oil MAZDA 323 1992 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 102 of 279

M FRONT AXLE

13EOMX-320

L 13EOMX-321

i . 13EOMX-32 13EOMX-322

3

Dust cover

1. Mark the new dust cover as the one removed.

2. Align the marks of the new dust cover and the steering

knuckle.

3. install the dust cover by using a steet plate and the SST.

Wheef bearing

lnstail the new wheel bearing by using the SST.

Front wheel hub assembly

1. Install the front wheel hub assembly by using the SST.

2. Verify that the wheel hub rotates smoothly.

Oil seal

Caution

l Use a new oil seal, and apply grease to the lip of

the seal.

‘0 tnstatt the oil seat flush with the steering knuckle.

Install the new oil seal by using the SST,

REA

PREP.

SST *

49 FO:

Pulter.

49 GOi

Hand E

(Part 3

49 GOi

49 FOE

Attach r

(Part 01

49 FOZ

--

49 FO2

Attach n

68 & 7’

(Part of

49 FO:!

--

49 FO:!’

t nstaller

bearing

--

49 GO3

Matter

49 G03:

lnstallef,

XW3

1

I 13EOMX-324 M--l 0

Page 103 of 279

_.:__ _:

M

I

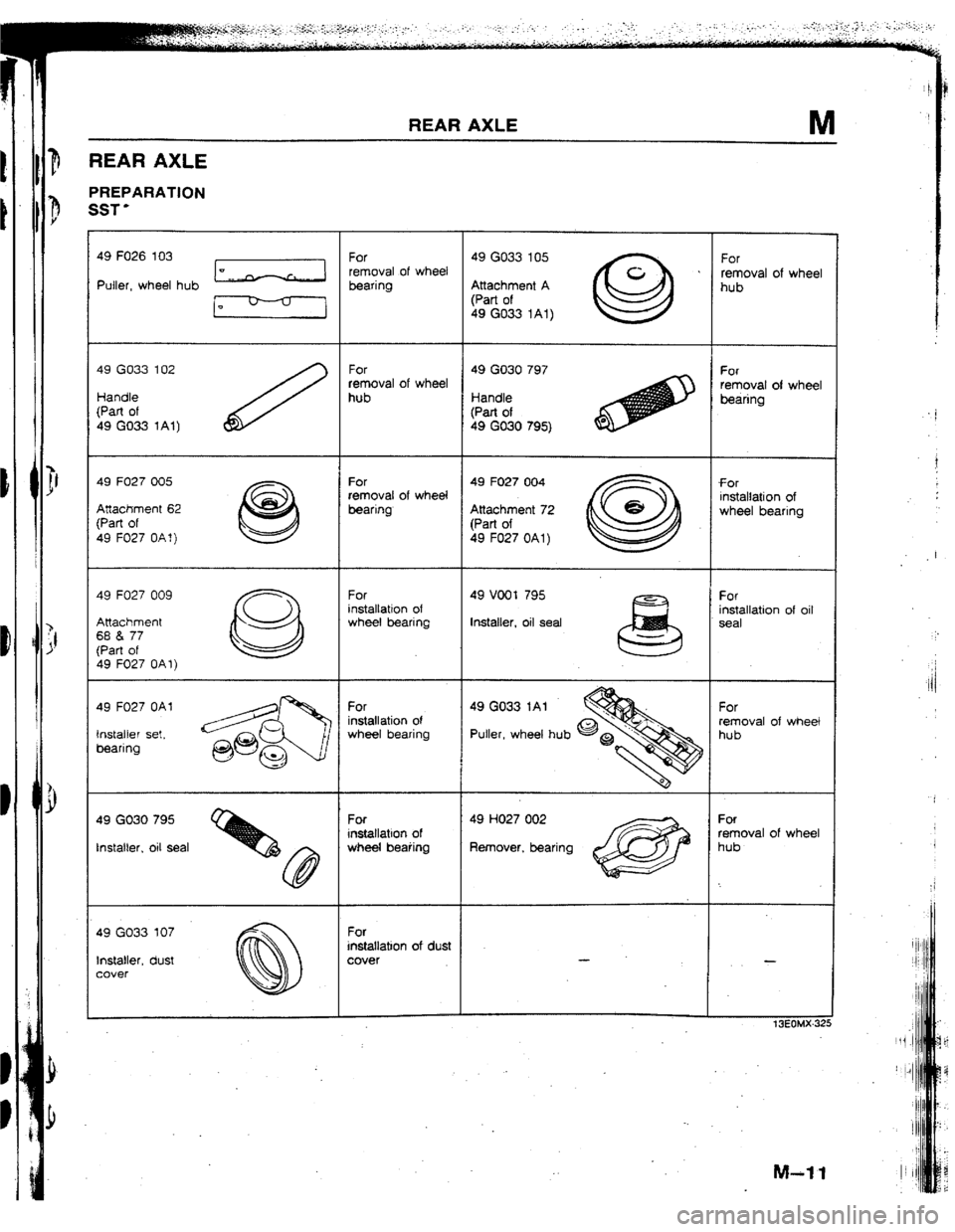

REAR AXLE

REAR

AXLE

PREPARATlON

SST’

49 FO26 103

Puller, wheel hub [cl Ei;;l of wheel ~a~~e~~~ ’ i!ovat of wheel

I- (Part of

49 GO33 1Al)

49 GO33 102

Handle

(Part of

49 GO33 1At) FC?r 49 GO30 797 For

removal of wheel removal of wheel

hub ktandte

bearing

(Part of

49 GO30 795)

49 FO27 005

Attachment 62

(Part of

49 FU27 OAf)

49 F027 009

Attachment

68 & 77 For 49 F027 004

f Of

removal of wheel installation of

bearing Attachment 72 wheel bearing

(Part of

49 F027 OAl)

installation of oil

Installer, oit seat

Instatter, oil seat Remover, bearing oval of wheel

49 GO33 107

Installer, dust

cover installation of dust

t3EOMX-32!

F

. i

t

I

Ii/

I

1

1

Page 109 of 279

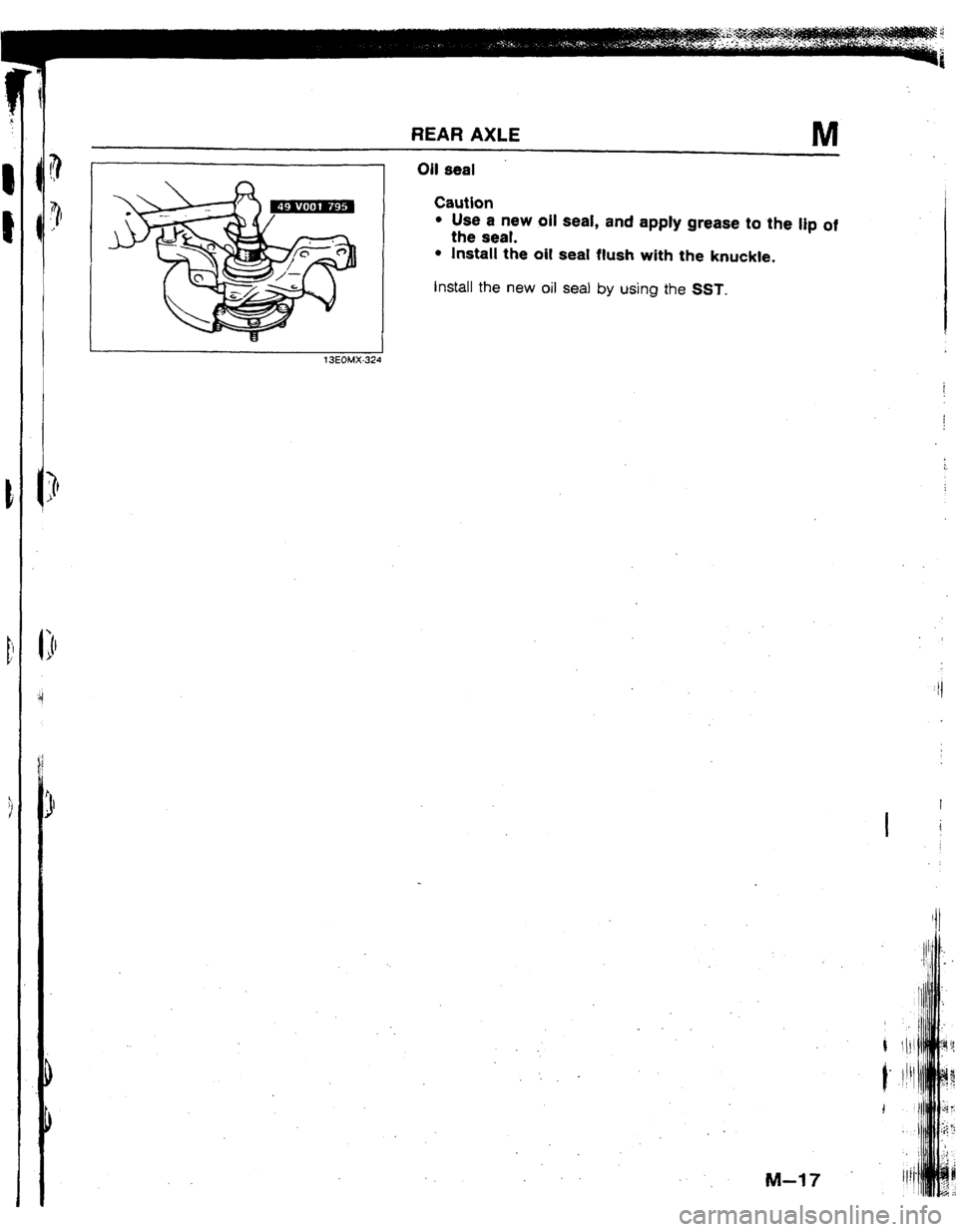

REAR AXLE M

n Oil seal

Caution

l Use a new oil seal, and apply grease to the lip of

the seal.

l Install the oil seal flush with the knuckle.

install the new oil seal by using the SST.

?3EOMX-324

I

I i

Page 116 of 279

I :

;!

i

I

I

CONVENTIONAL BRAKE SYSTEM P

CONVENTIONAL BRAKE SYSTEM

PREPARATION

SST

49 0259 770B

Wrench, fiare nut For

removal and 49 U043 OAO

Gauge set, oil

pressure For

Inspectron of

brake fluId

pressure

49 uo43 004

Gauge, oil

pressure

{Part 04

49 U043 OAO) For

inspection of

brake fluid

pressure 49 UO43 005

Joint

(Part of

49 UO43 OAO) For

inspection of

brake fluid

o pressure

49 0208 70tA

Air-out tool, boot For

removal of

piston seal 49 FAf8 602

Wrench, disc

brake piston For

removal and

installat!on of disc

call per piston

49 1258 071

Puller, bearing For 49 0221 600C

removal of caliper

a-- E;.;d tool, disc needle bearing For

installation of

brake pads

Page 135 of 279

R OUTLINE

OUTLINE

OUTLtNE OF CONSTRUCTION

l The%onstruction and operation of the suspension system are basically the same as for previous models.

l The coil spring and shock absorber specifications are changed.

l The stabilizer specifications are changed.

SPECIFICATIONS

13EORX-302

Front suspension

Suspension type

Sprmg type

Shock absorber

Stabrlmr

Specifications

Strut

Coil spring

Oil filled Total toe-rn

Front

wheel

atignment

(‘Unladen)

Rear suspension

Suspensron type

Sprmg type

Shock absorber

Stabrlrzer

Rear wheei

alrgnment

(‘Unladen) Maximum steering 38* f 3*

309 f 30

-0045 f 45’

2035’ f 45’

KIngpin angle degree

12*to’

We Oil fifled

Damprng force N [ kgl Ibf 1 .‘? .@g,$g&;qJ&,$. ‘: ‘., . . ” ‘, : :,

at 0.3 m 112

]ls I Contraction ;. ~ .. . . . . .__. ..:, .. .. ,I. ._ :. . . f: ; _... .:

Type Torsion bar

Diameter mm. f in ]

19.t (0.751

Total toe-in mm fin!

2.h 3 (0.08 f 0.121

degree

O”12’ f 18’

Camber angle degree -0°20’ f 45’

13EORX-303

l Fuel tank full, radrator coolant and engine oil at speclfled levels; and spare tire, jack, and tools in designated positions. Front Coil Spring Specifications

1 Identification mark color Wire diameter Coif .center

M l l

I Free length A a2 mm lin)

diameter mm [in) . mm 1 in) Coil number Rear Coil Spring Speci?ications

ldentlfication mark color M” Wire diameter Coil center

Free length

mm {in) diameter mm 1 in J

mm {in) Coil number

*’ Maln Identlfcatlon mark on second cgil from bottom.

*’ Auxrllary &entificatton mark on thrrd coil from bottom.

Shaded areas tndcate

new specifrcat+ons 13EORXCS05

(I .f

Page 156 of 279

![MAZDA 323 1992 Suplement Owners Manual TECHNICAL DATA TD

Hem

Camshafi

Engine

BP DOHC turbo

IN Standard

Cam height mm 1 in) Wear limrt

EX Standard

Wear llmrt

Standard

Journal diameter mm 1 In] (M.1 --NW

Out-of-round

Standard

Ca MAZDA 323 1992 Suplement Owners Manual TECHNICAL DATA TD

Hem

Camshafi

Engine

BP DOHC turbo

IN Standard

Cam height mm 1 in) Wear limrt

EX Standard

Wear llmrt

Standard

Journal diameter mm 1 In] (M.1 --NW

Out-of-round

Standard

Ca](/img/28/57055/w960_57055-155.png)

TECHNICAL DATA TD

Hem

Camshafi

Engine

BP DOHC turbo

IN Standard

Cam height mm 1 in) Wear limrt

EX Standard

Wear llmrt

Standard

Journal diameter mm 1 In] (M.1 --NW

Out-of-round

Standard

Camshaft bearing oil clearance mm { in ] (No. f-440.5)

Maximum

Camshaft runout mm {in)

Camshaft end play mm Iin] - Standard

Maximum

Winder block

Height mm {in)

Distortion mm {in]

Grinding mm (in)

Cylinder bore diameter Standard size

mm Iin) 0.25 [ 0.010) oversize .

0.50 [ 0.020 ] oversize

Cylinder bure taper and out-of-round mm [in]

Piston

44.094 { 1.7360 ]

43.894 f 1.7281 ]

44.603 [ 1.7560)

44.403 [ t .748t ;

X940-25.965 I 1.0213-l .0222 j

0.05 (0.002] max.

0.035-0.081 [ 0.0014-0.0032 )

0.15 (0.006)

0.03 (0.0012 1 max.

0.07-O. 19 [ 0.0028-0.0075 1

0.2 IO.008 1

221.5 (8.720)

0.15 [0.006) max.

0.20 [0.008] max.

83.006-83.013 13.2679-3.2682 ]

83.256-83.263

13.2778-3.2781 ]

83.506-83.513

( 3.2876-3.2879 )

0.019 [0.0007) max.

Piston diameter Standard size 82:954-82.974 13.2659-3.2667 1

Measured at 90° to pin

bore axis and 11 .Omm

oversize 83.21 I-83.217

10.433 in] below oil ring 0.25 j 0.010 ]

13.2760-3.2763 ]

groove mm {In)

0.50 { 0.020) oversize 83.461-83,467

{ 3.2859-3.2861 )

Piston to cybnder clearance

Piston ring

mm (in) Standard 0.039-0.052 [ 0.0015-0.0020 ]

Maximum

0.15 [0.006]

Thickness mm {in] Top

Second

, Top

End gap (Measured in the cylinder) Second

mm I in 1 Oil (rail)

Maximum

TOP

Ring groove width in piston

mm (in) Second

r

Oil

Piston ring-to-ring groove clearance TOP

mm (in] Second

Maximum

Piston pin

Diameter mm {in)

Piston-to-piston pin clearance mm iin]

Connecting rod bush-to-piston pin clearance mm Iin)

Connecting rod and connecting rod bearing

Length (Center to center) mm {in] 1

Bending mm [in]

Small end bore (Bush inner diameter) mm [in)

Big end bore mm {in)

Bfg end width mm [in) 1

Standard

Connecting rod side clearance mm I in 1 Maximum I

Crankshaft

Crankshaft iunout mm {ln) 1.470-l ,495 { 0.0579-0.0589 ]

1.47-l -49 [0.0579-0.0587 )

0.15-0.30 [ 0.006-0.012 1

0.35-0.50 { 0.014-0.019 1

0.20-0.70 (0.008-0.028 )

1.0 [0.039)

1.520-I .535 f0.0598~9.0604 f

1.52-l .54 ~0.0598-0.0606)

3.02-3.04 (0.1189-0.1197 1

0.025-0.065 { 0.001 O-0.0026 ]

0.03-OXI7 (O.O012--0.0028)

._

0.15 (0.006]

19.987-l 9.993 (.0.7869-0.7871 )

-0.005-0.013 { -0.0002-0.0005 1

O.Ql O-0.027 ~0.0004-0.0011 )

m D 132.85-132.95 (5.230-5.234 1

0.075 ( 0.0030 ] max./50 I1:97 ]

20.003-20.014 ( 0.7875-0.7880 1

48.000-48.016 [ 1.8898-l 48904 ]

21.838-21.890 (0.8598-0.86t81

0.11 O-O.262 f 0.0043-0.0103 1

0.30 [0.012)

0.04 (0.0016)

mdx.

TCI rl

Page 157 of 279

![MAZDA 323 1992 Suplement Owners Manual TD TECHNICAL DATA

LU8RlCATtON SYSTEM

Item

Lubricating method

011 pump Engine

BP DOHC turbo

Force-fed

6 . Trochoid gear

Relief pressure

kPa I kgf/cm’. psi] 343-441 [ 3.5-4.5, 50-64 1

Regula MAZDA 323 1992 Suplement Owners Manual TD TECHNICAL DATA

LU8RlCATtON SYSTEM

Item

Lubricating method

011 pump Engine

BP DOHC turbo

Force-fed

6 . Trochoid gear

Relief pressure

kPa I kgf/cm’. psi] 343-441 [ 3.5-4.5, 50-64 1

Regula](/img/28/57055/w960_57055-156.png)

TD TECHNICAL DATA

LU8RlCATtON SYSTEM

Item

Lubricating method

011 pump Engine

BP DOHC turbo

Force-fed

6 . Trochoid gear

Relief pressure

kPa I kgf/cm’. psi] 343-441 [ 3.5-4.5, 50-64 1

Regulated pressure kPa { kgf/cm’ , psi ] -rpm

294-392 { 3.0-4.0, 43--57.1.3,000

Inner rotor tooth tip to outer. rotor Standard

0.02-0.16 (OJOOS-O.O063]

clearance

mm {in]

Maximum I

0.20 [ 0.0078 )

Outer rotor to body clearance

Side clearance

Oil fIl!er

, TYpe

Relief pressure differential . mm [in) Standard

Maximum

mm {in) Standard

Maximum 1

kPa’ f kgf/cm’, psi 1 0.09-0.18 ~0.00354.Ofl71]

0.22 { 0.0087 1

0.03-0.11 ~0.0012-0.0043~

0.14 {0.0055)

Full-flow, paper element

. 78-118 (0.8-1.2. 11-17) Srade

----l-in

Viscosity

num her

Item

Cooling metha

Water pump

, We

Impeller diame

Number of imf

Speed ratio -

Water seal !$

Thermostat

Jype. _

Opening terq

/Full-open

1 F&open lift

I

Antifreeze E

TD-4

Page 159 of 279

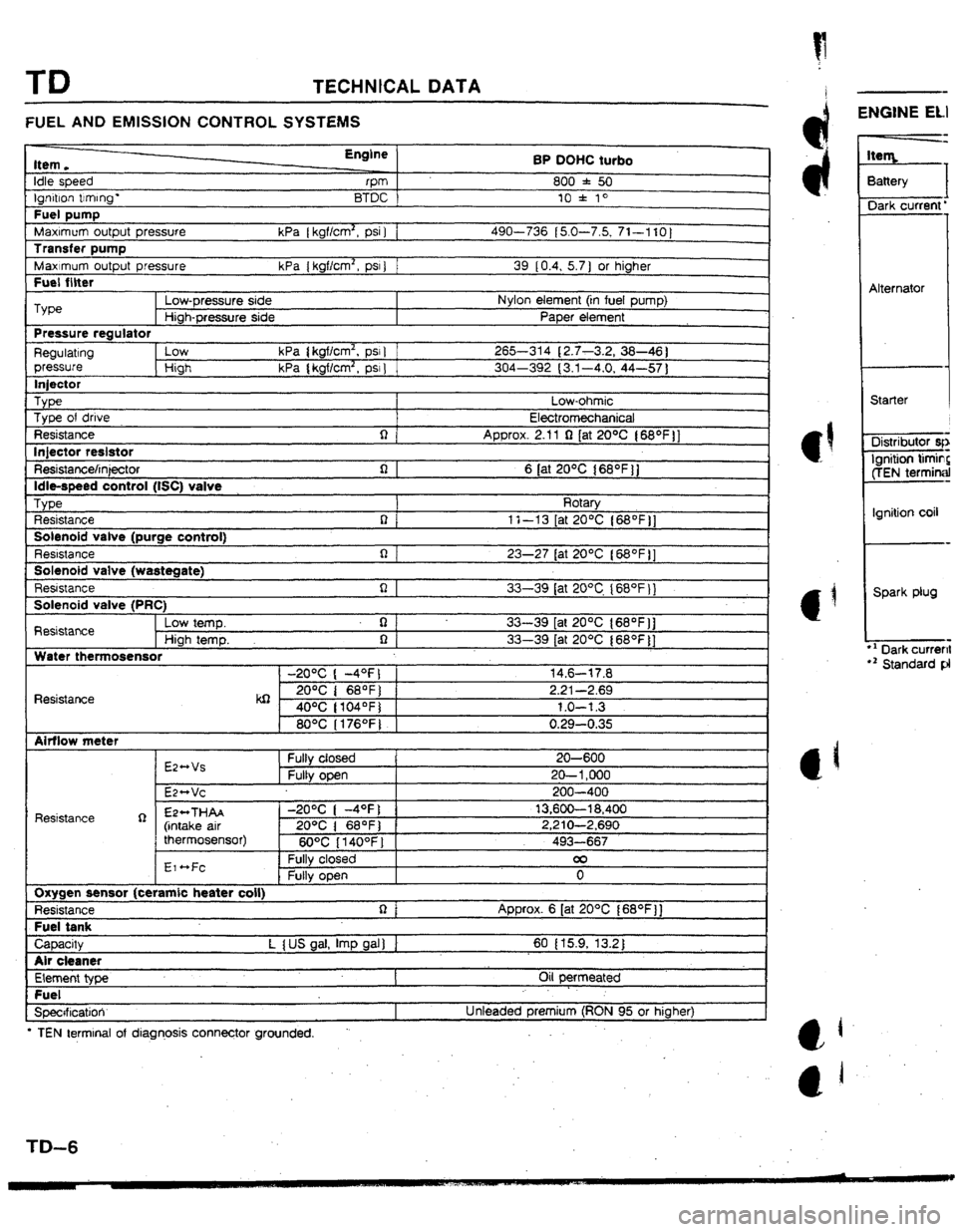

TO TECHNICAL DATA

FUEL AND EMISSION CONTROL SYSTEMS

Item.

Idle speed

tgf-don trrmng-

Fuel pump

MaxImum output pressure

Transfer pump

Maximum output pressure

Fuel filter Engine

rPm

BTDC

kPa [ kgf/cm2, psi 1 1

kPa { kgflcm2, PSI ) 1 BP OUHC turbo

800 f 50

10 l 10

490-736 (5.0-7.5, 71-1 IO]

39 10.4, 5.7 ) or higher

I Type

Low-pressure side Nylon element (in fuel pump)

Hiah-Dressure side PaDer element

Pressure regulator

Regulating low kPa ( kgflcm2, psr 1 265-314 (2.7-3.2, 38-46 1

pressure High kPa { kgflcm2, psr 1 304-392 (3.1-4.0, 44-57 1

lniector

_ Type Low-ohmic

Type of drive

Electromechanical

Resistance q

Approx. 2.11 Q (at 20% ( 68*f )]

lniector reslstor

L - Resistance/injector

Idle-speed control (tSC) valve

TvDe n 1 6 [at 20°C 168OFjj

I Rotarv

Resistance

Solenoid valve (purge control)

Resbstance

Solenoid valve {wastegate)

Resistance n(

R I

i-l I 1 t-13 [at ZO*C {68OF j]

23-27 tat 20°C l68OFll

. r.

33-39 lat 20°C I68OF 11

Solenoid valve (PRC)

Resistance Low temp. q

33-39 [at 2O*C {SS*F]]

High temp. 0 1 33-39 [at 20°C (68OF]]

Water thermosensor

-20°C ( -4OFJ 1 14.6-17.8

Resistance kQ 2o”c I 68OF) 2.21-2.69

40°C ( tO4OF) 1.0-l 3

80°C I176OFJ 0.29-0.35

Airflow meter

Resistance R E244Vs

E2*Vc Fuity closed

Fully open I 20-600

20- 1,000

200-400

EP++THAA

(intake air

thermosensor) -2O*C ( -4OFj 1 13,600-l 8,400

20% 1 68OF) 1 2,210-2,690

6O*C 114OOFl i 493-667

EI ~Fc

I Fully closed 00

0 1

Oxygen sensor (ceramic beater coil)

Resistance

Fuel tank Approx. 6 [at 20°C f68OF)]

I CaDacW L I US oal. ImD aal I I 60 I 15.9, 13.2 I

I

Air cleaner

Element type

Fuel

Specrficatioir Oil permeated

Unteaded premium (RON 95 or higher)

l TEN terminal of diagnosis connector grounded. .

-

ENGINE ELI

3attery

I

Dark current’

Alternator

Starter

Distributor qr

Ignition timin?

ffEN terminal

Ignition coil

Spark plug

l ’ Dark current

r2 Standard pl

Page 160 of 279

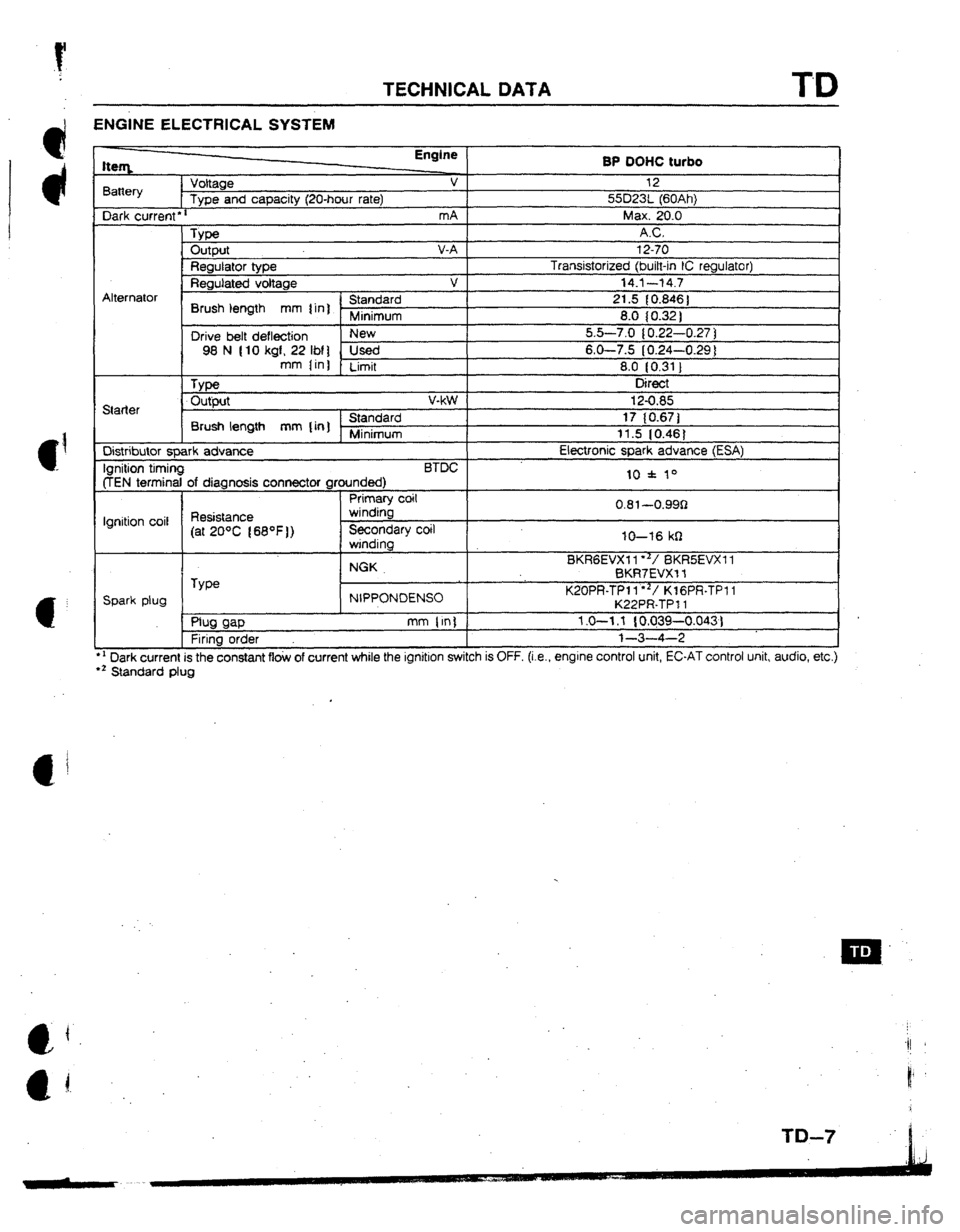

TECHNICAL DATA TD

ENGINE ELECTRICAL SYSTEM

l ’ Dark current is the constant flow of current while the ignition switch is OFF. (i.e., engrne control unit, EC-AT control unit, audio, etc.)

l z Standard plug tteq Engine

BP OOHC turbo

Battery Voltage v 12

Type and capacity (2U-hour rate) 55D23t (60Ah)

Dark current

l r mA Max. 20.0

_ Type AC.

Output V-A 12-70

Regulator type Transistorized (bitt-in IC regulator)

Regutated voltage v 14.1--t4.7

Alternator

’ Standard

Brush length mm 1 in] r 21.5 { 0.846 ]

Minimum 8.0 (0.32 )

Drive belt deflection New 5.5-7.0 10.22-0.27 ]

98 N (10 kgf, 22 IM] Used 6-O-7.5 (0.24-0.29 1

mm Iin)

Limit 8.0 IO.31 1

, Type Direct

Starter Output v-kW

Standard

Brush length mm {in] Minimum

Distributor spark advance

Ignition timing BTDC

(TEN terminal of diagnosis connector grounded)

Primary coit

Ignition coil Resistance winding

(at 20°C 168OF)) Secondary coil

winding

NGK

TYW

Spark plug NIPPONDENSO

, ml WP mm (in)

Firing order 12-0.85

17 (0.671

11.5 IO.481

Etectronic spark advance (ESA)

10 f 10

0.81~-0.99Q

IO-16 kfI

BKRGEVXI I**/ BKRSEVXI 1

BKR7EVX-f f

K20PR-TPl l”‘/ KlGPR-TPI 1

K22PR-TP 11

1.0-l .f { 0.039-0.043)

l-3-4-2

Page 162 of 279

![MAZDA 323 1992 Suplement Owners Manual TECHNICAL DATA TD

Item

t-2 slmfl fork and reverse gear Standard 0.1 O-O.45 [ 0.004-0.018 1

mm {in] Wear limit

I 0.95 (0.037 ]

3-4 shift fork and ctutch hub sleeve Standard 0.10-0.40 [0.004-O.OlS] MAZDA 323 1992 Suplement Owners Manual TECHNICAL DATA TD

Item

t-2 slmfl fork and reverse gear Standard 0.1 O-O.45 [ 0.004-0.018 1

mm {in] Wear limit

I 0.95 (0.037 ]

3-4 shift fork and ctutch hub sleeve Standard 0.10-0.40 [0.004-O.OlS]](/img/28/57055/w960_57055-161.png)

TECHNICAL DATA TD

Item

t-2 slmfl fork and reverse gear Standard 0.1 O-O.45 [ 0.004-0.018 1

mm {in] Wear limit

I 0.95 (0.037 ]

3-4 shift fork and ctutch hub sleeve Standard 0.10-0.40 [0.004-O.OlS]

mm [In]

Wear limit

I 0.90 (0.035 ]

5th shift fork and clutch hub sleeve Standard 0.10-0.36 {0.004-0.014]

mm [in]

Wear limit

I 0.86 [ 0.034 1

Reverse idle gear and reverse lever Standard 0.10-0.35 ~0.004-0.014 )

mm fin)

Wear limit

I 0.85 tO.033)

Standard o-0.05 [ 0-0.002 ]

Primary shaft gear mm [in ] 0.20 lO.OOS], 0.25 [O.OlO), 0.30 (0.012], 0.35 (0.014),

Adjustment shims 0.40 lO.OlS], 0.45 [O.OlS), 0.50 (0.020], 0.55 [0.022],

0.60 fO.0241. 0.65 f0.0261. 0.70 fO.0281

Standard t 0.03-0.08 { 0.001-0.003 1

Secondary shaft gear mm [in] 0.20 tO.O08], 0.25 {O.OlO], 0.30 (0.012], 0.35 [0.014),

Adjustment shims 0.40 (O.Ot6], 0.45 (0.018], 0.50 [0.020], 0.55 10.022),

0.60 IO.0241, 0.65 {0.026], 0.70 [0.028]

Center differential

Me Planetary carrier

Number of ring gear teeth

Number of pinion gear teeth Outer

Inner

Outer

Inner 59

75

14

! 14

Number of sun gear teeth

Number of idle-gear teeth

Bearing preload Pinion gear side

I 43

Idle gear side 43

37

N.m { kgfcm. inlbf 1 3.0-3.9 f30-40, 27-34 )

0.25 {O.OtOl, 0.30 {0.012],

CI---.-- ---I--A --I: _d---* -L!- aeanng pretoaa aqusrmenr snrm mm [in] 0.10

0.35

0.55

0.75

0.95

1.15 0.004 ], 0.20

0.014), 0.40

0.022 ) , 0.60

0.030 ) , 0.80

0.0371, 1.00

0.0451. 1.20 0.008

0.016

0.024

0.031

0.039

0.047 -

: 0.45 lO.O18], 0.50 !0.020],

: 0.65 0.85 (0.026] [0.033], p 0.70 0.90 [ { 0.028 0.035], 1,

I 1.05 (0.041], 1.10 [P.O43], r

End play of ring gear mm {in) 0.1510.36 i 0.006-0.012 ]

Ring gear end play adjustment washer mm {in) 1.20 40.047], 1.35 t0.053], 1.50 [0.059),

1.65 {0.065], 1.80 iO.071 1

End play of sun gear mm (in]

0.100-0.300 [ 0.0039-0.0118 ]

-

Sun gear adjustment washer mm {in] 3.5 lO.lSS], 3.7 (0.146). 3.9 (0.154].

4.1 IO.161 1, 4.3 [O.lSS]

Transfer Cattier

Final gear reduction ratio 4.214

Number of teeth

Oil Ring gear -

Pinion gear

Type

Capacity

L I US qt, Imp q?] . 37

11

API: GL-5

Above -18% lOoF]: SAE 90

Below -18OC {OOF]: SAE 8OW

0.5 [0.53. 0.44)