j.,: i .:.. ‘:.. ,, j j.: i.‘: ;:;:i :j;&?.:. .: .:.

__ : . . s.i-....‘:‘:. _.. j ;.’

Regulator type Transistorized (built-in IC regulator)

Regulated voltage v

14.1-14.7

I

C?*..*rlrrrl

Brush length mm [rn] }e 21.5 (0.846)

8.0 10.315)

I Drive belt deflection I 5.5-7.0 { 0.22-0.27 )

mm (intB8N (lOkgf,22Ibf) usea 6.0-7.5 (0.24-0.29 1

Limit 8.0 (0.311

, Type Direct

Starter Output v*$# : : ;..;. ‘:‘.. ._ .; : :‘: 7.:

.. .::“:.:j 1 ,5

. . . . .j$$g;g$y .“. :yy

Brush length mm {in] - Standard 17 [0.67]

Minimum

11.5 IO.4531

Dlstnbutor soark advance Electronic soark advance (ESA)

@EN termind of diagnosis connector grounded) II) f lo

I 1 Prtmary coil

**4 nn*

Ignltbon co11 Reststance 3

(at 20°C [68*F])

in IO-16 kQ lgnrtlon timing BTDC f ar

wrndfnb

I

Secondary 1

coil WindIn.. v.0 I

--v.yy 1

Spark plug NGK

NIPPONDENSU

Firing oraer

*Standard pfug

SUPPLEMENTAL SERVICE INFORMATION

The following points shown in this section are changed in comparison with 323 Workshop Manual

(1203-l O-89F) and 323 Workshop Manual Supplement (I 275-l O-91 C).

l Alternator . Starter

Specifications Specifications

l Spark plug

Specifications

13EGGX-303

G-2

Page 96 of 279

M SUPPLEMENTAL SERVICE INFORMATION

SUPPLEMENTAL SERVICE INFORMATION

The foIlowIng points in this section are changed in comparison with Mazda 323 Workshop Manuals

(1206-f O-89F) and (1229-l O-89L).

Front axle

l Removal I Inspection I Installation

l Disassembly I Inspection / Assembly

Rear axle

l Removal / Inspection I Installation l Disassembly / Inspection I Assembly

13EOMX-305

t

,

c

.

c!

M-4

.

r&

-s

FRC

PREF

SST

-m

49 0’

Pulle

--

49 Gl

Atkd

(Part

49 Gc

--

49 FC

I n.stail beam

--

49 F3

Attact

:Part

t 49 FO

--

49 Frl

4ttac P 58 8 : Part < $9 Fcl,

--

a9 G3

nstallt

Page 97 of 279

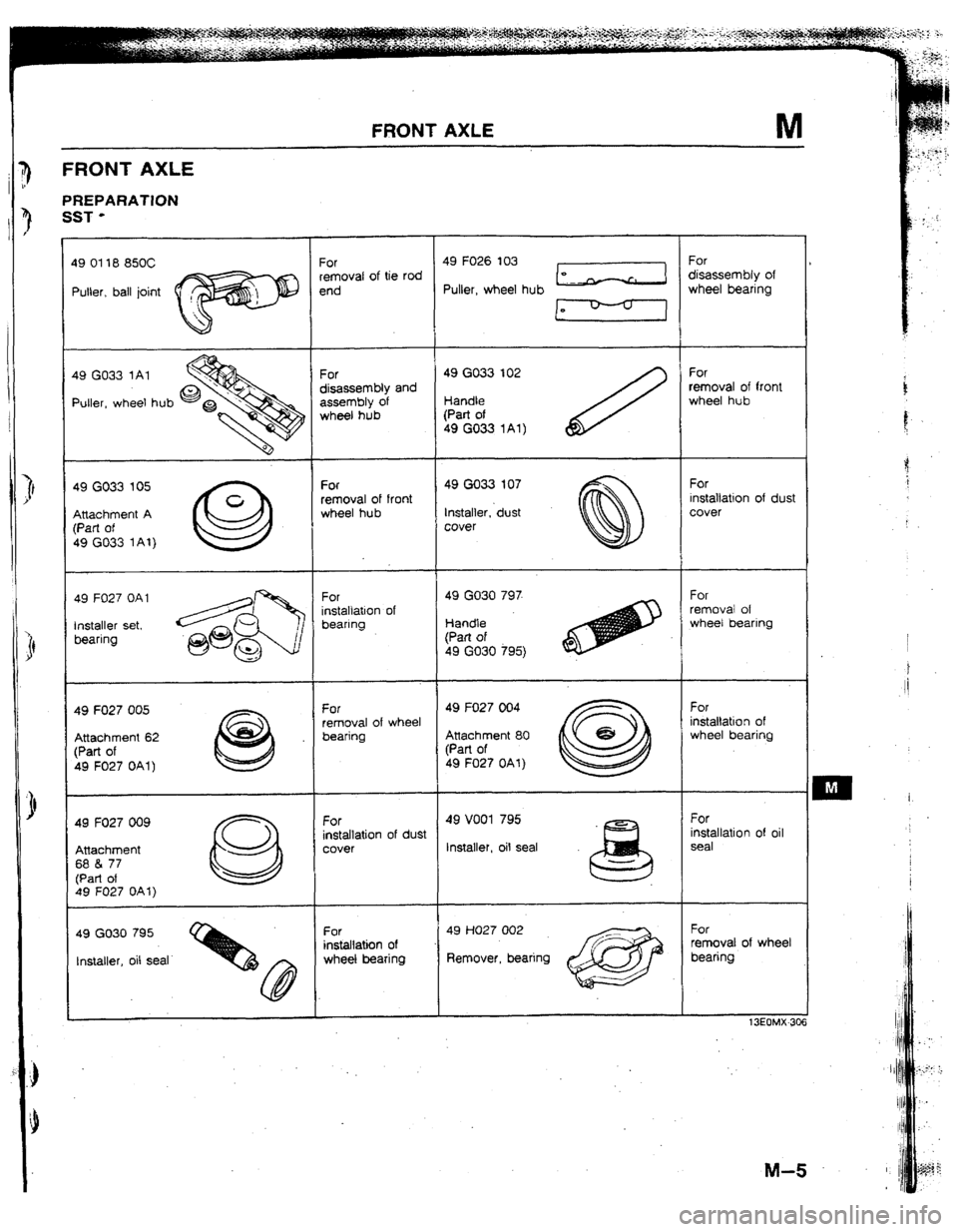

FRONT AXLE M

FRONT AXLE

PREPARATION

SST -

Puller, ball joint Puller, wheel hub

49 GO33 1Al

Puller, wheel hub

49 F027 005

49 FO27 009

Attachment

68 & 77 installation of dust

tnstaller, oil seal

Installer, oil seal 49 HO27 002

Remover, bearing

M-5

Page 100 of 279

M FRONT AXLE

Disassembly / Inspection / Assembly

1 I Disassemble in the order shown in the figure, referring to Disassembly Note.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse

order of disassemblv. referring to Assembly Note.

13EOMX-312

1 Oil. seal 5. Dust cover

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page M-l 0

2. Front wheel hub assembly Disassembly Note.. .,.._ 1 . . . . . . . . . . . . . . page M-

9

Disassembly Note I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Assembly Note . . . . 1 . . . . . . . . . . . . . . . . . . . . . M-10

below

Assembly Note .......,.II.,...,...I..... page M-l 0

3. Retaining ring

4. Wheel bearing

Disassembly Note.. . . . .,=.............. page M- 9

Assembly Note . . , . . . . . . . . . . . . . . . . , . . . . . . page M-l 0 6. Steering knuckle page

7. Hub bolt

Disassembly Note . . . . . . . . . , ..,,..-...., page M- 9

Assembly Note .........I..,............. page M- 9

c I

13EOMX-313

r

L 1 l3EOMX 314 M-8

Disassembly note

Front wheel hub assembly

1. Remove the front wheel hub assembly by using the SST.

2. Make an opening between the wheel hub and the bearing

race to allow for use of the SST.