brake MAZDA 323 1992 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 119 of 279

P CONVENTIONAL BRAKE SYSTEM

1 t3EOPX.314

@ 66.7 kPa

Iso0 mmHg.

19.7 inHg)

16EOPX-05t

1

13EOPX.315

P-8

POWER BRAKE UNIT

Quick Inspection (On-vehicle)

Power brake unit function check

(Method-using tester)

Connect the SST, vacuum gauge A, and pedal depression

force gauge B as shown in the figure. After bleeding the

air from the SST, conduct the test as described in the 3steps

below.

Note l

Use commercMty available vacuum gauge and ped.

al depression force gauge.

a) Checking for vacuum loss

Unloaded condition

1. Start the engine.

2. Stop the engine when the vacuum gauge reading reaches

66.7 kPa (500 mmHg, 19.7 inHg ) .

3. Observe the vacuum gauge for 15 seconds. If the gauge

shows 63.3-66.7 kPa [475--500 mmHg, 18.7-19.7

inHg 1, the unit is operating.

Loaded condition

1. Start the engine.

2. Depress the brake pedal with a fdrrce of 196 N I20 kgf,

44 Ibfj.

3. With the brake pedal depressed, stop the engine when the

vacuum gauge reading reaches 66.7 kPa {SO0 mmlig,

19.7 inHg].

4. Observe the vacuum gauge for 15 seconds. If the gauge

shows 63.3-66.7 kPa I475--500 mmHg; 18.7-l 9.7

inHg 1, the unit is operating.

b) Checking for hydraulic pressure

1, If with the engine stopped (vacuum 0 kPa (0 mmHg, 0

hltlg 1) the fluid pressure is within specification, the unit is

operating.

Pedal force N fkgf. Ibf]

Fluid pressure kPa (kgf/cm2, psi)

196 LZO. 441 1080 111. 1561 min.

2, Start the engine. Depress the brake pedal when.the vacu-

urn reaches 66.7 kPa 1500 mmHg, 19.7 intlg 1. If the flu-

id pressure is within specification, the unit is operating.

Pedal force N 1 kgf, fbf I Fluid pressure .kPa { kgflcm’. ps 1

196 I20,441 6670 {68, 967

1 min.

-- WlTHOU

&

d

I=-

-

1 MASTER CYUh

.

i_

Page 120 of 279

CONVENTIONAL BRAKE SYSTEM P

WlfH ABS

1 f3EOPX-3 I 7

I* 44 44’

/

13EOPX-318

MASTER CYLINDER PRESSURE kPa f kgffcm2, psi 1

16AOPX-m 0

PRUPORTIONING VALVE

Inspection

1. Connect the SST to the brake pipes with adapters as shown

in the figure.

Adapter and flare nut tightening torque:

12.8-21.5 Nsm f 130-220 kgfcm, I 134 90 inlbf 1

Note

l Disconnect and connect the brake pipes with SST.

2. Bleed the air from the brake system.

3. Depress the brake pedal until the master cylinder pressure

equals A; then record rear brake pressure A’.

4. Depress the brake pedal again, apply additional pressure

until the pressure equals B; then record pressure B’.

Fluid pressure

kPa { kgVcm2, psi]

A

A’ 8

8’

WITHOUT 1960

1960

ABS 120, 284 (20,284] 5880

1 al96 12, 28)

(60, 853) 2750 (28, 3881

*I96 12,281

WITH ABS $;;4 1960 f 20,284) 5880

1 *196 12,261 160, 853 3140 {32, 455)

1

*294 [3,42)

-,

--.

. p-g.’

Page 121 of 279

P CONVENTIONAL BRAKE SYSTEM

FRONT BRAKE (DISC)

t nspection (on-ve hicte)

Disc pad

t. Jack up the front of the vehicle and support it with safety

stands.

2. Remove the wheels.

3. Sight through the caliper inspection hole and inspect the

remaining thickness of the pads.

1

Thickness: 2.Omm f 0.08 in ] min.

I LlL”r *-cl , a 4. Replace the pads as a set (right and left wheels) if either

is at br ‘less than the mintmum thickness.

Removal / inspection I installation

1. Remove in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to InstaHation Note.

4. After installation, perform the following.

(1) Add fluid and bleed the air.

(2) Check for fluid leakage.

(3) Depress the pedal a few times, then verify that the brakes do not drag while rotating the wheel by hand.

102-137 (10.4-14.0,

22-29 (2.2-3.0, 16-21)

75.3-1011

1. Flexible hose 7. Outer shim

2. Bolt 8. Inner shim

3. Callper 9. Guide plate

Disassembly I t nspection / IO. Mounting support

Assembly . _. . . . . _. ._. . . . . . . . . . . . , i.. . . ,:, . page P-l 2 t 1. Disc plate

4. Boot Inspection . . . . . . . . . . . . . . . . . . . . . . . . .,......_.. page P-1 2

5. V-spring

6. Disc pad

Inspection . . . . . . . . . . . . . . . . . . . . .._.__....._........... above InstaUation Note . . . . . . . . . . . . . . . . . .._...... page P-l 1 DlSC PAC

Reptacem

I. Remove

2. tnstatl in

1; Em

2. V-spring

3. Disc paa

fnstatle

Page 122 of 279

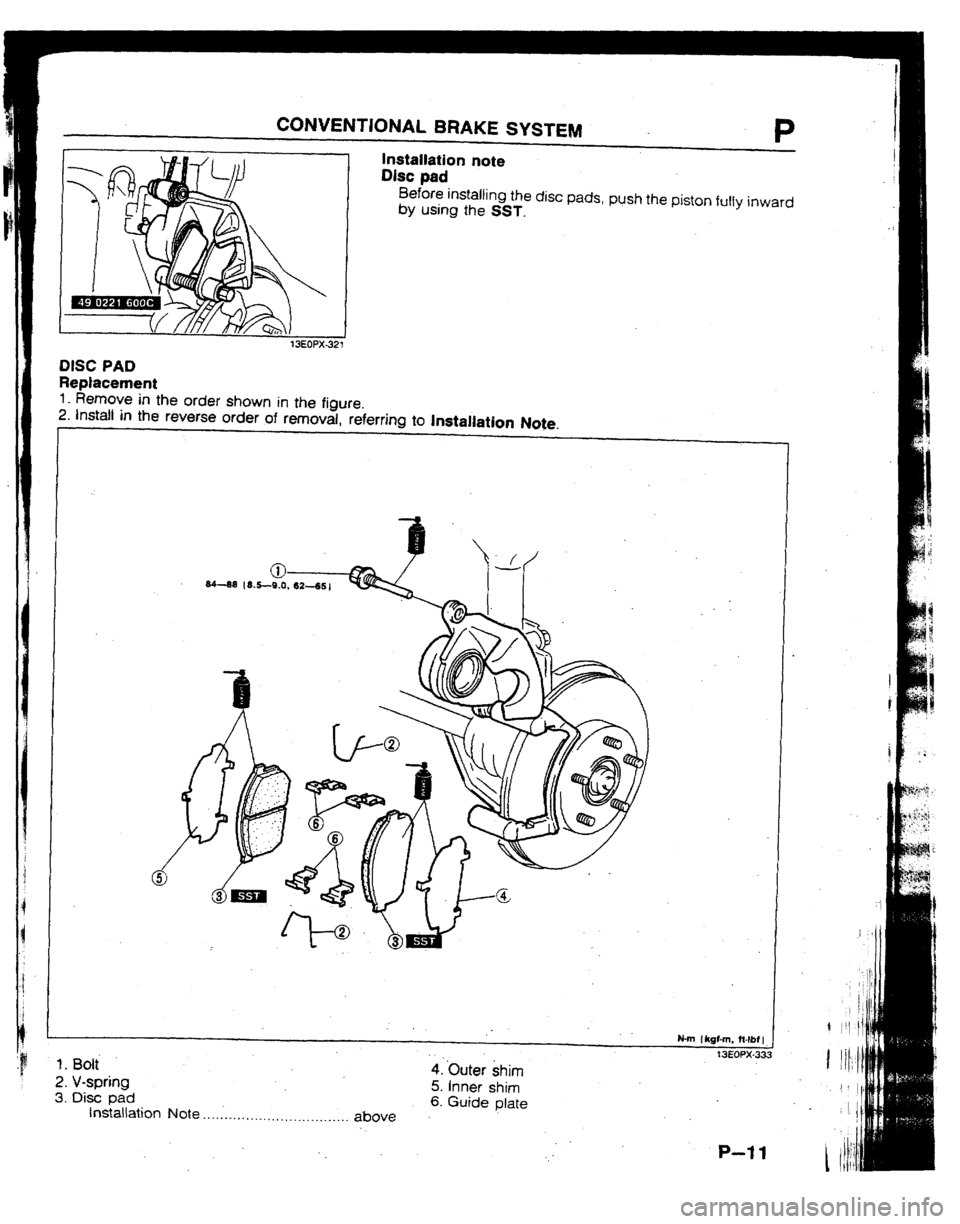

CONVENTIONAL BRAKE SYSTEM

- P

Installation note

I

I Disc pad

Before installing the disc pads, push the piston

fully inward by using the

SST.

13EOPX DISC PAD

Replacement

I_ Remove in the order shown in the

figure. 2. Instalt in the reverse order of removal, referring to Installation Note.

N-m fltgfm, ft4bf 1 1. Bolt t 3EOPX-33: 2. V-spring

4. ‘Outer shim

3. Disc pad 5. tnner shim

Installation Note . 6. Guide plate

. . . . . . . . . . . . . . . . . . . . ..l._.........

above -

P-1 I

Page 123 of 279

![MAZDA 323 1992 Suplement Owners Manual P CONVENTIONAL BRAKE SYSTEM

16EOPX-066

I

CALIPER DISC PLATE

Jnspection

Disc plate thickness

1. Measure the thickness of the disc plate.

Standard: 24mm (0.94 in)

Minimum: 22mm (0.87 in]

2- If MAZDA 323 1992 Suplement Owners Manual P CONVENTIONAL BRAKE SYSTEM

16EOPX-066

I

CALIPER DISC PLATE

Jnspection

Disc plate thickness

1. Measure the thickness of the disc plate.

Standard: 24mm (0.94 in)

Minimum: 22mm (0.87 in]

2- If](/img/28/57055/w960_57055-122.png)

P CONVENTIONAL BRAKE SYSTEM

16EOPX-066

I

CALIPER DISC PLATE

Jnspection

Disc plate thickness

1. Measure the thickness of the disc plate.

Standard: 24mm (0.94 in)

Minimum: 22mm (0.87 in]

2- If the

thickness is not within specification, replace the disc

plate.

Disc plate runout

Caution

l There must be no wheet bearing looseness.

4. Measure the runout at the outer edge of the contact sur-

face of the disc pad.

Runout: 0.1 mm [ 0.004 in ) max.

2. If the runout is not within specification, repair or replace the

disc plate.

Uisassembly I Inspection I Assembly

I, Disassemble in the order shown in the figure, referring to Disassembly Note.

2. Inspect ail parts and repair of replace as necessary.

3$ Assemble in the reverse order of disassemblv. referring to Assembly Note.

REPLACE

1, Dust seal

tnspect for damage and poor seating

2. Piston

Disassembly Note.:. .,._..... . . . . . . . . . . . page P-13

Inspect for wear

and rust

3. Piston seat

N-m 1 kgfcm, In-lbf I

13EOqX-32: 4. Bleeder cap, bleeder screw

Disassembly Note.. . . . . . . . . . . . . , . . . ._. . . page P-l 3

.. Assembly Note ..*.*......-*...*.........;

5. Caliper

body page P-13

Inspect for damage, wear and rust

Disassembly Note.. . . . . _. . . . . . . . . . . . . . page P-l 3

P-12 - G

Page 124 of 279

CONVENTIONAL BRAKE SYSTEM P

13EOPX-324

I %EOPX-071

Disassembly note

Piston

Caution

l Blow the compressed air slowly to prevent the pis-

ton from popping out.

I. Place a piece of wood in the caliper.

2. Blow compressed air through the pipe hole to force the pis-

ton out of the caLper.

Piston seal

Remove the piston seal from the caliper by using the SST.

I

Bleeder screw

Loosen the bleeder screw by using the SST.

Assembly note

Bleeder screw

Tightening the bteeder screw by using the SST.

Tightening torque:

5.9-8.8 Nom (60-90 kgfcm, 53-78 in&f ]

Page 125 of 279

P CONVENTIONAL BRAKE SYSTEM

f 6EOPX-073

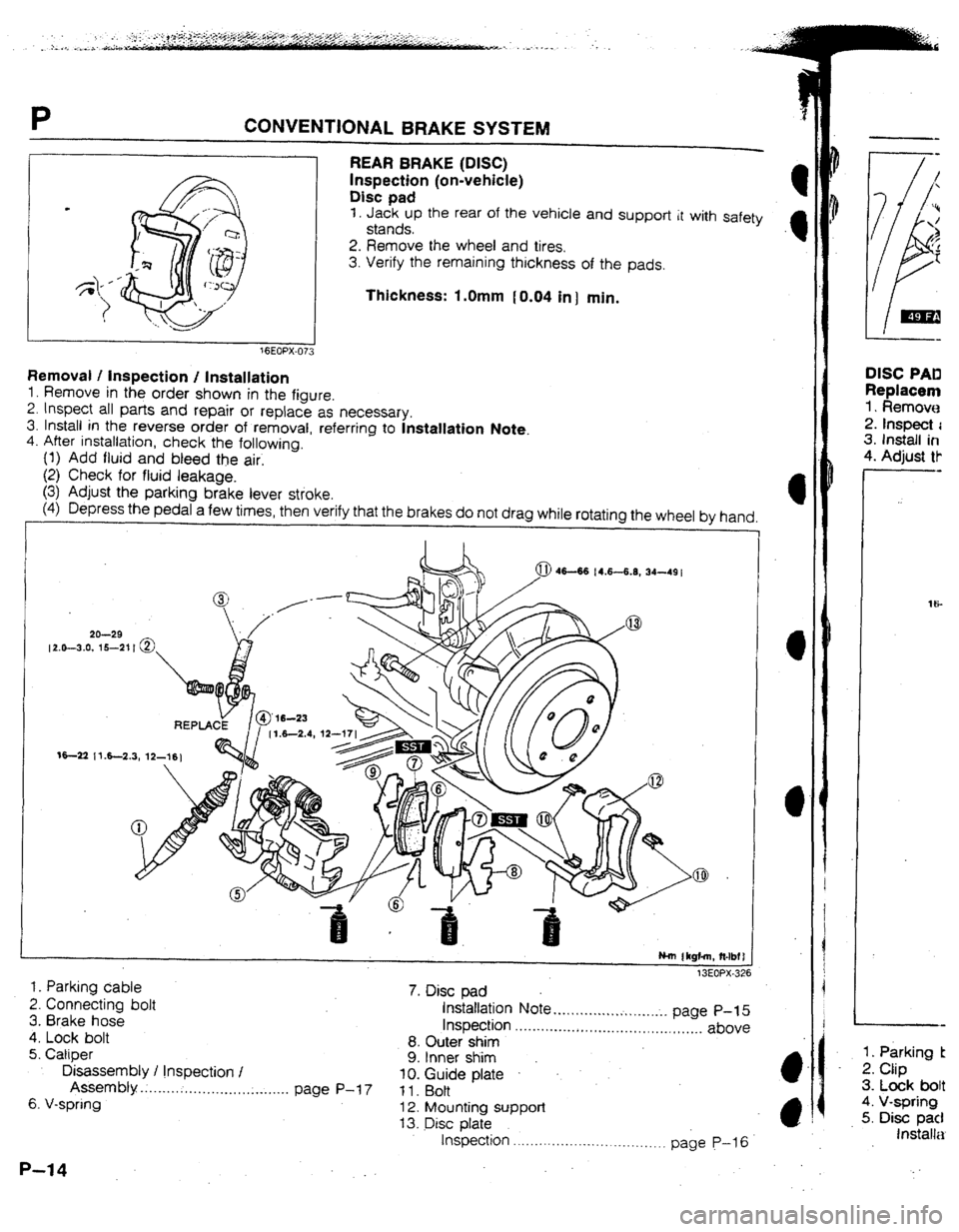

REAR BRAKE (DISC)

inspection (on-vehicle)

Disc pad

1, Jack up the rear of the vehicle and support it with safety

stands.

2, Remove the wheel and tires.

3. Verify the remaining thickness of the pads.

Thickness: f .Omm fU.04 in) min.

Removal I Inspection / Installation

1. Remove in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to Installation Note.

4. After instaHation, check the following.

(1) Add fluid and bteed the air.

(2) Check for fluid leakage.

(3) Adjust the parking brake lever stioke.

(4) Depress the pedal a few times, then verify that the brakes do not drag while rotating the wheel bv hand,

1. Parking cable

7. Disc pad

13EOPX-32f page P-15 ,..

. . ..I...... above 2. Connecting bolt installation

3. Brake hose Note . ..*. 1 ,...... I.r. . . . . .

4. Lock bolt Inspection . ..-f...........III.I.......,,.

8. Outer shim

5. Caliper 9. Inner shim

Disassembly I Inspection I

Assem bty IO. Guide plate .

-. . . _. . . . . . . . . . . . . . . . . , . . . . . . . . . . . page P-l 7

Il. Bolt

6, V-spring 12. Mounting support

I 3. Disc plate

Inspection . . . . . . . . . . . . . . . . . . . .._...._.~

P-1 4 . . . page p-16 DISC PAD

Replacem

1 s Remove

2. Inspect

i 3. Install in

4. Adjust tF

1. Parking t

2. Ciip

3. Lock bolt

4. V-spring

5. Disc pad

Installa

Page 126 of 279

CONVENTIONAL BF?AKE SYSTEM P

InstaHation note

Disc pad

Install the piston with the SST by turning it clockwise until

it stops.

13EOPX-327

DISC PAD Replacement

1. Remove in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3, Install in the reverse order of removal, referring to hstallation Note.

4. Adjust the parking brake lever stroke.

f . Parking

brake cable 2. Clip

3. Lock bolt

4. V-spring

5. Disc pad 6. Outer shim

7, lhner shim -

8. Guide plate

lnstaflation note . . . , . .._. . .I . . . . . . . . . . . . . . _. . . . . . . above . _’

.

P-1 5

Page 127 of 279

P CONVENTIONAL BRAKE SYSTEM

DtSC PLATE

Inspection

Disc plate thickness

I. Measure the thickness of the disc plate.

Standard: IOmm [ 0.39 in)

MInimum: 8mm (0.31 in 1

2, if the thickness is not within specification, replace the disc

plate.

Disc plate runout

Caution

l There must be not wheel bearing looseness.

I. Measure the runout at the outer edge of the contact sur-

face of the disc pad.

Runout: U.lmm [ 0.004 in) max.

2. If the runout is not within specification, repair or replace the

disc plate. CALIPE,

Disasstt

1. Disass

2. lnspec

3. Assem

i

1. Sleeve

2. Boot

I

1 3. Boot

4. RetainhI

5. Dust se2

i 6. Piston

Disaa

1 ASSen

i i InsP% InsP% 7. Piston st St

Disass E

8. Snap rin rl

9, stopper r

IO. Adjuster !r

. ’

tnspec

P-l 6

Page 128 of 279

CONVENTIONAL BRAKE SYSTEM P

CALIPER

Disassembly / fnspection / Assembly

Csation

l Replace the caliper assembly if a problem is found.

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

2, Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassemblv. referrina to Assembly Note.

REPL A

3 Hm 1 kgtm, ?btbl I

lC#EOPX-32

’ 1,

Sleeve 1 I. O-ring

2. Boot 12. Connecting link

i 3. Boot Inspect for damage and wear

4. Retaining ring 13. Return spring

5, Dust seal 34. Operating Iever

6. Piston 15. Boot

a* *

Disassembly Note . . . . . . .- . . . . . . . I*.- ,... page P-16

Assembly Note . . . . . . . . . . . . . . . . . . . . . . ..I.. page P-19

Inspect for wear and

rust 7. Piston seat

Disassembly Note *........ s . . . . . . . . . . -.. page P-1 8

8. Snap ring

9. stopper

IO. Adjuster spindle Inspect for damage and wear 16. Neeare oearrng

Disassembly Note ..........*...I..... ..* page P-l 8

Assembly Note .*.............*........e.* page P-19

17. Bleeder screw and rubber cap

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . . page P-18

Assembly Note . . ..*.................*....

page P-18

.I& Cable bracket

19. Caliper body inspect for damage, wear and rust