length MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 15 of 279

GI IDENTIFICATION NUMBER tOCATlONS/UNlTS/ABBREVIATlONS

IDENTIFICATION NUMBER LOCATIONS

VEHICLE tDENTtRCATtUN NUM8ER (VIM) ENGINE MODEL AND NUMBER

I

UNITS

N.rn { kgf m or kgfcm,

f-t&f or tn.lbf 1 . . . . . . . . . . . . . . . . Torque

rpm ._ . . . Revolutions per minute

A.. ,_...___.... Ampere(s)

v I... Volt(s)

$2 . .._..__......_.....__... Ohm(s) (resls‘tance)

kPa { kgflcm*, psr] . . . . . . . Pressure

{usually positive)

mmHg I inl-lg ] . . . . . . . . . Pressure

(usually negatrve)

W . . . ._ .._.__ .._ . . . . . . ..,......... Watt

titers [US qt, Imp qt 1 . V&me

mm { rn 1 . . . . . . . . . . . . . . . . . . . . . . . Length

89UOGX-006

ABBREWATIONS

ABDC _. . . . . . . . . . . After bottom dead

center

A/C . . . . . . . ._.. _. . . . . . . . . Air conditioner

ACC .__ . . . . . . . Accessones

ATX .._ ._ . . . . . . . . . . . . . . Automate transaxle

ATDC _.. __ _. . . . . After top dead center

ATF ,... ._....__._.. Automatic transmission

fluid

BAC ._ . . . . . . . . . . . . . . ,. Bypass air control

BBDC _. . . . . . . . . . . . . .._. Before bottom dead

center

BTDC ., ._._... . . . Before top dead center

CPU . . . . . . . . . Central processrng unit EC-AT

........................... Electronrcally-controlled

automatic transmlsslon

ECU ._ ....................... Engine control unit

EG 1 ..................... Electronc gasoll ne

injectron

E/L. ............................ Electrrcal load

EX .............................. Exhaust

IC ................................ Integrated clrcult

IGN ........................... lgnrtlon

IN ..... ........................ Intake

INT

............................... Intermittent

ISC ............................ Idle speed control

U-l ................................

Left hand

M..

........................... Motor

MIL

........ ...................... MatfunctIon Indicator

iamp

MTX. ........................... Manual transaxle

00.. .............................. Overdnve

Of F .............................. Swrtch off

ON

............................... Switch

on

PCV .............................. Positive crankcase

ventilation

PRC .......................... Pressure regulator

control

P/S ............................. Power steerrng

P/W ............................

Power window

RH ............................... Rlght hand

SST

............................. Special service tool

ST.. ............................... Starl

SW.. ............................. Switch

TDC. ............................ Top dead center

4WD .............................

4-wheel drive

03UGIX-802

INS7

If a t’

and

Whe

1, II-!

2. II-!

3. E-

4. Dr

W-1 2

Page 88 of 279

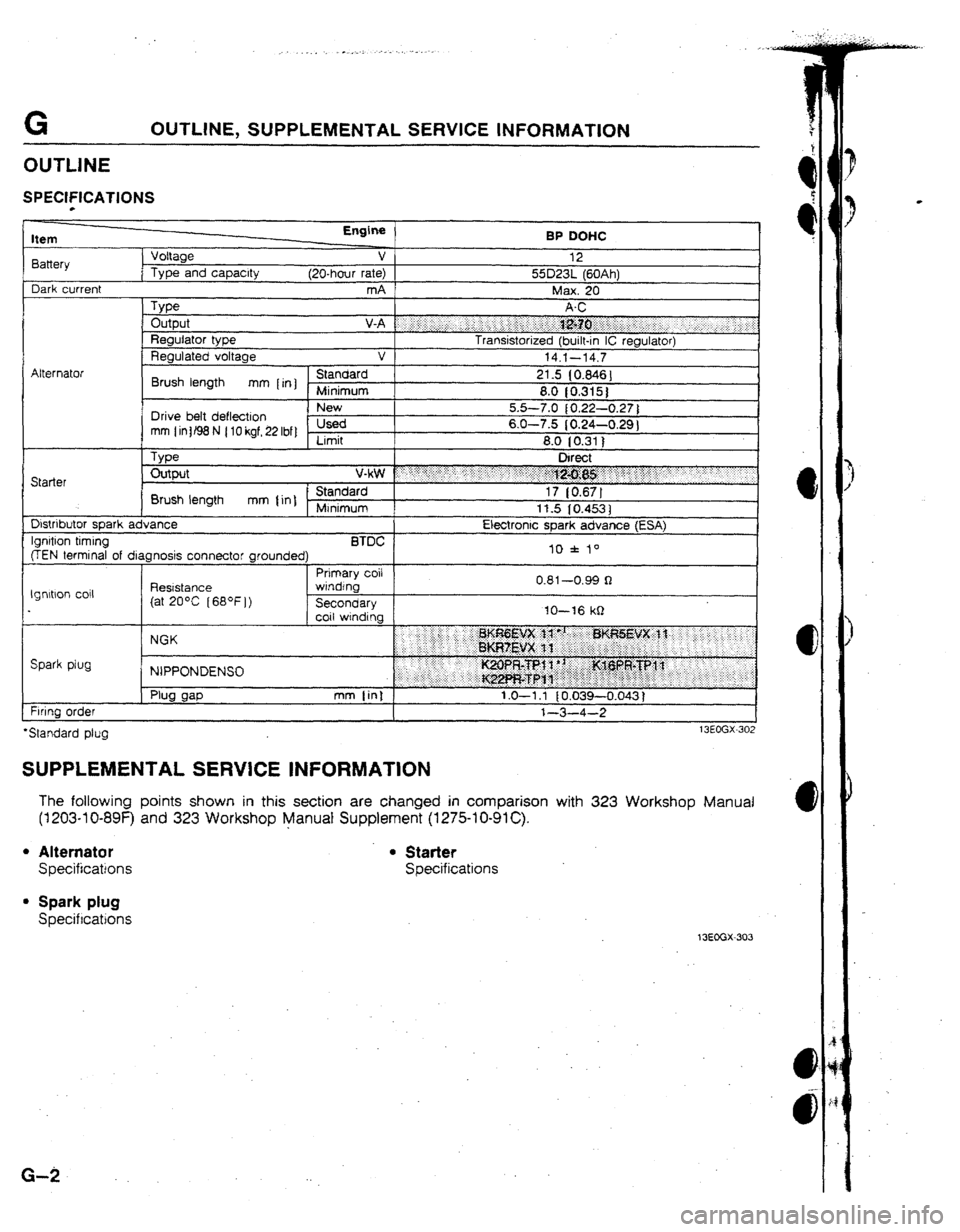

G OUTLINE, SUPPLEMENTAL SERVICE INFORMATION

SPECIFfCATfUNS

Item

8attery

Dark current Voltage

Type and capacity Engine

v

(20-hour rate)

mA BP DOHC

12

55D23L (60Ah)

Max. 20

Type Output V-A f “‘i j.,: i .:.. ‘:.. ,, j j.: i.‘: ;:;:i :j;&?.:. .: .:.

__ : . . s.i-....‘:‘:. _.. j ;.’

Regulator type Transistorized (built-in IC regulator)

Regulated voltage v

14.1-14.7

I

C?*..*rlrrrl

Brush length mm [rn] }e 21.5 (0.846)

8.0 10.315)

I Drive belt deflection I 5.5-7.0 { 0.22-0.27 )

mm (intB8N (lOkgf,22Ibf) usea 6.0-7.5 (0.24-0.29 1

Limit 8.0 (0.311

, Type Direct

Starter Output v*$# : : ;..;. ‘:‘.. ._ .; : :‘: 7.:

.. .::“:.:j 1 ,5

. . . . .j$$g;g$y .“. :yy

Brush length mm {in] - Standard 17 [0.67]

Minimum

11.5 IO.4531

Dlstnbutor soark advance Electronic soark advance (ESA)

@EN termind of diagnosis connector grounded) II) f lo

I 1 Prtmary coil

**4 nn*

Ignltbon co11 Reststance 3

(at 20°C [68*F])

in IO-16 kQ lgnrtlon timing BTDC f ar

wrndfnb

I

Secondary 1

coil WindIn.. v.0 I

--v.yy 1

Spark plug NGK

NIPPONDENSU

Firing oraer

*Standard pfug

SUPPLEMENTAL SERVICE INFORMATION

The following points shown in this section are changed in comparison with 323 Workshop Manual

(1203-l O-89F) and 323 Workshop Manual Supplement (I 275-l O-91 C).

l Alternator . Starter

Specifications Specifications

l Spark plug

Specifications

13EGGX-303

G-2

Page 95 of 279

OUTLINE M

OUTttNE

OUTLiNE OF CONSTRUCTION

l TKe construction and operation of the front and rear axles are basically the same as previous models.

l Because of the use of a high power engine, the following parts are modified to improve rigidity.

(I) Larger front and rear bearings are used.

(2) Larger front and rear knuckles are used.

(3) A five-stud wheel hub is used.

l An ice scraper is newly installed on the rear knuckle to prevent ice from building up on the brake caliper.

(Refer to page M-14.)

13EOMX-303

SPECIWCATIONS

Hem Speclficatlons

Front driveshaft

Joint type inside

Double offset joint

Outsrde Bell joint

Length of joint (between center of joint) Right

392 I15.4)

mm lrn)

Left 306 IO.831

Shaft drameter mm fin)

21.0 (0.83)

Rear driveshaft

Inside

Joint type Double offset joint

Outside 5ell joint

Length of joint (between center of joint) Right

519.5 [ 20.5 1

mm [in]

Left.

489.5 ( 19.3 )

Shaft diameter mm (in) 21.0 [O&3]

Joint shaft

I

Length of joint

Shaft diameter

Front axle

mm jin] 357.2 114.11

mm {in] 21.0 {0.83]

4

Bearing play axial direction mm tin)

0.05 IO.002 ]

I

Rear axle

Bearing play axial direction mm (inj

Rear dtfferentlal (viscous limited slip differential) 0.05 (0.002 1

Reduction aear Hypoid gear

Differentral gear

Drfferential ratio Straight bevel gear

3.909

Number of teeth Ring gear .

Drive binion aear

43

If

Fluid I Grade API Service GL-5

Above -t8*C (O*F) SAE 90

Viscosity .

Below -18*C i O*Fl SAE 8OW

1 I Capacity L I US qt, imp stl 1 0.65 !O.SS, 0.571

1

13EOMX-304

M-3

Page 135 of 279

R OUTLINE

OUTLINE

OUTLtNE OF CONSTRUCTION

l The%onstruction and operation of the suspension system are basically the same as for previous models.

l The coil spring and shock absorber specifications are changed.

l The stabilizer specifications are changed.

SPECIFICATIONS

13EORX-302

Front suspension

Suspension type

Sprmg type

Shock absorber

Stabrlmr

Specifications

Strut

Coil spring

Oil filled Total toe-rn

Front

wheel

atignment

(‘Unladen)

Rear suspension

Suspensron type

Sprmg type

Shock absorber

Stabrlrzer

Rear wheei

alrgnment

(‘Unladen) Maximum steering 38* f 3*

309 f 30

-0045 f 45’

2035’ f 45’

KIngpin angle degree

12*to’

We Oil fifled

Damprng force N [ kgl Ibf 1 .‘? .@g,$g&;qJ&,$. ‘: ‘., . . ” ‘, : :,

at 0.3 m 112

]ls I Contraction ;. ~ .. . . . . .__. ..:, .. .. ,I. ._ :. . . f: ; _... .:

Type Torsion bar

Diameter mm. f in ]

19.t (0.751

Total toe-in mm fin!

2.h 3 (0.08 f 0.121

degree

O”12’ f 18’

Camber angle degree -0°20’ f 45’

13EORX-303

l Fuel tank full, radrator coolant and engine oil at speclfled levels; and spare tire, jack, and tools in designated positions. Front Coil Spring Specifications

1 Identification mark color Wire diameter Coif .center

M l l

I Free length A a2 mm lin)

diameter mm [in) . mm 1 in) Coil number Rear Coil Spring Speci?ications

ldentlfication mark color M” Wire diameter Coil center

Free length

mm {in) diameter mm 1 in J

mm {in) Coil number

*’ Maln Identlfcatlon mark on second cgil from bottom.

*’ Auxrllary &entificatton mark on thrrd coil from bottom.

Shaded areas tndcate

new specifrcat+ons 13EORXCS05

(I .f

Page 149 of 279

![MAZDA 323 1992 Workshop Manual Suplement S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

C MAZDA 323 1992 Workshop Manual Suplement S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

C](/img/28/57055/w960_57055-148.png)

S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

Caution

l Do not damage the surrounding painted area.

Note

l tf the adhesive is difficult to remove, soften it by

using a hot air blower.

2. Clean and degrease the molding mounting surface of the

body and the bonding area of the molding.

3. Apply primer to the bonding area of the molding and allow

it to dry for approximately 30 minutes.

Caution

l Keep the area free of dirt, moisture, and grease.

l Do not touch the primed surfaces.

4. Apply strips of double-coated adhesive tape to the bond-

ing area of the molding.

Note

l Use 40 mm I-1.6 in) lengths of tape.

5. Apply urethane adhesive to the bonding area of the molding.

Caution

l The application range of urethane adhesive should

be approximately 5 mm f 0.2 iii ) wide and 60 mm

(2.4 in) long. Do not apply excessive adhesive.

6. Peel the protection paper from the double-coated adhesive

tape.

7. Align the molding to the body with the pin, and then install it,

8. Lightly press on the molding to obtain good adherence.

9. tnstall the fasteners.

Page 156 of 279

![MAZDA 323 1992 Workshop Manual Suplement TECHNICAL DATA TD

Hem

Camshafi

Engine

BP DOHC turbo

IN Standard

Cam height mm 1 in) Wear limrt

EX Standard

Wear llmrt

Standard

Journal diameter mm 1 In] (M.1 --NW

Out-of-round

Standard

Ca MAZDA 323 1992 Workshop Manual Suplement TECHNICAL DATA TD

Hem

Camshafi

Engine

BP DOHC turbo

IN Standard

Cam height mm 1 in) Wear limrt

EX Standard

Wear llmrt

Standard

Journal diameter mm 1 In] (M.1 --NW

Out-of-round

Standard

Ca](/img/28/57055/w960_57055-155.png)

TECHNICAL DATA TD

Hem

Camshafi

Engine

BP DOHC turbo

IN Standard

Cam height mm 1 in) Wear limrt

EX Standard

Wear llmrt

Standard

Journal diameter mm 1 In] (M.1 --NW

Out-of-round

Standard

Camshaft bearing oil clearance mm { in ] (No. f-440.5)

Maximum

Camshaft runout mm {in)

Camshaft end play mm Iin] - Standard

Maximum

Winder block

Height mm {in)

Distortion mm {in]

Grinding mm (in)

Cylinder bore diameter Standard size

mm Iin) 0.25 [ 0.010) oversize .

0.50 [ 0.020 ] oversize

Cylinder bure taper and out-of-round mm [in]

Piston

44.094 { 1.7360 ]

43.894 f 1.7281 ]

44.603 [ 1.7560)

44.403 [ t .748t ;

X940-25.965 I 1.0213-l .0222 j

0.05 (0.002] max.

0.035-0.081 [ 0.0014-0.0032 )

0.15 (0.006)

0.03 (0.0012 1 max.

0.07-O. 19 [ 0.0028-0.0075 1

0.2 IO.008 1

221.5 (8.720)

0.15 [0.006) max.

0.20 [0.008] max.

83.006-83.013 13.2679-3.2682 ]

83.256-83.263

13.2778-3.2781 ]

83.506-83.513

( 3.2876-3.2879 )

0.019 [0.0007) max.

Piston diameter Standard size 82:954-82.974 13.2659-3.2667 1

Measured at 90° to pin

bore axis and 11 .Omm

oversize 83.21 I-83.217

10.433 in] below oil ring 0.25 j 0.010 ]

13.2760-3.2763 ]

groove mm {In)

0.50 { 0.020) oversize 83.461-83,467

{ 3.2859-3.2861 )

Piston to cybnder clearance

Piston ring

mm (in) Standard 0.039-0.052 [ 0.0015-0.0020 ]

Maximum

0.15 [0.006]

Thickness mm {in] Top

Second

, Top

End gap (Measured in the cylinder) Second

mm I in 1 Oil (rail)

Maximum

TOP

Ring groove width in piston

mm (in) Second

r

Oil

Piston ring-to-ring groove clearance TOP

mm (in] Second

Maximum

Piston pin

Diameter mm {in)

Piston-to-piston pin clearance mm iin]

Connecting rod bush-to-piston pin clearance mm Iin)

Connecting rod and connecting rod bearing

Length (Center to center) mm {in] 1

Bending mm [in]

Small end bore (Bush inner diameter) mm [in)

Big end bore mm {in)

Bfg end width mm [in) 1

Standard

Connecting rod side clearance mm I in 1 Maximum I

Crankshaft

Crankshaft iunout mm {ln) 1.470-l ,495 { 0.0579-0.0589 ]

1.47-l -49 [0.0579-0.0587 )

0.15-0.30 [ 0.006-0.012 1

0.35-0.50 { 0.014-0.019 1

0.20-0.70 (0.008-0.028 )

1.0 [0.039)

1.520-I .535 f0.0598~9.0604 f

1.52-l .54 ~0.0598-0.0606)

3.02-3.04 (0.1189-0.1197 1

0.025-0.065 { 0.001 O-0.0026 ]

0.03-OXI7 (O.O012--0.0028)

._

0.15 (0.006]

19.987-l 9.993 (.0.7869-0.7871 )

-0.005-0.013 { -0.0002-0.0005 1

O.Ql O-0.027 ~0.0004-0.0011 )

m D 132.85-132.95 (5.230-5.234 1

0.075 ( 0.0030 ] max./50 I1:97 ]

20.003-20.014 ( 0.7875-0.7880 1

48.000-48.016 [ 1.8898-l 48904 ]

21.838-21.890 (0.8598-0.86t81

0.11 O-O.262 f 0.0043-0.0103 1

0.30 [0.012)

0.04 (0.0016)

mdx.

TCI rl

Page 160 of 279

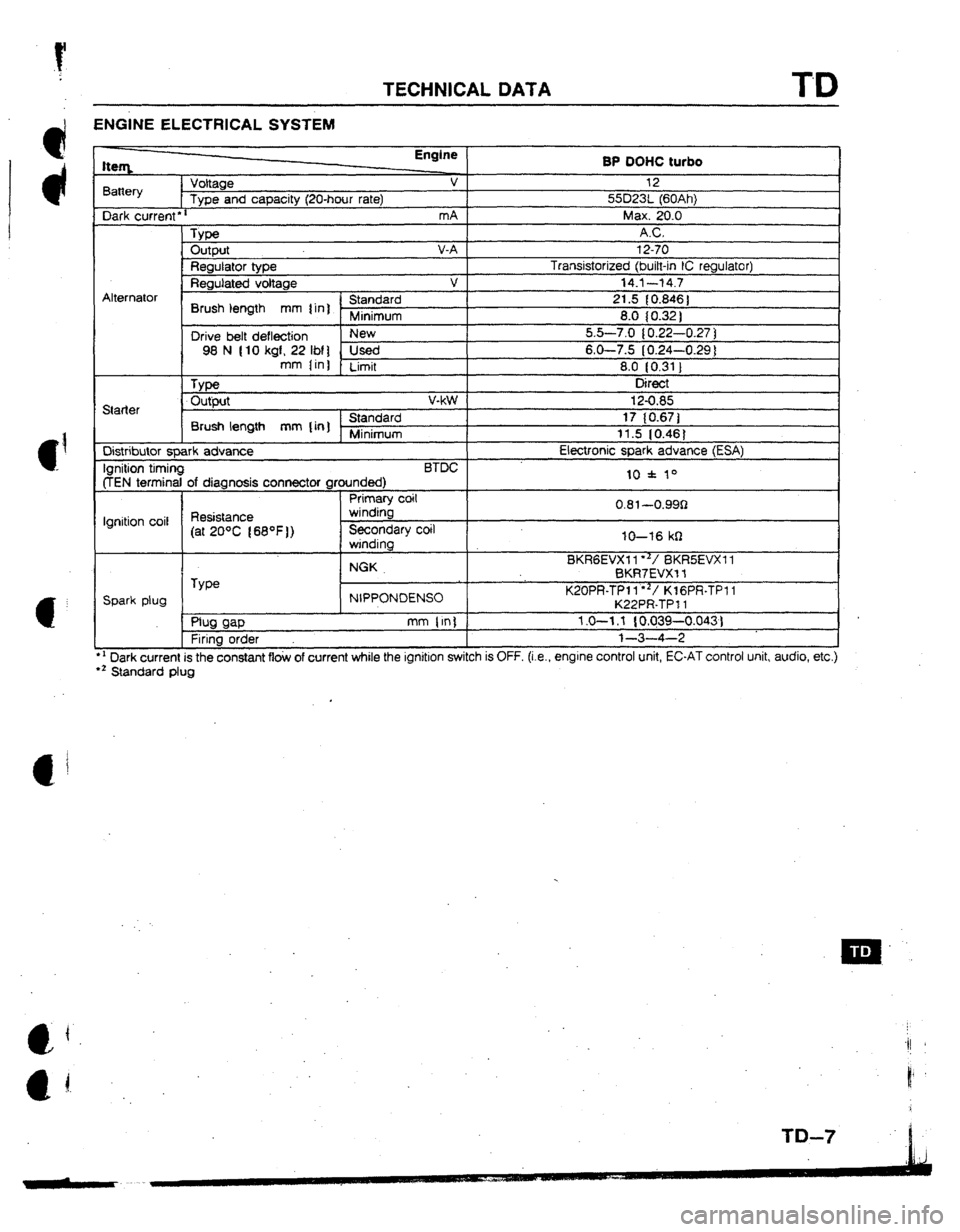

TECHNICAL DATA TD

ENGINE ELECTRICAL SYSTEM

l ’ Dark current is the constant flow of current while the ignition switch is OFF. (i.e., engrne control unit, EC-AT control unit, audio, etc.)

l z Standard plug tteq Engine

BP OOHC turbo

Battery Voltage v 12

Type and capacity (2U-hour rate) 55D23t (60Ah)

Dark current

l r mA Max. 20.0

_ Type AC.

Output V-A 12-70

Regulator type Transistorized (bitt-in IC regulator)

Regutated voltage v 14.1--t4.7

Alternator

’ Standard

Brush length mm 1 in] r 21.5 { 0.846 ]

Minimum 8.0 (0.32 )

Drive belt deflection New 5.5-7.0 10.22-0.27 ]

98 N (10 kgf, 22 IM] Used 6-O-7.5 (0.24-0.29 1

mm Iin)

Limit 8.0 IO.31 1

, Type Direct

Starter Output v-kW

Standard

Brush length mm {in] Minimum

Distributor spark advance

Ignition timing BTDC

(TEN terminal of diagnosis connector grounded)

Primary coit

Ignition coil Resistance winding

(at 20°C 168OF)) Secondary coil

winding

NGK

TYW

Spark plug NIPPONDENSO

, ml WP mm (in)

Firing order 12-0.85

17 (0.671

11.5 IO.481

Etectronic spark advance (ESA)

10 f 10

0.81~-0.99Q

IO-16 kfI

BKRGEVXI I**/ BKRSEVXI 1

BKR7EVX-f f

K20PR-TPl l”‘/ KlGPR-TPI 1

K22PR-TP 11

1.0-l .f { 0.039-0.043)

l-3-4-2

Page 163 of 279

![MAZDA 323 1992 Workshop Manual Suplement TD TECHNICAL DATA

Hem Engine

SP DOHC turbo

Note ) I

1 st and 2nd

Synchronizer ring outer diameter

’ I 67.7 I2.665)

mm [in] 3rd and 4th 67.7 12.665 )

5th and reverse 55.7 t2.192)

Synchronize MAZDA 323 1992 Workshop Manual Suplement TD TECHNICAL DATA

Hem Engine

SP DOHC turbo

Note ) I

1 st and 2nd

Synchronizer ring outer diameter

’ I 67.7 I2.665)

mm [in] 3rd and 4th 67.7 12.665 )

5th and reverse 55.7 t2.192)

Synchronize](/img/28/57055/w960_57055-162.png)

TD TECHNICAL DATA

Hem Engine

SP DOHC turbo

Note ) I

1 st and 2nd

Synchronizer ring outer diameter

’ I 67.7 I2.665)

mm [in] 3rd and 4th 67.7 12.665 )

5th and reverse 55.7 t2.192)

Synchronizer key dimension 1st and 2nd @ 19.0 {0.748], 04.3 (0.171, 05.0 10.20)

mm [in] 3rd and 4th @ 17.0 10.669J, 04.3 (0.171, @ 5.0 lO.20)

5th and reverse 0 17.0 10.6691, m4.3

10.171, @I 5.0 fO.201

PROPELLER SHAFT

Item

length

Outer diameter Engineflransaxie Model BP DOHC turbo

G25MX-R (GSMX-R)

Front 834.3 { 32.85 ]

mm fin] Center 584 122.99)

Rear

I 437 { 17.20)

Front 75 (2.95)

mm { in] Center 57 12.24) f

Rear 57 12.241

FRONT AND REAR AXLES

Item Specifications

Front driveshaft

Jomt type Inside Double oftset joint

Outside Bell jotnt

Length of joint (between center of joint) mm { rn t - Right 392 (15.4)

left 306 (0.83 ]

Shaft diameter mm {in] 21.0 to.831

I

Rear driveshaft

Joint type Inside 1

Outside 1

Length of joint (between center of joint) mm [in ] ’ Right

Left

Shaft diameter mm (in)

J&t shatt

Length of joint

Shaft diameter

Front axle

Bearing play axial direction mm [in] 1

Rear axle

Bearing play axial direction mm lin] 1

Rear differential (viscous limited slip differential) Double offset joint

Bell joint

519.5 (20.5 ]

489.5 [f9.3]

21.0 IO.831

357.2 1 t4.11

21 .O (0.83 )

0.050 IO.002 ]

0.050 (0.002 ]

*

Reduction gear

Different ia gear

Oifferential ratro

Number of teeth

Flurd

L Ring gear

Drive .pinion gear

Grade

Viscosity Above -18*C fO*F ]

Below -18*C lOoF)

, Capacity

L fUS qt, Imp c$l Hypoid gear

Straight bevel gear

3.909

43

11

API Service GL-5

SAE 90

SAE 80W

0.65 lQ.69, 0.571 STEERING SI

1 Free olav 8RAKING SY

Brake type

Brake pedat

Height

Free play 1

Reserve travel

Clearance whet

Master cylinde

Master cylinder

Front disc brai

. Tyl?e

Thickness of p&

Thickness of pa

Page 166 of 279

![MAZDA 323 1992 Workshop Manual Suplement SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ k MAZDA 323 1992 Workshop Manual Suplement SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ k](/img/28/57055/w960_57055-165.png)

SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ kgf, Ibf ] at 0.3 mls

Compressed 1

686 (70, 154)

Stabilizer Type Torsion bar

Oiameter mm {in]

23.0 (0.91 )

Total toe-in mm (in>

2 f 3 (0.08 f 0.12)

degree

0*12’ f 18’

Front wheel Turning angle Inner

38* f 3*

alignment

degree Outer

300 f 30

(* Unladen)

Camber angle degree

-u045’ f 45’

Caster angle degree

2035 f 45’

Kingpin angle

degree 12010’

Rear suspension

Suspension type

I Strut

Spring type

Coil spring

Type Oil

Shock absorber

Damping force Extended

882 (90. 1981

N I kgf, Ibf t at 0.3 mis Compressed

392 140, 88 1

Stabilizer , Type Torsion bar

Diameter mm [in] ?9.? { 0.75 1

Rear wheel

Totat toe-in mm {ini

2 f 3 (0.08 f 0.12)

alignment degree

0°t2’ f 18’

(‘Unladen)

Camber angle degree

-0020’ f 45’

l Fuel tank Ml; radiator coolant and engrne oil at speciffed levels; and spare tire, jack, and tools in designated poations.

Coil Spring Specifications

Item Wire diameter Coil center diameter Free length Coil identification mark coler

mm [in] mm (in) mm (in] number

M” Ae2

Front With sunroof 14.5

IO.57 1 l32.5-158.5 15.22-6.24 ) 271.5 1 IO.69 ] 3.35 Pink

Green

.

WIthout sunroof 14.4 IO.561 1 132.6-158.6 (5.22-6.241 267.0 I IO.51 ] 3.24 Light blue Red

With sunroof 8.8-l 2.5

[ 1 0.34-0.49 128.5-131.2 15.0~5.17) 334 { 13.151 6.19 Cream -

Rear .

I 1 Without sunroof I ff;;y;4”81 I t28.6-13t.j [5.06--5.16) / 335 113.19) 1 6.23 1 Pink 1 - I

l I Main rdentrficatlon mark color: Indicated on second coil from bottom.’ l 2 Auxiliary identification mark color: Indicated on third coil from buttom.

TD-13