suspension MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 24 of 279

![MAZDA 323 1992 Workshop Manual Suplement SCHEDULED MAINTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months’ ’

- 6 12 18 1 24 30 36 ] 42 48

Kllometers 1,000

10,000 20,000 30,000 1 40,0 MAZDA 323 1992 Workshop Manual Suplement SCHEDULED MAINTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months’ ’

- 6 12 18 1 24 30 36 ] 42 48

Kllometers 1,000

10,000 20,000 30,000 1 40,0](/img/28/57055/w960_57055-23.png)

SCHEDULED MAINTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months’ ’

- 6 12 18 1 24 30 36 ] 42 48

Kllometers 1,000

10,000 20,000 30,000 1 40,000 50,000 60,000 1 70,000

80,000

(Miles) (600)

(6,000) j(12,000)~(18,000)~(24,000) (30,000) (36,000)~(42,000) (48,000)

Chassis and body (Cont’d)

Steering and front suspension

I ’ I

I 1 I

MTX oil A R

Rear axle oil

I R A A R

A A A R I

Trabsfercarrier oil R A 1 A

R A A A R

Bolts, nuts on chassis and body T T 1

T , T T

Body condltlon (Visual only) Inspect annually

Exhaust system heat shields I 1 I

Tires (Including spare tjresj with inflation

pressure adjustment I

I I I

Hinges and catches A A

A 1 A

Underside of vehicle I

I i 1 I I

Seat belt I

I f

I ’ I

Dnveshafl dust boots I I 1 I I

13EOAX.304

A-5

Page 134 of 279

R

SUSPENSION

OUTLINE .................................................. R- 2

OUTLHdE OF CONSTRUCTION ................. R- 2

SPEC1FtCATlONS .................................... R- 2

13EORX-301

Page 135 of 279

R OUTLINE

OUTLINE

OUTLtNE OF CONSTRUCTION

l The%onstruction and operation of the suspension system are basically the same as for previous models.

l The coil spring and shock absorber specifications are changed.

l The stabilizer specifications are changed.

SPECIFICATIONS

13EORX-302

Front suspension

Suspension type

Sprmg type

Shock absorber

Stabrlmr

Specifications

Strut

Coil spring

Oil filled Total toe-rn

Front

wheel

atignment

(‘Unladen)

Rear suspension

Suspensron type

Sprmg type

Shock absorber

Stabrlrzer

Rear wheei

alrgnment

(‘Unladen) Maximum steering 38* f 3*

309 f 30

-0045 f 45’

2035’ f 45’

KIngpin angle degree

12*to’

We Oil fifled

Damprng force N [ kgl Ibf 1 .‘? .@g,$g&;qJ&,$. ‘: ‘., . . ” ‘, : :,

at 0.3 m 112

]ls I Contraction ;. ~ .. . . . . .__. ..:, .. .. ,I. ._ :. . . f: ; _... .:

Type Torsion bar

Diameter mm. f in ]

19.t (0.751

Total toe-in mm fin!

2.h 3 (0.08 f 0.121

degree

O”12’ f 18’

Camber angle degree -0°20’ f 45’

13EORX-303

l Fuel tank full, radrator coolant and engine oil at speclfled levels; and spare tire, jack, and tools in designated positions. Front Coil Spring Specifications

1 Identification mark color Wire diameter Coif .center

M l l

I Free length A a2 mm lin)

diameter mm [in) . mm 1 in) Coil number Rear Coil Spring Speci?ications

ldentlfication mark color M” Wire diameter Coil center

Free length

mm {in) diameter mm 1 in J

mm {in) Coil number

*’ Maln Identlfcatlon mark on second cgil from bottom.

*’ Auxrllary &entificatton mark on thrrd coil from bottom.

Shaded areas tndcate

new specifrcat+ons 13EORXCS05

(I .f

Page 154 of 279

TD

TECHNICAL DATA

ENGtNE ..................................................

TD- 2

LUBRICATlON SYSTEM ...........................

TD- 4

COOLING SYSTEM ..................................

TD- 5

FUEt AND EMISSION CONTROL

SYSTEMS

.............................................

TD- 6

ENGINE ELECTRICAL SYSTEM

................ TD- 7

CLUTCH .................................................

TD- 7

MANUAL TRANSAXLE AND TRANSFER

.... TD- 8

PROPELLER SHAFT

................................

TD-l 0

FRONT AND

REAR AXLES ....................... TD-lU

STEERING SYSTEM ................................

TD-11

BRAKING SYSTEM

..................................

TD-11

WHEELS AND TIRES

...............................

TD-12

SUSPENSION

......................................... TD-13

BODY ELECTRICAL SYSTEM

................... TD-14

STANDARD BOLT AND NUT TIGHTENING.

TORQUE ..............................................

TD-f 4

13ETOX-301

I

m I

Page 165 of 279

![MAZDA 323 1992 Workshop Manual Suplement TD TECHNICAL DATA

Power brake unit

Diameter

km Without ABS With ABS

mm [in] 188.4 I7.42) +215.2 18.47) [ -

More than 1,080 Itl, 15611 1

I cn I tding force

1- II ,I

I

r-km pressure per lrei

K MAZDA 323 1992 Workshop Manual Suplement TD TECHNICAL DATA

Power brake unit

Diameter

km Without ABS With ABS

mm [in] 188.4 I7.42) +215.2 18.47) [ -

More than 1,080 Itl, 15611 1

I cn I tding force

1- II ,I

I

r-km pressure per lrei

K](/img/28/57055/w960_57055-164.png)

TD TECHNICAL DATA

Power brake unit

Diameter

km Without ABS With ABS

mm [in] 188.4 I7.42) +215.2 18.47) [ -

More than 1,080 Itl, 15611 1

I cn I tding force

1- II ,I

I

r-km pressure per lrei

KYa 1 Kgr/cm-, PSI 196 120, 441

at 0 kPa ImmHg, inHgJ

‘) -

j/N tkgf, Ibfl More than 8,730 189, I,2701

1196 (20, 44)

at 66.7 1500, 19.7)

kPa ImmHg, InHgj

Rear wheel hydraulic control system

Type Dual proportlonrng valve 1 ProportionIng valve

Switching point (Master cylinder pressure) kPa t kgflcm2, psi) 1,960 {20, 284)

WHEELS AND TIRES

Item Type Standard Temporary Spare

Size 5 l/2-JJxt5 4-Tx15

Offset mm

Wheel (in) 47.5 { 1.87 j 45 it.771

Pitch circle diameter mm (in] 114.3 {4.50)

Material

I Aluminum alloy

I Steel

Size 195150R15 82V T125/7OD15

Tire

Air kPa i kgflcm2.

pressure psi 1 Front ‘L200 12.4, 351

l 2245 12.5, 36)

Rear “216 (2.2, 321 ‘*245 12.5, 361 412 (4.2, 60)

t-lorizontai 2.0 { 0.079 1 2.5

Runout limit mm [in! L IO.098 ]

Wheel and

Vertical 1 1.5 [0.059] 2.0 (0.079 j

tire

1lnbafanr.e a lo21 t 9 to.31 1 -

*le.. Up to 3 persons

*2 . . . -Full load

SUSPENSI

Front susp

Suspensiorr

Spw tyw:

Shock abs>

Stabilizer

Front wheel

alignment

(

l Unladen;

Rear suspj

Suspension

Spring typi

Shock absc

Stabilizer

Rear whet

alignment

(‘Unladenj

l Fuet tank f

Coil Sp&

+I Main rder

l 2 Auxiliary I

TD-12

Page 166 of 279

![MAZDA 323 1992 Workshop Manual Suplement SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ k MAZDA 323 1992 Workshop Manual Suplement SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ k](/img/28/57055/w960_57055-165.png)

SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ kgf, Ibf ] at 0.3 mls

Compressed 1

686 (70, 154)

Stabilizer Type Torsion bar

Oiameter mm {in]

23.0 (0.91 )

Total toe-in mm (in>

2 f 3 (0.08 f 0.12)

degree

0*12’ f 18’

Front wheel Turning angle Inner

38* f 3*

alignment

degree Outer

300 f 30

(* Unladen)

Camber angle degree

-u045’ f 45’

Caster angle degree

2035 f 45’

Kingpin angle

degree 12010’

Rear suspension

Suspension type

I Strut

Spring type

Coil spring

Type Oil

Shock absorber

Damping force Extended

882 (90. 1981

N I kgf, Ibf t at 0.3 mis Compressed

392 140, 88 1

Stabilizer , Type Torsion bar

Diameter mm [in] ?9.? { 0.75 1

Rear wheel

Totat toe-in mm {ini

2 f 3 (0.08 f 0.12)

alignment degree

0°t2’ f 18’

(‘Unladen)

Camber angle degree

-0020’ f 45’

l Fuel tank Ml; radiator coolant and engrne oil at speciffed levels; and spare tire, jack, and tools in designated poations.

Coil Spring Specifications

Item Wire diameter Coil center diameter Free length Coil identification mark coler

mm [in] mm (in) mm (in] number

M” Ae2

Front With sunroof 14.5

IO.57 1 l32.5-158.5 15.22-6.24 ) 271.5 1 IO.69 ] 3.35 Pink

Green

.

WIthout sunroof 14.4 IO.561 1 132.6-158.6 (5.22-6.241 267.0 I IO.51 ] 3.24 Light blue Red

With sunroof 8.8-l 2.5

[ 1 0.34-0.49 128.5-131.2 15.0~5.17) 334 { 13.151 6.19 Cream -

Rear .

I 1 Without sunroof I ff;;y;4”81 I t28.6-13t.j [5.06--5.16) / 335 113.19) 1 6.23 1 Pink 1 - I

l I Main rdentrficatlon mark color: Indicated on second coil from bottom.’ l 2 Auxiliary identification mark color: Indicated on third coil from buttom.

TD-13

Page 168 of 279

ST

SPECIAL TOOLS

c 1

GENERAL lNFORMATlON ........................ ST- 2

ENGINE

..................................................

ST- 3

CLUTCH AND MANUAL TRANSAXLE

........

ST- 4

FRONT AND REAR AXLES.

...................... ST-

5

STEERING ..............................................

ST- 6

BRAKING ...............................................

ST- 8

FRONT AND REAR SUSPENSION..

........... ST- 9

CHECKER AND OTHER EQWPMENT..

.......

ST-IO

13ESTX-301

c I

__

c I

Page 176 of 279

SPECIAL TOOLS ST

BRAKING (CONT’D)

TOOL NUMBER

81 DESCRIPTION PRIORITY tLLUSTRATION

49 1285 071

Puller, A

needle bearing

49 B066 001

Harness (ABS) A

49 BO66 OAO

retainer

49 B043 004

Socket wrench A

FRONT AN5 REAR SUSPENSION

c TOOL NUMBER

& DESCRIPTION PRIORITY ILLUSTRATION

1

49 8034 2AOA

Replacer set,

rubber bush A

49 8038 785

:

Installer, A

dust boot TOOL NUMBER

& DESCRIPTION PRIORITY

ILLUSTRATION

49 GO25 001

Installer, P ’

sensor rotor

49 LO43 002

retainer

49 LO43 003

Setting tool,

retainer A

49 LO43 004

Protector

q@

:

- - -

TOOL NUMBER

& DESCRIPTION

49 GO34 1AO

Compressor,

coil spring

support Mock

PRIORITY

A ILLUSTRATION

Page 185 of 279

GI Reading Wiring Diagrams

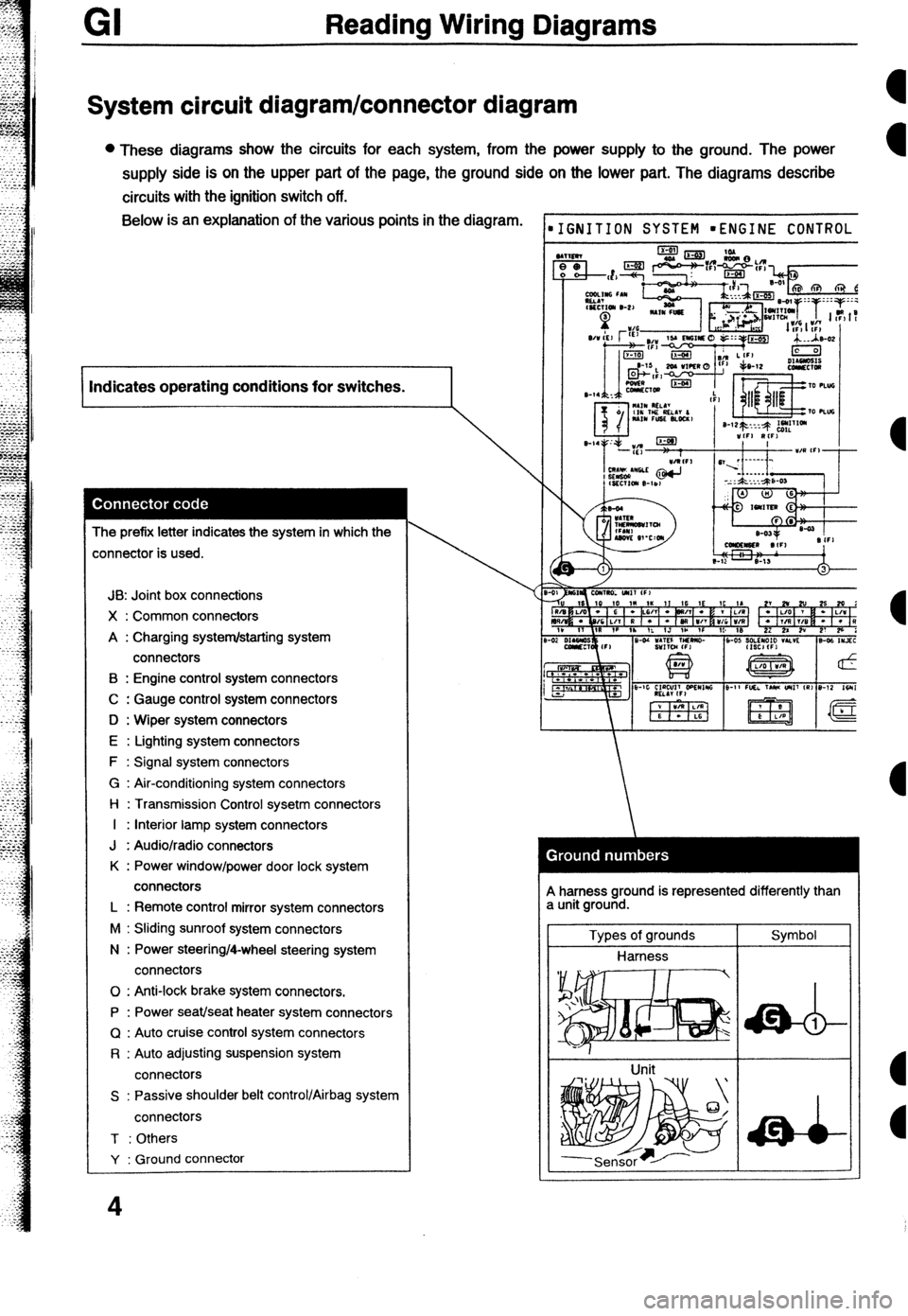

System circuit diagram/connector diagram

l These diagrams show the circuits for each system, from the power supply to the ground. The power

supply side is on the upper part of the page, the ground side on the lower part. The diagrams describe

circuits with the ignition switch off. Below is an explanation of the various points in the diagram.

I Indicates operating conditions for switches.

I

The prefix letter indicates the system in which the

:onnector is used.

JB: Joint box connections

X : Common connectors

A : Charging system/starting system

connectors

B : Engine control system connectors

C : Gauge control system connectors

D : Wiper system connectors

E : Lighting system connectors

F : Signal system connectors

G : Air-conditioning system connectors

l-l : Transmission Control sysetm connectors

I : Interior lamp system connectors

J : Audio/radio connectors

K : Power window/power door lock system

connectors

L : Remote control mirror system connectors

M : Sliding sunroof system connectors

N : Power steering/4-wheel steering system

connectors

0 : Anti-lock brake system connectors.

P : Power seat/seat heater system connectors

Q : Auto cruise control system connectors

R : Auto adjusting suspension system

connectors

S : Passive shoulder belt control/Airbag system

connectors

T : Others

Y : Ground connector

4

IGNITION SYSTEM mENGINE CONTROL

A harness ground is represented differently than

a unit ground.

Types of grounds

Harness

Unit Symbol

Page 191 of 279

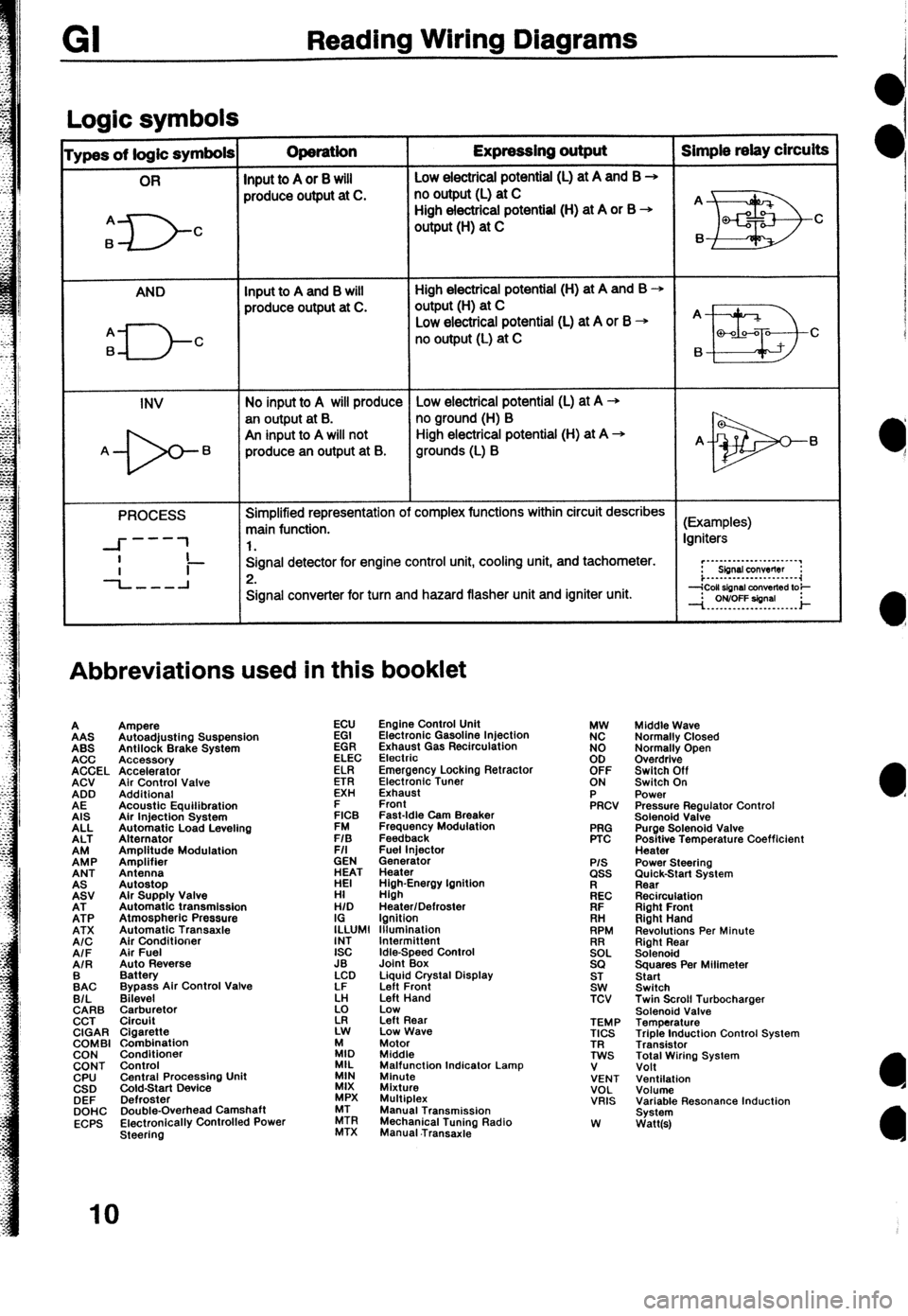

Reading Wiring Diagrams

Loaic symbols I

ypes of logic symbols Operation Expressing output Simple relay circuits

OR

Input to A or 8 will Low electricai potential (L) at A and B +

produce output at C. no output (L) at C

A

6

D- High electrical potential (H) at A or B +

C output (H) at C

AND Input to A and B will High electrical potential (H) at A and B +

produce output at C. output(H) at C

q---J-c

Low electrical potential (L) at A or B + A

no output (L) at C

B a-00-a C

6

INV No input to A will produce Low electrical potential (L) at A -+

an output at B. no ground (H) B

An input to A will not High electrical potential (H) at A +

A- 6 produce an output at B. grounds (L) B A- 6

PROCESS Simplified representation of complex functions within circuit describes

main function. (Examples)

---

--I- 1 1. Igniters

I

-L-l Signal detector for engine control unit, cooling unit, and tachometer.

Ii- 2. r”~“-‘-‘-““‘~~‘.“’

Sbnsl conwflw :

i...-..--.---......-.~~

Signal converter for turn and hazard flasher unit and igniter unit.

Abbreviations used in this booklet

A

AAS

ABS

ACC

ACCEL

ACV

ADD

AE

AIS

ALL

ALT

EP

ANT

EV

EP

ATX

A/C

AIF

AIR

:AC

B/L

CARB

CCT

CIGAR

COMBI

CON

CONT

CPU

CSD

DEF

DOHC

ECPS Ampere

Autoadjusting Suspension

Antilock Brake System

Accessory

Accelerator

Air Control Valve

Additional

Acoustic Equilibration

Air Injection System

Automatic Load Leveling

Alternator

Amplitude Modulation

Amplifier

Antenna

Autostop

Alr Supply Valve

Automatic transmission

Atmospheric Pressure

Automatic Transaxle

Air Conditioner

Air Fuel

Auto Reverse

Battery

Bypass Air Control Valve

Bilevel

$rr$:,tor

Cigarette

Combination

Conditioner

Control

Central Procassino Unit

&Id-Start Device -

Defroster

Double-Overhead Camshaft

Electronically Controlled Power

Steering ECU

EGI

EGR

ELEC

ELR

ETR

EXH

E

FICB

FM

F/S

F/I

GEN

ET

HI

H/D

I;LUMl

INT

ISC

JB

LCD

LF

k!

z Engine Control Unit

Electronic Gasoline Injection

Exhaust Gas Recirculation

Electrio

Emergency Locking Retractor

Electronic Tuner

Exhaust

Front

Fast-Idle Cam Breaker

Frequency Modulation

Feedback

Fuel lniector

Generator

Heater

High-Energy Ignition

High

Heater/Defroster

Ignition

lllumlnation

Idle-Speed Control

Joint Box

Liquid Crystal Display

Left Front

Left Hand

Low

Left Rear

Low Wave

:I, Motor

Middle

MIL

MIN Malfunction Indicator Lamp

Minute

MIX

Mixture

MPX Multiplex

ZR Manual Transmission

MTX Mechanical Tuning Radio

Manual .Transaxie PRG

PTC

P/S ass

kc

FIF

. . .

RH

RPM

!2EL

SQ

ST

SW

TCV

TEMP

TICS

TR

TWS

V

VENT

VOL

VRIS

W Middle Wave

Normally Closed

Normally Open

Overdrive

Switch Off

Switch On

Power

Pressure Regulator Control

Solenoid Valve

Purge Solenoid Valve

Positive Temperature Coefficient

Heater

Power Steering

;im&k-Start System

Recirculation

Right Front

Right Hand

Revolutions Per Minute

Right Rear

Solenoid

Squares Per Milimeter

Start

Switch

Twin Scroll Turbocharger

Solenoid Valve

Temperature

Triple Induction Control System

Transistor

Total Wiring System

Volt

Ventilation

Volume

Variable Resonance Induction

System

Watt(s)

IO