ABS MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 24 of 279

![MAZDA 323 1992 Workshop Manual Suplement SCHEDULED MAINTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months’ ’

- 6 12 18 1 24 30 36 ] 42 48

Kllometers 1,000

10,000 20,000 30,000 1 40,0 MAZDA 323 1992 Workshop Manual Suplement SCHEDULED MAINTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months’ ’

- 6 12 18 1 24 30 36 ] 42 48

Kllometers 1,000

10,000 20,000 30,000 1 40,0](/img/28/57055/w960_57055-23.png)

SCHEDULED MAINTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months’ ’

- 6 12 18 1 24 30 36 ] 42 48

Kllometers 1,000

10,000 20,000 30,000 1 40,000 50,000 60,000 1 70,000

80,000

(Miles) (600)

(6,000) j(12,000)~(18,000)~(24,000) (30,000) (36,000)~(42,000) (48,000)

Chassis and body (Cont’d)

Steering and front suspension

I ’ I

I 1 I

MTX oil A R

Rear axle oil

I R A A R

A A A R I

Trabsfercarrier oil R A 1 A

R A A A R

Bolts, nuts on chassis and body T T 1

T , T T

Body condltlon (Visual only) Inspect annually

Exhaust system heat shields I 1 I

Tires (Including spare tjresj with inflation

pressure adjustment I

I I I

Hinges and catches A A

A 1 A

Underside of vehicle I

I i 1 I I

Seat belt I

I f

I ’ I

Dnveshafl dust boots I I 1 I I

13EOAX.304

A-5

Page 28 of 279

![MAZDA 323 1992 Workshop Manual Suplement B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 1 MAZDA 323 1992 Workshop Manual Suplement B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 1](/img/28/57055/w960_57055-27.png)

B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 11 .Omm

IO.650 in 1 below 10.433 in 1 below

oil rmg groove. oil ring groove.

COOLING CHANNEL

*IL YTLET

OIL t NiET

l The piston skirt is shortened for reduced weight and friction. l A cast iron ring carrier is installed in the piston to reduce piston-ring groove wear. l A cooling channel is incorporated in the body of the piston. The 011 jet squirts oil into this cootrng channel

and the or! absorbs

the heat from around the ring lands, reducing piston ring and cylinder wat! wear

Bz-4

Page 31 of 279

EXHAUST ViitVE

EXHAUST SIDE

VALVE GUIDE

METALLIC SODIUM

(ABOUT 30% VOLUME)

VALVE STEM

.‘.‘*

:::I

:::I

VALVE HEAD

CYttNDER HEAD

IDENTlFtCATION OF METALLIC SODIUM-FILLED EXHAUST VALVE

l Superior he& dissipating .metallic sodium-filled exhaust valves are adopted. During engine operation, the

metalic sodium inside the valve stem melts. As the valve moves up and down, the sodium splashes around

inside the valve and helps to absorb heat from the cylinder head and to transfer it back to the engine

coolant through the valve guide. In this way, the combustion chamber temperature is reduced, reducing

knocking and improving fuel efficeincy.

l Special handling of sodium filled valves is required for personal safety. (See next page.)

B2-7

Page 98 of 279

M FRONT AXLE

WHEEL HUB, STEERING KNUCKLE

RemovaI / Inspection I Installation

1. Remove in the order shown in the figure, referring to Removal Note.

2. Inspect all parts and repair or replace as necessary.

3. InstaH in the reverse order of removal, referring to Installation Note.

Caution

l Loosely tighten the shock absorber bolts. Lower the vehicle and tighten the bolts to the specified

torque with the vehicle unladen.

4. Adjust the front wheel alianment.

16-22 ]1.6-2.3, 12-161 I

19.0-l 2.0, 65-86.7 I

1. Wheel hub nut

2. Wheel and tire

3. Locknut

Removal Note . . . . . . .._.. . . . . . . . . . . . . . . . . . . . page M-7

installation Note .I.........,..,............ page M-7

4. Brake caliper assembly

Service . _. . . . . . . . . ,__. . . , , . ._. _. , , . . . , . ._ ._. . . . . . Section P

5. Disc plate

lnspectioti .~~*.......*~...,......,,,.....*~...~. Section P

6. ABS wheel speed sensor (if equipped)

7. Tie rod end

Removal Note . . . . . . .._.......... I . .._.....= page M-7

lnstallatiofi Note . . .._... _.__......,....... page M-7

M-6

8. Lower ball joint

9. Steering knuckle, wheel hub, and dust cover

Inspect-wheel hub for cracks and damage

Inspect knuckle spindle for cracks and

damage

Inspect dust cuver for damage and dis-

tortion

Disassembly I Inspection I

Assembly . ..C1..............~...,.....,.....

page M-8

Page 104 of 279

REAR AXLE

WHEEL HUB, KNUCKLE

Removal I Inspection / installation

1. Remove in the order shown in the figure, referring to

Removal Note. 2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to Installation Note.

Caution

l Loosely tighten the shock absorber bolts. Lower the vehicle and tighten the bolts to the specified

torque with the vehicle unladen.

4. Adiust the rear wheel alianment.

16-22 1?.6-2.3, 12-16 I

7

IO.o-13.0,

66-66.7 1 1. Wheel and tire

2. Locknut

Removal Note..; . . . . . . . . , . . . . ,.......- -.. page M-f 3

Installation Note .._...,.,...._.__........ page M-13

I$ Brake caliper assembly

Service . . . . . . . . . . . ..e......._......... ,.,...,....

Section P

4. Disc plate

‘Service ..I....................__....... . . . . . . . . . Section P 5. Af3S wheel speed sensor (if equipped)

6. Wheel hub, knuckle

Disassembly I Inspect& /

Assem bty . . . . . . . ..I..........*..*.*...-... page M-14

Inspect wheel hub and knuckle for damage

or cracks

Inspect dust cover for damage or defor-

mation

M-12

Page 112 of 279

BRAKING SYSTEM

INDEX ..**.............=*..*..*....~.~............*.,.*...=.

P- 2

OUTLINE . . . . ..~....**.*...........*~...................***

1 P- 3

t il OUTLINE

OF CONSTRUCTION . . . . . . . s.e . . . .

l *..

P- 3

i SPECIFfCATIUNS

. . . . . . . . ..m...*.-..**......n.*.**...

P- 3

e , :

8 [ SERWCE /

SUPPLEMENTAL SERVICE INFORMATION s. P- 4

CONVENTIONAL BRAKE SYSTEM . . . .

l .m..m.s.m P-

5

PREPARATION

. ..* . . . . . . . . . . . . . . . . . . . l . . . . *.*..*.*..I P- 5

AIR BLEEDING (WITH ABS) . . . . . . l .* . . . . . . . . a . . . .

PA 6

POWER 8RAKE UNIT ..*.I..*....*..*....*...*..*..

P- 8

PROPORTJONING VALVE

l . . . . . . . . . . . . . . . . . l . . . . . .

P- 9

FRONT BRAKE (DISC)

. . . . ..**.*.........e.........

P-IO

DISC PAD

. . . . ..m*.m....*bL*m....*...............*......

P-l 1

DISC PLATE

..*..*..*.**..*..a.............*.-.*.....,.

P-12

CAMPER . . . ..m....I*.....*..m*..*......*......*....*...

P-l 2

REAR BRAKE (DISC)

. . . . . . . . . . . . . . . . . * . . . . . . . . l . . . . P-14

DISC PAD . . . . . . . . . . . . . . . . ..~.....................~.~...

P-l 5

DISC PLATE . . . . . . . . . . ..m.e..m....=...*...........*....

P-l 6

CALIPER . . . ..*..m.......I.......~m..~*..*.~......~...*.

P-97

13EOPX-301

Page 113 of 279

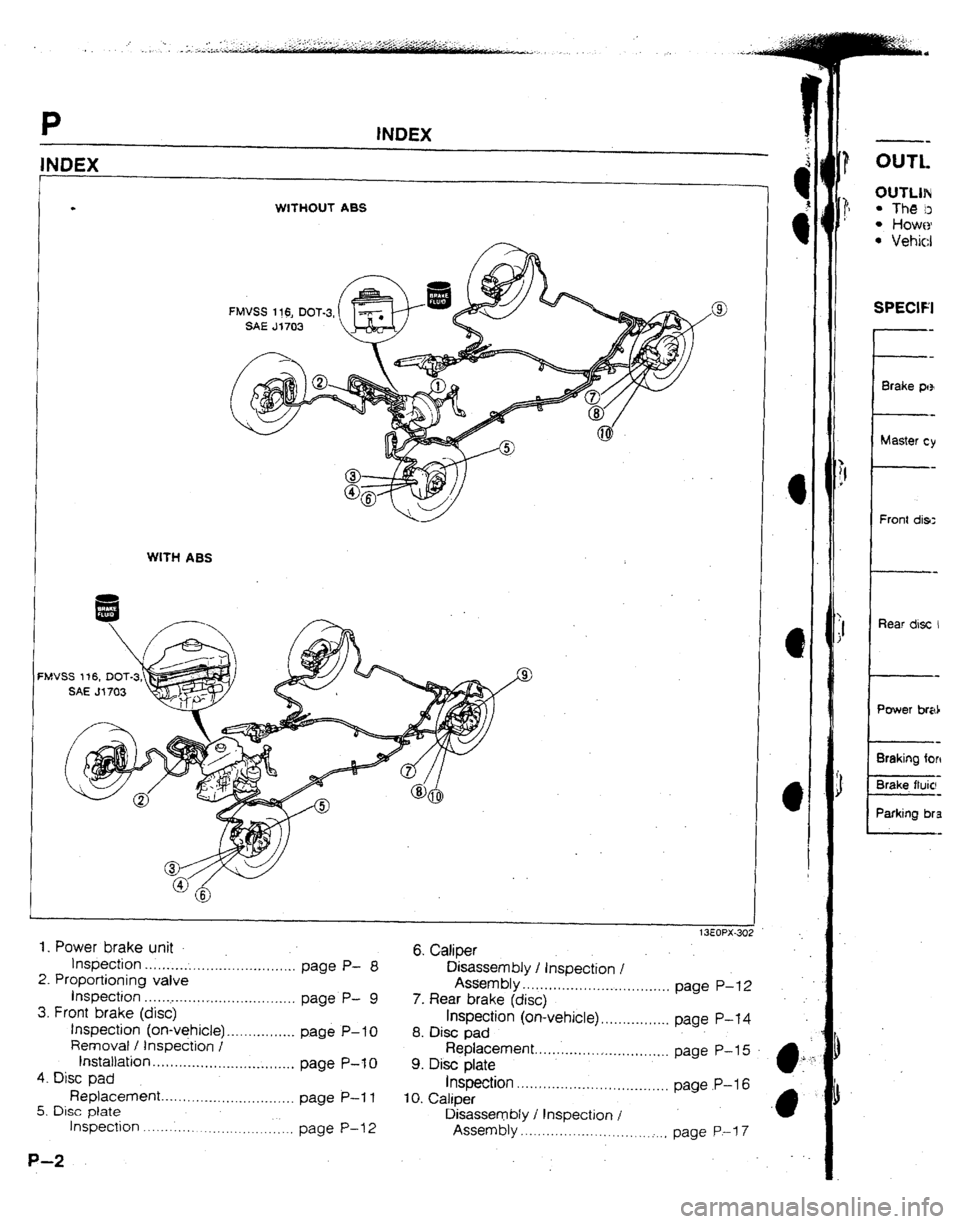

INDEX

. WfTHOUT ABS

WITH ASS

‘MVSS 1 t6, DOT-3

.

1. Power brake unit

tnspection . . . . . . . . . . . . . . . . . . . . . . . .._......... 6. Catiper

page P- 8

Disassembly / tnspection I

2. Proportioning valve

tnspection . . . . . . .._..... . . . . . . . . . . . . . . . . . . . . . Assembly

P- . . . . . . . . . . . . ..I............I.....I page P-12

9

3. Front brake (disc) page

7. Rear brake (disc)

tnspection (on-vehicle). . . . . . . . . . . . . . . . page hspechn (on-vehicle) . . . . . . . . . . . . . . . . page P-l 4

P- IO

Removai / tnspection I 8. Disc pad t nstattation Replacement

page P-to 9. Disc plate ............I..r.... 1 . . . . . . . ~_. page P-15 .

. ..t..I...-.......-..l.._*.......

4. Disc pad

Replacem& Inspection . . . . . , . . . . . .

. . . . . ..a. ..I......,,,..

. . ..I.....-............-...,...

5. Disc piate page P-11

IO. Caliper page P-16

Inspection . . . . . . ._. ._. ._. __. . . ._. page P-l 2 Disassembly I t nspection I

Assembly . . . . . . ..I........................I page P-l 7

P-2 --

OUTL OlJTLlN

l The D

l HOWO

l Vehicl SPECIFI

Front dis:

Rear disc I

Braking for4

Brake. fluic:

Parking bra

Page 114 of 279

OUTLlNE P

OUTLfNE

OUTLINE OF CONSTRUCTION

l The brake system remains similar to that of the previous model. l However, because all new models use a higher-horsepower engine, the brake system is enlarged as a whole.

l Vehicles without ABS use a portless-type master cylinder

13EOPX-303

SPECIFICATIONS

Brake pedal

Master cylinder

Front drsc brake

Rear disc brake

Power brake unit

Braking force control device

Brake fluid

Parking brake Item Specification

Type Suspended

I

PedaJ lever ratio 4.1

Max. stroke mm [in] 140 j5.511

I,

Type Tandem

Cylinder inner diameter mm {in] Without ABS: 25.4 j 1 .UO ]

With ABS: 23.8 to.941 3-

Type Ventilated disc ?

Cylinder bore mm [in)

57.2 12.253

Pad dimensions (area x thickness)

mm2 {rn2) xmm [In) 5,200 (8.OSl x 10 (0.39)

Disc plate dimensions mm (in]

(outer diameter x thickness) 274x24 (10.79x0.94)

Type Solid disc

Cylinder bore mm Jon]

34.9 j 1.37 ]

Pad dimensions (area x thrckness)

mm’ (in21 xmm [in) 3,200 I4.961 x8 (0.31)

DISC plate dimensions mm t,n]

(outer diameter x thickness) 280x10 (tl.02xu.39]

il

Type Without ABS: Vacuum multIplier

With ABS: Hydraulrc muttiplier

Diameter mm Iln]

(without ABS) 188.4 17.42) +215.2 t8.47)

We Without ABS: Dual proportioning valve

With ASS: Proportioning valve

FMVSS 116, DOT-3, SAE J1703

Mechanical twGrear-wheel control

Type

Operation system Center lever

13EOPX.304 t

Page 115 of 279

P SUPPLEMENTAL SERVICE INFORMATION I

. .

SUPPLEMENTAL SERVICE

INFORMATION

The following points in this section are changed and added in comparison with Workshop Manuals

(1206-I 0-89F), (I 229-I 0-89L) and (12751 O-91 c).

Air bleeding (with ABS)

Power brake unit (SST newly established)

l Inspection (on-vehicte)

Proportioning valve (SST newly established)

l Inspection

Front brake

l Inspection (on-vehicle)

Removai I Inspection / Installation

Disc pad

l Replacement

Disc plate

l Inspection

Caliper

l Disassembly I Inspection I Assembly

Rear brake

l Inspection (on-vehicle)

l Removal i Inspection I Installation

Disc pad

l Replacement 4

Disc plate

l Inspection

Caliper

l Disassembly I Inspection I Assembly 13EOPX-305

4

P-4

CON

PREP,

SST

Pm

49

ue4

Gauge, pressL r

(Part d

49 um

Pa

49 uw

HOti (Part 0;

49 uu4;

49 1258

Duiler, LH

Page 117 of 279

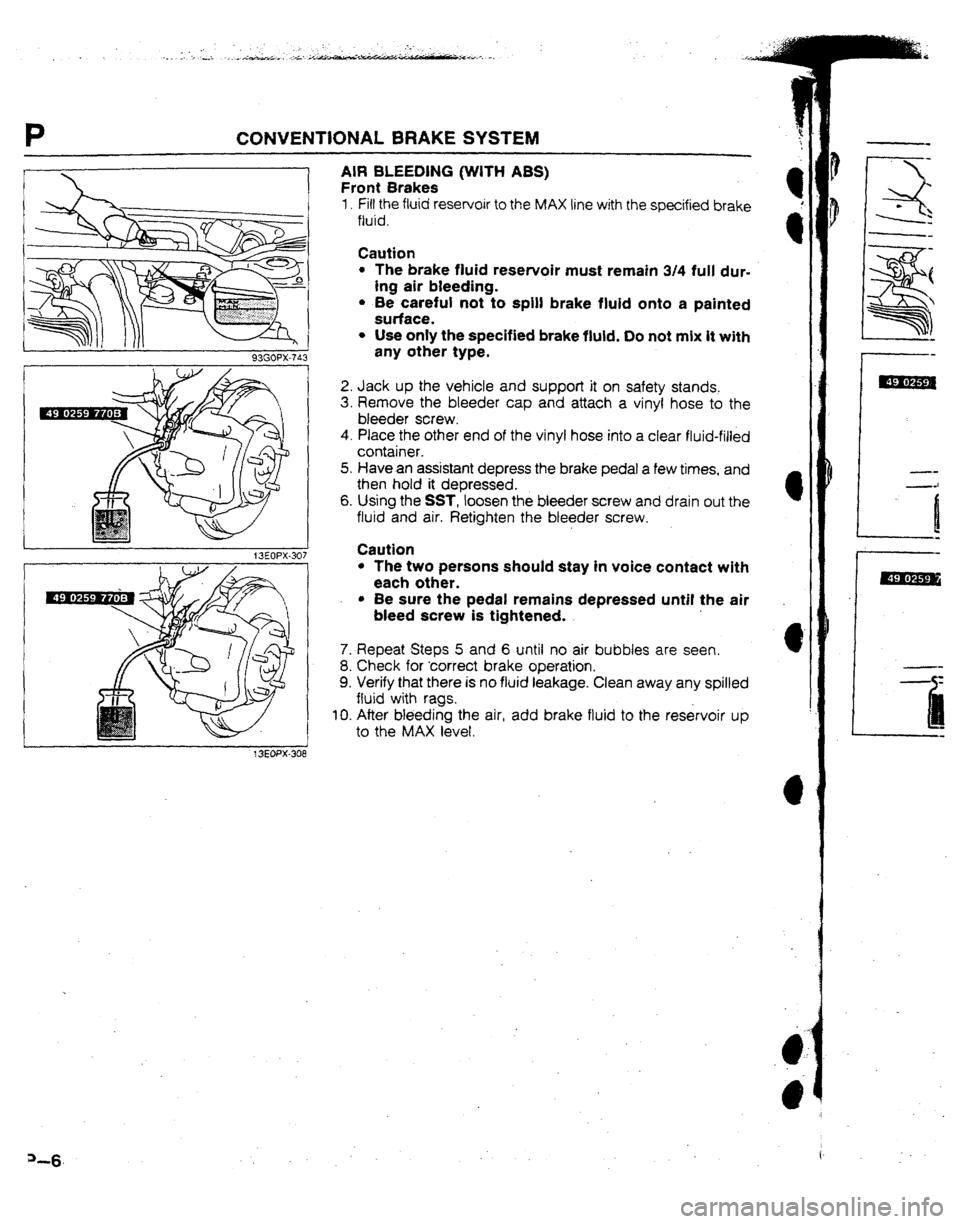

P CONVENTIONAL BRAKE SYSTEM

93GOW74:

13EOPX-307

AIR BLEEDlNG (WITH ABS)

Front Brakes

1. Fill the fluid reservoir to the MAX line with the specified brake

fluid.

Caution

l The brake fluid reservoir must remain 3/4 full dur-

ing air bleeding.

l Be careful not to spill brake fluid onto a painted

surface.

l Use only the specified brake fluid. Do not mix it with

any other type.

2. Jack up the vehicle and support it on safety stands.

3. Remove the bleeder cap and attach a vinyl hose to the

bleeder screw.

4. PIace the other end of the vinyl hose into a clear fluid-filled

container.

5. Have an assistant depress the brake pedal a few times, and

then hold it depressed.

6. Using the SST, loosen the bleeder screw and drain out the

fluid and air. Retighten the bleeder screw.

Caution

l The two persons should stay in voice contact with

each other.

l Be sure the pedal remains depressed until the air

bleed screw is tightened.

7. Repeat Steps 5 and 6 until no air bubbles are seen.

8. Check for ‘correct brake operation.

9. Verify that there is no fluid leakage. Clean away any spilled

fluid with rags.

IO. After bleeding the air, add brake fluid to the reservoir up

to the MAX level.