torque MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 6 of 279

3

3

,

>

1.

3

>

>

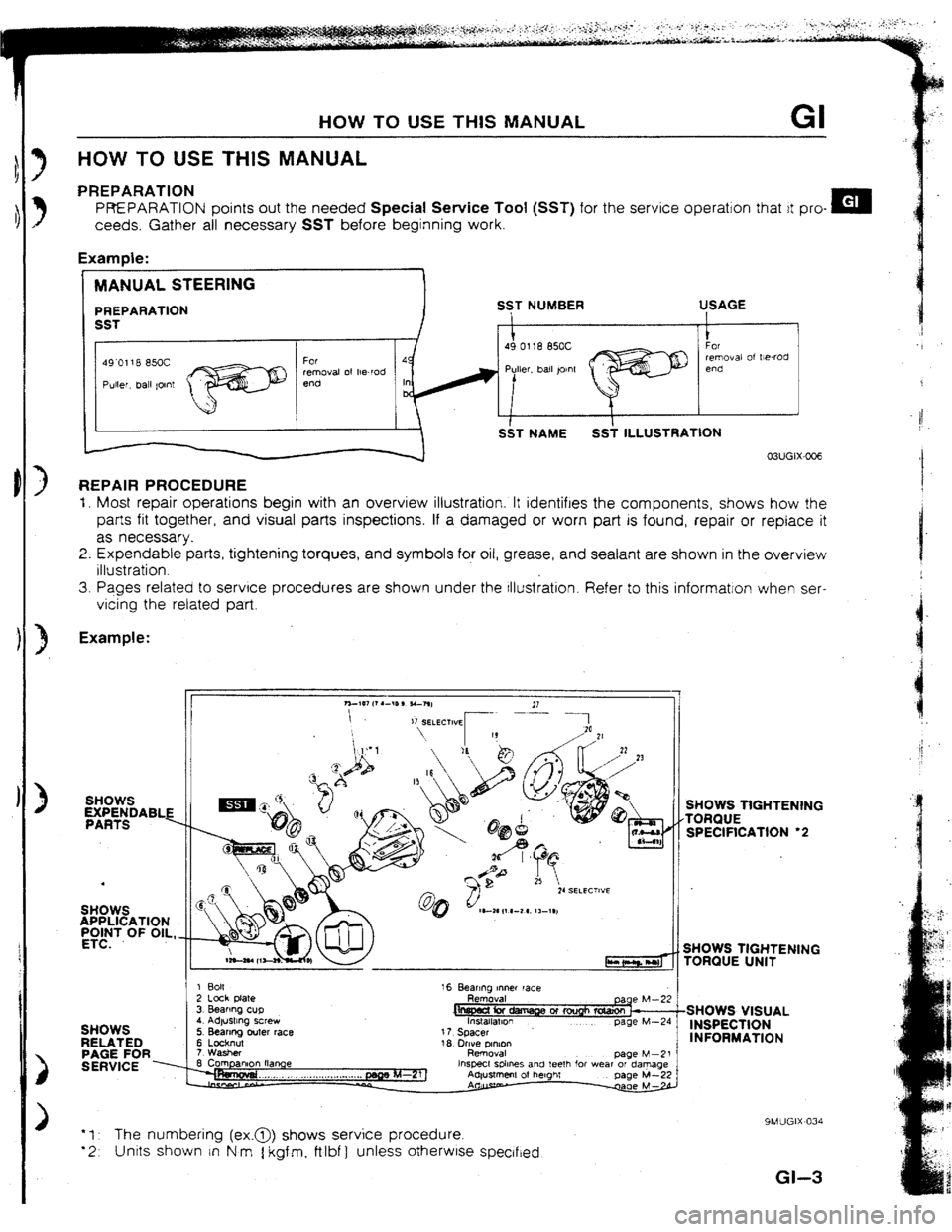

HOW TO USE THIS MANUAL GI

HOW TO USE THIS MANUAL

PREPARATION

PREPARATION points out the needed Special Service Tool (SST) for the service operation that it pro- m

ceeds. Gather all necessary SST before beginning work.

Examde:

MANUAL STEERING

PREPARATlON

SST

49’0118 85oC

Puller, ball tolnt For

removal of he-rod

end SST NUMBER

1

49 0118 85oC USAGE

1

For

removal of Wrod

end

S&T NAME SS; ILLUSTRATlON

REPAIR PROCEDURE

I. Most repair operations begin with an overview illustration. It identifies the components, shows how the

parts fit together, and visual parts inspections. If a damaged or worn part is found, repair or replace it

as necessary.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

illustration.

3. Pages related to service procedures are shown under the tllustration. Refer to this informatron when ser-

vicing the related part

Example:

SHOWS

yA;ytDABLE

.

SHOWS

APPLICATION

;v’dT OF OlL, _

SH

RE

2

3ws .ATED

3E FOR

?VICE . 1 Bolt

2 Lock Nate

3 Bearmg cup

4 Adtustmg screw

5 Bearing outer race

6 Locknut

7 Washer 16 Beanno Inner race

Rem&al

17 Spacer page M-24

18 lhve olnion

Daoe M-21

hspect sphes and teeIh for wear ordaqge SHOWS TIGHTENING

TORQUE

SPECIFICATION

l 2

SHOWS TIGHTENING

TORQUE UNIT

:

SHOWS VISUAL

INSPECTION

INFORMATION

9MlJGIX~034

*I The numbering (ex.@> shows service procedure.

l 2 Unrts shown in N m 1 kgf m, ftlbf ] unless otherwlse speclfted

Gl-3

Page 9 of 279

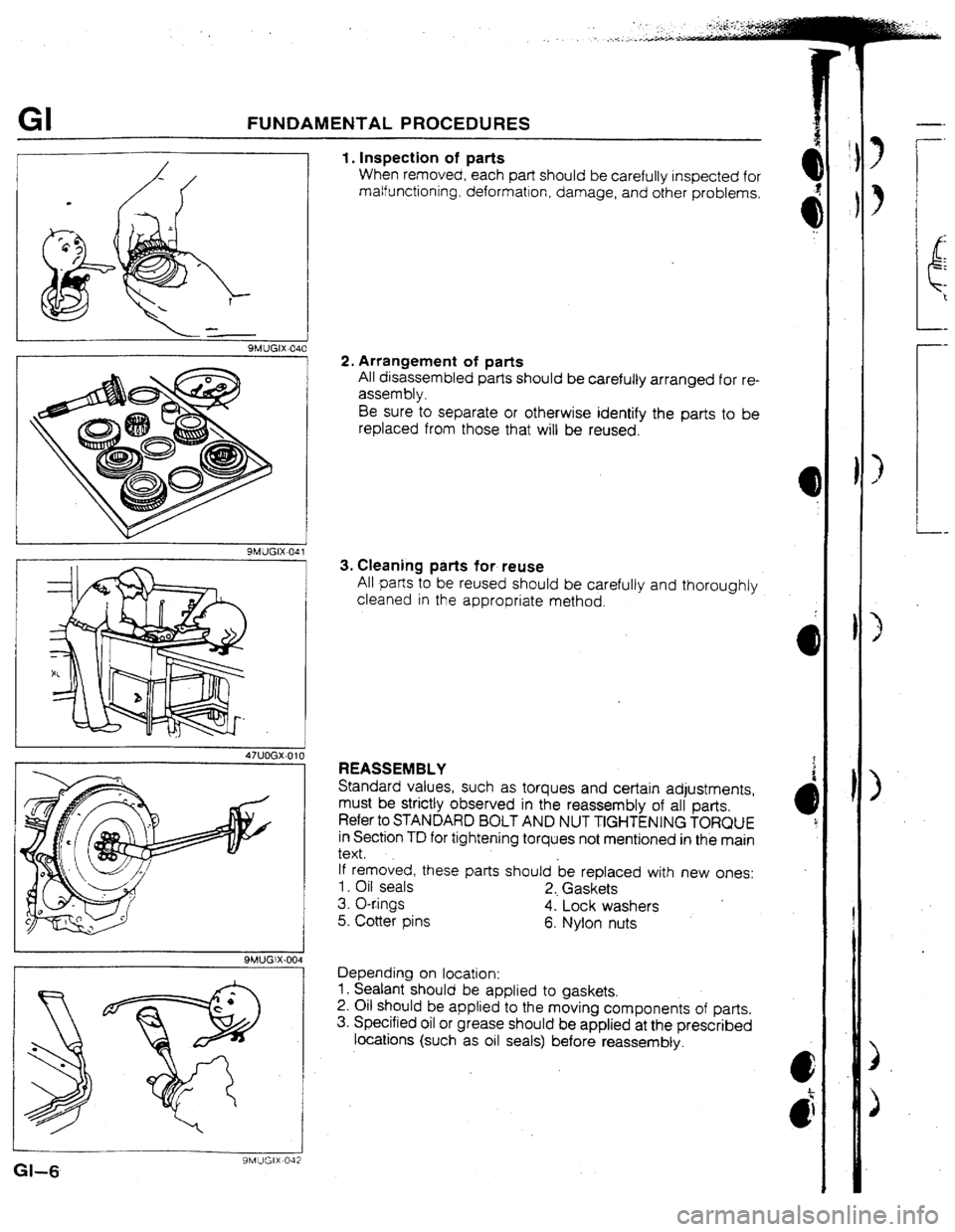

GI FUNDAMENTAL PROCEDURES

I. Inspection of parts

When removed, each part should be carefully inspected for

malfunctioning, deformation, damage, and other problems.

2. Arrangement of parts

All disassembled parts should be carefully

arranged for re-

assembly.

Be sure to separate or otherwise identify the parts to be

replaced from those that will be reused.

3. Cteaning parts for reuse

All parts to be reused should be carefully and thoroughly

cleaned in the appropriate method.

Gl-6

9MUGIX-042

REASSEMBtY

Standard values, such as torques and certain adjustments,

must be

strictly observed in the reassembly of all parts.

Refer to STANDARD BOLT AND NUT TIGHTENING TORQUE

in Section TD for tightening torques not mentioned in the main

text.

tf removed, these parts should be replaced with new ones:

1. Oil seals

2, Gaskets

3. O-r.ings

4. Lock washers

.

5. Cotter pins

6. Nylon nuts

Depending on location:

1. Sealant should be applied to gaskets.

2. Oil should be applied

to the moving components of parts.

3. Specified oil or grease should be applied at the prescribed

locations (such as oil seals) before reassembty.

Page 15 of 279

GI IDENTIFICATION NUMBER tOCATlONS/UNlTS/ABBREVIATlONS

IDENTIFICATION NUMBER LOCATIONS

VEHICLE tDENTtRCATtUN NUM8ER (VIM) ENGINE MODEL AND NUMBER

I

UNITS

N.rn { kgf m or kgfcm,

f-t&f or tn.lbf 1 . . . . . . . . . . . . . . . . Torque

rpm ._ . . . Revolutions per minute

A.. ,_...___.... Ampere(s)

v I... Volt(s)

$2 . .._..__......_.....__... Ohm(s) (resls‘tance)

kPa { kgflcm*, psr] . . . . . . . Pressure

{usually positive)

mmHg I inl-lg ] . . . . . . . . . Pressure

(usually negatrve)

W . . . ._ .._.__ .._ . . . . . . ..,......... Watt

titers [US qt, Imp qt 1 . V&me

mm { rn 1 . . . . . . . . . . . . . . . . . . . . . . . Length

89UOGX-006

ABBREWATIONS

ABDC _. . . . . . . . . . . After bottom dead

center

A/C . . . . . . . ._.. _. . . . . . . . . Air conditioner

ACC .__ . . . . . . . Accessones

ATX .._ ._ . . . . . . . . . . . . . . Automate transaxle

ATDC _.. __ _. . . . . After top dead center

ATF ,... ._....__._.. Automatic transmission

fluid

BAC ._ . . . . . . . . . . . . . . ,. Bypass air control

BBDC _. . . . . . . . . . . . . .._. Before bottom dead

center

BTDC ., ._._... . . . Before top dead center

CPU . . . . . . . . . Central processrng unit EC-AT

........................... Electronrcally-controlled

automatic transmlsslon

ECU ._ ....................... Engine control unit

EG 1 ..................... Electronc gasoll ne

injectron

E/L. ............................ Electrrcal load

EX .............................. Exhaust

IC ................................ Integrated clrcult

IGN ........................... lgnrtlon

IN ..... ........................ Intake

INT

............................... Intermittent

ISC ............................ Idle speed control

U-l ................................

Left hand

M..

........................... Motor

MIL

........ ...................... MatfunctIon Indicator

iamp

MTX. ........................... Manual transaxle

00.. .............................. Overdnve

Of F .............................. Swrtch off

ON

............................... Switch

on

PCV .............................. Positive crankcase

ventilation

PRC .......................... Pressure regulator

control

P/S ............................. Power steerrng

P/W ............................

Power window

RH ............................... Rlght hand

SST

............................. Special service tool

ST.. ............................... Starl

SW.. ............................. Switch

TDC. ............................ Top dead center

4WD .............................

4-wheel drive

03UGIX-802

INS7

If a t’

and

Whe

1, II-!

2. II-!

3. E-

4. Dr

W-1 2

Page 43 of 279

F3 TURBOCHARGERCONTROL

TURBOCHARGERCONTROL

OUTLINE

l The-capacity of the air-to-air intercooler is increased to reduce the intake air temperature and to the tm-

prove engine performance.

l With addition of the improved wastegate control system, the engine’s high rpm torque is increased.

TURBOCHARG

INTERCOOLER

SYSTEM DIAGRAM

WASTEGATE SOLENOrD VALVE

F3-10

Page 98 of 279

M FRONT AXLE

WHEEL HUB, STEERING KNUCKLE

RemovaI / Inspection I Installation

1. Remove in the order shown in the figure, referring to Removal Note.

2. Inspect all parts and repair or replace as necessary.

3. InstaH in the reverse order of removal, referring to Installation Note.

Caution

l Loosely tighten the shock absorber bolts. Lower the vehicle and tighten the bolts to the specified

torque with the vehicle unladen.

4. Adjust the front wheel alianment.

16-22 ]1.6-2.3, 12-161 I

19.0-l 2.0, 65-86.7 I

1. Wheel hub nut

2. Wheel and tire

3. Locknut

Removal Note . . . . . . .._.. . . . . . . . . . . . . . . . . . . . page M-7

installation Note .I.........,..,............ page M-7

4. Brake caliper assembly

Service . _. . . . . . . . . ,__. . . , , . ._. _. , , . . . , . ._ ._. . . . . . Section P

5. Disc plate

lnspectioti .~~*.......*~...,......,,,.....*~...~. Section P

6. ABS wheel speed sensor (if equipped)

7. Tie rod end

Removal Note . . . . . . .._.......... I . .._.....= page M-7

lnstallatiofi Note . . .._... _.__......,....... page M-7

M-6

8. Lower ball joint

9. Steering knuckle, wheel hub, and dust cover

Inspect-wheel hub for cracks and damage

Inspect knuckle spindle for cracks and

damage

Inspect dust cuver for damage and dis-

tortion

Disassembly I Inspection I

Assembly . ..C1..............~...,.....,.....

page M-8

Page 99 of 279

FRONT AXLE M

13EOMX308

13EOMX-310

1

13EOMX-311

Removal note

Locknut

Caution

l Do not damage the drive shaft.

l Do not reuse the locknut.

1.

Raise the staked portion of the locknut using a chisel.

2. Lock the

hub by applying the brakes.

3. Remove the locknut.

Tie rod end

Caution i

l Do not damage the dust boot.

t

Losen the nut and disconnect the tie rod end bv using the

I

SST.

P

Installation note

Tie rod end

Caution

l Do not damage the dust boot.

tnstall the nut and secure it with the new cotter

Tightening torque:

43-56 N-m (4.3-5.8 kgf,m, 31-41 ft-lbf

Locknut

lnstail a new

locknut and stake it, as shown. pin.

Tightening torque: 236-318 N-m

f 24.0-32.5 kgfm, 174-235 ftelbf ]

M-7.

Page 104 of 279

REAR AXLE

WHEEL HUB, KNUCKLE

Removal I Inspection / installation

1. Remove in the order shown in the figure, referring to

Removal Note. 2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to Installation Note.

Caution

l Loosely tighten the shock absorber bolts. Lower the vehicle and tighten the bolts to the specified

torque with the vehicle unladen.

4. Adiust the rear wheel alianment.

16-22 1?.6-2.3, 12-16 I

7

IO.o-13.0,

66-66.7 1 1. Wheel and tire

2. Locknut

Removal Note..; . . . . . . . . , . . . . ,.......- -.. page M-f 3

Installation Note .._...,.,...._.__........ page M-13

I$ Brake caliper assembly

Service . . . . . . . . . . . ..e......._......... ,.,...,....

Section P

4. Disc plate

‘Service ..I....................__....... . . . . . . . . . Section P 5. Af3S wheel speed sensor (if equipped)

6. Wheel hub, knuckle

Disassembly I Inspect& /

Assem bty . . . . . . . ..I..........*..*.*...-... page M-14

Inspect wheel hub and knuckle for damage

or cracks

Inspect dust cover for damage or defor-

mation

M-12

Page 105 of 279

REAR AXLE M

Removal note

Locknut

Caution

l Do not damage the drive shaft.

l Do not reuse the locknut.

I. Raise the staked portion of the tocknut using a chisel.

2. Lock the hub by applying the brakes.

3. Remove the locknut.

1 13EOMX-308

13EOMX-327 installation note

Locknut

Install a new locknut and stake it, as shown.

Tightening torque: 236-318 N-m

[ 24.0-32.5 kgfm, f 74-235 ftelbf

‘I

Page 120 of 279

CONVENTIONAL BRAKE SYSTEM P

WlfH ABS

1 f3EOPX-3 I 7

I* 44 44’

/

13EOPX-318

MASTER CYLINDER PRESSURE kPa f kgffcm2, psi 1

16AOPX-m 0

PRUPORTIONING VALVE

Inspection

1. Connect the SST to the brake pipes with adapters as shown

in the figure.

Adapter and flare nut tightening torque:

12.8-21.5 Nsm f 130-220 kgfcm, I 134 90 inlbf 1

Note

l Disconnect and connect the brake pipes with SST.

2. Bleed the air from the brake system.

3. Depress the brake pedal until the master cylinder pressure

equals A; then record rear brake pressure A’.

4. Depress the brake pedal again, apply additional pressure

until the pressure equals B; then record pressure B’.

Fluid pressure

kPa { kgVcm2, psi]

A

A’ 8

8’

WITHOUT 1960

1960

ABS 120, 284 (20,284] 5880

1 al96 12, 28)

(60, 853) 2750 (28, 3881

*I96 12,281

WITH ABS $;;4 1960 f 20,284) 5880

1 *196 12,261 160, 853 3140 {32, 455)

1

*294 [3,42)

-,

--.

. p-g.’

Page 124 of 279

CONVENTIONAL BRAKE SYSTEM P

13EOPX-324

I %EOPX-071

Disassembly note

Piston

Caution

l Blow the compressed air slowly to prevent the pis-

ton from popping out.

I. Place a piece of wood in the caliper.

2. Blow compressed air through the pipe hole to force the pis-

ton out of the caLper.

Piston seal

Remove the piston seal from the caliper by using the SST.

I

Bleeder screw

Loosen the bleeder screw by using the SST.

Assembly note

Bleeder screw

Tightening the bteeder screw by using the SST.

Tightening torque:

5.9-8.8 Nom (60-90 kgfcm, 53-78 in&f ]